Uh-oh!

Posted by Rural

Alzibiff, this one is for you.

So I had a failed print last night. The filament got stuck, the hobbed bolt clogged up, and the print continued for at least an hour before I noticed. This evening, I had plans to pull the filament from the extruder, respool it onto an appropriately large spool, perhaps anneal it, and continue printing. Alas, I've hit a snag.

I can't get the filament out. Tried reverse extruding at 80C and 185C and it remains stuck firmly. Even with a fair bit of force applied by hand it doesn't budge.

Looks like I'm going to learn about the insides of the hot-end tonight. Suggestions?

So I had a failed print last night. The filament got stuck, the hobbed bolt clogged up, and the print continued for at least an hour before I noticed. This evening, I had plans to pull the filament from the extruder, respool it onto an appropriately large spool, perhaps anneal it, and continue printing. Alas, I've hit a snag.

I can't get the filament out. Tried reverse extruding at 80C and 185C and it remains stuck firmly. Even with a fair bit of force applied by hand it doesn't budge.

Looks like I'm going to learn about the insides of the hot-end tonight. Suggestions?

|

Re: Uh-oh! October 09, 2013 03:31AM |

Registered: 12 years ago Posts: 212 |

Rural,

Yup - another one to keep me away from the temptation of leaving things alone for hours on end!

Only one suggestion - learn about the insides of the hot-end tonight

Others (as well as myself) have had the same problem and there are a number of posts on the forum with advice how to get things moving again - well worth a trawl.

To prevent it happening again, it would be worth trying to work out why it happened in the first place. The most common reason (I think) is that heat builds up around the top of the JHead when you have a long and slow to print first layer.

When the first layer has a lot of 'filled in' bits which are typically printed at half the speed of other layers, the filament moves quite slowly through the JHead and can start to soften - the beginning of the clogging up process. Nophead has concluded that heat travels to the top of the JHead area by convection rather than by conduction and now uses a self sealing silicone tape around the hot end to keep the heat where it should be. (Take a look at the Mendel90 design improvements here: [www.hydraraptor.blogspot.co.uk]

Other fixes include attaching a small fan to the X carriage to disturb the air around the top of the JHead.

Alan

Edited 1 time(s). Last edit at 10/09/2013 03:33AM by Alzibiff.

Yup - another one to keep me away from the temptation of leaving things alone for hours on end!

Only one suggestion - learn about the insides of the hot-end tonight

Others (as well as myself) have had the same problem and there are a number of posts on the forum with advice how to get things moving again - well worth a trawl.

To prevent it happening again, it would be worth trying to work out why it happened in the first place. The most common reason (I think) is that heat builds up around the top of the JHead when you have a long and slow to print first layer.

When the first layer has a lot of 'filled in' bits which are typically printed at half the speed of other layers, the filament moves quite slowly through the JHead and can start to soften - the beginning of the clogging up process. Nophead has concluded that heat travels to the top of the JHead area by convection rather than by conduction and now uses a self sealing silicone tape around the hot end to keep the heat where it should be. (Take a look at the Mendel90 design improvements here: [www.hydraraptor.blogspot.co.uk]

Other fixes include attaching a small fan to the X carriage to disturb the air around the top of the JHead.

Alan

Edited 1 time(s). Last edit at 10/09/2013 03:33AM by Alzibiff.

|

Re: Uh-oh! October 09, 2013 08:43AM |

Registered: 11 years ago Posts: 88 |

That could be the problem, but the problem occurred well into the print, at a Z of around 1cm, after 5-6 hours. The layers it was working on were mostly fill. For the bulk of those layers, it would have been moving at 60mm/s. So I have my doubts. My guess is that it was just the filament hanging up on the spool, but I'll never really know.

I have read Nophead's latest blog post. Looking forward to encorporating most of his improvements, but first I have to get the head cleared...

Alzibiff Wrote:

-------------------------------------------------------

> Rural,

> Yup - another one to keep me away from the

> temptation of leaving things alone for hours on

> end!

>

> Only one suggestion - learn about the insides of

> the hot-end tonight

> Others (as well as myself) have had the same

> problem and there are a number of posts on the

> forum with advice how to get things moving again -

> well worth a trawl.

> To prevent it happening again, it would be worth

> trying to work out why it happened in the first

> place. The most common reason (I think) is that

> heat builds up around the top of the JHead when

> you have a long and slow to print first layer.

>

> When the first layer has a lot of 'filled in' bits

> which are typically printed at half the speed of

> other layers, the filament moves quite slowly

> through the JHead and can start to soften - the

> beginning of the clogging up process. Nophead has

> concluded that heat travels to the top of the

> JHead area by convection rather than by conduction

> and now uses a self sealing silicone tape around

> the hot end to keep the heat where it should be.

> (Take a look at the Mendel90 design improvements

> here:

> [www.hydraraptor.blogspot.co.uk]

> rchive.html

> Other fixes include attaching a small fan to the X

> carriage to disturb the air around the top of the

> JHead.

