Help! Filament jammed!

Posted by QuackingPlums

|

Help! Filament jammed! July 19, 2013 04:31AM |

Registered: 11 years ago Posts: 369 |

Half way through a print last night I noticed that no more filament was coming out. It must have been going for at least five layers or so but I couldn't see because for a change I was printing with the fan assembly fitted to see if my corners came out any smoother.

The extruder gear was still turning fine but the filament wasn't moving - yet nothing was fouling the filament above the extruder and the spool itself was turning freely. Manually extruding or retracting using Pronterface exhibited the same behaviour.

After cranking up the E temp to 210 and pulling on the filament with some radio pliers I eventually heard a "snap" as the filament broke, and bringing with it a rather swollen lump that must have gotten stuck in the J-head entrance. This happened during normal printing, not a filament swap, and my retract settings are still only in the region of mm, not cm, so I can't understand why this has happened.

In any case, how do I now remove the jam? I've tried cranking up the E temp again but it still won't extrude, and now there's nothing left accessible that I can pull out even with the spring-loaded bearing removed. Do I need to dismantle the J-Head?

Edited 1 time(s). Last edit at 07/19/2013 04:33AM by QuackingPlums.

The extruder gear was still turning fine but the filament wasn't moving - yet nothing was fouling the filament above the extruder and the spool itself was turning freely. Manually extruding or retracting using Pronterface exhibited the same behaviour.

After cranking up the E temp to 210 and pulling on the filament with some radio pliers I eventually heard a "snap" as the filament broke, and bringing with it a rather swollen lump that must have gotten stuck in the J-head entrance. This happened during normal printing, not a filament swap, and my retract settings are still only in the region of mm, not cm, so I can't understand why this has happened.

In any case, how do I now remove the jam? I've tried cranking up the E temp again but it still won't extrude, and now there's nothing left accessible that I can pull out even with the spring-loaded bearing removed. Do I need to dismantle the J-Head?

Edited 1 time(s). Last edit at 07/19/2013 04:33AM by QuackingPlums.

|

Re: Help! Filament jammed! July 19, 2013 05:22AM |

Registered: 12 years ago Posts: 212 |

QuackingPlums Wrote:

-------------------------------------------------------

Do I need to dismantle the J-Head?

Yup!

What has most likely happened is that the filament has, for some reason gone soft higher up in the JHead and then started to buckle rather than push the filament below it through the hot end. This can happen if you have a large area to fill at a speed which is not providing enough throughput to prevent the filament softening in the JHead itself - I believe the problems start on the first layer which is often printed at 50% of the speed which other layers are printed at - printing may continue for a while after the first layer but eventually stops as the filament continues to soften and buckle. (Heat gets that far up by convection and radiation I believe - NOT by conduction).

If you remove the JHead from the Wade's block you will see a plug of filament at its entrance. You can now try a few techniques ..... switch the hot end on but be careful where is it pointing now that it is in fresh air - try 90C to start with but be prepared to go higher if needs be. You may also need a hot air blower or some way of warming up the plug of filament at the top of the JHead so that you can grab hold of it with a pair of fine nose pliers and pull it out. Take your time, it can take a while but eventually you should be able to remove all the PLA. At some point you will most likely need to unscrew the hex grub screw which is at the top of the JHead and prevents the PTFE liner coming out - there is a washer between the liner and the hollow hex grub screw so watch out you don't lose it.

When you have reassembled everything, take time to clean out the hobbed bolt - its teeth will be full of PLA - while it was turning, the filament was not moving and the bolt will have been grinding away, filling up the space between the teeth.

Hope this makes sense - no doubt others will be able to clarify and add to the above.

Alan

EDIT

I am assuming that you were using PLA by the way as what you describe would be very unusual with ABS which has a much higher glass transition temperature and will not soften as easily as PLA will.

Edited 3 time(s). Last edit at 07/19/2013 06:37AM by Alzibiff.

-------------------------------------------------------

Do I need to dismantle the J-Head?

Yup!

What has most likely happened is that the filament has, for some reason gone soft higher up in the JHead and then started to buckle rather than push the filament below it through the hot end. This can happen if you have a large area to fill at a speed which is not providing enough throughput to prevent the filament softening in the JHead itself - I believe the problems start on the first layer which is often printed at 50% of the speed which other layers are printed at - printing may continue for a while after the first layer but eventually stops as the filament continues to soften and buckle. (Heat gets that far up by convection and radiation I believe - NOT by conduction).

