Just to say that in my obsession to make a folding reprap, I'll try to build my latest version based on 20x20 T-slot !

FoldaRap

But feedback/suggestion about it (and or the aluminium extrusion, and/or suppliers) are welcome before I buy the needed parts (hoping I won't forgot t-nuts or something that will make multiple orders).

(hoping I won't forgot t-nuts or something that will make multiple orders).

FoldaRap

But feedback/suggestion about it (and or the aluminium extrusion, and/or suppliers) are welcome before I buy the needed parts

(hoping I won't forgot t-nuts or something that will make multiple orders).

(hoping I won't forgot t-nuts or something that will make multiple orders).

|

Re: FoldaRap March 24, 2012 08:50AM |

Registered: 13 years ago Posts: 615 |

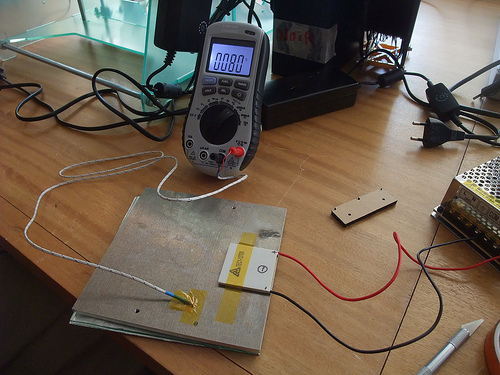

I'm not far from the first test of the first prototype, but I have to take some decision and want to keep a track of my thought...

Power Supply : my goal is to use a 12V power supply because on the eMaker sanguinololu, fed in 19V, the additionals outputs, for fans by example, are by consequence also in 19V, and feeding a 8v fan in 19v is not very good for it's life...

With that I'm learning again basic electronic, that's good (forgotten the ohm law and things)

(forgotten the ohm law and things)

This thread and some friends helped me to understand how much current I need : [forums.reprap.org]

The same elements at 12v instead of 19v will take more time to heat-up.

So, at 12v we need between 10-20A (or 120 - 240 W).

Nophead recommended 20A to be safe and have margin.

Bwevans is using a 12v 12.5A (so 150W) psu with success.

I measured my huxley total consumption at 8A so around 150W at 19V, so the psu of bwevans is a good start but I'll probably take one which is a little bigger.

But not too much as I want to put it under the bed of the folding reprap (all the 20A I found were often 200*120*40mm, except this one [www.rs-particuliers.com] but which is expensive)

I'm hesitating between [www.ebay.com] (150W and ~110*140*40mm), [www.ebay.com] (180W and 130*100*40),or these 200W which seems to good to be true ? ( [www.ebay.com] and [www.ebay.com] or is it because they are only rated for 220V ? Otherwise they would be perfect) [edit : after asking the IRC I also learned the difference between a crude electronic transformer and a real psu].

But anyways that imply that I need to make my own bed.

As the supply is mostly related to the choice of the heated bed.

It seems that we need around 30 - 90 W to be able to reach 55 - 110 °C (I don't intend to use abs, but we never know )

)

I firstly thought of using the reprappro pcb heatbed, which is probably the same as this one [www.thingiverse.com] (4,5-6,6 Ohms / at 19v it will output 80-54W), but only 32-22W at 12v, probably too low.

Thus I identified three option :

I'll see if a 180W and a peltier are good

Don't hesitate to correct me if I'm wrong somewhere or if you have an idea that can help

Edited 1 time(s). Last edit at 03/24/2012 05:51PM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

Power Supply : my goal is to use a 12V power supply because on the eMaker sanguinololu, fed in 19V, the additionals outputs, for fans by example, are by consequence also in 19V, and feeding a 8v fan in 19v is not very good for it's life...

With that I'm learning again basic electronic, that's good

(forgotten the ohm law and things)

(forgotten the ohm law and things)This thread and some friends helped me to understand how much current I need : [forums.reprap.org]

The same elements at 12v instead of 19v will take more time to heat-up.

So, at 12v we need between 10-20A (or 120 - 240 W).

Nophead recommended 20A to be safe and have margin.

Bwevans is using a 12v 12.5A (so 150W) psu with success.

I measured my huxley total consumption at 8A so around 150W at 19V, so the psu of bwevans is a good start but I'll probably take one which is a little bigger.

But not too much as I want to put it under the bed of the folding reprap (all the 20A I found were often 200*120*40mm, except this one [www.rs-particuliers.com] but which is expensive)

I'm hesitating between [www.ebay.com] (150W and ~110*140*40mm), [www.ebay.com] (180W and 130*100*40),

But anyways that imply that I need to make my own bed.

