back to direct drive Nema14

Posted by Emmanuel

|

back to direct drive Nema14 December 16, 2012 09:18PM |

Registered: 13 years ago Posts: 615 |

I'm trying something on the Foldarap #000...

After having considered to have manufactured custom geared motors like the PG35L but with better specs ( [forums.reprap.org] ), I'm now going back to the original idea : direct drive nema14.

Because there was something that I should have tried at that time when I switched to the PG35L : just raise the driver current. (when the nema14 was starting to skip steps).

And on video : [www.youtube.com]

This need more testing to be confirmed but everything seems good so far

I raised the Vref current of the pololu from 0.4v to 0.45v (= from 1A to 1.13A to the motor)

And I'm printing at the same speed as with the PG35L, but with the lightning retractions that I like on direct drive setups.

I was stuck at 25mm/s during the early tries with a direct drive nema14, then up to 70mm/s with the pg35l and not tested above, so this is a jump from 25 to 50mm/s for this new try.

For the print settings :

Also, I'm not used to play with acceleration settings, so I copied some that I found in an Orca firmware I had around.

I may try to go higher then

For the exact setup :

Nema14 : 35STH36-1004A from LDO-motors

Drive gear : stainless-steel insert from mendel-parts

Idler bearing : a rubber-roller salvaged from a Stratasys cartridge (I added a spray of PTFE to the printed idler)

And the spring was almost not compressed.

This. Looks. Promising. (at least from my point of view)

about // liberapay // flickr // wiki // thingiverse - github

After having considered to have manufactured custom geared motors like the PG35L but with better specs ( [forums.reprap.org] ), I'm now going back to the original idea : direct drive nema14.

Because there was something that I should have tried at that time when I switched to the PG35L : just raise the driver current. (when the nema14 was starting to skip steps).

And on video : [www.youtube.com]

This need more testing to be confirmed but everything seems good so far

I raised the Vref current of the pololu from 0.4v to 0.45v (= from 1A to 1.13A to the motor)

And I'm printing at the same speed as with the PG35L, but with the lightning retractions that I like on direct drive setups.

I was stuck at 25mm/s during the early tries with a direct drive nema14, then up to 70mm/s with the pg35l and not tested above, so this is a jump from 25 to 50mm/s for this new try.

For the print settings :

; generated by Slic3r 0.9.7 on 2012-12-17 at 01:45:50 ; Marlin-RC2 ; absolute X Y Z E ; 140 E-step-mm ; 195°C / 52°C ; layer_height = 0.25 ; perimeters = 2 ; top_solid_layers = 0 ; bottom_solid_layers = 0 ; fill_density = 0 ; perimeter_speed = 50 ; infill_speed = 45 ; travel_speed = 200 ; scale = 1 ; nozzle_diameter = 0.5 ; filament_diameter = 1.70 ; extrusion_multiplier = 1 ; perimeters extrusion width = 0.48mm ; infill extrusion width = 0.49mm ; first layer extrusion width = 0.50mm

Also, I'm not used to play with acceleration settings, so I copied some that I found in an Orca firmware I had around.

I may try to go higher then

#define DEFAULT_AXIS_STEPS_PER_UNIT {80, 80, 3200, 140} // FoldaRap 1200 for PG35L

#define DEFAULT_MAX_FEEDRATE {500, 500, 5, 45} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {9000,9000,50,5000} // X, Y, Z, E maximum start speed for accelerated moves.

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves // 1500

#define DEFAULT_RETRACT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for r retracts // 1200 for PG35L

#define DEFAULT_XYJERK 20.0 // (mm/sec)

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec) // 1 for PG35L

For the exact setup :

Nema14 : 35STH36-1004A from LDO-motors

Drive gear : stainless-steel insert from mendel-parts

Idler bearing : a rubber-roller salvaged from a Stratasys cartridge (I added a spray of PTFE to the printed idler)

And the spring was almost not compressed.

This. Looks. Promising. (at least from my point of view)

about // liberapay // flickr // wiki // thingiverse - github

|

Re: back to direct drive Nema14 December 18, 2012 07:49PM |

Registered: 13 years ago Posts: 615 |

More videos :

[www.youtube.com]

[youtu.be]

[youtu.be]

[youtu.be]

[youtu.be]

[youtu.be] (extruder-idler close-up)

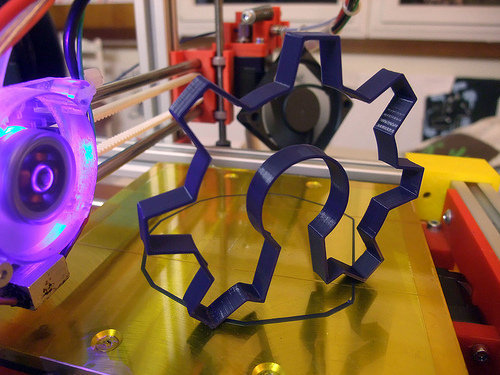

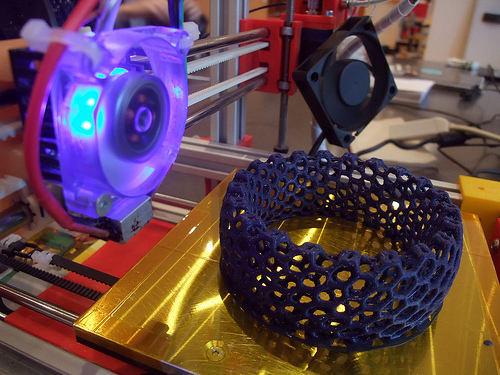

DSCF3437 by watsdesign, on Flickr

And a last video [www.flickr.com]

^^

[www.youtube.com]

[youtu.be]

[youtu.be]

[youtu.be]

[youtu.be]

[youtu.be] (extruder-idler close-up)

DSCF3437 by watsdesign, on Flickr

And a last video [www.flickr.com]

^^

|

Re: back to direct drive Nema14 December 22, 2012 11:20AM |

Registered: 13 years ago Posts: 615 |

I'm trying to tune a little the acceleration settings.

