After some weeks with my Foldarap.

Posted by Foldarap85

|

After some weeks with my Foldarap. January 16, 2014 11:42AM |

Registered: 10 years ago Posts: 14 |

Hello,

I wanted to give you a feedback with my now functional Foldarap and also ask a view question because I still have some minor issues.

I printed the active cooling part available here : [www.thingiverse.com], it doesn’t seems more efficient than this small part : [www.thingiverse.com]. I believe the holes are too small…

I had an issue with the peltier… it stopped working after one week… a brought a new one at 20€ (not a 5$ Chinese one) and this one seems to be a lot more powerful, the plate is hot on 2 minutes against 10 for the original one. I also added a cooling system on the cold side (or heating since the back is cold) because it might be why the first one stopped working…

I still have to shorten the wires, I discovered too late in the manual the size of the wires…

I successfully printed a lot of parts using the Slicer configuration provided by Emmanuel [github.com] but strangely when I try to accelerate a little the extruder motor seems to be missing steps.. .this might be the speed limit with this hot end.

Now for the part where I need your help :

I wanted to give you a feedback with my now functional Foldarap and also ask a view question because I still have some minor issues.

I printed the active cooling part available here : [www.thingiverse.com], it doesn’t seems more efficient than this small part : [www.thingiverse.com]. I believe the holes are too small…

I had an issue with the peltier… it stopped working after one week… a brought a new one at 20€ (not a 5$ Chinese one) and this one seems to be a lot more powerful, the plate is hot on 2 minutes against 10 for the original one. I also added a cooling system on the cold side (or heating since the back is cold) because it might be why the first one stopped working…

I still have to shorten the wires, I discovered too late in the manual the size of the wires…

I successfully printed a lot of parts using the Slicer configuration provided by Emmanuel [github.com] but strangely when I try to accelerate a little the extruder motor seems to be missing steps.. .this might be the speed limit with this hot end.

Now for the part where I need your help :

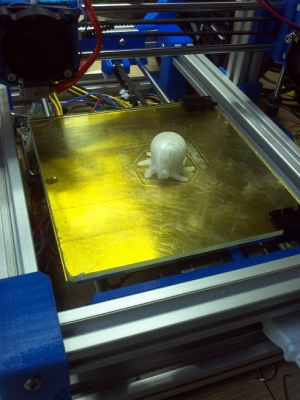

- I a printing on glass (with no kapton) which is working fine for small parts, but seems not to be efficient with bigger parts (cf picture attached)… I will try back printing on the aluminium bed with kapton but I will gladly take advice from you to avoid the corners to peel off….

- I don’t know how to print from SD card… I can’t find documentation on the web… I am using pronterface, I click on send to SD and nothing happened… I don’t know how to debug it and also I didn’t find if there is limitation on the SD card… is a 16 GB card too big ?

- I seem to have surges issues… or maybe something else (that’s also why I want to print from SD, to remove the computer factor) .

- When I am printing from the computer the print stops (nothing written in the pronterface console but the connexion from computer to the printer is cut, I have to disconnect and reconnect) randomly… sometime I have no issues during one day, sometime I stops every 2 to 15 minutes… with no special activates in my home.

- I think it is about power because when I start and stop a 12V halogen light with its coil transformer it cuts the connection and the print almost every time and I can see some spikes (with my old oscilloscope) on the output of the power supply of the printer.

- I tried to put some ferrite on the cable with no change and also add capacitor of 47 or 100 or 1000 µF on the output of the power supply… I don’t change anything…

- I also tried to change the USB cable, and with another one of 1m it seems to be worse… (also this cable is forking fine with other material)

Thank you for reading me and for your advice.

Regards,

Foldarap85

|

Re: After some weeks with my Foldarap. January 20, 2014 11:05AM |

Registered: 10 years ago Posts: 14 |

Hi FoldaRap85,

Sd printing has great advantages. Mine works fine with a 2Gb card. Format type is best FAT32.

It should be in the Melzi on startup, if not you should initialize it.

When printing from sd card a display and rotary encoder is recommended: any 128x64 SPI display supported by u8glib will do fine.

From time to time a have the same "reset"-issue as you do, even when printing from RPi-OctoPrint. Not found a solution yet, I am suspecting the Reset jumper-pins to be responsible...

Sd printing has great advantages. Mine works fine with a 2Gb card. Format type is best FAT32.

It should be in the Melzi on startup, if not you should initialize it.

When printing from sd card a display and rotary encoder is recommended: any 128x64 SPI display supported by u8glib will do fine.

From time to time a have the same "reset"-issue as you do, even when printing from RPi-OctoPrint. Not found a solution yet, I am suspecting the Reset jumper-pins to be responsible...

|

Re: After some weeks with my Foldarap. January 21, 2014 04:24PM |

Registered: 10 years ago Posts: 14 |

Hello,

Thank you for your answer ggaljoen ! I will try to find a 2 GB card, I tried with 8 and 16 and no surprise, it doesn't work...

About my other issues :

Anyway this is really better than before!

EDIT : Oh and I don't have no more surges issues... I have removed my little 12V lamp and no more problems...

Also : Si vous voulez que je traduise en français c'est possible.

Edited 1 time(s). Last edit at 01/21/2014 04:56PM by Foldarap85.

Thank you for your answer ggaljoen ! I will try to find a 2 GB card, I tried with 8 and 16 and no surprise, it doesn't work...

About my other issues :

- I added kapton on the glass and it work better for bigger parts ! Also glass is more flat than the aluminium !