If you remove the JHead from the Wade's block you will see a plug of filament at its entrance. You can now try a few techniques ..... switch the hot end on but be careful where is it pointing now that it is in fresh air - try 90C to start with but be prepared to go higher if needs be. You may also need a hot air blower or some way of warming up the plug of filament at the top of the JHead so that you can grab hold of it with a pair of fine nose pliers and pull it out. Take your time, it can take a while but eventually you should be able to remove all the PLA. At some point you will most likely need to unscrew the hex grub screw which is at the top of the JHead and prevents the PTFE liner coming out - there is a washer between the liner and the hollow hex grub screw so watch out you don't lose it.

When you have reassembled everything, take time to clean out the hobbed bolt - its teeth will be full of PLA - while it was turning, the filament was not moving and the bolt will have been grinding away, filling up the space between the teeth.

Hope this makes sense - no doubt others will be able to clarify and add to the above.

Alan

EDIT

I am assuming that you were using PLA by the way as what you describe would be very unusual with ABS which has a much higher glass transition temperature and will not soften as easily as PLA will.

Edited 3 time(s). Last edit at 07/19/2013 06:37AM by Alzibiff.

|

Re: Help! Filament jammed! July 19, 2013 06:50AM |

Registered: 11 years ago Posts: 369 |

Thanks for the reply! Yes, I am printing in notorious black PLA. Of all days, when I have a bunch of stuff I need printing out! Grrr!

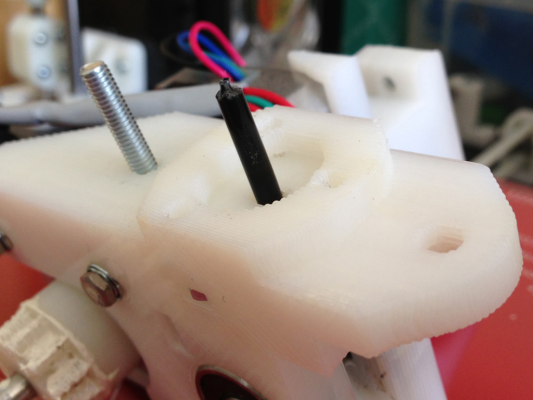

Ok, well I've taken off the extruder assembly and detached the J-head, and I can see this (extruder shown upside down):

It looks like the filament is fine all the way down to the extrusion zone (where I assume it narrows?) and that the filament only swelled and buckled near the top of the J-head where it meets the extruder assembly.

This is looking down the filament path from where the sprung bearing has been removed (extruder right way up now):

You can just see the top of the swollen filament that is now jammed in the extruder.

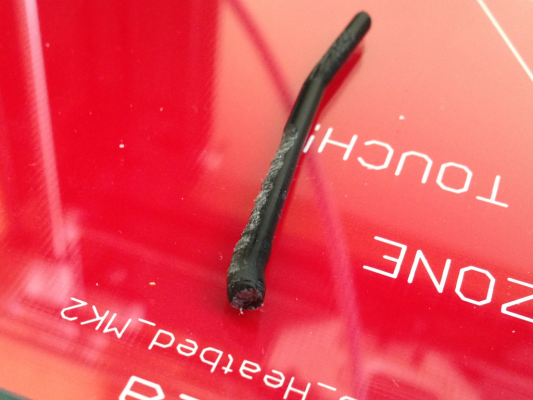

This is the piece of filament that I pulled out with pliers:

The left hand side has been chewed up by the hobbed bolt and the bottom is where it swelled/buckled - presumably because this bit is now less dense and therefore weaker...

I guess it's possible that the swelling was actually inside the J-head but in pulling it out with pliers I inadvertently caused it to pull the bulge into the extruder assembly itself? Is that likely?

So given that it looks like the PLA softened itself way up at the top of the J-head, is there anything I can do to help prevent this?

I *did* make a small change last night, which was to put the minimum layer time back to 30s in an attempt to get tidier corners (I had it down to 15s on my earlier prints). Do I need to drop it back to 15s or is this a symptom of something else?

