Foldarap #21

Posted by bools

|

Foldarap #21 January 27, 2013 04:01PM |

Registered: 11 years ago Posts: 7 |

Hi Emmanuel !

Very nice kit overall, I'm impressed by the easyness of building the

machine. However some points still bother me and get me stuck in the

pursuit of the building.

_Contact switches:_ builders need to be aware of the different lengths of

wire, I first disn't. I'll had a remark on the wiki later.

Is the placement of the contact switches important~? For instance my

front foot haven't any holes for mounting and I did understand were to

glue it.

M3 screws are very hard to screw in the holes of the switch and thus

it's quite hard to screw it in the plastic. I hope to precise placement

is needed…

_Hot-end:_ The lasercut meduim part is just a template and is not needed

since holes are already there, right?

I didn't get any of the white tape that you put on the threads of the

nozzle, is it a needed part? If so, where can I get it? Whithout it

seems quite hard to tighten the nozzle.

_Y-carriage:_ Mine seems to be a bit too large and the screw don't go

very well an the medium part. I guess larger washer and longer holes in

the medium could help. Also three washer par screw would be better in

order to have: screew head - washer - medium - washer - spring - washer

- nut.

_Extruder:_ I got the extruder-idler_pg35l-brass-insert-603zz version.

But it's not exactly the same version as the photo in the guide, and the

screw and bearing isn't attached and is only maintained by the filament

and the pulley. Thus it's not that easy to keep it in place.

_Electronics:_ there is no heatsink on the stepper drivers I get

contrary to the photos in the guide, is it normal? no risk of bad smokes? ;-)

I didn't understand the checking step for the stepper drivers, is it

needed for the kit mounting or did you already chekced them?

_Wiring:_ I find easier to place the PSU after doing most of the wiring

since it gives more room for fingers!

Some other random points~:

- T-nuts: two types in the bag I get, one is very effective, the other

is quite difficult to put in place and generally don't go

perpendicular to the extrusion.

- Some printed parts needs a bit of work with the exacto knife.

- Holes for the M3 nuts in many printed parts are ofen too loose: in

order to prevent the nut to slip, I needed to put some tape.

- What kind of grease do you use for the smooth rods and the

PLA/aluminium contacts?

Sorry for the long message, I hope it will be usefull for others!

--

Nicolas

Very nice kit overall, I'm impressed by the easyness of building the

machine. However some points still bother me and get me stuck in the

pursuit of the building.

_Contact switches:_ builders need to be aware of the different lengths of

wire, I first disn't. I'll had a remark on the wiki later.

Is the placement of the contact switches important~? For instance my

front foot haven't any holes for mounting and I did understand were to

glue it.

M3 screws are very hard to screw in the holes of the switch and thus

it's quite hard to screw it in the plastic. I hope to precise placement

is needed…

_Hot-end:_ The lasercut meduim part is just a template and is not needed

since holes are already there, right?

I didn't get any of the white tape that you put on the threads of the

nozzle, is it a needed part? If so, where can I get it? Whithout it

seems quite hard to tighten the nozzle.

_Y-carriage:_ Mine seems to be a bit too large and the screw don't go

very well an the medium part. I guess larger washer and longer holes in

the medium could help. Also three washer par screw would be better in

order to have: screew head - washer - medium - washer - spring - washer

- nut.

_Extruder:_ I got the extruder-idler_pg35l-brass-insert-603zz version.

But it's not exactly the same version as the photo in the guide, and the

screw and bearing isn't attached and is only maintained by the filament

and the pulley. Thus it's not that easy to keep it in place.

_Electronics:_ there is no heatsink on the stepper drivers I get

contrary to the photos in the guide, is it normal? no risk of bad smokes? ;-)

I didn't understand the checking step for the stepper drivers, is it

needed for the kit mounting or did you already chekced them?

_Wiring:_ I find easier to place the PSU after doing most of the wiring

since it gives more room for fingers!