As the supply is mostly related to the choice of the heated bed.

It seems that we need around 30 - 90 W to be able to reach 55 - 110 °C (I don't intend to use abs, but we never know

)

)I firstly thought of using the reprappro pcb heatbed, which is probably the same as this one [www.thingiverse.com] (4,5-6,6 Ohms / at 19v it will output 80-54W), but only 32-22W at 12v, probably too low.

Thus I identified three option :

- * ni-chrome wire, approx. 6ohm for 270mm (found on mendel-parts which is the spare I have), so 24W@12v, 48W@12v if I make it 135mm long, but 13cm is maybe a little short to cover the 140x140mm bed...

* power resistor, 2 or 3 of 1ohm : to have 48 - 72W

* a peltier element (cdnreprap and others were having success with that [forums.reprap.org]), it seems usable at 12v, and I just bought one 12708 on ebay rated at 1,5 - 1,6 ohms [www.ebay.com] around 80W and a deltaT of 67°C (so at 20°C ambient it can go as high as 87°C, when I usually set my bed at 55-70°C) and the cold side will be toward the printed-frog and electronics which is always good to cool ^^

I'll see if a 180W and a peltier are good

Don't hesitate to correct me if I'm wrong somewhere or if you have an idea that can help

Edited 1 time(s). Last edit at 03/24/2012 05:51PM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

|

Re: FoldaRap March 27, 2012 12:29PM |

Registered: 13 years ago Posts: 601 |

|

Re: FoldaRap March 27, 2012 04:40PM |

Registered: 13 years ago Posts: 615 |

|

Re: FoldaRap April 01, 2012 03:37PM |

Registered: 13 years ago Posts: 615 |

on the heatbed element :

After having listed

*nichrome,

*resistors,

*or peltier element

a recent post from Open3DP (yay they are open again), shows that we can also make use of existing products like

*"Motorcycle handlebar warmers" ^^

And from the Alu-XL mendel, I looked toward

*silicon heatpad that seem to be also an interesting solution...

To be continued

After having listed

*nichrome,

*resistors,

*or peltier element

a recent post from Open3DP (yay they are open again), shows that we can also make use of existing products like

*"Motorcycle handlebar warmers" ^^

And from the Alu-XL mendel, I looked toward

*silicon heatpad that seem to be also an interesting solution...

To be continued

|

Re: FoldaRap April 06, 2012 06:21PM |

Registered: 13 years ago Posts: 615 |

Also on the heatbed, but concerning the plate this time :

We are often using aluminum plate to spread the heat, with a glass plate on top of it as print surface (kapton-free), but (after a talk with a friend), what about ceramic plate ?

+ I remember people who used ceramic tile as print surface

+ ceramics are very resistant to thermal shocks and thus can replace both the alu and glass plates !

+ some technical ceramics are also good thermo-conductors

- but are probably hard to find or costlier than an alu plate

When looking for that sort of glass-ceramic, I finally stumbled upon one industrial : [www.vio-verres.com] which say : "a 3mm plate, heated at 1200°C and dipped into cold water, don't shater."

Overkill, but that confirm it exist

Maybe for the next prototype as I'm already going to use the previous alu bed of my eMaker Huxley ; but I'd love the simplicity of a peltier element just sticked to a ceramic bed =)

(that would make the foldarap even moreawesome experimental ^^)

about // liberapay // flickr // wiki // thingiverse - github

We are often using aluminum plate to spread the heat, with a glass plate on top of it as print surface (kapton-free), but (after a talk with a friend), what about ceramic plate ?

+ I remember people who used ceramic tile as print surface

+ ceramics are very resistant to thermal shocks and thus can replace both the alu and glass plates !

+ some technical ceramics are also good thermo-conductors

- but are probably hard to find or costlier than an alu plate

When looking for that sort of glass-ceramic, I finally stumbled upon one industrial : [www.vio-verres.com] which say : "a 3mm plate, heated at 1200°C and dipped into cold water, don't shater."

Overkill, but that confirm it exist

Maybe for the next prototype as I'm already going to use the previous alu bed of my eMaker Huxley ; but I'd love the simplicity of a peltier element just sticked to a ceramic bed =)

(that would make the foldarap even more

about // liberapay // flickr // wiki // thingiverse - github

|

Re: FoldaRap April 08, 2012 05:45AM |

Registered: 13 years ago Posts: 615 |

More notes about ceramics...