Ok, well I've taken off the extruder assembly and detached the J-head, and I can see this (extruder shown upside down):

It looks like the filament is fine all the way down to the extrusion zone (where I assume it narrows?) and that the filament only swelled and buckled near the top of the J-head where it meets the extruder assembly.

This is looking down the filament path from where the sprung bearing has been removed (extruder right way up now):

You can just see the top of the swollen filament that is now jammed in the extruder.

This is the piece of filament that I pulled out with pliers:

The left hand side has been chewed up by the hobbed bolt and the bottom is where it swelled/buckled - presumably because this bit is now less dense and therefore weaker...

I guess it's possible that the swelling was actually inside the J-head but in pulling it out with pliers I inadvertently caused it to pull the bulge into the extruder assembly itself? Is that likely?

So given that it looks like the PLA softened itself way up at the top of the J-head, is there anything I can do to help prevent this?

I *did* make a small change last night, which was to put the minimum layer time back to 30s in an attempt to get tidier corners (I had it down to 15s on my earlier prints). Do I need to drop it back to 15s or is this a symptom of something else?

|

Re: Help! Filament jammed! July 19, 2013 07:04AM |

Registered: 11 years ago Posts: 369 |

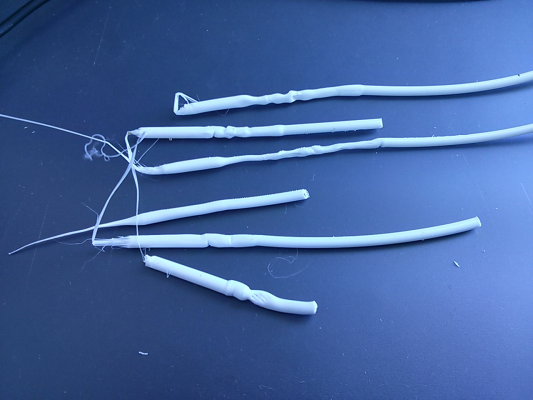

Oo, interesting. The remaining bit pulled out from the extruder assembly with little effort and looks like this:

You can see how the filament doubled-back on itself several times before filling up all the space in that oval-shaped hole and causing the bolt to slip!

Is this consistent with the theory that somehow my filament got above its GTT due to convection/radiation higher up? Would a round extruder path (vs. the oval one) have reduced the chances of this occurring? How exactly is heat getting up to this point in the filament?

Edited 1 time(s). Last edit at 07/19/2013 07:05AM by QuackingPlums.

You can see how the filament doubled-back on itself several times before filling up all the space in that oval-shaped hole and causing the bolt to slip!

Is this consistent with the theory that somehow my filament got above its GTT due to convection/radiation higher up? Would a round extruder path (vs. the oval one) have reduced the chances of this occurring? How exactly is heat getting up to this point in the filament?

Edited 1 time(s). Last edit at 07/19/2013 07:05AM by QuackingPlums.

|

Re: Help! Filament jammed! July 19, 2013 07:22AM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

After cranking up the E temp to 210

What temperature were you extruding at?

It is not clear whether softening too high is cause or effect. For example too low a temperature causes the filament to stop feeding and then it hangs around long enough to soften. Also the force on it is higher so it doesn't need to soften much before it buckles. Raising the temperature 10 or 20C can fix the problem.

To cool the top of the hot end you could try insulating the heater block by wrapping in it something like self vulcanising tape. Most of the heat at the top is by convection, not conduction.

Another thing to try would be to drill a few small holes in the top of the fan duct so some air blows upwards.

[www.hydraraptor.blogspot.com]

|

Re: Help! Filament jammed! July 19, 2013 07:43AM |

Registered: 11 years ago Posts: 369 |

Quote

What temperature were you extruding at?

Well, when I first got this PLA I started out at 210 because that's just been my starting point for new filament.

When I asked in another thread about those little nodules that get left behind when printing things with multiple "towers" someone suggested (it may have been you Chris!

) that it can happen when my E temp is too high, causing the filament to "drip" as it travels from tower to tower.

) that it can happen when my E temp is too high, causing the filament to "drip" as it travels from tower to tower. I did the manual turn test on the Wades gear as suggested to see what temperature the filament would extrude easily, and I discovered that 180 was fine. I actually have my settings at 200 first layer, 190 others (at 180 I was getting lifting at the edges) and have been printing for a day or two with *slightly* better corners, but nowhere near as neat as some photos on here. The nozzle is still dripping, albeit slightly less at 190.

