Why my printed object is 1mm shorter?

Posted by yun

|

Why my printed object is 1mm shorter? May 04, 2013 05:50AM |

Registered: 11 years ago Posts: 10 |

I recently noticed that the objects printed by my Mendel90 is always 1mm shorter then design. For testing purpose I printed a 8mm x 8mm x 5mm block. The printed object I got was 7.98mm x 8.05mm x 4.05mm. I am pretty satisfied by the dimensions on X and Y direction, but on Z direction, it is almost 1mm shorter than my design.

I tried to print taller object, say 8mm x 8mm x 10mm. The object I got was 8.92mm height, which is again 1mm shorter than expected.

Does anyone have idea how could this happen? What should I do to fix this issue? Thanks in advanced.

Edited 2 time(s). Last edit at 05/04/2013 05:55AM by yun.

I tried to print taller object, say 8mm x 8mm x 10mm. The object I got was 8.92mm height, which is again 1mm shorter than expected.

Does anyone have idea how could this happen? What should I do to fix this issue? Thanks in advanced.

Edited 2 time(s). Last edit at 05/04/2013 05:55AM by yun.

|

Re: Why my printed object is 1mm shorter? May 04, 2013 07:27AM |

Registered: 11 years ago Posts: 42 |

|

Re: Why my printed object is 1mm shorter? May 04, 2013 11:07AM |

Registered: 11 years ago Posts: 10 |

Hi Banjer, thanks for the reply! I just checked the g-code and I can see the these commands at the end:

So I think the Z value of last layer is 5.1mm. It seems ok since my layer height is 0.3mm, and there are 17 layers to print for the 5mm height block.

Do you have idea where is the problem? Thanks a lot.

G92 E0 G1 Z5.100 F7800.000 G1 X-2.950 Y-2.950 G1 F1800.000 E1.00000 G1 X2.950 Y-2.950 F600.000 E1.08679 G1 X2.950 Y2.950 E1.17357 G1 X-2.950 Y2.950 E1.26036 G1 X-2.950 Y-2.887 E1.34622 G1 X-2.950 Y-2.950 E1.34714 G1 X-3.369 Y-3.369 F7800.000 G1 X3.369 Y-3.369 F600.000 E1.44625 G1 X3.369 Y3.369 E1.54536 G1 X-3.369 Y3.369 E1.64447 G1 X-3.369 Y-3.306 E1.74265 G1 X-3.369 Y-3.369 E1.74358 G1 X-3.788 Y-3.788 F7800.000 G1 X3.788 Y-3.788 F600.000 E1.85501 G1 X3.788 Y3.788 E1.96644 G1 X-3.788 Y3.788 E2.07787 G1 X-3.788 Y-3.725 E2.18838 G1 X-3.788 Y-3.788 E2.18930 G1 X-3.425 Y-3.579 F7800.000 G1 F1800.000 E1.18930 G92 E0 G1 X2.665 Y-2.398 F7800.000 G1 F1800.000 E1.00000 G1 X2.398 Y-2.665 F848.613 E1.00558 G1 X1.802 Y-2.665 E1.01439 G1 X2.665 Y-1.802 E1.03242 G1 X2.665 Y-1.207 E1.04123 G1 X1.207 Y-2.665 E1.07173 G1 X0.611 Y-2.665 E1.08053 G1 X2.665 Y-0.611 E1.12348 G1 X2.665 Y-0.016 E1.13229 G1 X0.016 Y-2.665 E1.18770 G1 X-0.580 Y-2.665 E1.19651 G1 X2.665 Y0.580 E1.26437 G1 X2.665 Y1.176 E1.27318 G1 X-1.176 Y-2.665 E1.35350 G1 X-1.771 Y-2.665 E1.36230 G1 X2.665 Y1.771 E1.45508 G1 X2.665 Y2.367 E1.46389 G1 X-2.367 Y-2.665 E1.56912 G1 X-2.665 Y-2.367 E1.57535 G1 X2.367 Y2.665 E1.68058 G1 X1.771 Y2.665 E1.68939 G1 X-2.665 Y-1.771 E1.78217 G1 X-2.665 Y-1.176 E1.79098 G1 X1.176 Y2.665 E1.87130 G1 X0.580 Y2.665 E1.88011 G1 X-2.665 Y-0.580 E1.94797 G1 X-2.665 Y0.016 E1.95678 G1 X-0.016 Y2.665 E2.01218 G1 X-0.611 Y2.665 E2.02099 G1 X-2.665 Y0.611 E2.06394 G1 X-2.665 Y1.207 E2.07275 G1 X-1.207 Y2.665 E2.10324 G1 X-1.802 Y2.665 E2.11205 G1 X-2.665 Y1.802 E2.13009 G1 X-2.665 Y2.398 E2.13889 G1 X-2.398 Y2.665 E2.14447 G1 F1800.000 E1.14447 G92 E0 M107 M104 S0 ; turn off temperature G28 X0 ; home X axis M84 ; disable motors G28 ; home all axes ; filament used = 40.5mm (0.3cm3)