As a reference, thermal conductivity of aluminium (99,9%) : 237; glass : 1,2 W/m.K

Some ceramics can goes up to 150-180 [global.kyocera.com]

Those based on Aluminium Nitride (nitrure d'aluminium in French) seems to be among the bests.

But [www.electronics-cooling.com] have a good point saying that the value can differ greatly between manufacturers due to the composition of the ceramic, and often goes lower when the temperature increase (e.g; AIN start at 200W/m.K at room temp. and can go down to 80)

Maybe not such a good idea, if we don't put a glass plate on top of the actual aluminium plate used, we already have only one plate, which was the goal...

But I'll keep that ceramic idea in mind for futur prototypes, to have both advantages of a kapton-free one-plate ^^

--

Some companies found :

Kunze

CeramTec

Sceram

Technicalglass

"aluminum nitride (or AIN) ceramic" were good keywords

some more links when searching through a material-library :

Eutit

Pyrolave

Neoceram

Coorstek.com

Hexoloy

Precision-ceramics

Edited 3 time(s). Last edit at 04/15/2012 08:58PM by Emmanuel.

As a reference, thermal conductivity of aluminium (99,9%) : 237; glass : 1,2 W/m.K

Some ceramics can goes up to 150-180 [global.kyocera.com]

Those based on Aluminium Nitride (nitrure d'aluminium in French) seems to be among the bests.

But [www.electronics-cooling.com] have a good point saying that the value can differ greatly between manufacturers due to the composition of the ceramic, and often goes lower when the temperature increase (e.g; AIN start at 200W/m.K at room temp. and can go down to 80)

Maybe not such a good idea, if we don't put a glass plate on top of the actual aluminium plate used, we already have only one plate, which was the goal...

But I'll keep that ceramic idea in mind for futur prototypes, to have both advantages of a kapton-free one-plate ^^

--

Some companies found :

Kunze

CeramTec

Sceram

Technicalglass

"aluminum nitride (or AIN) ceramic" were good keywords

some more links when searching through a material-library :

Eutit

Pyrolave

Neoceram

Coorstek.com

Hexoloy

Precision-ceramics

Edited 3 time(s). Last edit at 04/15/2012 08:58PM by Emmanuel.

|

Re: FoldaRap April 16, 2012 07:20PM |

Registered: 13 years ago Posts: 615 |

The peltier works great ! (I was confident after having seen cdnreprap using a 50x50mm one at 110°c, but still that's cool ^^)

Not had printed on the bed yet, but the experience of this afternoon is very positive : from 20°C to 50°C in few seconds for the element (I was a little scared at first), progressively warming the bed up to 80°C and probably more with more time (but I'll only need 60°c for pla).

Cost of this hassle-free-solution : 6$ --> adopted !

Edited 1 time(s). Last edit at 04/16/2012 07:22PM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

Not had printed on the bed yet, but the experience of this afternoon is very positive : from 20°C to 50°C in few seconds for the element (I was a little scared at first), progressively warming the bed up to 80°C and probably more with more time (but I'll only need 60°c for pla).

Cost of this hassle-free-solution : 6$ --> adopted !

Edited 1 time(s). Last edit at 04/16/2012 07:22PM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

|

Re: FoldaRap May 02, 2012 07:07PM |

Registered: 13 years ago Posts: 615 |

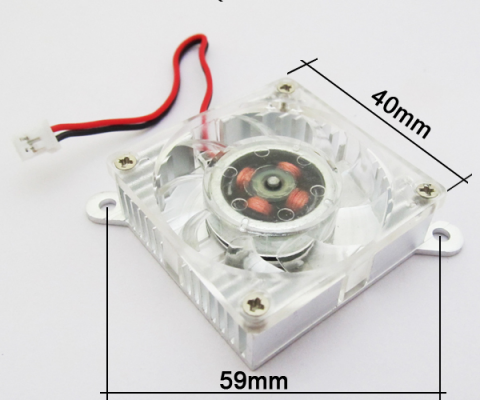

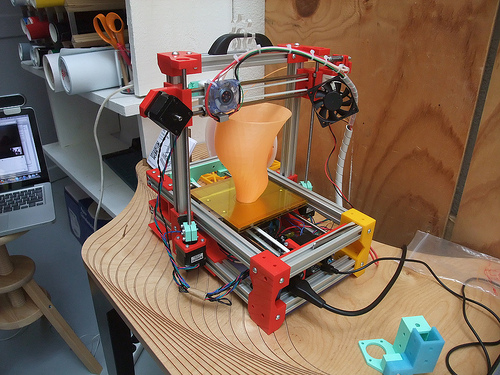

Today I was able to make one of the latest choice left in the design of this folding reprap.