Some other random points~:

- T-nuts: two types in the bag I get, one is very effective, the other

is quite difficult to put in place and generally don't go

perpendicular to the extrusion.

- Some printed parts needs a bit of work with the exacto knife.

- Holes for the M3 nuts in many printed parts are ofen too loose: in

order to prevent the nut to slip, I needed to put some tape.

- What kind of grease do you use for the smooth rods and the

PLA/aluminium contacts?

Sorry for the long message, I hope it will be usefull for others!

--

Nicolas

|

Re: Foldarap #21 January 28, 2013 10:42AM |

Registered: 13 years ago Posts: 615 |

bools Wrote:

-------------------------------------------------------

> Hi Emmanuel !

>

> Very nice kit overall, I'm impressed by the

> easyness of building the

> machine. However some points still bother me and

> get me stuck in the

> pursuit of the building.

Thanks ! Lets see that...

> > _Contact switches:_ builders need to be aware of

> the different lengths of

> wire, I first disn't. I'll had a remark on the

> wiki later.

The logic is RGB, red, green, blue = XYZ

(it's also mentioned at each step which color to pick)

> > Is the placement of the contact switches

> important~? For instance my

> front foot haven't any holes for mounting and I

> did understand were to

> glue it.

There should be a small mark in the plastic to help placing it

> > M3 screws are very hard to screw in the holes of

> the switch and thus

> it's quite hard to screw it in the plastic. I hope

> to precise placement

> is needed…

Indeed, I guess the holes are for M2 screws, hence my preference to glue them instead of filling the holes ^^'

> > _Hot-end:_ The lasercut meduim part is just a

> template and is not needed

> since holes are already there, right?

Right, it's in the build manual for those who want to make it by themself but it's already done in my kit

> > I didn't get any of the white tape that you put on

> the threads of the

> nozzle, is it a needed part? If so, where can I

> get it? Whithout it

> seems quite hard to tighten the nozzle.

It's not absolutely needed (I've several head without plumbing tape) but you can basicaly find it in any hardware store (plubing or PTFE tape)

> > _Y-carriage:_ Mine seems to be a bit too large and

> the screw don't go

> very well an the medium part. I guess larger

> washer and longer holes in

> the medium could help. Also three washer par screw

> would be better in

> order to have: screew head - washer - medium -

> washer - spring - washer

> - nut.

Hmm I see, the both have been made (with or without this additional washer) and works

> > _Extruder:_ I got the

> extruder-idler_pg35l-brass-insert-603zz version.

> But it's not exactly the same version as the photo

> in the guide, and the

> screw and bearing isn't attached and is only

> maintained by the filament

> and the pulley. Thus it's not that easy to keep it

> in place.

Yep, like for the rubber roller version, the filament keep everything together

> > _Electronics:_ there is no heatsink on the stepper

> drivers I get

> contrary to the photos in the guide, is it normal?

> no risk of bad smokes? ;-)

Don't worry, they are very good drivers, nicely designed to be effectively cooled by the pcb, don't need an heatsink

> > I didn't understand the checking step for the

> stepper drivers, is it

> needed for the kit mounting or did you already

> chekced them?

Already done

> > _Wiring:_ I find easier to place the PSU after

> doing most of the wiring

> since it gives more room for fingers!

Didn't though of that

> > Some other random points~:

> - T-nuts: two types in the bag I get, one is

> very effective, the other is quite difficult to put in place and generally don't go perpendicular to the extrusion.

I know, but it's like lottery when I buy them : /

> - Some printed parts needs a bit of work with

> the exacto knife.

> - Holes for the M3 nuts in many printed parts

> are ofen too loose: in order to prevent the nut to slip, I needed to put some tape.

Ah, I need to check that

> - What kind of grease do you use for the smooth rods and the PLA/aluminium contacts?

"3in1" oil for the printed parts that slide on aluminium, but even olive oil could work I believe

It's far from perfect for the moment, but we can work on it ^^

about // liberapay // flickr // wiki // thingiverse - github

-------------------------------------------------------

> Hi Emmanuel !