>

> Alan

I have read Nophead's latest blog post. Looking forward to encorporating most of his improvements, but first I have to get the head cleared...

Alzibiff Wrote:

-------------------------------------------------------

> Rural,

> Yup - another one to keep me away from the

> temptation of leaving things alone for hours on

> end!

>

> Only one suggestion - learn about the insides of

> the hot-end tonight

> Others (as well as myself) have had the same

> problem and there are a number of posts on the

> forum with advice how to get things moving again -

> well worth a trawl.

> To prevent it happening again, it would be worth

> trying to work out why it happened in the first

> place. The most common reason (I think) is that

> heat builds up around the top of the JHead when

> you have a long and slow to print first layer.

>

> When the first layer has a lot of 'filled in' bits

> which are typically printed at half the speed of

> other layers, the filament moves quite slowly

> through the JHead and can start to soften - the

> beginning of the clogging up process. Nophead has

> concluded that heat travels to the top of the

> JHead area by convection rather than by conduction

> and now uses a self sealing silicone tape around

> the hot end to keep the heat where it should be.

> (Take a look at the Mendel90 design improvements

> here:

> [www.hydraraptor.blogspot.co.uk]

> rchive.html

> Other fixes include attaching a small fan to the X

> carriage to disturb the air around the top of the

> JHead.

>

> Alan

|

Re: Uh-oh! October 09, 2013 08:59AM |

Registered: 11 years ago Posts: 88 |

|

Re: Uh-oh! October 09, 2013 09:49AM |

Registered: 11 years ago Posts: 42 |

I had similar problems with white PLA, I'm almost certain it was due to the spool not feeding right. The filament stopped feeding and the heat started spreading up and swelled it where the hot end meets the wade block.

If I were you I'd cut the filament above the wave block. Take out the three bolts holding the hot end in and carefully remove the hot end, taking into mind the wiring for the resistor and thermistor.

Once the hot end is loose you can heat it back up and try removing the swelled filament by hand.

If I were you I'd cut the filament above the wave block. Take out the three bolts holding the hot end in and carefully remove the hot end, taking into mind the wiring for the resistor and thermistor.

Once the hot end is loose you can heat it back up and try removing the swelled filament by hand.

|

Re: Uh-oh! October 09, 2013 03:04PM |

Registered: 11 years ago Posts: 88 |

Thanks Jonny. I agree that that is probably the issue.

Maybe I'm just being obtuse, but I can't figure out how to remove the hot-end without first removing the filament. There don't seem to be any bolts holding it in. Instead it looks to slide into a t-slot until it snaps into place. With filament running into the extruder it can't be removed.

Am I missing something?

Maybe I'm just being obtuse, but I can't figure out how to remove the hot-end without first removing the filament. There don't seem to be any bolts holding it in. Instead it looks to slide into a t-slot until it snaps into place. With filament running into the extruder it can't be removed.

Am I missing something?

|

Re: Uh-oh! October 09, 2013 05:15PM |

Registered: 11 years ago Posts: 42 |

|

Re: Uh-oh! October 09, 2013 08:20PM |

Registered: 11 years ago Posts: 88 |

|

Re: Uh-oh! October 10, 2013 07:08AM |

Admin Registered: 17 years ago Posts: 7,879 |

The catch22 version of the extruder was fixed at the end of December when it became apparent J-Heads could jam in this way.

The only way I can think of fixing it is to heat the whole hot end and Wade's block to about 80C to soften the PLA without softening the ABS. You should then be able to pull it out. The way I would try to do that is put in on the heated bed set to 80C with something insulating over the top, such as an upturned cardboard box. Then you would need gloves to handle it.

Failing that you will need a new Wade's block and some screws and washers. PM me if you need one.

[www.hydraraptor.blogspot.com]

The only way I can think of fixing it is to heat the whole hot end and Wade's block to about 80C to soften the PLA without softening the ABS. You should then be able to pull it out. The way I would try to do that is put in on the heated bed set to 80C with something insulating over the top, such as an upturned cardboard box. Then you would need gloves to handle it.

Failing that you will need a new Wade's block and some screws and washers. PM me if you need one.

[www.hydraraptor.blogspot.com]

|

Re: Uh-oh! October 10, 2013 09:05AM |

Registered: 11 years ago Posts: 88 |

|

Re: Uh-oh! October 15, 2013 12:53AM |

Registered: 11 years ago Posts: 88 |

So I was able to try heating the hot-end and Wade's block to about 80C to remove the filament. Tried cardboard to insulate everything, but was unable to get the hot-end past about 40C with the bed at 85C. (I may not have been patient enough.) With the bed and the hot-end at 80C, it seemed to work well. I was able to feel the filament stretch a bit as I removed it. However, it snapped right at where it enters the hot-end.

Attempting to push PLA through the hot-end failed. The hobbed bolt just clogs up.

It would have been nice if all of the plastic was yanked out of the hot-end, but since it isn't, I get to do my first cleaning of a hot-end. At least now I can remove the extruder from the Wade's block in a non-destructive way.