From that thread there was some interesting but rare numbers.

So I raised a little my settings :

#define DEFAULT_RETRACT_ACCELERATION 5000 (was 3000)

#define DEFAULT_XYJERK 25.0 (was 20)

And the speed retract in Slic3r from 15 to 20mm/s

Will try with that numbers and a few other things

about // liberapay // flickr // wiki // thingiverse - github

From that thread there was some interesting but rare numbers.

Quote

Jamesdanielv

i use a setting between 20-35 for jerk settings. and 1 on the z axis setting. this is about right for my machine. any faster print quality suffers, and i have parts start to loosen up. you do want this as high as possible because prints will take less time. there are a lot of short moves in a print job. this setting effects the short moves. acceleration kicks in afterwards.

I think default settings are around 15. currently I have set my latest printer a prusa to 25 for x,y and 1 for z.

Quote

Sublime

For Tantillus I have the Acceleration set to 10000 for E and the Jerk set to 100 because of the need for a 5.5mm retract on the Bowden cable and we want it instantaneous. This may not work for most printers since on a bowden machine the filament springiness is enough to accelerate the extruder backwards really fast and prevent skipped steps while retracting.

So I raised a little my settings :

#define DEFAULT_RETRACT_ACCELERATION 5000 (was 3000)

#define DEFAULT_XYJERK 25.0 (was 20)

And the speed retract in Slic3r from 15 to 20mm/s

Will try with that numbers and a few other things

about // liberapay // flickr // wiki // thingiverse - github

|

Re: back to direct drive Nema14 December 23, 2012 07:53PM |

Registered: 13 years ago Posts: 615 |

As expected it's way faster now

printing : [www.youtube.com]

another extruder close-up (to compare with the previous) : [www.youtube.com]

about // liberapay // flickr // wiki // thingiverse - github

printing : [www.youtube.com]

another extruder close-up (to compare with the previous) : [www.youtube.com]

about // liberapay // flickr // wiki // thingiverse - github

|

Re: back to direct drive Nema14 December 24, 2012 06:26AM |

Registered: 13 years ago Posts: 615 |

A new try :

#define DEFAULT_MAX_FEEDRATE {500, 500, 5, 50} (E was 45)

#define DEFAULT_MAX_ACCELERATION {9000,9000,50,10000} (E was 5000)

#define DEFAULT_ACCELERATION 3000

#define DEFAULT_RETRACT_ACCELERATION 10000 (was 5000)

#define DEFAULT_XYJERK 24.0 // (mm/sec) (was 25)

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec) // 1 for PG35L

[/code]

And the travel speed in Slic3r from 200 to 500 mm/s, and retract speed from 20 to 25 mm/s

Will need more test for the print speeds, but the travel seems better (less resonance)

Edited 1 time(s). Last edit at 12/24/2012 10:47AM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

#define DEFAULT_MAX_FEEDRATE {500, 500, 5, 50} (E was 45)

#define DEFAULT_MAX_ACCELERATION {9000,9000,50,10000} (E was 5000)

#define DEFAULT_ACCELERATION 3000

#define DEFAULT_RETRACT_ACCELERATION 10000 (was 5000)

#define DEFAULT_XYJERK 24.0 // (mm/sec) (was 25)

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec) // 1 for PG35L

[/code]

And the travel speed in Slic3r from 200 to 500 mm/s, and retract speed from 20 to 25 mm/s

Will need more test for the print speeds, but the travel seems better (less resonance)

Edited 1 time(s). Last edit at 12/24/2012 10:47AM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

|

Re: back to direct drive Nema14 January 15, 2013 03:14AM |

Registered: 11 years ago Posts: 86 |

Hello Emmanuel,

On my first prototype of MARepRap, the retraction parameter in Slic3r is 30 mm/s and this works fine. I think you could go from 20 to 30 mm/s.

Anyway, very good topic, I'm goind to improve my prototype parameters.

Edited 1 time(s). Last edit at 01/15/2013 08:43AM by pyroboynroses.

On my first prototype of MARepRap, the retraction parameter in Slic3r is 30 mm/s and this works fine. I think you could go from 20 to 30 mm/s.

Anyway, very good topic, I'm goind to improve my prototype parameters.

Edited 1 time(s). Last edit at 01/15/2013 08:43AM by pyroboynroses.

|

Re: back to direct drive Nema14 January 15, 2013 08:38AM |

Registered: 13 years ago Posts: 615 |

|

Re: back to direct drive Nema14 January 25, 2013 05:03AM |

Registered: 13 years ago Posts: 615 |

|

Re: back to direct drive Nema14 January 25, 2013 08:46AM |

Admin Registered: 12 years ago Posts: 2,569 |

|

Re: back to direct drive Nema14 January 25, 2013 09:08AM |

Registered: 13 years ago Posts: 615 |

|

Re: back to direct drive Nema14 January 25, 2013 03:43PM |

Registered: 11 years ago Posts: 18 |

|

Re: back to direct drive Nema14 January 28, 2013 04:49AM |

Registered: 13 years ago Posts: 615 |

|

Re: back to direct drive Nema14 January 28, 2013 04:52AM |

Registered: 11 years ago Posts: 86 |

Sorry, only registered users may post in this forum.