Installing e3d Hotend

Posted by academicdave

|

Installing e3d Hotend May 08, 2014 08:15PM |

Registered: 10 years ago Posts: 51 |

|

Re: Installing e3d Hotend May 09, 2014 06:59AM |

Registered: 10 years ago Posts: 439 |

The thermistor supplied needs the line in configuration.h to read

#define TEMP_SENSOR_0 5

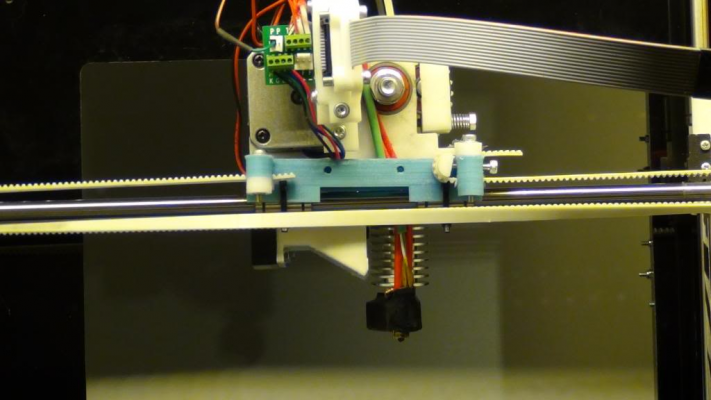

The hotend fan can be wired to the left probe pin (gnd) and the left heater wire on the small pcb (+12 volts). Wired in that fashion it is on all the time. I used a larger fan mounted on the carriage.

I printed a new X-carriage for the mounting. Details at

[www.thingiverse.com]

The E3D is longer so the Z_HOME_POS needs recalibrating as in the original instructions with the kit.

Mine now reads:

#define Z_HOME_POS (179.6)

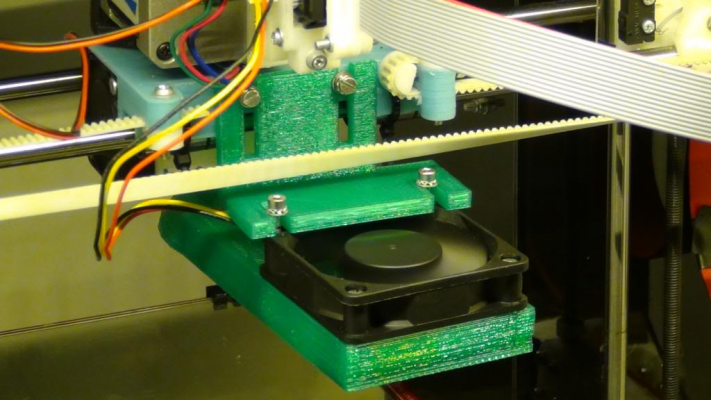

The print cooling fan need a different mounting due to the size change. My modified version is at

[www.thingiverse.com]

Edited 1 time(s). Last edit at 05/09/2014 07:09AM by Ralph.Hilton.

#define TEMP_SENSOR_0 5

The hotend fan can be wired to the left probe pin (gnd) and the left heater wire on the small pcb (+12 volts). Wired in that fashion it is on all the time. I used a larger fan mounted on the carriage.

I printed a new X-carriage for the mounting. Details at

[www.thingiverse.com]

The E3D is longer so the Z_HOME_POS needs recalibrating as in the original instructions with the kit.

Mine now reads:

#define Z_HOME_POS (179.6)

The print cooling fan need a different mounting due to the size change. My modified version is at

[www.thingiverse.com]

Edited 1 time(s). Last edit at 05/09/2014 07:09AM by Ralph.Hilton.

|

Re: Installing e3d Hotend May 10, 2014 05:49AM |

Registered: 10 years ago Posts: 51 |

|

Re: Installing e3d Hotend May 13, 2014 05:51PM |

Registered: 10 years ago Posts: 111 |

I have been printing only 2 weeks and destroyed my peek Jhead when the thermistor fell out.

Today I received this hotend from E3D and it looks fantasticly well build.