If I raise the temperature back to 200 then I fear I may get my fuzzy corners back, but any lower and it either doesn't stick to the bed or I get this issue of blocking my extruder.

|

Re: Help! Filament jammed! July 19, 2013 10:31AM |

Registered: 11 years ago Posts: 369 |

Ok this is getting annoying now. It has happened twice more. I've cranked the extrusion temperature back up to 210 (which was printing fine before, albeit with lots of dripping between fast moves) and I have cleaned out the hobbed bolt after each incident. The last run barely made it half way through the second layer. Could it be that it's *too* hot today for PLA printing? Is my PLA too soft before it even gets into the extruder?

|

Re: Help! Filament jammed! July 19, 2013 11:58AM |

Registered: 14 years ago Posts: 3,742 |

Try a small fan pointed at the insulator portion of the hot end and see if that fixes the problem.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Help! Filament jammed! July 19, 2013 01:02PM |

Registered: 11 years ago Posts: 369 |

Hmm. I started printing with the extruder fan attached again this week as I was trying bridges, but none of the prints that have failed so far have needed the fan. In fact, the fan doesn't come on at all so is it possible that with the fan housing in such close proximity to the hot end, all the heat that normally dissipates is now being held next to the insulator portion and causing this?

Would it be better to remove the fan assembly entirely or to tick the box to have the fan on all the time?

Would it be better to remove the fan assembly entirely or to tick the box to have the fan on all the time?

|

Re: Help! Filament jammed! July 19, 2013 01:30PM |

Registered: 14 years ago Posts: 3,742 |

I would first try having the fan ON all the time.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Help! Filament jammed! July 19, 2013 01:58PM |

Admin Registered: 17 years ago Posts: 7,879 |

You want the fan on after the first layer for PLA. I remove it completely for ABS.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Help! Filament jammed! July 19, 2013 02:53PM |

Registered: 12 years ago Posts: 212 |

My £0.02......

I bought a 25mm 12V DC fan from somewhere on a famous internet auction site and made a clip (which I need to redesign as it is too loose really) which attaches it to the X carriage - pointing towards the top of the JHead. The fan is wired to permanent 12V on the extruder PCB. Fingers crossed but this has worked without problems for months. I keep the fan which Chris supplied with the kit permanently fixed for both PLA and ABS and I can get top quality prints from both materials. I will try and post a photograph later this weekend if I get the chance.

and made a clip (which I need to redesign as it is too loose really) which attaches it to the X carriage - pointing towards the top of the JHead. The fan is wired to permanent 12V on the extruder PCB. Fingers crossed but this has worked without problems for months. I keep the fan which Chris supplied with the kit permanently fixed for both PLA and ABS and I can get top quality prints from both materials. I will try and post a photograph later this weekend if I get the chance.

Alan

I bought a 25mm 12V DC fan from somewhere on a famous internet auction site

and made a clip (which I need to redesign as it is too loose really) which attaches it to the X carriage - pointing towards the top of the JHead. The fan is wired to permanent 12V on the extruder PCB. Fingers crossed but this has worked without problems for months. I keep the fan which Chris supplied with the kit permanently fixed for both PLA and ABS and I can get top quality prints from both materials. I will try and post a photograph later this weekend if I get the chance.

and made a clip (which I need to redesign as it is too loose really) which attaches it to the X carriage - pointing towards the top of the JHead. The fan is wired to permanent 12V on the extruder PCB. Fingers crossed but this has worked without problems for months. I keep the fan which Chris supplied with the kit permanently fixed for both PLA and ABS and I can get top quality prints from both materials. I will try and post a photograph later this weekend if I get the chance.Alan

|

Re: Help! Filament jammed! July 19, 2013 07:27PM |

Registered: 11 years ago Posts: 369 |

Took the fan off, printed fine first time. I must be right on the limit of that filament retaining enough rigidity to get through the extruder!

I like the sound of a cooling fan Alan but I can't see where I can fit it if I have the extruder fan assembly as well - the hot end is pretty well tucked away in its own little alcove, which I guess explains why it can get so hot up there.

