New X-Motor/Idler designs.

Posted by SanjayM

|

New X-Motor/Idler designs. September 25, 2013 07:12PM |

Registered: 12 years ago Posts: 177 |

Just got a new kit from nophead. Earlier than expected and wonderfully packaged as always. (My 3rd/4th Mendel90 kit from nophead - happy repeat customer)

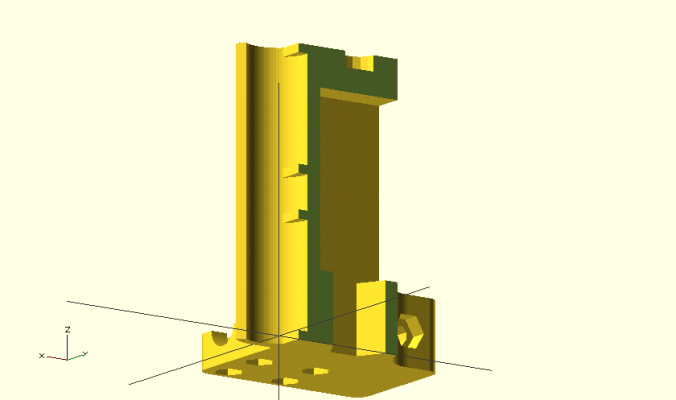

Noticed some rather large design changes to the X-Ends,

[github.com]

[github.com]

The new bar clamp is particularly welcome.

I was wondering what the motivation/reasoning behind making Z-Axis linear bearing holders/lead-screw guides 'boxier' as opposed to the previous tapered version?

I assume the X-Motor mounting system has been redesigned to make it a less challenging print with less support cleanup and better airflow to let the motor cool?

Either way I'm really happy to see that development on the M90 is still going on, and improvements are still being implemented despite the fact that nophead is obviously incredibly busy trying to get kits out the door.

Sanjay

Noticed some rather large design changes to the X-Ends,

[github.com]

[github.com]

The new bar clamp is particularly welcome.

I was wondering what the motivation/reasoning behind making Z-Axis linear bearing holders/lead-screw guides 'boxier' as opposed to the previous tapered version?

I assume the X-Motor mounting system has been redesigned to make it a less challenging print with less support cleanup and better airflow to let the motor cool?

Either way I'm really happy to see that development on the M90 is still going on, and improvements are still being implemented despite the fact that nophead is obviously incredibly busy trying to get kits out the door.

Sanjay

|

Re: New X-Motor/Idler designs. September 25, 2013 09:08PM |

Registered: 15 years ago Posts: 81 |

|

Re: New X-Motor/Idler designs. September 26, 2013 03:59AM |

Registered: 11 years ago Posts: 369 |

I can't see how the lead screw brass nuts are held in position at the top of those channels - are they narrow enough to just keep them from spinning? I guess they must be.

The new X-motor bracket looks much easier to print (the 45degree overhang up and across will be interesting!) so I will have a go at that soon - especially as my X-idler bracket clamp has developed a split so I'm already on borrowed time. I'm a little sad that my Cute Spocktopus will no longer have a perch on top of the X-motor though...!

The new X-motor bracket looks much easier to print (the 45degree overhang up and across will be interesting!) so I will have a go at that soon - especially as my X-idler bracket clamp has developed a split so I'm already on borrowed time. I'm a little sad that my Cute Spocktopus will no longer have a perch on top of the X-motor though...!

|

Re: New X-Motor/Idler designs. September 27, 2013 02:06PM |

Registered: 13 years ago Posts: 248 |

The manual got updated too, to reflect changes and a few new photos also!

I'm sure Chris will be along with comments when he gets a chance, but it does look like the brass nut (z nut) now is just trapped between the side walls at the top of the channel.

I notice the j-head hotend ships with a sleeve wrapping, and the cooling fan ducting has a little hole to keep the ducting that sits around the hotend cool also. lots of little changes. Nice!

The x-motor bracket should be a lot easier to print now, and take less material. I thought just two screws to the front looked like very little to be holding the motor, but I notice from the manual that there is a third supporting point at the rear of the motor.