So I think the Z value of last layer is 5.1mm. It seems ok since my layer height is 0.3mm, and there are 17 layers to print for the 5mm height block.

Do you have idea where is the problem? Thanks a lot.

|

Re: Why my printed object is 1mm shorter? May 04, 2013 11:25AM |

Registered: 13 years ago Posts: 102 |

|

Re: Why my printed object is 1mm shorter? May 04, 2013 12:28PM |

Registered: 11 years ago Posts: 77 |

|

Re: Why my printed object is 1mm shorter? May 04, 2013 12:28PM |

Registered: 11 years ago Posts: 10 |

Hi hexitex, thanks for the suggestion. Yes it is a nophed kit, so I would like to change the z-speed in slicer. I am using Slic3r, I can see some settings for speed under the "Print Settings" tab, but could not find the setting for z-speed. Could you let me know where is the configuration of z-speed? Thank you.

|

Re: Why my printed object is 1mm shorter? May 04, 2013 12:34PM |

Registered: 11 years ago Posts: 10 |

|

Re: Why my printed object is 1mm shorter? May 04, 2013 12:45PM |

Registered: 11 years ago Posts: 77 |

|

Re: Why my printed object is 1mm shorter? May 04, 2013 12:48PM |

Admin Registered: 17 years ago Posts: 7,879 |

Slic3r expects the firmware to limit the Z speed, which it does, so it shouldn't be a problem with the firmware supplied with the kit.

The Z pointers should be set to point to the bars when the axis is homed and levelled. Then any time it is homed, if they don't both point to the bar one has slipped.

Having said that I can't think how the object could be consistently 1mm short. It would have some very squashed layers which should be obvious looking at the sides.

Try printing something with a 45 degree slope and see if it ends up with steps in it.

[www.hydraraptor.blogspot.com]

The Z pointers should be set to point to the bars when the axis is homed and levelled. Then any time it is homed, if they don't both point to the bar one has slipped.

Having said that I can't think how the object could be consistently 1mm short. It would have some very squashed layers which should be obvious looking at the sides.

Try printing something with a 45 degree slope and see if it ends up with steps in it.

[www.hydraraptor.blogspot.com]

|

Re: Why my printed object is 1mm shorter? May 04, 2013 02:46PM |

Registered: 11 years ago Posts: 10 |

Hi Fl0yd and nohead, thanks a lot for the suggestions. They are very helpful and I have found the problem by following the direction you suggested.

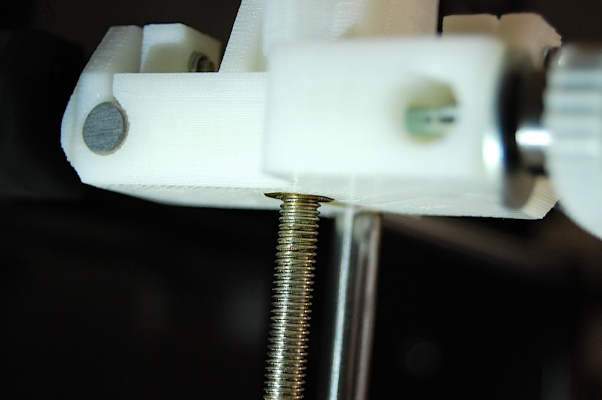

It seems the problem is on my X ideler, the ideler bracket does not follow the M6 brass nut all the time. It is ok after moving the idler up:

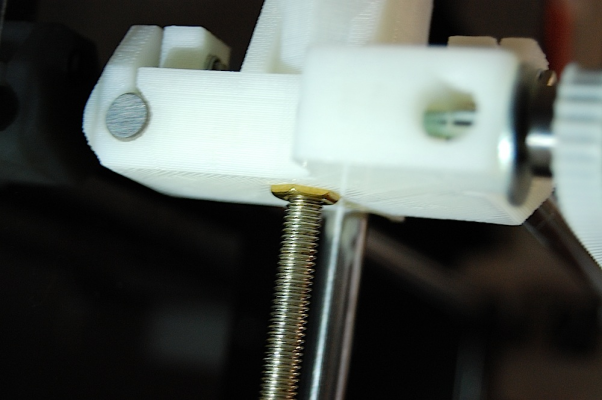

However after moving the idler down, the brass nut is pulled out of the slot, so the extruder is always higher than the expected postion.

