Questions about extruder fan/shroud, and how important it is.

Posted by scubaguy

|

Questions about extruder fan/shroud, and how important it is. November 11, 2014 01:52AM |

Registered: 9 years ago Posts: 38 |

So I'm building my first 3d printer. The mendel90 kit I bought off ebay came with a carriage fan shroud, but seems to be missing the carriage fan bracket.

I started building a bracket myself out of sheet aluminum, but then I started to wonder just how important is this fan shroud?

I'm a little uneasy about the shroud in general right now because, not only am I hacking together a bracket, but I had to trim the shroud down a little to even fit around the hotend, its so close to the heat block I worry it might melt. Also the belt clearance seems like it will be very slim, apparently traveling through a slim gap below the bracket, but above the shroud, as well as inbetween the fan and carriage itself. I know the belt is supposed to be tight and shouldn't have any slop, but man, that seems like a small little hole to go through, especially when the belt has a half twist in it, seems like a snag could happen.

I'm debating on just replacing the shroud with a small little 40-50mm fan mounted at an angle like I've seen done before. Or even pondering the idea of leaving it off in the beginning until I can print something better, (only printing pla in the beginning anyways), though I'm real worried about heat radiating up and messing up my extruder or carriage, which are made of pla.

I've got zero printing experience so can't really make an educated decision. Anyone have any advice or input on my dilemma? Thanks.

I started building a bracket myself out of sheet aluminum, but then I started to wonder just how important is this fan shroud?

I'm a little uneasy about the shroud in general right now because, not only am I hacking together a bracket, but I had to trim the shroud down a little to even fit around the hotend, its so close to the heat block I worry it might melt. Also the belt clearance seems like it will be very slim, apparently traveling through a slim gap below the bracket, but above the shroud, as well as inbetween the fan and carriage itself. I know the belt is supposed to be tight and shouldn't have any slop, but man, that seems like a small little hole to go through, especially when the belt has a half twist in it, seems like a snag could happen.

I'm debating on just replacing the shroud with a small little 40-50mm fan mounted at an angle like I've seen done before. Or even pondering the idea of leaving it off in the beginning until I can print something better, (only printing pla in the beginning anyways), though I'm real worried about heat radiating up and messing up my extruder or carriage, which are made of pla.

I've got zero printing experience so can't really make an educated decision. Anyone have any advice or input on my dilemma? Thanks.

|

Re: Questions about extruder fan/shroud, and how important it is. November 11, 2014 03:17AM |

Registered: 11 years ago Posts: 369 |

This doesn't sound like a nophead Mendel90 kit by your description, (which is fine I guess, it is open source after all) but the parts shouldn't be too close if they were printed from the well-documented plans. Have you got a picture?

The fan on the Mendel90 is for cooling the job, not the hot end. The PEEK based J-Head doesn't need active cooling, unlike the metal-finned alternatives - I think these are the ones where you see a fan sticking out at an angle.

The later fan shroud model has a hole in the upper side to direct some of the airflow around the upper part of the hot end - this should prevent any softening of the plastic in that area which can be caused by convection.

General consensus is that you don't need the fan for ABS and only for PLA when printing bridges. Therefore you should be able to print yourself a fan bracket without the fan attached.

The fan on the Mendel90 is for cooling the job, not the hot end. The PEEK based J-Head doesn't need active cooling, unlike the metal-finned alternatives - I think these are the ones where you see a fan sticking out at an angle.

The later fan shroud model has a hole in the upper side to direct some of the airflow around the upper part of the hot end - this should prevent any softening of the plastic in that area which can be caused by convection.

General consensus is that you don't need the fan for ABS and only for PLA when printing bridges. Therefore you should be able to print yourself a fan bracket without the fan attached.

|

Re: Questions about extruder fan/shroud, and how important it is. November 11, 2014 05:34AM |

Registered: 10 years ago Posts: 541 |

Actually, the fan shroud is quite an important item.

For printing with PLA it is recommended to enable the fan for all layers but the first. In fact, I believe the use of the fan is what permits the Mendel90 to produce the superb results it does.

Additionally, as QuackingPlums mentioned, the fan shroud has a small hole to direct a little air onto the hotend. This, along with the red silicon insulating tape on the hotend, prevents jamming of PLA at low flow rates with frequent retraction.

Personally, I would not consider leaving the fan off a printer used for printing PLA.

Also, anything around the hotend (the Wade's block and fan shroud in particular) should be made from ABS. You will find that PLA will deform over time.

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 11/11/2014 05:36AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

For printing with PLA it is recommended to enable the fan for all layers but the first. In fact, I believe the use of the fan is what permits the Mendel90 to produce the superb results it does.

