Printing the bearing holders

Posted by plankton

|

Printing the bearing holders February 05, 2015 09:25AM |

Registered: 9 years ago Posts: 100 |

Has anyone else had problems printing the linear bearing holders (Y axis, and in the X carriage), and how did you dial in your print to fix it?

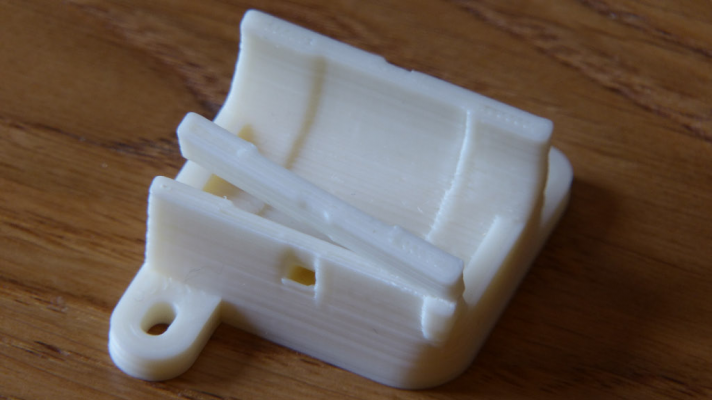

I started by printing the X carriage in ABS, then found the bearing holders split along layer boundaries when I inserted the bearings, similar to this Y axis bearing holder:

So I spent some time printing a single Y axis bearing holder with different settings to see what affected boundary strength. Things that helped were

In the end my solution was to combine my improved settings, with slightly redesigned parts:

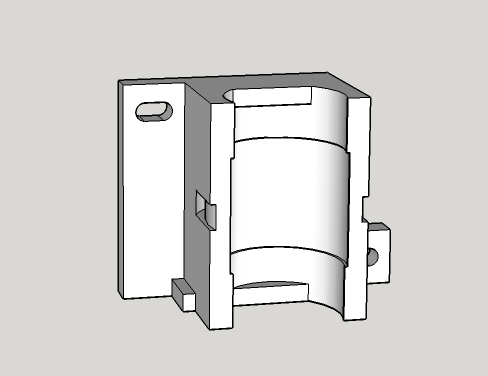

I designed this bearing holder in Sketchup, to print in the other orientation, so layer boundaries are not stressed by inserting the bearings.

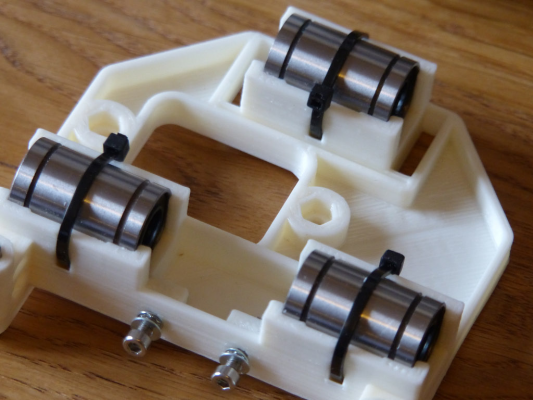

For the X carriage I added strengthening pillars to the end of each bearing holder (you can see the walls wrap around the ends of each bearing, in the picture below).

Obviously not everyone has this problem, so my redesign is really masking a weakness in my printing, I'd be interested to hear how other people get stronger layer boundaries?

Edited 3 time(s). Last edit at 02/05/2015 12:17PM by plankton.

Tim

Printers:

Prusa i3 (plywood box frame)

RAMPS 1.4 and Arduino Mega

Mendel 90 (sturdy)

Smoothieware

My RepRap Blog

I started by printing the X carriage in ABS, then found the bearing holders split along layer boundaries when I inserted the bearings, similar to this Y axis bearing holder:

So I spent some time printing a single Y axis bearing holder with different settings to see what affected boundary strength. Things that helped were

- increasing hotend temperature to the max I felt comfortable with on my J-head (about 242 C)

- and unexpectedly (to me) increasing the layer height from 0.3 to 0.4mm, although in retrospect I suppose that should have been obvious that reducing the number of boundaries would reduce the number of weak points.