>

> Very nice kit overall, I'm impressed by the

> easyness of building the

> machine. However some points still bother me and

> get me stuck in the

> pursuit of the building.

Thanks ! Lets see that...

> > _Contact switches:_ builders need to be aware of

> the different lengths of

> wire, I first disn't. I'll had a remark on the

> wiki later.

The logic is RGB, red, green, blue = XYZ

(it's also mentioned at each step which color to pick)

> > Is the placement of the contact switches

> important~? For instance my

> front foot haven't any holes for mounting and I

> did understand were to

> glue it.

There should be a small mark in the plastic to help placing it

> > M3 screws are very hard to screw in the holes of

> the switch and thus

> it's quite hard to screw it in the plastic. I hope

> to precise placement

> is needed…

Indeed, I guess the holes are for M2 screws, hence my preference to glue them instead of filling the holes ^^'

> > _Hot-end:_ The lasercut meduim part is just a

> template and is not needed

> since holes are already there, right?

Right, it's in the build manual for those who want to make it by themself but it's already done in my kit

> > I didn't get any of the white tape that you put on

> the threads of the

> nozzle, is it a needed part? If so, where can I

> get it? Whithout it

> seems quite hard to tighten the nozzle.

It's not absolutely needed (I've several head without plumbing tape) but you can basicaly find it in any hardware store (plubing or PTFE tape)

> > _Y-carriage:_ Mine seems to be a bit too large and

> the screw don't go

> very well an the medium part. I guess larger

> washer and longer holes in

> the medium could help. Also three washer par screw

> would be better in

> order to have: screew head - washer - medium -

> washer - spring - washer

> - nut.

Hmm I see, the both have been made (with or without this additional washer) and works

> > _Extruder:_ I got the

> extruder-idler_pg35l-brass-insert-603zz version.

> But it's not exactly the same version as the photo

> in the guide, and the

> screw and bearing isn't attached and is only

> maintained by the filament

> and the pulley. Thus it's not that easy to keep it

> in place.

Yep, like for the rubber roller version, the filament keep everything together

> > _Electronics:_ there is no heatsink on the stepper

> drivers I get

> contrary to the photos in the guide, is it normal?

> no risk of bad smokes? ;-)

Don't worry, they are very good drivers, nicely designed to be effectively cooled by the pcb, don't need an heatsink

> > I didn't understand the checking step for the

> stepper drivers, is it

> needed for the kit mounting or did you already

> chekced them?

Already done

> > _Wiring:_ I find easier to place the PSU after

> doing most of the wiring

> since it gives more room for fingers!

Didn't though of that

> > Some other random points~:

> - T-nuts: two types in the bag I get, one is

> very effective, the other is quite difficult to put in place and generally don't go perpendicular to the extrusion.

I know, but it's like lottery when I buy them : /

> - Some printed parts needs a bit of work with

> the exacto knife.

> - Holes for the M3 nuts in many printed parts

> are ofen too loose: in order to prevent the nut to slip, I needed to put some tape.

Ah, I need to check that

> - What kind of grease do you use for the smooth rods and the PLA/aluminium contacts?

"3in1" oil for the printed parts that slide on aluminium, but even olive oil could work I believe

It's far from perfect for the moment, but we can work on it ^^

about // liberapay // flickr // wiki // thingiverse - github

|

Re: Foldarap #21 January 28, 2013 11:48AM |

Registered: 11 years ago Posts: 48 |

|

Re: Foldarap #21 February 08, 2013 04:30AM |

Registered: 11 years ago Posts: 7 |

Thanks for all the kind answers!

I choose english to help the international builders but don't hesitate to switch back to french if you prefer.

Last weeks, I didn't had much time but still find some time to work on my foldarap and implement your advices. I still have one or two question and I hope I'm 2h far from first printing!

_Wiring_:

I didn't find were to connect the fans.

Do you use the suplementary power input for the motors? In that case, I just have to connect the secondary GND, +12 of the PSU to the card?

