Speeds, Feeds and Flows

Posted by Mogal

|

Speeds, Feeds and Flows June 22, 2013 01:32PM |

Registered: 11 years ago Posts: 250 |

I'd like to start a little database of everyone's settings.

Something to help each other get their settings bang on.

I know there are variables that we can not control, but this

should help us all in getting our settings dialed in.

(Based on Nophead's Mendel90 only)

-----

Material used: PLA

Nozzle temp: 200c (this is high, but I have poor quality plastic)

Bed temp: 45c

Nozzle: 0.5mm

Here is my setup/settings

FIRMWARE:

Marlin v1.0.0 RC2

XYJERK 20.0 (mm/sec)

ZJERK 1 (mm/sec)

EJERK 5.0 (mm/sec)

EEPROM Settings:

Acceleration: (M201) X2000 Y2000 Z4000 E4000

Feedrate: (M203) X200 Y200 Z5 E400

Acceleration: (M204) X2000 Y2000 Z4000 E4000

Slic3r Settings (current settings, still adjusting)

layer height: 0.3mm (my fav height)

First layer height: 85%

Fill density: 25%

Pattern: honeycomb

Parimeters: 20mm/s

Small parimeters: 15mm/s

External Parimeters: 70%

Infill 30mm/s

Solid infill: 30mm/s

Top solid infill: 30mm/s

Support material: 30mm/s

bridges: 30mm/s

gap fill: 20mm/s

Non-Print moves: 150mm/s

First layer speed: 50%

Extrusion Width (This still has me a little stumped)

Default: 0

First layer: 0

Perimeters: 0

Infill: 0

Solid infill: 0

Top Solid infill: 0

Support: 0

So I'd like you to enter your settings in as above(add in more settings if needed)

I have not used any other slicer, so if you can enter your detail in for them, that would be great!

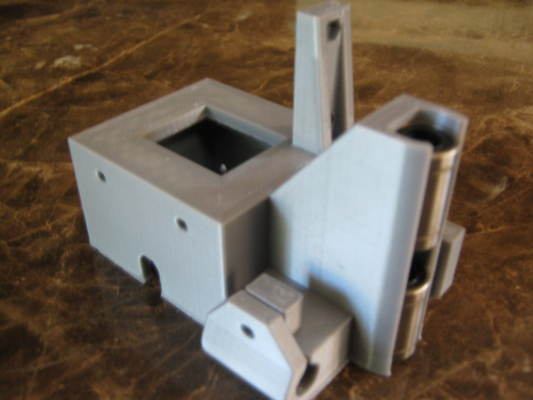

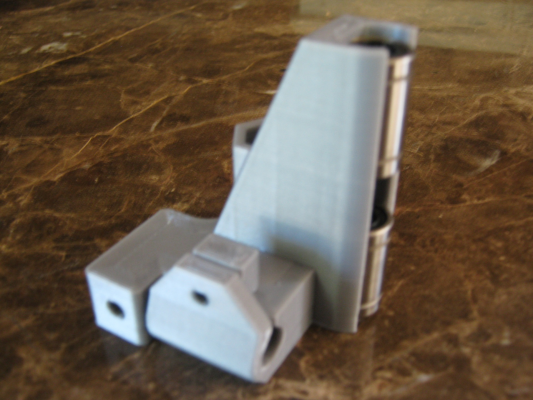

The parts here were made with the above settings.

(Edit) Forgot the jerk settings

Edited 1 time(s). Last edit at 06/24/2013 07:08AM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Something to help each other get their settings bang on.

I know there are variables that we can not control, but this

should help us all in getting our settings dialed in.

(Based on Nophead's Mendel90 only)

-----

Material used: PLA

Nozzle temp: 200c (this is high, but I have poor quality plastic)

Bed temp: 45c

Nozzle: 0.5mm

Here is my setup/settings

FIRMWARE:

Marlin v1.0.0 RC2

XYJERK 20.0 (mm/sec)

ZJERK 1 (mm/sec)

EJERK 5.0 (mm/sec)

EEPROM Settings:

Acceleration: (M201) X2000 Y2000 Z4000 E4000

Feedrate: (M203) X200 Y200 Z5 E400

Acceleration: (M204) X2000 Y2000 Z4000 E4000

Slic3r Settings (current settings, still adjusting)

layer height: 0.3mm (my fav height)

First layer height: 85%

Fill density: 25%

Pattern: honeycomb

Parimeters: 20mm/s

Small parimeters: 15mm/s

External Parimeters: 70%

Infill 30mm/s

Solid infill: 30mm/s

Top solid infill: 30mm/s

Support material: 30mm/s

bridges: 30mm/s

gap fill: 20mm/s

Non-Print moves: 150mm/s

First layer speed: 50%

Extrusion Width (This still has me a little stumped)

Default: 0

First layer: 0

Perimeters: 0

Infill: 0

Solid infill: 0

Top Solid infill: 0

Support: 0

So I'd like you to enter your settings in as above(add in more settings if needed)

I have not used any other slicer, so if you can enter your detail in for them, that would be great!