Thnx very much Ralph Hilton to give all I need to configure the hotend.

It took quite some time to prepare the hotend and install this in my Mendel.

Issues I encountered:

When putting the top of the heatsink into the bottom of the wades block I noticed 1 side goes deeper and the washer is not touching and holding up the heatsink firmly on one side. I fixed it by bending the washer a bit so it makes contact with the heatsink.

I followed the manual on ebay and so I installed the fan allready before putting it onto the x-carriage. Only solution was to take the fan off again and put the hotend on the x-carriage first. Screwing the fan back on sideways makes installing this hotend a challenge.

Because of the fanholder I had no room anymore to put on the wingnut on the left side of the x-carriage. Turning the fanholder is not possible.

I fixed it by screwing on a normal nut instead.

Today I received this hotend from E3D and it looks fantasticly well build.

Thnx very much Ralph Hilton to give all I need to configure the hotend.

It took quite some time to prepare the hotend and install this in my Mendel.

Issues I encountered:

When putting the top of the heatsink into the bottom of the wades block I noticed 1 side goes deeper and the washer is not touching and holding up the heatsink firmly on one side. I fixed it by bending the washer a bit so it makes contact with the heatsink.

I followed the manual on ebay and so I installed the fan allready before putting it onto the x-carriage. Only solution was to take the fan off again and put the hotend on the x-carriage first. Screwing the fan back on sideways makes installing this hotend a challenge.

Because of the fanholder I had no room anymore to put on the wingnut on the left side of the x-carriage. Turning the fanholder is not possible.

I fixed it by screwing on a normal nut instead.

|

Re: Installing e3d Hotend May 14, 2014 10:49AM |

Registered: 11 years ago Posts: 71 |

Quote

Ralph.Hilton

The print cooling fan need a different mounting due to the size change. My modified version is at

[www.thingiverse.com]

thanks for sharing the fan setup! i'm currently trying to modify a E3D 1.75mm direct drive setup (http://www.thingiverse.com/thing:147705) for the Mendel90. The one item I hadn't figured out yet was the cooling fan.

|

Re: Installing e3d Hotend May 18, 2014 07:00AM |

Registered: 10 years ago Posts: 48 |

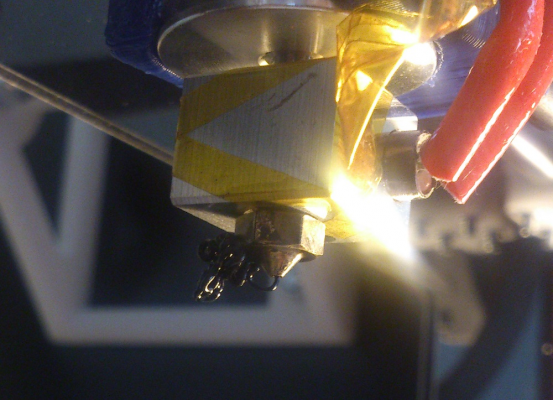

Just installed the E3D-v5 on my mendel90.

But we cant seem to get it to work good.

See the attached image.

3mm PLA

195 degreeC

5 mm extruded @ 50 mm/m

The extruded PLA just curles back onto the nozzle. What could be the reason for this?

|

Re: Installing e3d Hotend May 18, 2014 09:58AM |

Admin Registered: 17 years ago Posts: 7,879 |

PLA often curles when extruded into mid air. It is of no consequence once the nozzle is close enough to the bed.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Installing e3d Hotend May 18, 2014 01:59PM |

Registered: 10 years ago Posts: 48 |

|

Re: Installing e3d Hotend May 19, 2014 10:31AM |

Registered: 10 years ago Posts: 439 |

|

Re: Installing e3d Hotend May 19, 2014 02:25PM |

Registered: 10 years ago Posts: 48 |

|

Re: Installing e3d Hotend May 21, 2014 04:38PM |

Registered: 10 years ago Posts: 48 |

I am not quote sure I get correct readings from the thermistor.

If I should measure the temperature of the hot end where should I put the thermocouple?

Should I just hold it against the nozzle tip from the outside?