So... How does one remove the hot-end from the Wade's block? Turn it 180-degrees? (Which would demand removing the zip-tie from the wiring.)

Attempting to push PLA through the hot-end failed. The hobbed bolt just clogs up.

It would have been nice if all of the plastic was yanked out of the hot-end, but since it isn't, I get to do my first cleaning of a hot-end. At least now I can remove the extruder from the Wade's block in a non-destructive way.

So... How does one remove the hot-end from the Wade's block? Turn it 180-degrees? (Which would demand removing the zip-tie from the wiring.)

|

Re: Uh-oh! October 15, 2013 06:12AM |

Admin Registered: 17 years ago Posts: 7,879 |

They were pressed in using a vice a small jig piece, which was a printed part.

You can just force it out sideways but in my experience they are not tight enough when re-inserted. I think you will need a new block.

[www.hydraraptor.blogspot.com]

You can just force it out sideways but in my experience they are not tight enough when re-inserted. I think you will need a new block.

[www.hydraraptor.blogspot.com]

|

Re: Uh-oh! October 15, 2013 02:47PM |

Registered: 11 years ago Posts: 88 |

|

Re: Uh-oh! October 15, 2013 09:07PM |

Registered: 11 years ago Posts: 88 |

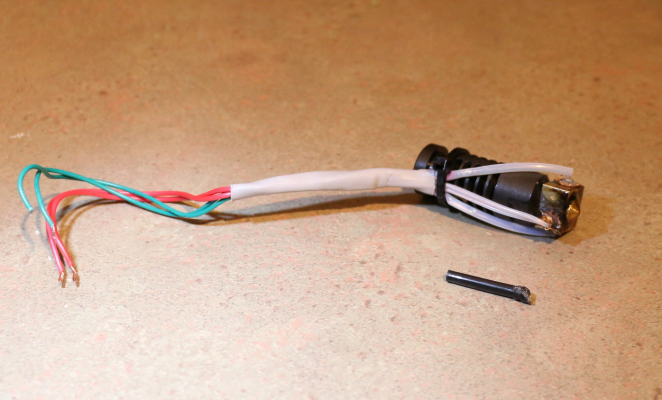

Got the jhead out. The break in the filament was such that I was just able to get a hex-key into the nut at the top of the jhead. With the nut off, I was able to pull out the filament and red tube of insulative plastic(?). In the picture, you can see the filament that was removed. The funky end was at the top (ie. the picture has it the wrong way relative to the jhead).

Alzibiff diagnosed it correctly. At first, I had doubt. Clearly, he was correct. As this was my first really large and long print, with a new type of filament, this fits.

Now to reassemble everything and (nervously) test...

Alzibiff diagnosed it correctly. At first, I had doubt. Clearly, he was correct. As this was my first really large and long print, with a new type of filament, this fits.

Now to reassemble everything and (nervously) test...

|

Re: Uh-oh! October 16, 2013 12:39AM |

Registered: 11 years ago Posts: 88 |

My printer is back in action! Printing off the android that came with the kit right now. It looks as good as any android I've printed yet. (I haven't printed off an android since I first got the printer working, so I don't have to look that closely to tell.)

The jhead isn't held as securely as it was before, but it's close. To be honest, it was a little on the loose side to begin with. On the other hand, it was tight enough to be a real challenge to pop out.

With the jhead cleared of filament and everything back together, I did a test extrude at 190C with some Repraper black PLA. It stuck to the nozzle and formed drops. Let it cool to 80C then pulled the filament (reversed 100mm at 100mm/min with a bit of manual force applied too). Snipped the end of the filament off, reloaded it into the extruder, heated to 190C once again, and repeated the test extrude. It oozed out as one would expect. Checked what was on the SD card to print, saw android.g and hit go. First layer printed a little squished (Z home is now off again), but the rest went fine.

As soon as I get some ABS (in the mail now), I'll print a new Wade's. Guess I'll be ordering some insulative tape as well.

Thanks to all that helped. Hope I provided some entertainment along the way.

The jhead isn't held as securely as it was before, but it's close. To be honest, it was a little on the loose side to begin with. On the other hand, it was tight enough to be a real challenge to pop out.

With the jhead cleared of filament and everything back together, I did a test extrude at 190C with some Repraper black PLA. It stuck to the nozzle and formed drops. Let it cool to 80C then pulled the filament (reversed 100mm at 100mm/min with a bit of manual force applied too). Snipped the end of the filament off, reloaded it into the extruder, heated to 190C once again, and repeated the test extrude. It oozed out as one would expect. Checked what was on the SD card to print, saw android.g and hit go. First layer printed a little squished (Z home is now off again), but the rest went fine.

As soon as I get some ABS (in the mail now), I'll print a new Wade's. Guess I'll be ordering some insulative tape as well.

Thanks to all that helped. Hope I provided some entertainment along the way.

Sorry, only registered users may post in this forum.