Polymer Tube Couplings

Posted by Emmanuel

|

Polymer Tube Couplings September 01, 2012 09:58AM |

Registered: 13 years ago Posts: 615 |

[reprap.org]

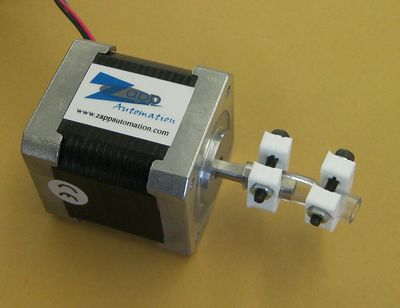

Recently I wanted to investigate the non-printed coupling idea. Trading a custom part for something that you can easily find "on-the-shelves". And I got some interesting results.

As seen on the reprappro mendel (only described as "poly tube" but with two small printed parts), or some Prusa I3 prototypes (bare tubing).

I didn't found much information on the exact material being used, nor the size of the tubing.

You need something a little smaller than the motor's shaft but quite thick to don't be too soft.

I guess-ordered some "aquarium silicone tubing" 4mm inner diameter and 6mm outer, that seemed good.

It grip well, it's hard to insert both the rod and the shaft until the middle of the tube, if half-cut to insert the shaft you can add zip-ties to secure it.

When turning the rod, there is some play before the motor follow (worse case when cut all the length with zip-ties on both rod and shaft).

When turning the motor there is no play, but not sure how it will do with the x-axis weight.

I found it too flexible at the junction, it could work but I feared of a Z-backlash.

Some days later, when reading conversations on the IRC I got confirmed on the dimensions but not on the exact material.

So I ordered all the type of tubing I could find :

1) silicone (already tried as above)

2) heatshrink tubing 3:1 ratio (12mm to 4mm) with adhesive

3) vinyl

-polyurethane (ordered, in transit)

-pvc (ordered, in transit)

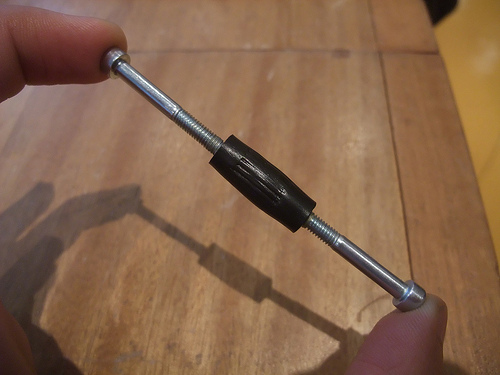

It will be worth to edit a wiki page once I tried all of them, but I can already tell you that the heatshrink tubing is the most rigid yet with a little flexibility. With the adhesive it is an almost non removable coupling.

The only annoying thing is that you must pay attention when you apply heat while keeping things centered (maybe easier for two shaft of the same diameter as showed on my try with two bolts, so that will probably need to replace the M6 rod by an M5, compared to the actual printed coupling which is 5mm/6mm)

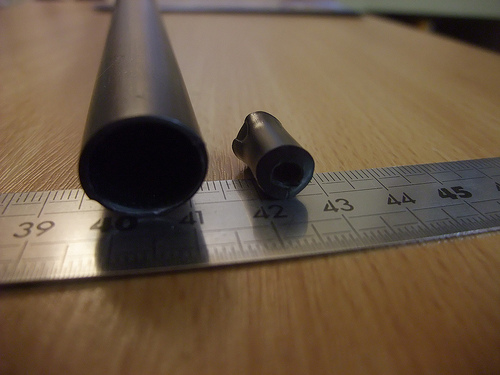

I really like the third I could try.

In fact it's not a tubing but a vinyl end cap probably used in RC hobby cars

It's 4mm inner diam. and 10mm outside, 22mm length once you cut through the end.

It grip firmly on the 5mm motor shaft and the threaded rod (once you thread it in).

When turning the rod, there is a very very small play before the motor follow.

When turning the motor there is no play. I don't know yet how it will handle the x-axis weight but this one is promising.

I will try to replace a printed coupling by these one on my foldarap and then report back.

Edited 1 time(s). Last edit at 09/01/2012 01:36PM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

Recently I wanted to investigate the non-printed coupling idea. Trading a custom part for something that you can easily find "on-the-shelves". And I got some interesting results.

As seen on the reprappro mendel (only described as "poly tube" but with two small printed parts), or some Prusa I3 prototypes (bare tubing).

I didn't found much information on the exact material being used, nor the size of the tubing.

You need something a little smaller than the motor's shaft but quite thick to don't be too soft.

I guess-ordered some "aquarium silicone tubing" 4mm inner diameter and 6mm outer, that seemed good.

It grip well, it's hard to insert both the rod and the shaft until the middle of the tube, if half-cut to insert the shaft you can add zip-ties to secure it.

When turning the rod, there is some play before the motor follow (worse case when cut all the length with zip-ties on both rod and shaft).

When turning the motor there is no play, but not sure how it will do with the x-axis weight.