I added the Azteeg X1 wiring on the wiki page, don't hesitate to remove if you don't find it usefull.

And some remarks:

_Y carriage_:

I had the same difficulties as Ju de tomate with it: the screew go on the side and don't grip well an the medium plate. His trick is working well: just add some rubber band to hold them.

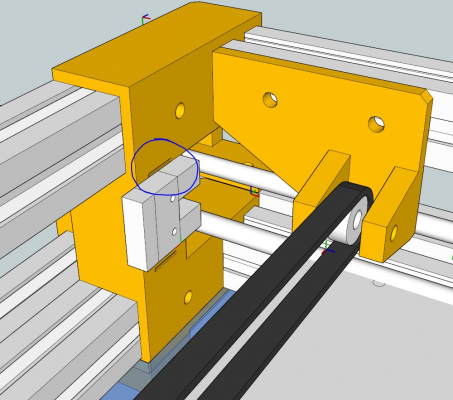

_X carriage_:

I had to un tight a bit the screw holding the hot end, otherwise the X carriage go less smoothly on the rods.

_X belt tensionning_:

The printed part too hold the motor was a bit meesy and thus the motor don't move and does not allow to put some tension on the belt. I plan to use this thing or this one to add some tension on the belt. For references: also this simplier one and simpliest?.

I added a remark on the wiki about the X motor mounting, one should place it as close as possible to the extrusion in a first place to be able to add tension. Same don't hesitate to modify/remove!

And one last question, I can't remember the name of the wiki user who is exploring autonomous printing solutions. I plan to use OctoPrint and my rpi to make my foldarap a true network-enable autonomous 3D printer! I'll keep you updated.

Have a nice day!

--

Nicolas

I choose english to help the international builders but don't hesitate to switch back to french if you prefer.

Last weeks, I didn't had much time but still find some time to work on my foldarap and implement your advices. I still have one or two question and I hope I'm 2h far from first printing!

_Wiring_:

I didn't find were to connect the fans.

Do you use the suplementary power input for the motors? In that case, I just have to connect the secondary GND, +12 of the PSU to the card?

I added the Azteeg X1 wiring on the wiki page, don't hesitate to remove if you don't find it usefull.

And some remarks:

_Y carriage_:

I had the same difficulties as Ju de tomate with it: the screew go on the side and don't grip well an the medium plate. His trick is working well: just add some rubber band to hold them.

_X carriage_:

I had to un tight a bit the screw holding the hot end, otherwise the X carriage go less smoothly on the rods.

_X belt tensionning_:

The printed part too hold the motor was a bit meesy and thus the motor don't move and does not allow to put some tension on the belt. I plan to use this thing or this one to add some tension on the belt. For references: also this simplier one and simpliest?.

I added a remark on the wiki about the X motor mounting, one should place it as close as possible to the extrusion in a first place to be able to add tension. Same don't hesitate to modify/remove!

And one last question, I can't remember the name of the wiki user who is exploring autonomous printing solutions. I plan to use OctoPrint and my rpi to make my foldarap a true network-enable autonomous 3D printer! I'll keep you updated.

Have a nice day!

--

Nicolas

|

Re: Foldarap #21 February 08, 2013 06:14AM |

Registered: 11 years ago Posts: 48 |

|

Re: Foldarap #21 February 08, 2013 05:45PM |

Registered: 11 years ago Posts: 7 |

Thanks ju de tomate.

Tonight I finish the mounting of the foldarap and hoped to do my first print. Hoped…

I have a problem with the hotend: it did reach the desired temperature. The temperature stabilized at 135°C so I still miss 40°C to be able to print.

I have no idea whatsoever to tackle with this problem…

Any hints?

Tonight I finish the mounting of the foldarap and hoped to do my first print. Hoped…

I have a problem with the hotend: it did reach the desired temperature. The temperature stabilized at 135°C so I still miss 40°C to be able to print.

I have no idea whatsoever to tackle with this problem…

Any hints?

|

Re: Foldarap #21 February 09, 2013 02:47AM |

Registered: 11 years ago Posts: 7 |

I've continued some test to bring some more information.