- changing filament to a new reel, from a different supplier, helped as well

- I also found I was under extruding, so dialed in the extrusion multiplier to account for the fact that ABS is softer than PLA so the hobbed bolt teeth sink in further, thus giving a smaller effective diameter to the bolt (as Nophead has pointed out)

In the end my solution was to combine my improved settings, with slightly redesigned parts:

I designed this bearing holder in Sketchup, to print in the other orientation, so layer boundaries are not stressed by inserting the bearings.

For the X carriage I added strengthening pillars to the end of each bearing holder (you can see the walls wrap around the ends of each bearing, in the picture below).

Obviously not everyone has this problem, so my redesign is really masking a weakness in my printing, I'd be interested to hear how other people get stronger layer boundaries?

Edited 3 time(s). Last edit at 02/05/2015 12:17PM by plankton.

Tim

Printers:

Prusa i3 (plywood box frame)

RAMPS 1.4 and Arduino Mega

Mendel 90 (sturdy)

Smoothieware

My RepRap Blog

|

Re: Printing the bearing holders February 05, 2015 12:08PM |

Admin Registered: 17 years ago Posts: 7,879 |

At the break point in your picture it looks like there is a gap with no infill. I print 0.4mm layers 0.6mm wide with a single outline and there is always infill all the way up.

I assume 142 C is a typo? I print ABS at 250C (measured inside the nozzle) with a J-head.

[www.hydraraptor.blogspot.com]

I assume 142 C is a typo? I print ABS at 250C (measured inside the nozzle) with a J-head.

[www.hydraraptor.blogspot.com]

|

Re: Printing the bearing holders February 05, 2015 01:26PM |

Registered: 9 years ago Posts: 100 |

Hmm, you may be right about the small gap (that example certainly does), I thought I had tried single perimeter, but can't find any examples in my failure bin. I'll do some more testing with single walls, and keeping an eye on the infill, when I get a chance.

Yes it was a typo, I was printing at 242C of course. I don't have the means to measure temperature inside the nozzle, but I was going by what Hotends.com say:

Tim

Printers:

Prusa i3 (plywood box frame)

RAMPS 1.4 and Arduino Mega

Mendel 90 (sturdy)

Smoothieware

My RepRap Blog

Yes it was a typo, I was printing at 242C of course. I don't have the means to measure temperature inside the nozzle, but I was going by what Hotends.com say:

I've noticed my hotend briefly overshoots by 2 or 3 degrees when first heating up to printing temperature, hence keeping my max at 242 (measured from the thermistor) should keep me a couple of degrees below the specified limit at all times. If you measure inside the nozzle, how much offset do you see between that and the thermistor temperature?Quote

Please note: The maximum operating temperature is 247 degrees Celsius as PEEK will soften at 248 degrees Celsius. Due to many variables, affecting the accuracy of the temperature readings and settings, caution is recommended when extruding at temperatures approaching this limit.

Tim

Printers:

Prusa i3 (plywood box frame)

RAMPS 1.4 and Arduino Mega

Mendel 90 (sturdy)

Smoothieware

My RepRap Blog

|

Re: Printing the bearing holders February 05, 2015 01:41PM |

Admin Registered: 17 years ago Posts: 7,879 |

With the thermistor table I created for Mendel90 the thermistor agrees with a thermocouple placed inside within a couple of degrees. See [hydraraptor.blogspot.co.uk]. The original Marlin tables were not accurate.

I don't agree with Brian's statement about PEEK. I do my first layer at 255C and the rest at 250C and my hot ends last for years. They only die when I get contaminated filament that blocks them. The overpressure can then destroy the PTFE liner.

[www.hydraraptor.blogspot.com]

I don't agree with Brian's statement about PEEK. I do my first layer at 255C and the rest at 250C and my hot ends last for years. They only die when I get contaminated filament that blocks them. The overpressure can then destroy the PTFE liner.

[www.hydraraptor.blogspot.com]

|

Re: Printing the bearing holders February 05, 2015 01:54PM |

Admin Registered: 17 years ago Posts: 7,879 |

I should add that I only use and supply 1% Epcos thermistors but J-heads from direct from hotends.com are shipped with 3% Semitek nowadays.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.