I didn't notice this issue when calibrating Z axis, so I had to increase the Z_HOME_POS value about 1mm to make sure the extruder can touch the glass. By doing so, the extruder is actually too low for printing. When the extruder moved up, the M6 brass nut will be pushed back into the slot and "eat" some height. I believe that's what happened.

This picture shows the first few layers are squashed.

What will be the best way to fix this issue then? Can I glue the M6 brass nut with the bracket together? Or should I put a heavy object on the X idler to make sure it always follow the nut?

Any idea will be appreciated.

It seems the problem is on my X ideler, the ideler bracket does not follow the M6 brass nut all the time. It is ok after moving the idler up:

However after moving the idler down, the brass nut is pulled out of the slot, so the extruder is always higher than the expected postion.

I didn't notice this issue when calibrating Z axis, so I had to increase the Z_HOME_POS value about 1mm to make sure the extruder can touch the glass. By doing so, the extruder is actually too low for printing. When the extruder moved up, the M6 brass nut will be pushed back into the slot and "eat" some height. I believe that's what happened.

This picture shows the first few layers are squashed.

What will be the best way to fix this issue then? Can I glue the M6 brass nut with the bracket together? Or should I put a heavy object on the X idler to make sure it always follow the nut?

Any idea will be appreciated.

|

Re: Why my printed object is 1mm shorter? May 04, 2013 04:06PM |

Admin Registered: 17 years ago Posts: 7,879 |

The weight of the axis normally keeps the nut in place. If it doesn't the most likely thing is the axis is not level or the Z rods are not parallel and the so the Z axis is binding.

If you drive it to the bottom and then manually slide it up and down (leaving the nuts at the bottom) does it move freely? If not drive it to the top and loosen and re-tighten the right bar clamp the drive it to the bottom and loosen and re-tighten the Z motor bracket. That should make the bars exactly parallel.

When the axis is lowered to the bed the base of each X end should be the same height above the base of the machine. Also when at the top the distance to the bar clamps should be the same.

If it isn't and the axis has been levelled to the bed it implies the bed is not level for some reason. That can be fixed by adding washers under some of the bed pillars.

I had a machine behave like that. The reason was the Y carriage was bent on the side with one bearing. I think I bent when I dropped a spool on the bed. The solution was to add washers on one side, front and back to get it level to within a fraction of a millimetre, then adjust the Z axis to get it spot on.

Edited 1 time(s). Last edit at 05/04/2013 04:08PM by nophead.

[www.hydraraptor.blogspot.com]

If you drive it to the bottom and then manually slide it up and down (leaving the nuts at the bottom) does it move freely? If not drive it to the top and loosen and re-tighten the right bar clamp the drive it to the bottom and loosen and re-tighten the Z motor bracket. That should make the bars exactly parallel.

When the axis is lowered to the bed the base of each X end should be the same height above the base of the machine. Also when at the top the distance to the bar clamps should be the same.

If it isn't and the axis has been levelled to the bed it implies the bed is not level for some reason. That can be fixed by adding washers under some of the bed pillars.

I had a machine behave like that. The reason was the Y carriage was bent on the side with one bearing. I think I bent when I dropped a spool on the bed. The solution was to add washers on one side, front and back to get it level to within a fraction of a millimetre, then adjust the Z axis to get it spot on.

Edited 1 time(s). Last edit at 05/04/2013 04:08PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Why my printed object is 1mm shorter? May 05, 2013 07:39AM |

Registered: 11 years ago Posts: 10 |

Hi nophead, thanks for the help. I adjust the Z rods again and now it works fine.

I printed the 8mm x 8mm x 5mm block again and this time I got 8.03mm x 7.92mm x 4.82mm. Although it is still 0.19mm shorter, I think it is acceptable and I am satisfied with the result. Problem is solved

Great thanks to the kind people here :-)

I printed the 8mm x 8mm x 5mm block again and this time I got 8.03mm x 7.92mm x 4.82mm. Although it is still 0.19mm shorter, I think it is acceptable and I am satisfied with the result. Problem is solved

Great thanks to the kind people here :-)

Sorry, only registered users may post in this forum.