The cooling solution for the hotend-x-carriage.

I finally found a fan compact enough to allow the sliding of the XZ-axis (saving ~10mm compared to the fan+heatsink originally in the eMaker/Reprappro hotend), and the nice thing with it's alu frame is that it will also serve to cool the printed parts.

The last thing to test now is the direct driven nema14 extruder.

We're almost done !

about // liberapay // flickr // wiki // thingiverse - github

The cooling solution for the hotend-x-carriage.

I finally found a fan compact enough to allow the sliding of the XZ-axis (saving ~10mm compared to the fan+heatsink originally in the eMaker/Reprappro hotend), and the nice thing with it's alu frame is that it will also serve to cool the printed parts.

The last thing to test now is the direct driven nema14 extruder.

We're almost done !

about // liberapay // flickr // wiki // thingiverse - github

|

Re: FoldaRap May 11, 2012 07:55PM |

Registered: 13 years ago Posts: 615 |

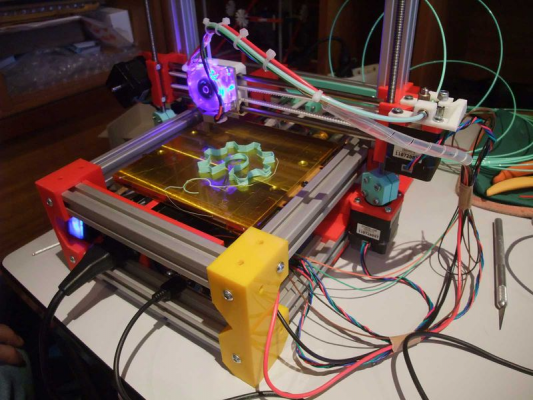

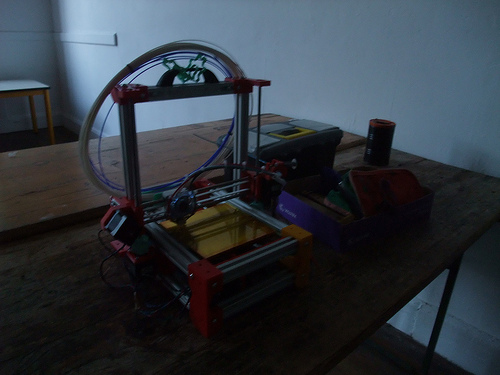

I dit it ! It moves !!

[www.flickr.com]

[www.flickr.com]

And I'm just realizing the extent of work which was done...at first I was like "yeah let's do it", but I was far to imagine the ambition it is to design a new reprap... hundreds of hours... but to finally see the entire model almost finished.

It take some perseverance, but it's fun Tonight I was both glad and exhausted, glad to make another reprap (which is quite a big piece of project), trying to document it the best I can, and exhausted by the time it require, sometimes for a minor change.

Tonight I was both glad and exhausted, glad to make another reprap (which is quite a big piece of project), trying to document it the best I can, and exhausted by the time it require, sometimes for a minor change.

By the way, if the bot is moving (with a Marlin firmware), I'm starting to see the next improvements (moving the "release" line a little further ^^') :

- change the underplate layout for the psu+board (at least I just have to lasercut a new plate, and not to reprint all the feet)

- to make the wiring easier and more tidied up

- when moving in z, it wobble a lot ! (that was the risk to get rid of the z-bearings, but I've already two solutions to try, with one like others did : by using the alu beam to slide on)

Anyway, it's probably the most compact reprap I could have done, there is almost no margin to fit the wires or slide the Y-axis, everything is a "just fit", when I seen the few space I had to pass the cable I doubted it was possible but still wanted to try, and with the help of a friend (thanks Mathias!) we dit it.

So the wiring is the next big target, as it was hard to anticipate in Sketchup and this prototype is good for experiencing and to refine that.

about // liberapay // flickr // wiki // thingiverse - github

[www.flickr.com]

[www.flickr.com]

And I'm just realizing the extent of work which was done...at first I was like "yeah let's do it", but I was far to imagine the ambition it is to design a new reprap... hundreds of hours... but to finally see the entire model almost finished.