The parts here were made with the above settings.

(Edit) Forgot the jerk settings

Edited 1 time(s). Last edit at 06/24/2013 07:08AM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Speeds, Feeds and Flows June 24, 2013 03:22AM |

Registered: 11 years ago Posts: 369 |

|

Re: Speeds, Feeds and Flows June 24, 2013 07:11AM |

Registered: 11 years ago Posts: 250 |

These were printed with PLA.

Removed from the printer as pictured (No modifications)

Cheers!

Chris

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Removed from the printer as pictured (No modifications)

Cheers!

Chris

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Speeds, Feeds and Flows June 25, 2013 11:00PM |

Registered: 11 years ago Posts: 250 |

Okay, I figured out the macro setting on my camera...

So I thought I would show the details of the prints.

If you look at IMG_1875, you can see what I believe to be an air bubble from the plastic?

I also found the new version of josefprusa calculator v3.

With that, I discovered I had a layer hieght error. Turns out 0.2921mm hieght

will give me no hieght errors. Whereas the 0.3mm that I was using was giving me an

error of 0.516mm over 10cm!!

I highly recommend checking your settings with the calculator!

Cheers!

Chris

LOL I love my Mendel90

Now if I could only figure out Skienforge

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

So I thought I would show the details of the prints.

If you look at IMG_1875, you can see what I believe to be an air bubble from the plastic?

I also found the new version of josefprusa calculator v3.

With that, I discovered I had a layer hieght error. Turns out 0.2921mm hieght

will give me no hieght errors. Whereas the 0.3mm that I was using was giving me an

error of 0.516mm over 10cm!!

I highly recommend checking your settings with the calculator!

Cheers!

Chris

LOL I love my Mendel90

Now if I could only figure out Skienforge

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Speeds, Feeds and Flows June 26, 2013 04:59AM |

Admin Registered: 17 years ago Posts: 7,879 |

Are you using non-metric lead screws?

I don't understand why you would ever get a cumulative error. Marlin receives an absolute Z position to go to. It should convert it to the nearest microstep position and go there, so the biggest error should be half a micro step.

In practice microsteps are not as accurate as full steps, so you get better precision if your layer height is a multiple of whole steps, or better still four whole steps, i.e. 25um with M8, 20um with M6.

[www.hydraraptor.blogspot.com]

I don't understand why you would ever get a cumulative error. Marlin receives an absolute Z position to go to. It should convert it to the nearest microstep position and go there, so the biggest error should be half a micro step.

In practice microsteps are not as accurate as full steps, so you get better precision if your layer height is a multiple of whole steps, or better still four whole steps, i.e. 25um with M8, 20um with M6.

[www.hydraraptor.blogspot.com]

|

Re: Speeds, Feeds and Flows June 26, 2013 09:33AM |

Registered: 11 years ago Posts: 250 |

I'm using 3/16-20 acme lead screws.

Sorry Chris i really don't know, I'm just going by what the calculator says.

When I punch in the numbers for the 3/16-20 and 0.3 layer height... the calc tells

me there is the error there... punch in 0.2921 and there is zero error...?

Thanx for the extra information... I'll keep playing and tweaking.

Cheers,

Chris

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Sorry Chris i really don't know, I'm just going by what the calculator says.

When I punch in the numbers for the 3/16-20 and 0.3 layer height... the calc tells

me there is the error there... punch in 0.2921 and there is zero error...?

Thanx for the extra information... I'll keep playing and tweaking.

Cheers,

Chris

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Speeds, Feeds and Flows July 12, 2013 12:01PM |

Registered: 11 years ago Posts: 369 |

I've copied your settings now and recalibrated everything to much finer tolerances than before, but I still can't get my prints anywhere near as perfect as yours!

One of the biggest issues I can see is that every time I retract a tiny nubbin of plastic gets left behind. Over the height of the object this eventually leaves a visible filament of plastic that is only loosely connected to the object - it peels off very easily using fingers alone but the finish is very rough, almost like perforations.

My layers are also suffering a little from x/y accuracy, which I hope is just a belt tension issue. It'll take a few more prints to get to the bottom of that I think.

One of the biggest issues I can see is that every time I retract a tiny nubbin of plastic gets left behind. Over the height of the object this eventually leaves a visible filament of plastic that is only loosely connected to the object - it peels off very easily using fingers alone but the finish is very rough, almost like perforations.