I found it too flexible at the junction, it could work but I feared of a Z-backlash.

Some days later, when reading conversations on the IRC I got confirmed on the dimensions but not on the exact material.

So I ordered all the type of tubing I could find :

1) silicone (already tried as above)

2) heatshrink tubing 3:1 ratio (12mm to 4mm) with adhesive

3) vinyl

-polyurethane (ordered, in transit)

-pvc (ordered, in transit)

It will be worth to edit a wiki page once I tried all of them, but I can already tell you that the heatshrink tubing is the most rigid yet with a little flexibility. With the adhesive it is an almost non removable coupling.

The only annoying thing is that you must pay attention when you apply heat while keeping things centered (maybe easier for two shaft of the same diameter as showed on my try with two bolts, so that will probably need to replace the M6 rod by an M5, compared to the actual printed coupling which is 5mm/6mm)

I really like the third I could try.

In fact it's not a tubing but a vinyl end cap probably used in RC hobby cars

It's 4mm inner diam. and 10mm outside, 22mm length once you cut through the end.

It grip firmly on the 5mm motor shaft and the threaded rod (once you thread it in).

When turning the rod, there is a very very small play before the motor follow.

When turning the motor there is no play. I don't know yet how it will handle the x-axis weight but this one is promising.

I will try to replace a printed coupling by these one on my foldarap and then report back.

Edited 1 time(s). Last edit at 09/01/2012 01:36PM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

|

Re: Polymer Tube Couplings September 01, 2012 02:53PM |

Registered: 13 years ago Posts: 615 |

Not sure I will try the other tubing, the vinyl end cap seems perfect

[youtu.be]

[youtu.be]

Unfortunately they are sold by 50 and I haven't found lower quantity yet, but that probably exist : /

If you need just few of them I listed some spares on emakershop : [www.emakershop.com]

Edited 1 time(s). Last edit at 09/01/2012 03:01PM by Emmanuel.

[youtu.be]

[youtu.be]

Unfortunately they are sold by 50 and I haven't found lower quantity yet, but that probably exist : /

If you need just few of them I listed some spares on emakershop : [www.emakershop.com]

Edited 1 time(s). Last edit at 09/01/2012 03:01PM by Emmanuel.

|

Re: Polymer Tube Couplings September 03, 2012 02:21AM |

Admin Registered: 16 years ago Posts: 13,884 |

... look at the attached images in this post: [forums.reprap.org]

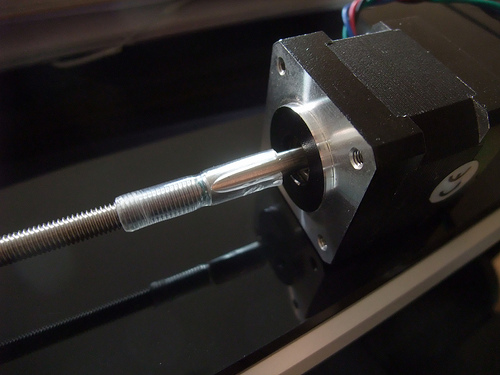

I'm using tubes for pneumatic connections, that can withstand until 10bar and are slightly elastic (so you can screw them onto the threaded rod), but stiff enough, so they won't twist, even if the motor is highly overpowered (e.g. NEMA23 or NEMA 54 with >2Nm torque)

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

I'm using tubes for pneumatic connections, that can withstand until 10bar and are slightly elastic (so you can screw them onto the threaded rod), but stiff enough, so they won't twist, even if the motor is highly overpowered (e.g. NEMA23 or NEMA 54 with >2Nm torque)

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Polymer Tube Couplings September 03, 2012 02:25PM |

Registered: 13 years ago Posts: 615 |

|

Re: Polymer Tube Couplings September 04, 2012 03:38AM |

Admin Registered: 16 years ago Posts: 13,884 |

... maybe one of my key jobs is to rememeber/point to old threads, where same/similar ideas were discussed or presented

Another point is, that with maybe 30+ years of experiece in RP-development on comercial and DIY level there is some viable kow-how to share

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Polymer Tube Couplings September 27, 2012 05:54PM |

Registered: 13 years ago Posts: 615 |

|

Re: Polymer Tube Couplings December 31, 2012 11:23PM |

Registered: 12 years ago Posts: 539 |

|

Re: Polymer Tube Couplings January 03, 2013 01:35PM |

Registered: 13 years ago Posts: 615 |

I don't know for the Prusa I3, personally I'm using the black vinyl one pictured above and it works nice

I got them on ebay, and sell also some on emakershop : [www.emakershop.com]

about // liberapay // flickr // wiki // thingiverse - github

I got them on ebay, and sell also some on emakershop : [www.emakershop.com]

about // liberapay // flickr // wiki // thingiverse - github

|

Re: Polymer Tube Couplings January 09, 2013 03:50AM |

Admin Registered: 16 years ago Posts: 13,884 |

... I've used standard pneumatic tubes from Festo - should be PU as specified here: [www.festo.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.