With the fan on: temp of the hotend stabilize @at 135°C

With the fan off (I temporaly un plugged it): temp of the hot end stabilize at 170°C

So my conclusion is that either:

- heating resitor do not bring enought heat,

- the cooling system (rad + fan, even fan only) is too efficient.

One idea I had after some reading in the forum is that the hole for the resistor in the heating block is too big and thus the resistor do not tight fit in it. I've try to add more thermic paste to help but it didn't change anything.

Because of my tests, my filament has melt in the pfte bowden tube and I think I'll need a new one :-(

@Emmanuel: do you have some spares that I can buy to you?

So I have now two problems: clean the mess, find why the hot end is not hot enough

Thanks for your help!

Damn, I was so close to the first print yesterday!

With the fan on: temp of the hotend stabilize @at 135°C

With the fan off (I temporaly un plugged it): temp of the hot end stabilize at 170°C

So my conclusion is that either:

- heating resitor do not bring enought heat,

- the cooling system (rad + fan, even fan only) is too efficient.

One idea I had after some reading in the forum is that the hole for the resistor in the heating block is too big and thus the resistor do not tight fit in it. I've try to add more thermic paste to help but it didn't change anything.

Because of my tests, my filament has melt in the pfte bowden tube and I think I'll need a new one :-(

@Emmanuel: do you have some spares that I can buy to you?

So I have now two problems: clean the mess, find why the hot end is not hot enough

Thanks for your help!

Damn, I was so close to the first print yesterday!

|

Re: Foldarap #21 February 09, 2013 10:13AM |

Registered: 11 years ago Posts: 7 |

Eureka! My heating block was touching the rad and thus disipate a lot of power in the air. I Just putted 3 layer of kapton between them and it now reach higher temp.

Still I have to set a 197°C hot end temp to get 185°C, perhaps some problem with the PID parameters.

However, still not able to print :-( It seems that not enough PLA is extruded. Is that a Firmware problem ?

Currently playing with the M221command to see if I can experimentaly compensate for that. Not a proper solution...

I'll keep you guys updated!

Still I have to set a 197°C hot end temp to get 185°C, perhaps some problem with the PID parameters.

However, still not able to print :-( It seems that not enough PLA is extruded. Is that a Firmware problem ?

Currently playing with the M221command to see if I can experimentaly compensate for that. Not a proper solution...

I'll keep you guys updated!

|

Re: Foldarap #21 February 09, 2013 12:52PM |

Registered: 11 years ago Posts: 7 |

I finish to be able to print !

I set the extruder multiplier to 800% and get that first print.

The quality is not wonderfull and i think i need to fine tune this parameter. Curently testing 760% seems to be better.

I have some noob questions. How far from the print schould be the head? Mine is very near to it and I wonder if it also explain the moderate quality. How to modify this? I guess the slic3r conf but not sure it is the rigth place.

@Emmanuel: do you have any recommendation on wich conf file to use?

Have a nice week-end folks!

I set the extruder multiplier to 800% and get that first print.

The quality is not wonderfull and i think i need to fine tune this parameter. Curently testing 760% seems to be better.

I have some noob questions. How far from the print schould be the head? Mine is very near to it and I wonder if it also explain the moderate quality. How to modify this? I guess the slic3r conf but not sure it is the rigth place.

@Emmanuel: do you have any recommendation on wich conf file to use?

Have a nice week-end folks!

|

Re: Foldarap #21 February 09, 2013 01:41PM |

Registered: 11 years ago Posts: 48 |

For the slicer I use this file : config_slic3r-097_foldarap012.ini on the [github.com]

Also for me when I tried to extrude 5mm, PLA move on only around 1mm.

Emmanuel explain me how to modify the firmware because the firmware on the sanguino is for extruder with Nema 17 :

Firmware modification : #define STEPS_MM_E 1200 // 1200 for PG35L 140 for Nema14

I can give you more information if you want.

