Mondrian build thread

Posted by gmh39

|

Mondrian build thread January 14, 2014 01:39PM |

Registered: 10 years ago Posts: 553 |

So I was doing some research for my next printer and I came across the Mondrian (http://www.thingiverse.com/thing:22956). It fits the bill for pretty much everything I want (scalable, z-only build plate, reprap, and H-bot).

Pretty pumped I found it. Going to start printing the parts tonight. I've got an old Rapman kit laying around, so I should have most of the parts already, just need to get some extrusions.

One question I do have for Emmanuel is, what is the best way to do the z-axis? It looks like you are using belts, but might switch to a lead screw?

-Greg

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

Pretty pumped I found it. Going to start printing the parts tonight. I've got an old Rapman kit laying around, so I should have most of the parts already, just need to get some extrusions.

One question I do have for Emmanuel is, what is the best way to do the z-axis? It looks like you are using belts, but might switch to a lead screw?

-Greg

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Mondrian build thread January 15, 2014 01:32PM |

Registered: 10 years ago Posts: 553 |

Nevermind, found the BOM.

Edited 1 time(s). Last edit at 01/15/2014 01:35PM by gmh39.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

Edited 1 time(s). Last edit at 01/15/2014 01:35PM by gmh39.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Mondrian build thread February 02, 2014 04:02PM |

Registered: 10 years ago Posts: 12 |

I followed the Foldarap2 from the beginning of the project till the last Hbot revision where he went over to the rack and pinion. At the point I started doing my own fork of the foldarap2 hbot. I could never get them to work the greatest. Too much drag, binding, and deflection to make the hbot work properly. I really liked the corner brackets and the belt inside the channels of the Tslots but the brackets just flexed to much for me and the belt had way to much resistance. I started using rod and bearings and eventually just redid my whole Hbot from scratch.

I dont mean to put down the foldarap hbot revisions at all, because they were a large inspiration for my current hbot. I can see why he abandoned the hbot for now

I dont mean to put down the foldarap hbot revisions at all, because they were a large inspiration for my current hbot. I can see why he abandoned the hbot for now

|

Re: Mondrian build thread February 03, 2014 09:50AM |

Registered: 10 years ago Posts: 553 |

Quote

cakeslob

I followed the Foldarap2 from the beginning of the project till the last Hbot revision where he went over to the rack and pinion. At the point I started doing my own fork of the foldarap2 hbot. I could never get them to work the greatest. Too much drag, binding, and deflection to make the hbot work properly. I really liked the corner brackets and the belt inside the channels of the Tslots but the brackets just flexed to much for me and the belt had way to much resistance. I started using rod and bearings and eventually just redid my whole Hbot from scratch.

I dont mean to put down the foldarap hbot revisions at all, because they were a large inspiration for my current hbot. I can see why he abandoned the hbot for now

Thanks for the input!

Yea, I am doing a redesign of some of the parts, specifically the corners (intergrating motors completely) and making it a corexy, or at least I am going to try to. I have heard that the H bot configuration is prone to binding because of the uneven forces (I think that was it), and I am really looking for something that wont have that problem.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Mondrian build thread February 04, 2014 06:53PM |

Registered: 13 years ago Posts: 615 |

Yes, if you can use the CoreXY layout, it will avoid the biding problem with a simple H-layout (or for an H you'll need an expensive frame to make it work). I'de be curious to see your variation if you keep some parts of the Mondrian but manage to use a coreXY.

I built an H bot also to understand how it works, and after that I realized why Ilan made his CoreXY like that

I built an H bot also to understand how it works, and after that I realized why Ilan made his CoreXY like that

|

Re: Mondrian build thread February 05, 2014 09:22AM |

Registered: 10 years ago Posts: 553 |

Quote

Emmanuel

Yes, if you can use the CoreXY layout, it will avoid the biding problem with a simple H-layout (or for an H you'll need an expensive frame to make it work). I'de be curious to see your variation if you keep some parts of the Mondrian but manage to use a coreXY.

I built an H bot also to understand how it works, and after that I realized why Ilan made his CoreXY like that

It's taking me longer than I thought, but that's just cause work is picking up. I'll do my best to keep this thread updated.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Mondrian build thread February 05, 2014 04:23PM |

Registered: 10 years ago Posts: 12 |

which is what I opted to do. I took out the corner brackets and made more rigid metal brackets.Quote

Emmanuel

(or for an H you'll need an expensive frame to make it work).