I like the sound of a cooling fan Alan but I can't see where I can fit it if I have the extruder fan assembly as well - the hot end is pretty well tucked away in its own little alcove, which I guess explains why it can get so hot up there.

|

Re: Help! Filament jammed! July 19, 2013 08:02PM |

Registered: 11 years ago Posts: 1,320 |

This is a known problem printing PLA with a J head. I have a 25 mm fan pointing at the upper portion of the hot end insulator. It is wired directly to 12 volts, although I also have a toggle switch so I can turn it off for ABS. With this arrangement, I have never had a jam - in over a year of use.

|

Re: Help! Filament jammed! July 20, 2013 04:29AM |

Registered: 11 years ago Posts: 369 |

Those of you who have fans blowing at the top of your J-heads, could I ask you to post a picture please? Do you keep the extruder fan assembly attached as well? I'm trying to get half-decent bridges working in PLA so I need to have the extruder fan, and I can't see how to keep that AND have enough room to blow at the top of the J-head.

Chris' suggestion is to drill some holes at the top of the fan assembly so that some of the air is directed upwards but I'm not sure if that's such a good idea; for starters it's a beautiful piece of kit and it would be a travesty to drill into it, plus the whole thing is designed to direct air downward so I'm not convinced that simply drilling holes in it will direct enough airflow up around the J-head.

Chris' suggestion is to drill some holes at the top of the fan assembly so that some of the air is directed upwards but I'm not sure if that's such a good idea; for starters it's a beautiful piece of kit and it would be a travesty to drill into it, plus the whole thing is designed to direct air downward so I'm not convinced that simply drilling holes in it will direct enough airflow up around the J-head.

|

Re: Help! Filament jammed! July 20, 2013 08:34AM |

Admin Registered: 17 years ago Posts: 7,879 |

It would need to be tried but as I have never had a problem printing PLA with a J-Head I can't test myself. My guess is a small amount of airflow will make a huge difference, as would insulating the heater block.

In terms of printing holes in it, they would need support membranes (as the holes are in mid air), which would need to be drilled out anyway. It would be neater than drilling them though..

Room temperature is about 10C warmer than normal in the UK at the moment, so that could be enough to make the difference. I.e. 30C rather than 20C.

[www.hydraraptor.blogspot.com]

In terms of printing holes in it, they would need support membranes (as the holes are in mid air), which would need to be drilled out anyway. It would be neater than drilling them though..

Room temperature is about 10C warmer than normal in the UK at the moment, so that could be enough to make the difference. I.e. 30C rather than 20C.

[www.hydraraptor.blogspot.com]

|

Re: Help! Filament jammed! July 20, 2013 01:48PM |

Registered: 11 years ago Posts: 1,320 |

I will post a picture after I get home.

I have a total of 3 fans connected to my x carriage (I do not have a Mendel 90, nor do I have a Bowden setup). I have a pair of 40 mm fans, wired in parallel, attached to pivot points on the front and rear of my x carriage. These are connected to my RAMPS board and are thus controlled by g code. The third fan is 25 mm and is mounted to the underside of the carriage on the left hand side up high right against the carriage. It is wired through a toggle switch directly to 12v. All of these fans are permanently mounted.

I had to design my own carriage to incorporate all of this.

I am in the process of building my own design delta printer, and I already have the 25 mm fan mount in the design as I am using a J head there as well. I do not have the other fans on the carriage though to keep the carriage moment of inertia as small as possible.

I have a total of 3 fans connected to my x carriage (I do not have a Mendel 90, nor do I have a Bowden setup). I have a pair of 40 mm fans, wired in parallel, attached to pivot points on the front and rear of my x carriage. These are connected to my RAMPS board and are thus controlled by g code. The third fan is 25 mm and is mounted to the underside of the carriage on the left hand side up high right against the carriage. It is wired through a toggle switch directly to 12v. All of these fans are permanently mounted.

I had to design my own carriage to incorporate all of this.

I am in the process of building my own design delta printer, and I already have the 25 mm fan mount in the design as I am using a J head there as well. I do not have the other fans on the carriage though to keep the carriage moment of inertia as small as possible.

|

Re: Help! Filament jammed! July 21, 2013 07:27AM |

Registered: 12 years ago Posts: 41 |

I just a similar problem after I tried printing again after a month.