Should I stick i down the same way as the filament an measure the nozzle from the inside?

If I should measure the temperature of the hot end where should I put the thermocouple?

Should I just hold it against the nozzle tip from the outside?

Should I stick i down the same way as the filament an measure the nozzle from the inside?

|

Re: Installing e3d Hotend May 21, 2014 05:37PM |

Admin Registered: 17 years ago Posts: 7,879 |

It needs to be on the inside to read an accurate value. It definitely won't work pressed against the outside, it tends to read much lower.

To measure accurately from the outside it would need to be embedded into the heater block like the thermistor is.

[www.hydraraptor.blogspot.com]

To measure accurately from the outside it would need to be embedded into the heater block like the thermistor is.

[www.hydraraptor.blogspot.com]

|

Re: Installing e3d Hotend February 08, 2015 04:18PM |

Registered: 10 years ago Posts: 48 |

Since asking these questions I got the printer running well with PLA and did not bother with the temperature difference.

But I have now been trying ABS and I now again notice the incorrect readings of temp.

So now its time to measure the temp inside the extruder.

But then I have a new question. If I plot my measured values vs. thermistor readings in pronterface how do I correct the difference?

Cheers

But I have now been trying ABS and I now again notice the incorrect readings of temp.

So now its time to measure the temp inside the extruder.

But then I have a new question. If I plot my measured values vs. thermistor readings in pronterface how do I correct the difference?

Cheers

|

Re: Installing e3d Hotend February 08, 2015 07:13PM |

Admin Registered: 17 years ago Posts: 7,879 |

You need to make a new table for the thermistor. See [hydraraptor.blogspot.co.uk]

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Installing e3d Hotend February 09, 2015 03:26AM |

Registered: 10 years ago Posts: 48 |

OK, reading thruu the page you linked to I think I understand what I need to do.

Based on this:

"If you set the temperature to a value in an existing table and let it settle and then measure it with a thermocouple you know that the ADC value for the measured temperature is the value in the table for the set temperature. You can then produce a new more accurate table."

I set the temp to a value at the time in the table. Let it settle and then take a measurment with my thermocuple inside the hotend. The measured value is then inserted at that point in the table. If I do this for all points in the table I have corrected it.

Am I right in my assumption?

Regards

Amr_dwarf

Based on this:

"If you set the temperature to a value in an existing table and let it settle and then measure it with a thermocouple you know that the ADC value for the measured temperature is the value in the table for the set temperature. You can then produce a new more accurate table."

I set the temp to a value at the time in the table. Let it settle and then take a measurment with my thermocuple inside the hotend. The measured value is then inserted at that point in the table. If I do this for all points in the table I have corrected it.

Am I right in my assumption?

Regards

Amr_dwarf

|

Re: Installing e3d Hotend February 09, 2015 04:30AM |

Admin Registered: 17 years ago Posts: 7,879 |

You could do that but you only need three points: room temp, one at extrusion temp and one in the middle. The Python script will then calculate the rest of the table for you.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Installing e3d Hotend February 09, 2015 05:01AM |

Registered: 10 years ago Posts: 48 |

|

Re: Installing e3d Hotend February 09, 2015 09:39AM |

Admin Registered: 17 years ago Posts: 7,879 |

Just use the highest. I think the Steinhart-Hart equation is accurate to less than a degree over the full range with just three accurate widely spaced points.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Installing e3d Hotend February 10, 2015 10:01PM |

Registered: 12 years ago Posts: 88 |

|

Re: Installing e3d Hotend February 11, 2015 03:36AM |

Admin Registered: 17 years ago Posts: 7,879 |

|

Re: Installing e3d Hotend February 13, 2015 06:44AM |

Registered: 12 years ago Posts: 88 |

|

Re: Installing e3d Hotend February 13, 2015 07:34AM |

Admin Registered: 17 years ago Posts: 7,879 |

You can't measure the resistance directly without disconnecting it. But the method I described and my python script can use inferred ADC values to calculate the table.

E.g. if you set it to say 240C with an existing table you know when it has stabilised the ADC value must equal the value for 240C in that table. If you measure it as say 245C then you know the ADC value at 245C is what is in the table for 240C. My script can then work out the resistance from the ADC values.