I took the belting out of the tslot channels for less drag, I eventually had to take out the aluminium extrusion pla style bearing and get real bearing and by then it was hardly a foldarap2.

I really want to belt in frame to work for me though . The next thing I try will be using a 40x20 aluminium extrusion and some milluing work.

This is from july 2013 looks a little different now

|

Re: Mondrian build thread February 07, 2014 04:37PM |

Registered: 10 years ago Posts: 553 |

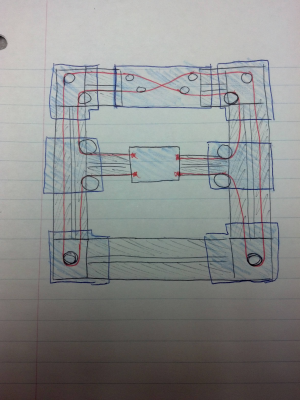

So I came up with this layout for the CoreXY-Mondrian variant.

black = extrusion/motor

blue = printed part

red = spectra line

It integrates the motors into the corners, uses Spectra line instead of belts, and keeps the line inside of the aluminum extrusions.

What do you guys think? See any problems?

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

black = extrusion/motor

blue = printed part

red = spectra line

It integrates the motors into the corners, uses Spectra line instead of belts, and keeps the line inside of the aluminum extrusions.

What do you guys think? See any problems?

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Mondrian build thread February 09, 2014 11:35PM |

Registered: 10 years ago Posts: 162 |

Quote

gmh39

Quote

cakeslob

I followed the Foldarap2 from the beginning of the project till the last Hbot revision where he went over to the rack and pinion. At the point I started doing my own fork of the foldarap2 hbot. I could never get them to work the greatest. Too much drag, binding, and deflection to make the hbot work properly. I really liked the corner brackets and the belt inside the channels of the Tslots but the brackets just flexed to much for me and the belt had way to much resistance. I started using rod and bearings and eventually just redid my whole Hbot from scratch.

I dont mean to put down the foldarap hbot revisions at all, because they were a large inspiration for my current hbot. I can see why he abandoned the hbot for now

Thanks for the input!

Yea, I am doing a redesign of some of the parts, specifically the corners (intergrating motors completely) and making it a corexy, or at least I am going to try to. I have heard that the H bot configuration is prone to binding because of the uneven forces (I think that was it), and I am really looking for something that wont have that problem.

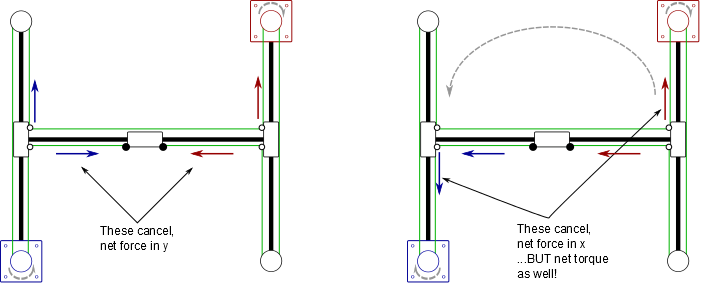

The problem isn't necessarily binding (although it could be if it was reeeeaallly bad). The problem is that the force balance in the h-bot configuration results in torque on the gantry. Here is an image I made a few months ago to describe it.

This mainly manifests itself in small angle rotation of the linear rods permitted by the clearance of the bearings. The resulting distortion is easiest seen by elliptical shapes along the 45 degree directions when printing circles.

I have *mostly* eliminated h-bot distortion on the UConduit h-bot by:

- spacing the outside bearings farther apart

- using LME8UU adjustable bearings and applying tension on them to reduce clearance to the rods

- replacing LM8UUs with LML8UUs

Anything you do to reduce the angles by which the linear rod can go through the bearings will help. It is manageable without expensive linear rails. I am getting good prints without noticeable distortion, but in the end, I think corexy is physically a superior drive system. When I produce my second version, it will probably be a dual option h-bot/corexy... though I expect to be switching to corexy myself.

*Also, https://groups.google.com/forum/#!forum/h-bot-and-corexy-3d-printers might have some helpful information for those thinking about h-bot/corexy printers.

Edited 1 time(s). Last edit at 02/09/2014 11:36PM by iquizzle.

|

Re: Mondrian build thread February 10, 2014 08:37AM |

Registered: 10 years ago Posts: 553 |

Quote

iquizzle

Quote

gmh39

Quote

cakeslob

I followed the Foldarap2 from the beginning of the project till the last Hbot revision where he went over to the rack and pinion. At the point I started doing my own fork of the foldarap2 hbot. I could never get them to work the greatest. Too much drag, binding, and deflection to make the hbot work properly. I really liked the corner brackets and the belt inside the channels of the Tslots but the brackets just flexed to much for me and the belt had way to much resistance. I started using rod and bearings and eventually just redid my whole Hbot from scratch.