Extruder gear turned fine but there was no plastic coming out of the hotend. So i took the extruder apart and saw that the plastic was "buckled" above the hotend. I tried to turn the heat back on and remove the filament manually from the hotend. But in the end the filament broke and now the hotened is filled with filament. I tried again to heat up the extruder and push the filament manually through the hotend, but this doesn't work.

Any ideas how i can remove the filament and print again?

- drilling the filament?

- turn the hotend back on and use a hot air blower to heat up the filament and try again to push it manually through the hotend?

that's the two ideas that I have ... but I thought it might be better to ask here first before I do something stupid.

hope someone can help, thx.

Extruder gear turned fine but there was no plastic coming out of the hotend. So i took the extruder apart and saw that the plastic was "buckled" above the hotend. I tried to turn the heat back on and remove the filament manually from the hotend. But in the end the filament broke and now the hotened is filled with filament. I tried again to heat up the extruder and push the filament manually through the hotend, but this doesn't work.

Any ideas how i can remove the filament and print again?

- drilling the filament?

- turn the hotend back on and use a hot air blower to heat up the filament and try again to push it manually through the hotend?

that's the two ideas that I have ... but I thought it might be better to ask here first before I do something stupid.

hope someone can help, thx.

|

Re: Help! Filament jammed! July 21, 2013 09:30AM |

Registered: 11 years ago Posts: 77 |

|

Re: Help! Filament jammed! July 21, 2013 09:41AM |

Admin Registered: 17 years ago Posts: 7,879 |

I assume it is PLA. If you have a heat gun then heat the top end of the extruder to about 70C. It then becomes like rubber and you can grip it with snipe nosed pliers and pull out the bit in the hex grub screw. It should then work again. It is only the fact that the hole through the grub screw is bigger than the normal filament path that is the Achilles heel of the JHead.

Don't attempt to drill it as you will damage the PTFE liner because PLA is much harder than PTFE so the drill will go sideways. You can use the blunt end of a 3mm drill to push the rest of the PLA down the tube with the hot end at extrusion temperature.

[www.hydraraptor.blogspot.com]

Don't attempt to drill it as you will damage the PTFE liner because PLA is much harder than PTFE so the drill will go sideways. You can use the blunt end of a 3mm drill to push the rest of the PLA down the tube with the hot end at extrusion temperature.

[www.hydraraptor.blogspot.com]

|

Re: Help! Filament jammed! July 21, 2013 11:30AM |

Registered: 11 years ago Posts: 67 |

|

Re: Help! Filament jammed! July 21, 2013 01:38PM |

Registered: 12 years ago Posts: 41 |

|

Re: Help! Filament jammed! August 09, 2013 02:48PM |

Registered: 12 years ago Posts: 41 |

Lately the "buckling up" of my filament, jamming the extruder and therefore not finishing the prints are happening quite often

Any idea how I can solve this issue. It's not everytime I print. Sometimes it just happens ~10 minutes into the print, sometimes I can just print fine (1.5h was the biggest I printed recently without a problem). But lately it jammed more than it prints fine If I notice it soon enough I can retract the filament, cut off the "buckle" and put the filament back in. If i don't notice it gets that big than I wether can't extract or retract anymore and I have to take the extruder apart.

If I notice it soon enough I can retract the filament, cut off the "buckle" and put the filament back in. If i don't notice it gets that big than I wether can't extract or retract anymore and I have to take the extruder apart.

It's white PLA from grrf.de . I print with 210° and also tried 200° ... no difference. It worked fine with 210° two months ago before I took a break printing. Didn't turn on the fan yet.

Any idea how I can solve this issue. It's not everytime I print. Sometimes it just happens ~10 minutes into the print, sometimes I can just print fine (1.5h was the biggest I printed recently without a problem). But lately it jammed more than it prints fine

If I notice it soon enough I can retract the filament, cut off the "buckle" and put the filament back in. If i don't notice it gets that big than I wether can't extract or retract anymore and I have to take the extruder apart.

If I notice it soon enough I can retract the filament, cut off the "buckle" and put the filament back in. If i don't notice it gets that big than I wether can't extract or retract anymore and I have to take the extruder apart.It's white PLA from grrf.de . I print with 210° and also tried 200° ... no difference. It worked fine with 210° two months ago before I took a break printing. Didn't turn on the fan yet.

|

Re: Help! Filament jammed! August 09, 2013 05:28PM |

Admin Registered: 17 years ago Posts: 7,879 |

It is probably because the weather is hotter than it was two months ago. Looks like you need to have a fan blowing on the top of the hot end.