Also for me when I tried to extrude 5mm, PLA move on only around 1mm.

Emmanuel explain me how to modify the firmware because the firmware on the sanguino is for extruder with Nema 17 :

Firmware modification : #define STEPS_MM_E 1200 // 1200 for PG35L 140 for Nema14

I can give you more information if you want.

|

Re: Foldarap #21 February 11, 2013 08:36AM |

Registered: 13 years ago Posts: 615 |

*Tu a bien fait d'ajouter ça au wiki

*Pour le user c'était "Spiritdude"

*spares parts, j'en ai

*température du block, c'est étrange qu'il touche le radiateur, il fallait peut-être pas autant le visser (autrement il y a toujours un écart)

*firmware, en effet celui uploadé dans ta carte n'avait pas la bonne valeur, c'est 1200 pour le moteur blanc comme l'a dit Ju (d'ailleurs merci Ju de partager ton expérience ^^)

*Pour le user c'était "Spiritdude"

*spares parts, j'en ai

*température du block, c'est étrange qu'il touche le radiateur, il fallait peut-être pas autant le visser (autrement il y a toujours un écart)

*firmware, en effet celui uploadé dans ta carte n'avait pas la bonne valeur, c'est 1200 pour le moteur blanc comme l'a dit Ju (d'ailleurs merci Ju de partager ton expérience ^^)

|

Re: Foldarap #21 February 11, 2013 09:13AM |

Registered: 11 years ago Posts: 7 |

Merci ju de tomate, j'ai recompilé le firmware avec cette modif et c'est parfait maintenant !

À noter, j'ai également changé :

- ajout de #define EEPROM_SETTINGS et #define EEPROM_CHITCHAT c'est pratique de voir la conf et la modifier en direct

- et #define QUICK_HOME, on gagne quelques secondes pendant le homing en bougeant X et Y en même temps jusquau premier endstop activé

Bénéfice supplémantaire du changement, impréssion 50% plus rapide, avec l'ancien il s'arretait longtemps a chaque changement de direction, je pense que c'était lié à la rétractation qui était exagéré.

@Emmanuel, pas besoin de pièces supplémentaire, la cata de vendredi soir s'est arrangé toute seule, merci !

Très intéressante la page de Spiritdude, j'ai hâte d'essayer tout ça

Effectivement j'avait trop visser le block et pas assez le nez, je rajoute ça comme warning au wiki.

Déjà quelques bonnes impréssions, ça fait plaisir !

Prochaine étape : + de précision ! J'ai déjà fait le test sur le concours de DeuxVis (upload de photo bientôt) et j'obtiens 2 dixième de précision, va falloir multiplier la précision par 4 si je veux pouvoir faire des pièces de Foldarap.

À noter, j'ai également changé :

- ajout de #define EEPROM_SETTINGS et #define EEPROM_CHITCHAT c'est pratique de voir la conf et la modifier en direct

- et #define QUICK_HOME, on gagne quelques secondes pendant le homing en bougeant X et Y en même temps jusquau premier endstop activé

Bénéfice supplémantaire du changement, impréssion 50% plus rapide, avec l'ancien il s'arretait longtemps a chaque changement de direction, je pense que c'était lié à la rétractation qui était exagéré.

@Emmanuel, pas besoin de pièces supplémentaire, la cata de vendredi soir s'est arrangé toute seule, merci !

Très intéressante la page de Spiritdude, j'ai hâte d'essayer tout ça

Effectivement j'avait trop visser le block et pas assez le nez, je rajoute ça comme warning au wiki.

Déjà quelques bonnes impréssions, ça fait plaisir !

Prochaine étape : + de précision ! J'ai déjà fait le test sur le concours de DeuxVis (upload de photo bientôt) et j'obtiens 2 dixième de précision, va falloir multiplier la précision par 4 si je veux pouvoir faire des pièces de Foldarap.

|

Re: Foldarap #21 February 12, 2013 08:04AM |

Registered: 13 years ago Posts: 615 |

Sorry, only registered users may post in this forum.