My layers are also suffering a little from x/y accuracy, which I hope is just a belt tension issue. It'll take a few more prints to get to the bottom of that I think.

|

Re: Speeds, Feeds and Flows July 12, 2013 01:02PM |

Registered: 11 years ago Posts: 250 |

Here are my (Slic3r) retract settings:

Length: 1

Lift Z: 0

Speed: 30 mm/s

Extra length on restart: 0

Min travel after retract: 2

Retract on layer change: checked

Wipe before retract: unchecked

Not 100% on this, but temps maybe playing a roll with having 'nubbins' in your prints.

If its too hot, the plastic becomes too Viscous.

What material and temps are you using?

Also if you have backlash (loose belts) that may be causing it too.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Length: 1

Lift Z: 0

Speed: 30 mm/s

Extra length on restart: 0

Min travel after retract: 2

Retract on layer change: checked

Wipe before retract: unchecked

Not 100% on this, but temps maybe playing a roll with having 'nubbins' in your prints.

If its too hot, the plastic becomes too Viscous.

What material and temps are you using?

Also if you have backlash (loose belts) that may be causing it too.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Speeds, Feeds and Flows July 12, 2013 01:40PM |

Admin Registered: 17 years ago Posts: 7,879 |

Usually loose bits of plastic stuck to the edges of the object are deposited at the start of a run, not the end. If they are left at the end of a run then they would be solidly attached. What happens is if the retract is not far enough the plastic oozes during long moves and the ooze can get stuck to the object as the nozzle crosses a perimeter. Because the ooze has cooled it doesn't stick well and is easily removed.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Speeds, Feeds and Flows July 12, 2013 06:45PM |

Registered: 11 years ago Posts: 369 |

Hmm, ok that might be it. I haven't been watching every print as closely since it seems to be working fine otherwise. Today I chose to study it but at the point where it happens the nozzle is hopping between two "towers" and the perimeter starts and ends in the same spot (obviously!)

I've got Faberdashery classic black loaded at the moment and am printing at 200 (210 first layer) as this seemed to be a good temperature for the Village Green I had in the kit. I've also got the bed cranked up to 75 (90 first layer) but that's probably a hangover from my cheapo PLA that doesn't even stick at that temperature...

I suppose it really does depend on too many factors but I really wish there was a database/lookup table of good temperatures to start from for each colour... it's taking me a while to understand the symptoms of too high/too low temps.

I've got Faberdashery classic black loaded at the moment and am printing at 200 (210 first layer) as this seemed to be a good temperature for the Village Green I had in the kit. I've also got the bed cranked up to 75 (90 first layer) but that's probably a hangover from my cheapo PLA that doesn't even stick at that temperature...

I suppose it really does depend on too many factors but I really wish there was a database/lookup table of good temperatures to start from for each colour... it's taking me a while to understand the symptoms of too high/too low temps.

|

Re: Speeds, Feeds and Flows July 13, 2013 02:26AM |

Admin Registered: 17 years ago Posts: 7,879 |

The temperature seems to vary even with the same plastic. Village green worked best at 220C for me but recently a few people say it needs to be lower.

Also a table might work between Mendel90 users but a lot of people use less accurate thermistors and thermistor tables and different hot ends.

The best way to determine it is to hand feed some by turning the big gear to see if it is too viscous to feed easily or too runny to form a filament.

[www.hydraraptor.blogspot.com]

Also a table might work between Mendel90 users but a lot of people use less accurate thermistors and thermistor tables and different hot ends.

The best way to determine it is to hand feed some by turning the big gear to see if it is too viscous to feed easily or too runny to form a filament.

[www.hydraraptor.blogspot.com]

|

Re: Speeds, Feeds and Flows July 13, 2013 04:27AM |

Registered: 11 years ago Posts: 369 |

So motors off, start with a low E temp such as 180, wait for it to reach target, then turn the wheel to see if it extrudes and keep increasing until it does?

When I was talking about having a table I did (rather selfishly) mean just here, for us Mendel90 users but even then I'm guessing that variables like filament batch, thickness of glass (those IKEA mirrors work a treat by the way!) etc would probably make the error margin significant enough to render the lookup useless.

When I was talking about having a table I did (rather selfishly) mean just here, for us Mendel90 users but even then I'm guessing that variables like filament batch, thickness of glass (those IKEA mirrors work a treat by the way!) etc would probably make the error margin significant enough to render the lookup useless.

|

Re: Speeds, Feeds and Flows July 13, 2013 06:40AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes turn the wheel to see if it will extrude without too much torque. Don't force it or it will strip the filament and then you will need to clean the hobbed bolt. That is the reason for doing it by hand rather than the motor.

There is the start of a table in the Mendel90 manual from my findings but already people disagree with it. There are a couple of Mendel90 users that insist 185C is correct for the village green supplied in the kit. I cannot explain that at all. PLA has always been far too viscous at 185C for me to extrude.