It take some perseverance, but it's fun

Tonight I was both glad and exhausted, glad to make another reprap (which is quite a big piece of project), trying to document it the best I can, and exhausted by the time it require, sometimes for a minor change.

Tonight I was both glad and exhausted, glad to make another reprap (which is quite a big piece of project), trying to document it the best I can, and exhausted by the time it require, sometimes for a minor change.By the way, if the bot is moving (with a Marlin firmware), I'm starting to see the next improvements (moving the "release" line a little further ^^') :

- change the underplate layout for the psu+board (at least I just have to lasercut a new plate, and not to reprint all the feet)

- to make the wiring easier and more tidied up

- when moving in z, it wobble a lot ! (that was the risk to get rid of the z-bearings, but I've already two solutions to try, with one like others did : by using the alu beam to slide on)

Anyway, it's probably the most compact reprap I could have done, there is almost no margin to fit the wires or slide the Y-axis, everything is a "just fit", when I seen the few space I had to pass the cable I doubted it was possible but still wanted to try, and with the help of a friend (thanks Mathias!) we dit it.

So the wiring is the next big target, as it was hard to anticipate in Sketchup and this prototype is good for experiencing and to refine that.

about // liberapay // flickr // wiki // thingiverse - github

|

Re: FoldaRap May 15, 2012 10:09AM |

Admin Registered: 12 years ago Posts: 2,569 |

It's so cute ! Congrats on the progress.

Are you going to use the extrusions channels for the wiring ?

Edited 1 time(s). Last edit at 05/15/2012 10:10AM by DeuxVis.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

Are you going to use the extrusions channels for the wiring ?

Edited 1 time(s). Last edit at 05/15/2012 10:10AM by DeuxVis.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: FoldaRap May 16, 2012 08:48AM |

Registered: 13 years ago Posts: 615 |

Thanks =)

I tried to use the extrusion for the wiring but it was more a problem than an advantage, as some parts are sliding on the beams (and I'll use more of this to replace the usual stud+bearings).

But I plan to use the underplate to make everything more tidy just before mounting the plate under the machine

I tried to use the extrusion for the wiring but it was more a problem than an advantage, as some parts are sliding on the beams (and I'll use more of this to replace the usual stud+bearings).

But I plan to use the underplate to make everything more tidy just before mounting the plate under the machine

|

Re: FoldaRap May 24, 2012 05:45PM |

Registered: 13 years ago Posts: 615 |

It's printing !!!

It's printing !!!

- Printed at 25mm/s to be safe, with the old Sprinter of the eMaker Huxley (btw I had to switch back to relative extrusion in skeinforge after a first weird print with the extruder spinning way too much). Gcode made with skeinforge-47 and the same profile as for my Huxley expect a minor tweak about the z-offset

- I added an M3 washer between the printed parts of the XZ axis (hinge/motor-bracket) and the base of the frame, near each bolt used to clamp the axis in place. That seem to have solved a good part of the misalignment of the z-threaded-rods (maybe due to a little tolerance forgotten between the two halves of the hinges).

- The extruder was assisted by hand, the pressure of the bearing-idler was too low, nonetheless the first tests shows that even a Nema14 with just 14nm torque can have some potential in direct drive pushing a 1,75mm filament (thanks to the hotend I think)

about // liberapay // flickr // wiki // thingiverse - github

|

Re: FoldaRap May 24, 2012 07:19PM |

Registered: 11 years ago Posts: 25 |

Really nice work.

Congrats for the first print

I´m following your buildlog since the first Post and I would love to build that one for myself,

specially cause i aint got the Space to put a Mendel o.e. on my workbench :/

( it´s really small ^^ )

Keep up the good work.

Regards from Germany.

Congrats for the first print

I´m following your buildlog since the first Post and I would love to build that one for myself,

specially cause i aint got the Space to put a Mendel o.e. on my workbench :/

( it´s really small ^^ )

Keep up the good work.

Regards from Germany.

|

Re: FoldaRap May 25, 2012 06:48AM |

Registered: 11 years ago Posts: 28 |

|

Re: FoldaRap May 25, 2012 04:11PM |

Registered: 13 years ago Posts: 615 |

Thank you and everyone for the encouragements, they are well appreciated

I'm a bit surprised by the enthusiasm of hackerspace's friends who are eager to see me finish this to organize workshops to build many Foldarap, that make me a little anxious ^^'

But I'd be curious to see other people making one for themselves (that also push me at finishing the BOM).