[www.hydraraptor.blogspot.com]

E.g. if you set it to say 240C with an existing table you know when it has stabilised the ADC value must equal the value for 240C in that table. If you measure it as say 245C then you know the ADC value at 245C is what is in the table for 240C. My script can then work out the resistance from the ADC values.

[www.hydraraptor.blogspot.com]

|

Re: Installing e3d Hotend February 13, 2015 12:17PM |

Registered: 12 years ago Posts: 88 |

|

Re: Installing e3d Hotend February 13, 2015 02:11PM |

Admin Registered: 17 years ago Posts: 7,879 |

|

Re: Installing e3d Hotend February 13, 2015 04:09PM |

Registered: 12 years ago Posts: 88 |

So here is what I did .. Took a real T0 .. room t0=20 and r0=120700

For the t1 in the script the resistance was 94 and t2 was 256 with resistance 42

When I set the host to 209 .. the real temperature via a thermocouple was 178.3, and at 256 .. it was 218.5

So .. I put t1=178.3 and t2=218.5 leaving the resistance alone and generated the script ...

Is that the idea??

Thanks!

For the t1 in the script the resistance was 94 and t2 was 256 with resistance 42

When I set the host to 209 .. the real temperature via a thermocouple was 178.3, and at 256 .. it was 218.5

So .. I put t1=178.3 and t2=218.5 leaving the resistance alone and generated the script ...

Is that the idea??

Thanks!

|

Re: Installing e3d Hotend February 14, 2015 06:45AM |

Admin Registered: 17 years ago Posts: 7,879 |

It would only be correct if you started with my table. If you are starting with a different table you don't have the resistance values so you need to use ADC values from that table instead.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Installing e3d Hotend February 14, 2015 07:58AM |

Registered: 12 years ago Posts: 88 |

|

Re: Installing e3d Hotend February 14, 2015 02:01PM |

Admin Registered: 17 years ago Posts: 7,879 |

In my fork of Marlin for Mendel90 I added two Steinhart-Hart tables for the two Epcos thermistors that I use as tables 8 and 9.

Table 8 corresponds to the default values in the script but 92 and 42 are not resistances, they are ADC values from which resistances are calculated. It is also the same table shown on my blog.

More than likely you are using a different table to start with as I assume you are using a different thermistor. If so you need to use two temperatures that are actually in your table and the ADC values that correspond to those. Then you know your measured temperatures correspond to those ADC values. You input those into the script and it converts the ADC values to resistances and makes a new table.

[www.hydraraptor.blogspot.com]

Table 8 corresponds to the default values in the script but 92 and 42 are not resistances, they are ADC values from which resistances are calculated. It is also the same table shown on my blog.

More than likely you are using a different table to start with as I assume you are using a different thermistor. If so you need to use two temperatures that are actually in your table and the ADC values that correspond to those. Then you know your measured temperatures correspond to those ADC values. You input those into the script and it converts the ADC values to resistances and makes a new table.

[www.hydraraptor.blogspot.com]

|

Re: Installing e3d Hotend February 16, 2015 03:11PM |

Registered: 12 years ago Posts: 88 |

|

Re: Installing e3d Hotend February 16, 2015 04:47PM |

Admin Registered: 17 years ago Posts: 7,879 |

If you are able to run it at a stable temperature you must be using a table. It might not be right for your thermistor but it doesn't matter as long as you are able to run it at representative temperatures and it is stable.

You don't need to know the resistance because you can get the ADC value from that table and my script will calculate the resistance. You do have to know which table you have selected and you need to pick temperatures that have entries in that table with corresponding ADC values. You then measure the actual temperature and you have a tn, adcn pair.

[www.hydraraptor.blogspot.com]

You don't need to know the resistance because you can get the ADC value from that table and my script will calculate the resistance. You do have to know which table you have selected and you need to pick temperatures that have entries in that table with corresponding ADC values. You then measure the actual temperature and you have a tn, adcn pair.

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.

So confusing

So confusing