[www.hydraraptor.blogspot.com]

There is the start of a table in the Mendel90 manual from my findings but already people disagree with it. There are a couple of Mendel90 users that insist 185C is correct for the village green supplied in the kit. I cannot explain that at all. PLA has always been far too viscous at 185C for me to extrude.

[www.hydraraptor.blogspot.com]

|

Re: Speeds, Feeds and Flows July 13, 2013 12:43PM |

Registered: 13 years ago Posts: 2,947 |

The volume per second of plastic being melted determines the temperature needed. So if people are printing at lower layer heights or lower speeds the temperature needs to be lower. It is a result of the dwell time in the hotend and the actual temperature we need the plastic as it extrudes not the temperature you have the hotend set at.

The calculator in my signature estimates the temperature to set the hotend to extrude for the given flow rate. Since the defaults are for Tantillus you would want to use the intermediate or advanced or expert mode so you can input your normal base line data for an M90. So far some Tantillus users have said it works for them and that they use it to determine their settings and temperatures. I use it for all of my settings and to make the profiles for Tantillus.

The calculator in my signature estimates the temperature to set the hotend to extrude for the given flow rate. Since the defaults are for Tantillus you would want to use the intermediate or advanced or expert mode so you can input your normal base line data for an M90. So far some Tantillus users have said it works for them and that they use it to determine their settings and temperatures. I use it for all of my settings and to make the profiles for Tantillus.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Speeds, Feeds and Flows July 13, 2013 03:37PM |

Admin Registered: 17 years ago Posts: 7,879 |

These temperature differences are reported printing the same G code I supply as a simple test of the kit so will all be running at the same flow rate.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Speeds, Feeds and Flows July 14, 2013 04:20AM |

Registered: 11 years ago Posts: 369 |

When I merged the T3P3 Panelolu code into my Mendel90 code I noticed that the thermistor constants differed about half way down the list - I guess when you took your respective forks you both added new thermistors but in a different order. I had to be careful to select the right one after the merge; kdiff would have left me with the wrong one selected. I don't know if this is significant, as there might not be that many people using Panelolu, but could it be possible that some machines have got the wrong thermistor selected in the firmware and as a result are reporting the wrong temperatures?

|

Re: Speeds, Feeds and Flows July 14, 2013 08:10AM |

Admin Registered: 17 years ago Posts: 7,879 |

I think I checked people that reported low temperatures to me were using my fork of the firmware with the correct tables.

Yes the T3P3 fork is from a much more recent version of Marlin, so the table slots I had used had been used by somebody else. Other tables will give incorrect results, which is why I created my own.

[www.hydraraptor.blogspot.com]

Yes the T3P3 fork is from a much more recent version of Marlin, so the table slots I had used had been used by somebody else. Other tables will give incorrect results, which is why I created my own.

[www.hydraraptor.blogspot.com]

|

Re: Speeds, Feeds and Flows July 15, 2013 12:52PM |

Registered: 11 years ago Posts: 369 |

My retraction settings are as follows:

Length: 1mm

Lift Z: 0.3 (= 1 layer)

Speed: 30mm/s

Extra length on restart: 0mm

Minimum travel after retraction: 2mm

Retract on layer change: ticked

I don't seem to have a "wipe before retract" option (still on 0.9.9).

I've been using lift to try to get rid of these loose bits of plastic but it doesn't seem to be having any effect - I just tried another print today with multiple "towers" and the nubbins are very obvious, but curiously mostly on only one of my eight towers.

I also tried lowering my temps to 180E, 70B (190E 90B first layer) but now I'm getting slight lifting at the edges and the skirt didn't stick at all - the nozzle dragged most of it across the bed until I pulled it away with a pair of tweezers!

When I did the manual wheel turn test the plastic extruded fine at 180. My cold-extrusion limit is set to 175 so I can't go much lower without reloading my firmware. This didn't bug me until I saw the quality of your prints!

Length: 1mm

Lift Z: 0.3 (= 1 layer)

Speed: 30mm/s

Extra length on restart: 0mm

Minimum travel after retraction: 2mm

Retract on layer change: ticked

I don't seem to have a "wipe before retract" option (still on 0.9.9).

I've been using lift to try to get rid of these loose bits of plastic but it doesn't seem to be having any effect - I just tried another print today with multiple "towers" and the nubbins are very obvious, but curiously mostly on only one of my eight towers.

I also tried lowering my temps to 180E, 70B (190E 90B first layer) but now I'm getting slight lifting at the edges and the skirt didn't stick at all - the nozzle dragged most of it across the bed until I pulled it away with a pair of tweezers!

When I did the manual wheel turn test the plastic extruded fine at 180. My cold-extrusion limit is set to 175 so I can't go much lower without reloading my firmware. This didn't bug me until I saw the quality of your prints!

Sorry, only registered users may post in this forum.