I dont mean to put down the foldarap hbot revisions at all, because they were a large inspiration for my current hbot. I can see why he abandoned the hbot for now

Thanks for the input!

Yea, I am doing a redesign of some of the parts, specifically the corners (intergrating motors completely) and making it a corexy, or at least I am going to try to. I have heard that the H bot configuration is prone to binding because of the uneven forces (I think that was it), and I am really looking for something that wont have that problem.

The problem isn't necessarily binding (although it could be if it was reeeeaallly bad). The problem is that the force balance in the h-bot configuration results in torque on the gantry. Here is an image I made a few months ago to describe it.

This mainly manifests itself in small angle rotation of the linear rods permitted by the clearance of the bearings. The resulting distortion is easiest seen by elliptical shapes along the 45 degree directions when printing circles.

I have *mostly* eliminated h-bot distortion on the UConduit h-bot by:

- spacing the outside bearings farther apart

- using LME8UU adjustable bearings and applying tension on them to reduce clearance to the rods

- replacing LM8UUs with LML8UUs

Anything you do to reduce the angles by which the linear rod can go through the bearings will help. It is manageable without expensive linear rails. I am getting good prints without noticeable distortion, but in the end, I think corexy is physically a superior drive system. When I produce my second version, it will probably be a dual option h-bot/corexy... though I expect to be switching to corexy myself.

*Also, https://groups.google.com/forum/#!forum/h-bot-and-corexy-3d-printers might have some helpful information for those thinking about h-bot/corexy printers.

I was going to go with your UConduit printer before I found the Mondrian. But that is great insight into H-bot printer design. One of the reasons I am going with the CoreXY is because I do not want to have to deal with the with the binding to any degree.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Mondrian build thread February 10, 2014 05:16PM |

Registered: 10 years ago Posts: 12 |

Quote

iquizzle

The problem isn't necessarily binding (although it could be if it was reeeeaallly bad). The problem is that the force balance in the h-bot configuration results in torque on the gantry. Here is an image I made a few months ago to describe it.

This mainly manifests itself in small angle rotation of the linear rods permitted by the clearance of the bearings. The resulting distortion is easiest seen by elliptical shapes along the 45 degree directions when printing circles.

I have *mostly* eliminated h-bot distortion on the UConduit h-bot by:

- spacing the outside bearings farther apart

- using LME8UU adjustable bearings and applying tension on them to reduce clearance to the rods

- replacing LM8UUs with LML8UUs

Anything you do to reduce the angles by which the linear rod can go through the bearings will help. It is manageable without expensive linear rails. I am getting good prints without noticeable distortion, but in the end, I think corexy is physically a superior drive system. When I produce my second version, it will probably be a dual option h-bot/corexy... though I expect to be switching to corexy myself.

*Also, https://groups.google.com/forum/#!forum/h-bot-and-corexy-3d-printers might have some helpful information for those thinking about h-bot/corexy printers.

this was a binding issue, with no floating rail on my version of the foldarap and imperfect pla linear bushings for the aluminium extrusions. toss in the hbot deflection and she bind she bind

The uconduit and the uconduit i reverse engineered didnt bind but it had tons of flex when I tried to use it with a belt.

The design Im using now is crazy rigid and has very little deflection even with the hbot belt config. Im still not going corexy but I do have a corexy solution to try and minimize all that.

|

Re: Mondrian build thread February 16, 2014 05:01PM |

Registered: 13 years ago Posts: 615 |

|

Re: Mondrian build thread February 17, 2014 08:47AM |

Registered: 10 years ago Posts: 553 |

Quote

Emmanuel

Thanks for sharing, it's always interesting to see

gmh39, your drawing could be possible, if you add panels on the frame (wood, acrylic, etc) you can remove one Y extrusion of the frame

How would I use 1 Y extrusion if I am running corexy? Or are you talking about the top most extrusion in the drawing?

I forgot to mention that the extrusion for the Z axis will be going vertical below where the belts cross. So it will for a T joint of sorts.

I was working on the CAD this weekend and got the motor corners just about finished. I'll post a render when I have the XY gantry done.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

Sorry, only registered users may post in this forum.