I'm sure Chris will be along with comments when he gets a chance, but it does look like the brass nut (z nut) now is just trapped between the side walls at the top of the channel.

I notice the j-head hotend ships with a sleeve wrapping, and the cooling fan ducting has a little hole to keep the ducting that sits around the hotend cool also. lots of little changes. Nice!

The x-motor bracket should be a lot easier to print now, and take less material. I thought just two screws to the front looked like very little to be holding the motor, but I notice from the manual that there is a third supporting point at the rear of the motor.

|

Re: New X-Motor/Idler designs. September 27, 2013 03:10PM |

Admin Registered: 17 years ago Posts: 7,879 |

I am in the process of blogging the changes at the moment but the nut sits in a nut trap at the top, it isn't trapped between the walls.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: New X-Motor/Idler designs. September 27, 2013 06:50PM |

Registered: 11 years ago Posts: 369 |

|

Re: New X-Motor/Idler designs. September 28, 2013 05:36AM |

Registered: 10 years ago Posts: 541 |

Hi,

Did you figure out how to assemble the washer stack at the rear of the new motor housing? If you follow the manual you'll have quite a time placing the washers. Here's what I did:

1) Offer the motor up into the housing but don't fit the two front screws yet.

2) Visually assess how many washers you need to insert at the rear (there need to be enough to apply a slight outward force. Too few will be ineffective).

3) Remove the motor from the mount.

4) Feed the long screw through the back of the motor mount and add the washer stack onto the screw inside the mount.

5) Slide the motor into place and retract the long screw sufficiently to clear the motor body while still retaining the washer stack.

6) Align the motor at the front and push home the long screw then fit the front two screws and tighten all three screws.

Regards,

Neil Darlow

Did you figure out how to assemble the washer stack at the rear of the new motor housing? If you follow the manual you'll have quite a time placing the washers. Here's what I did:

1) Offer the motor up into the housing but don't fit the two front screws yet.

2) Visually assess how many washers you need to insert at the rear (there need to be enough to apply a slight outward force. Too few will be ineffective).

3) Remove the motor from the mount.

4) Feed the long screw through the back of the motor mount and add the washer stack onto the screw inside the mount.

5) Slide the motor into place and retract the long screw sufficiently to clear the motor body while still retaining the washer stack.

6) Align the motor at the front and push home the long screw then fit the front two screws and tighten all three screws.

Regards,

Neil Darlow

|

Re: New X-Motor/Idler designs. September 28, 2013 09:18AM |

Admin Registered: 17 years ago Posts: 7,879 |

It isn't necessary to put enough washers in to provide outwards force. That is probably why you found it difficult. It just needs as many as will fit easily.

The washers pack out the head of the bolt which acts like a dowel in the back bracket. The front screws locate the motor in the Y direction and stop it rotating about Y. The back screw stops it rotating about Z or X.

[www.hydraraptor.blogspot.com]

The washers pack out the head of the bolt which acts like a dowel in the back bracket. The front screws locate the motor in the Y direction and stop it rotating about Y. The back screw stops it rotating about Z or X.

[www.hydraraptor.blogspot.com]

|

Re: New X-Motor/Idler designs. September 28, 2013 05:30PM |

Registered: 15 years ago Posts: 81 |

I think there must be a bug somewhere, because the STLs in the git repo don't have the nut trap inside - I couldn't see it in the gcode preview when I sliced, so I used openscad to take a cross section by differencing a cube from the dibond version of the x_idler_bracket.stl:

(BTW, how does one inline an image instead of having it as an attachment?)

(BTW, how does one inline an image instead of having it as an attachment?)

|

Re: New X-Motor/Idler designs. September 28, 2013 06:58PM |

Registered: 15 years ago Posts: 81 |

|

Re: New X-Motor/Idler designs. September 29, 2013 07:09AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes it seems to be a bug in openscad. A simple cube with an enclosed cavity inside seems to produce an STL with the internal faces the wrong way round. I will raise a bug report.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: New X-Motor/Idler designs. September 29, 2013 07:46AM |

Admin Registered: 17 years ago Posts: 7,879 |

Sorry, only registered users may post in this forum.