I have never needed a fan on the hot end to extrude PLA but some people do. I have suggested before that maybe a few holes in the top of the fan duct would fix it but I don't think anybody has tried it.

Another solution might be insulation around the heater block to stop hot air rising from it.

Edited 1 time(s). Last edit at 08/09/2013 08:21PM by nophead.

[www.hydraraptor.blogspot.com]

I have never needed a fan on the hot end to extrude PLA but some people do. I have suggested before that maybe a few holes in the top of the fan duct would fix it but I don't think anybody has tried it.

Another solution might be insulation around the heater block to stop hot air rising from it.

Edited 1 time(s). Last edit at 08/09/2013 08:21PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Help! Filament jammed! August 09, 2013 07:12PM |

Registered: 11 years ago Posts: 369 |

I've taken my fan housing off completely and the problem has gone away for me. I also found that keeping the doors and windows open (but not so far that there's a breeze blowing through the room) also helped to keep the ambient temperature low enough for the print to be successful. I've managed prints in excess of 5 hours now.

|

Re: Help! Filament jammed! August 11, 2013 04:35AM |

Registered: 10 years ago Posts: 194 |

QuackingPlums,

Just curious, what is the temperature setting that you have settled at and was able to print without jamming with? You are still using PLA, right?

I have been having a very similar problem with you, and I'm still trying to figure out what the right temperature setting for me is... I am using (black) PLA also. Well, I actually just tried to switch to ABS after so much jamming, but I couldn't print with ABS, either! So, I suspect if I got a bad batch of ABS filament (like full of air bubbles or something), so I'm back to trying to print again with PLA, which I was able to print hours without jamming previously.

Thank you!

QuackingPlums Wrote:

-------------------------------------------------------

> I've taken my fan housing off completely and the

> problem has gone away for me. I also found that

> keeping the doors and windows open (but not so far

> that there's a breeze blowing through the room)

> also helped to keep the ambient temperature low

> enough for the print to be successful. I've

> managed prints in excess of 5 hours now.

Just curious, what is the temperature setting that you have settled at and was able to print without jamming with? You are still using PLA, right?

I have been having a very similar problem with you, and I'm still trying to figure out what the right temperature setting for me is... I am using (black) PLA also. Well, I actually just tried to switch to ABS after so much jamming, but I couldn't print with ABS, either! So, I suspect if I got a bad batch of ABS filament (like full of air bubbles or something), so I'm back to trying to print again with PLA, which I was able to print hours without jamming previously.

Thank you!

QuackingPlums Wrote:

-------------------------------------------------------

> I've taken my fan housing off completely and the

> problem has gone away for me. I also found that

> keeping the doors and windows open (but not so far

> that there's a breeze blowing through the room)

> also helped to keep the ambient temperature low

> enough for the print to be successful. I've

> managed prints in excess of 5 hours now.

|

Re: Help! Filament jammed! August 11, 2013 05:55AM |

Registered: 12 years ago Posts: 41 |

|

Re: Help! Filament jammed! August 11, 2013 12:34PM |

Registered: 11 years ago Posts: 369 |

Quote

Yamster

Just curious, what is the temperature setting that you have settled at and was able to print without jamming with? You are still using PLA, right?

I print Faberdashery Classic Black PLA at E200/190 and B90/75 (first layer/other layer, as read from the thermistors).

My fan is removed completely now, since the bridges weren't that much better with it on.

It's worth noting that the problem coincided with two things: the ambient temperature in my den rocketing skyward and me reducing my first layer print speeds to see if I could mimic the print quality of another user on this board. I don't know which event is the root cause of the problem but I suppose I could try it again once summer temperatures go away for good.

FWIW I get much better quality prints using black ABS at E235, B135

HTH

|

Re: Help! Filament jammed! August 11, 2013 03:42PM |

Registered: 12 years ago Posts: 41 |

|

Re: Help! Filament jammed! April 25, 2015 11:20AM |

Registered: 9 years ago Posts: 8 |

Sorry, only registered users may post in this forum.