I'm a bit surprised by the enthusiasm of hackerspace's friends who are eager to see me finish this to organize workshops to build many Foldarap, that make me a little anxious ^^'

But I'd be curious to see other people making one for themselves (that also push me at finishing the BOM).

|

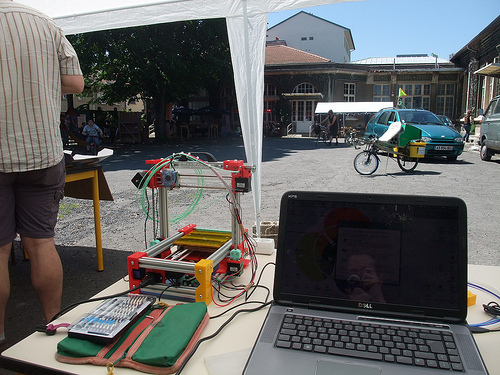

Re: FoldaRap May 26, 2012 07:35PM |

Registered: 13 years ago Posts: 615 |

First real test of usage this week-end :

traveling on a bike : ok ! (fortunately it's quite robust ^^)

quick installation : ok ! (5-10min maybe, taking my time)

(end of day1)

And I was pleasantly surprised by my new extruder idler, it worked all the day, printing little arms to make useless machines or open-hardware logos to show during the diy-festival (a sort of local mini-maker-fair)

(a sort of local mini-maker-fair)

[edit] : but the nema14 reach it's limit around 25mm/s

(I knew it couldn't work in theory, from the advices we usually read, but I still wanted to try direct-drive with it ^^)

Edited 1 time(s). Last edit at 05/28/2012 06:55AM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

traveling on a bike : ok ! (fortunately it's quite robust ^^)

quick installation : ok ! (5-10min maybe, taking my time)

(end of day1)

And I was pleasantly surprised by my new extruder idler, it worked all the day, printing little arms to make useless machines or open-hardware logos to show during the diy-festival

(a sort of local mini-maker-fair)

(a sort of local mini-maker-fair)[edit] : but the nema14 reach it's limit around 25mm/s

(I knew it couldn't work in theory, from the advices we usually read, but I still wanted to try direct-drive with it ^^)

Edited 1 time(s). Last edit at 05/28/2012 06:55AM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

|

Re: FoldaRap May 29, 2012 01:43PM |

Registered: 11 years ago Posts: 25 |

Really nice work  ( Can´t say that often enough ^^ )

( Can´t say that often enough ^^ )

The Prints are looking really great with the new Idler.

Keep up you great effort to bring 3d Printing further

I would so so love to be one of your "adventurous test pilots"

But im still a noob in all this "RepRap'ing" even though it really catched my interrest.

( Can´t say that often enough ^^ )

( Can´t say that often enough ^^ )The Prints are looking really great with the new Idler.

Keep up you great effort to bring 3d Printing further

I would so so love to be one of your "adventurous test pilots"

But im still a noob in all this "RepRap'ing" even though it really catched my interrest.

|

Re: FoldaRap May 30, 2012 07:02PM |

Registered: 13 years ago Posts: 615 |

If that interest you I will try to offer few kits and assembled machines during this summer

That will allow me to refine the BOM, since the first orders were made in January ^^'

I have enough money and spares to build 2-3 machines, but I may try to set up a small crowdfunding campaign on Ulule.com (a French Kickstarter) to make more for friends and beta-testers (but ten max, I don't want to see it go like the campaigns we see these days, I just want to refine this project to the point that anyone can safely do it by himself).

At first I preferred to target experienced users, but with the assembly made much easier (not Ikea yet but it's the spirit ; I also want to make a build manual like for Lego models ^^) and some little things that I think I'll always test (like the hotend), it could be interesting to also have the point of view of a newcomer

about // liberapay // flickr // wiki // thingiverse - github

That will allow me to refine the BOM, since the first orders were made in January ^^'

I have enough money and spares to build 2-3 machines, but I may try to set up a small crowdfunding campaign on Ulule.com (a French Kickstarter) to make more for friends and beta-testers (but ten max, I don't want to see it go like the campaigns we see these days, I just want to refine this project to the point that anyone can safely do it by himself).