Additionally, as QuackingPlums mentioned, the fan shroud has a small hole to direct a little air onto the hotend. This, along with the red silicon insulating tape on the hotend, prevents jamming of PLA at low flow rates with frequent retraction.

Personally, I would not consider leaving the fan off a printer used for printing PLA.

Also, anything around the hotend (the Wade's block and fan shroud in particular) should be made from ABS. You will find that PLA will deform over time.

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 11/11/2014 05:36AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Questions about extruder fan/shroud, and how important it is. November 11, 2014 10:09AM |

Registered: 10 years ago Posts: 439 |

|

Re: Questions about extruder fan/shroud, and how important it is. November 12, 2014 01:16AM |

Registered: 9 years ago Posts: 38 |

Thanks for the input. I hacked together an aluminum bracket to use until I can print out the real thing.

I didn't get around to taking a photo of the clearance around the hotend. I think the shroud was printed the right size, because the fan fits correctly, but then I just have what I believe is a common and typical hotend. A j-head MK-V. It was just a little bit too big to fit inside through the hole, so I had to trim some layers and widen the diamater of the hole by about 4-5mm, but I still just have about 1mm clearance around the corners of the hotend heat block. Is it normal for clearance to be so small? Maybe I'll try to baby it through until I can print a larger one or something.

I didn't get around to taking a photo of the clearance around the hotend. I think the shroud was printed the right size, because the fan fits correctly, but then I just have what I believe is a common and typical hotend. A j-head MK-V. It was just a little bit too big to fit inside through the hole, so I had to trim some layers and widen the diamater of the hole by about 4-5mm, but I still just have about 1mm clearance around the corners of the hotend heat block. Is it normal for clearance to be so small? Maybe I'll try to baby it through until I can print a larger one or something.

|

Re: Questions about extruder fan/shroud, and how important it is. November 12, 2014 05:37AM |

Admin Registered: 17 years ago Posts: 7,879 |

There should be enough clearance with a J-head MKVB, even with silicone tape wrapped around the heat block. That is the hot end it is designed for. It does need to be oriented the right way round as the block is off centre.

I don't understand how you could widen it by 4-5mm as the walls are only 1.2mm thick and tapered.

[www.hydraraptor.blogspot.com]

I don't understand how you could widen it by 4-5mm as the walls are only 1.2mm thick and tapered.

[www.hydraraptor.blogspot.com]

|

Re: Questions about extruder fan/shroud, and how important it is. November 12, 2014 09:15PM |

Registered: 9 years ago Posts: 38 |

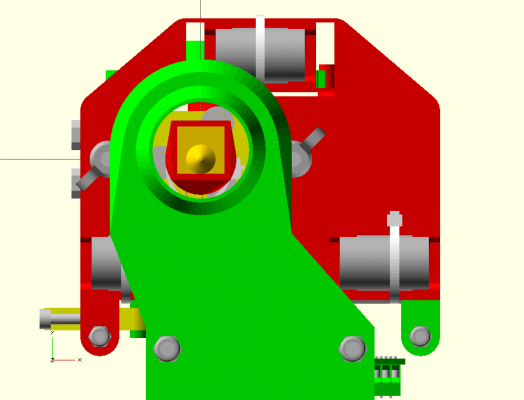

OK, I took a photo to show what I'm working with. I obviously need to adjust my homemade bracket a little to get the hotend more correctly centered, right now I think 2 corners are touching and 2 have a gap.

But basically, before it was like putting a square peg in a round hole. The corners of the hotend were too big to fit (this was even before I put the 2 wraps of silicone tape). I cut off about 5-7 layers from the inner tapered part of the shroud in order to increase the diamater of the opening, and give it the slight clearance it currently has, which I'm guessing will be about 1-1.5mm clearance around each corner once I get it centered.

Maybe my hotend is a little different, and bigger, since it is more rectangular than the one in the render above which is more square.

Edited 1 time(s). Last edit at 11/12/2014 09:16PM by scubaguy.

But basically, before it was like putting a square peg in a round hole. The corners of the hotend were too big to fit (this was even before I put the 2 wraps of silicone tape). I cut off about 5-7 layers from the inner tapered part of the shroud in order to increase the diamater of the opening, and give it the slight clearance it currently has, which I'm guessing will be about 1-1.5mm clearance around each corner once I get it centered.

Maybe my hotend is a little different, and bigger, since it is more rectangular than the one in the render above which is more square.

Edited 1 time(s). Last edit at 11/12/2014 09:16PM by scubaguy.

|

Re: Questions about extruder fan/shroud, and how important it is. November 13, 2014 04:56AM |

Admin Registered: 17 years ago Posts: 7,879 |

Looks like it isn't a genuine J-head MKV as it should be square and made from brass.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.