- The issue is that the Y axes seemed to have big issues moving (maybe the glass was too heavy...) So I added lubricant on the bars and removed the glass

- And now I have the issue you can see in the photos, the front of the part is perfectly flat and the back is completly not flat.. and I don't understand how it is possible.... If you have any begining of explanation....

Anyway this is really better than before!

EDIT : Oh and I don't have no more surges issues... I have removed my little 12V lamp and no more problems...

Also : Si vous voulez que je traduise en français c'est possible.

Edited 1 time(s). Last edit at 01/21/2014 04:56PM by Foldarap85.

|

Re: After some weeks with my Foldarap. January 22, 2014 02:59AM |

Registered: 10 years ago Posts: 14 |

Hi,

Your sticking issue is something else; I am not there yet, been printing smaller things on cold blue tape. But I read some articles about glass plate preparation with hairspray and other tricks. Did you try something alike?

From what I think, both are related to Y movement troubles.

The Y-carrier should move completely smooth by its own weight when tilting your foldarap almost 90° back and forth. The plastic bearings do not need to be lubricated!

The problem might be the combination of the printed Y tube holders and the laser cut carriage plate: they can be slightly out of line / shifted. I solved this by mounting the side with 2 bearings through the precutted holes. On the single side I only used one precutted holes to aling the bearing with the plate.

Maybe Y belt tension is more or less involved...

Does this explanation make any sense to you?

English will be fine as my mother tongue is dutch (but I do understand "français" pretty well ;-) )

Quote

Foldarap85

About my other issues :

- I added kapton on the glass and it work better for bigger parts ! Also glass is more flat than the aluminium !

Your sticking issue is something else; I am not there yet, been printing smaller things on cold blue tape. But I read some articles about glass plate preparation with hairspray and other tricks. Did you try something alike?

Quote

Foldarap85

- The issue is that the Y axes seemed to have big issues moving (maybe the glass was too heavy...) So I added lubricant on the bars and removed the glass

- And now I have the issue you can see in the photos, the front of the part is perfectly flat and the back is completly not flat.. and I don't understand how it is possible.... If you have any begining of explanation....

From what I think, both are related to Y movement troubles.

The Y-carrier should move completely smooth by its own weight when tilting your foldarap almost 90° back and forth. The plastic bearings do not need to be lubricated!

The problem might be the combination of the printed Y tube holders and the laser cut carriage plate: they can be slightly out of line / shifted. I solved this by mounting the side with 2 bearings through the precutted holes. On the single side I only used one precutted holes to aling the bearing with the plate.

Maybe Y belt tension is more or less involved...

Does this explanation make any sense to you?

English will be fine as my mother tongue is dutch (but I do understand "français" pretty well ;-) )

|

Re: After some weeks with my Foldarap. January 28, 2014 07:37PM |

Registered: 10 years ago Posts: 241 |

It looks like you're using ABS. Kapton tape and a heat bed are almost required to get a good print. Adding raft layers, extra disks to the corners of the file, or a cooling fan are ways people have helped with this.

Switching to PLA can help. I've tried the hairspray technique and haven't had any luck. The last helpful hint is to clean everything with 100% acetone. Even the top of the blue painters tape. Try not to let it seep under though, this will let it peel up.

Switching to PLA can help. I've tried the hairspray technique and haven't had any luck. The last helpful hint is to clean everything with 100% acetone. Even the top of the blue painters tape. Try not to let it seep under though, this will let it peel up.

|

Re: After some weeks with my Foldarap. February 01, 2014 10:12AM |

Registered: 10 years ago Posts: 14 |

@KingRahl : No I am not using ABS, I am using PLA but when the plate is not clean enought and when the parts are too large it can be difficult.

@ggaljoen : About the glass I didn't try more than kapton yet, I will try later. About the Y axis I think I soled it was a little bit to tense and alos the gear on the motor was not tight enough...

So, after some weeks (and some vacation) I seem to have no more problems !

I discovered that the gear on the motor axis was not tight enough.. and maybe the belt was too tight...

I also disvovered that the big issues I had (example photo IMG_20140116_084153.jpg) are because of the thing I am printing, when the hot end move too fast and when the part is upper than it should (it happend when very small tips appears like in the photo) it can make the X or Y axis shift. I solved it by moving slower (the hot end probably melt the PLA before anything happend)

So it is working for now !

Thank for your help !

@ggaljoen : About the glass I didn't try more than kapton yet, I will try later. About the Y axis I think I soled it was a little bit to tense and alos the gear on the motor was not tight enough...

So, after some weeks (and some vacation) I seem to have no more problems !

I discovered that the gear on the motor axis was not tight enough.. and maybe the belt was too tight...

I also disvovered that the big issues I had (example photo IMG_20140116_084153.jpg) are because of the thing I am printing, when the hot end move too fast and when the part is upper than it should (it happend when very small tips appears like in the photo) it can make the X or Y axis shift. I solved it by moving slower (the hot end probably melt the PLA before anything happend)

So it is working for now !

Thank for your help !

|

Re: After some weeks with my Foldarap. May 04, 2014 08:28AM |

Registered: 10 years ago Posts: 26 |

hello !

I succeed in printing on cold glass

I used standart UHU stic glue and a 4mm glass panel (I tried the Pritt brand but didn't worked)

Just disable bed heating and print.

now it stick very strongly on the plate... even too strong !

I want to make a quick release system for the panel now... to be continue!

I succeed in printing on cold glass

I used standart UHU stic glue and a 4mm glass panel (I tried the Pritt brand but didn't worked)

Just disable bed heating and print.

now it stick very strongly on the plate... even too strong !

I want to make a quick release system for the panel now... to be continue!

Sorry, only registered users may post in this forum.