At first I preferred to target experienced users, but with the assembly made much easier (not Ikea yet but it's the spirit ; I also want to make a build manual like for Lego models ^^) and some little things that I think I'll always test (like the hotend), it could be interesting to also have the point of view of a newcomer

about // liberapay // flickr // wiki // thingiverse - github

|

Re: FoldaRap June 02, 2012 08:04AM |

Registered: 11 years ago Posts: 25 |

|

Re: FoldaRap June 30, 2012 08:55AM |

Registered: 13 years ago Posts: 615 |

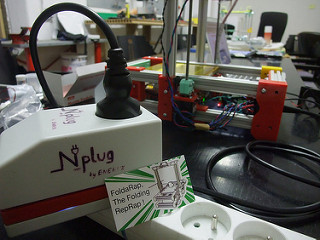

And after a long wait the campaign finally began : [www.ulule.com] ^^

|

Re: FoldaRap July 15, 2012 04:46PM |

Registered: 13 years ago Posts: 615 |

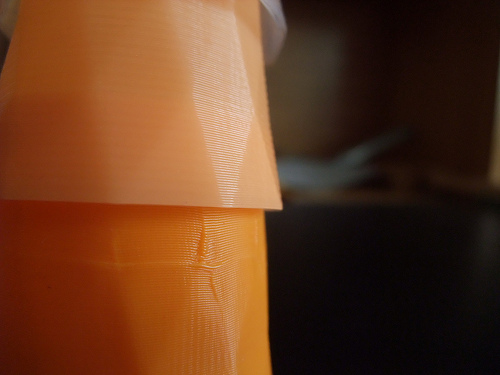

Some more pics/videos of printing (trying not to flood the wiki ^^)

[youtu.be] (a low-res cup)

[youtu.be] (the "ultimaker's tornado")

[youtu.be] (same)

I also had fun in making "russian-doll" low-res cup by changing the scale

They are all made with the Foldarap #000 (between 300 and 250µ layer height), except the bright orange one (printed on my eMaker-Huxley).

(natural pla from mendel-parts, squeezy orange from faberdashery, light orange from reprapworld)

The orange cup at 60% size is probably one of my best print with the foldarap, it just have a very subtle rigged surface (probably need to thighten a little the y-belt as it's only in that direction)

(the little artifact on the lower cup is due to the heat, printing too thin without a fan)

Edited 1 time(s). Last edit at 07/15/2012 04:49PM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

[youtu.be] (a low-res cup)

[youtu.be] (the "ultimaker's tornado")

[youtu.be] (same)

I also had fun in making "russian-doll" low-res cup by changing the scale

They are all made with the Foldarap #000 (between 300 and 250µ layer height), except the bright orange one (printed on my eMaker-Huxley).

(natural pla from mendel-parts, squeezy orange from faberdashery, light orange from reprapworld)

The orange cup at 60% size is probably one of my best print with the foldarap, it just have a very subtle rigged surface (probably need to thighten a little the y-belt as it's only in that direction)

(the little artifact on the lower cup is due to the heat, printing too thin without a fan)

Edited 1 time(s). Last edit at 07/15/2012 04:49PM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

|

Re: FoldaRap July 16, 2012 01:28PM |

Registered: 11 years ago Posts: 16 |

Great work! And thanks for doing such an amazing job of documenting the build process.

I stumbled upon your machine, while doing research to make a portable, solar powered printer. With my project being open source appropriate technology your printer would be a perfect fit. I have already mentioned and linked your work on the project page.

I was wondering if you've taken a power consumption reading?

Also, how much longer is your crowdfunding campaign running? I am pushing to get the funding for one of your printers approved quickly

I stumbled upon your machine, while doing research to make a portable, solar powered printer. With my project being open source appropriate technology your printer would be a perfect fit. I have already mentioned and linked your work on the project page.

I was wondering if you've taken a power consumption reading?

Also, how much longer is your crowdfunding campaign running? I am pushing to get the funding for one of your printers approved quickly

|

Re: FoldaRap July 16, 2012 07:20PM |

Registered: 13 years ago Posts: 615 |

Hey thanks !

I seen your project page on appropedia, and I would like to see an independently powered reprap (remember someone who did it some month ago, with two big solar panels and a car battery). I'm wondering if a recumbent bike could generate enough power as another way (and because I will have one at reach to eventually experiment).

(remember someone who did it some month ago, with two big solar panels and a car battery). I'm wondering if a recumbent bike could generate enough power as another way (and because I will have one at reach to eventually experiment).

Unfortunately I have not measured its full consumption yet : / But I want to !

I need an ampere-meter ring, or to find the time to do that with my multimeter.

For a reasonable comparison, if we used blue tape (or any cold-bed solution) instead of a heated-bed, it could be probably around 70-90W (thinking of my old mendel).

And for the campaign, it will end the 8th of August

about // liberapay // flickr // wiki // thingiverse - github

I seen your project page on appropedia, and I would like to see an independently powered reprap

(remember someone who did it some month ago, with two big solar panels and a car battery). I'm wondering if a recumbent bike could generate enough power as another way (and because I will have one at reach to eventually experiment).

(remember someone who did it some month ago, with two big solar panels and a car battery). I'm wondering if a recumbent bike could generate enough power as another way (and because I will have one at reach to eventually experiment).Unfortunately I have not measured its full consumption yet : / But I want to !

I need an ampere-meter ring, or to find the time to do that with my multimeter.

For a reasonable comparison, if we used blue tape (or any cold-bed solution) instead of a heated-bed, it could be probably around 70-90W (thinking of my old mendel).

And for the campaign, it will end the 8th of August

about // liberapay // flickr // wiki // thingiverse - github

|

Re: FoldaRap July 17, 2012 01:14PM |

Registered: 11 years ago Posts: 16 |

I wonder if the project you're refering to was ours as well? It had two panels and four batteries. That could run the printer for 4 days on one charge. But we have decided to just power it for the one day to greatly reduce the size of battery required. It will all fit into a small suitcase when it is done, thanks in a big way to your printer!

The recumbent bike can produce about 75-100W, so it would be able to run the printer no problem, without the heated bed. But you would probably want to add batteries, so it can print without stopping, and then just charge the battery back up, bit by bit whenever you feel you need some exercise!

Power meters are getting quite cheap now a days, if you're ever curious about power consumption, they are a quick and easy solution.

The recumbent bike can produce about 75-100W, so it would be able to run the printer no problem, without the heated bed. But you would probably want to add batteries, so it can print without stopping, and then just charge the battery back up, bit by bit whenever you feel you need some exercise!

Power meters are getting quite cheap now a days, if you're ever curious about power consumption, they are a quick and easy solution.

|

Re: FoldaRap July 20, 2012 08:32AM |

Registered: 13 years ago Posts: 615 |

It was this one : [www.youtube.com] it was just a guy in his backyard I believe (but one battery for a short time).

I'll look if I can find a power meters, I think the one a friend have made could be fine

about // liberapay // flickr // wiki // thingiverse - github

I'll look if I can find a power meters, I think the one a friend have made could be fine

about // liberapay // flickr // wiki // thingiverse - github

|

Re: FoldaRap July 23, 2012 10:39AM |

Registered: 11 years ago Posts: 16 |

That would be great! We are ordering your "Do-it-yourself" kit today, but I won't be able to start designing the rest of the circuit until I have a solid number for power consumption. I will be documenting the build, and keeping the entire system as low cost as possible, with BOM and build instructions. Hope you like it!

|

Re: FoldaRap July 26, 2012 07:07PM |

Registered: 13 years ago Posts: 615 |

|

Re: FoldaRap August 18, 2012 03:41AM |

Registered: 13 years ago Posts: 615 |

Ok I've a first rough number

I'm not 100% sure of the consumption we measured Wednesday's night, but the peak was around 80W (the watt-meter may not measure well the motors, my friends who build it explained me, something about if it's only a resistive thing or if inductive, the algorithm may not react correctly ... I'll try with a commercial watt-meter next time).

But for the heating consumption only it's probably around that, the peltier reach very quickly the 55°C so even if rated 80W it probably don't have the time to be at full capacity ; while the 6,8ohm hotdend supposedly draw 20W. And once the bed is at temp it use few current to maintain it (4-5mm alu plate bed ftw ^^).

Then you add the motors, but still it's way lower than what I expected, which is good

about // liberapay // flickr // wiki // thingiverse - github

I'm not 100% sure of the consumption we measured Wednesday's night, but the peak was around 80W (the watt-meter may not measure well the motors, my friends who build it explained me, something about if it's only a resistive thing or if inductive, the algorithm may not react correctly ... I'll try with a commercial watt-meter next time).

But for the heating consumption only it's probably around that, the peltier reach very quickly the 55°C so even if rated 80W it probably don't have the time to be at full capacity ; while the 6,8ohm hotdend supposedly draw 20W. And once the bed is at temp it use few current to maintain it (4-5mm alu plate bed ftw ^^).

Then you add the motors, but still it's way lower than what I expected, which is good

about // liberapay // flickr // wiki // thingiverse - github

|

Re: FoldaRap August 21, 2012 03:36PM |

Registered: 11 years ago Posts: 16 |

Sorry, only registered users may post in this forum.