[SOLVED] Printing small areas in ABS without droop?

Posted by neildarlow

|

[SOLVED] Printing small areas in ABS without droop? October 16, 2014 04:54AM |

Registered: 10 years ago Posts: 541 |

Hi,

I have been taking my first steps with printing ABS and, using nophead's filament stretching technique, I have printed with excellent results.

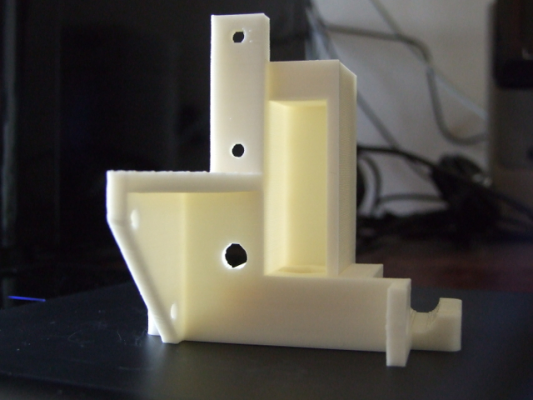

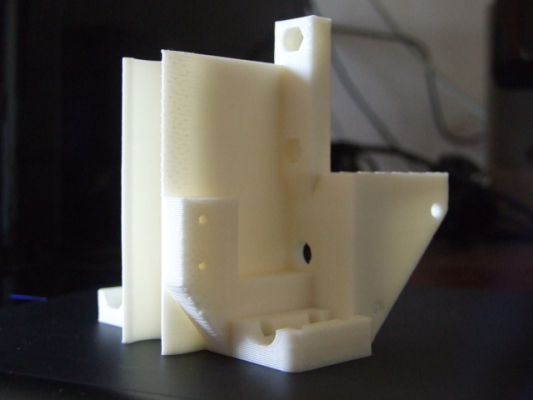

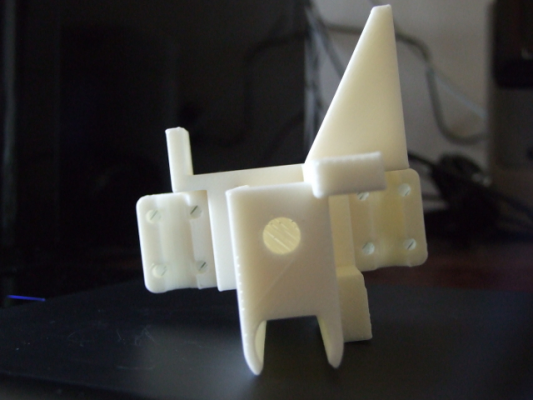

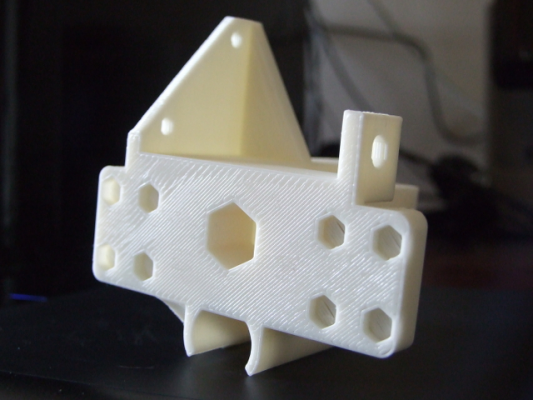

A problem has arisen with the X Motor Bracket. I have printed all the overhangs, nut trap membranes and horizontal area above the motor without any sagging threads.

The area causing problems is the upper 1cm of the ribbon cable clamp which is isolated from the main body. Here the material is starting to sag, especially over the top of the nut trap.

What is the best strategy for eliminating this:

1) Reduced print speed (I am printing at 40mm/s and this 12mmx6mm feature prints quite quickly)?

2) Make use of the fan (I have read that it is better not to use the fan with ABS but would some cooling help e.g. something down to M106 S60)?

3) Print multiples? Not for this one, it uses a lot of plastic and time.

I can obviously do things like impose a minimum layer time but I do not want to use insanely low print speeds. I am also concerned about the effect using the fan may have on the rest of the structure. It does seem to retain a lot of heat.

I am printing at 220C with a bed surface temperature of 110C (125C setpoint) using ABS juice directly on glass (yes, it does work).

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 10/17/2014 06:24AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

I have been taking my first steps with printing ABS and, using nophead's filament stretching technique, I have printed with excellent results.

A problem has arisen with the X Motor Bracket. I have printed all the overhangs, nut trap membranes and horizontal area above the motor without any sagging threads.

The area causing problems is the upper 1cm of the ribbon cable clamp which is isolated from the main body. Here the material is starting to sag, especially over the top of the nut trap.

What is the best strategy for eliminating this:

1) Reduced print speed (I am printing at 40mm/s and this 12mmx6mm feature prints quite quickly)?

2) Make use of the fan (I have read that it is better not to use the fan with ABS but would some cooling help e.g. something down to M106 S60)?

3) Print multiples? Not for this one, it uses a lot of plastic and time.

I can obviously do things like impose a minimum layer time but I do not want to use insanely low print speeds. I am also concerned about the effect using the fan may have on the rest of the structure. It does seem to retain a lot of heat.

I am printing at 220C with a bed surface temperature of 110C (125C setpoint) using ABS juice directly on glass (yes, it does work).

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 10/17/2014 06:24AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Printing small areas in ABS without droop? October 16, 2014 10:56AM |

Admin Registered: 17 years ago Posts: 7,879 |

I use a minimum layer time of 20 seconds so it will slow down to a crawl for that tower. If I print one then I would get droop over the nut trap but it can be removed with a penknife and the hole reamed so it would be a usable part.

I normally print two together to avoid the slow down and get less droop. Because the minimum layer time is the same for twice the area it prints those vertical bits twice as fast, so it is more efficient as well as having less droop. Also there is considerable travel between them, so the extrusion speed is more than twice as fast.

I think the main reason for the droop is not the lack of cooling. It is because it slows down so much that the die swell is much less, so the filament tension is less. You could try not slowing down and turning the fan on for just those layers instead. I have never tried a fan on ABS with a heated bed. I don't even fit the fan on my production machines.

Edited 1 time(s). Last edit at 10/16/2014 10:57AM by nophead.

[www.hydraraptor.blogspot.com]

I normally print two together to avoid the slow down and get less droop. Because the minimum layer time is the same for twice the area it prints those vertical bits twice as fast, so it is more efficient as well as having less droop. Also there is considerable travel between them, so the extrusion speed is more than twice as fast.

I think the main reason for the droop is not the lack of cooling. It is because it slows down so much that the die swell is much less, so the filament tension is less. You could try not slowing down and turning the fan on for just those layers instead. I have never tried a fan on ABS with a heated bed. I don't even fit the fan on my production machines.

Edited 1 time(s). Last edit at 10/16/2014 10:57AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Printing small areas in ABS without droop? October 17, 2014 05:31AM |

Registered: 10 years ago Posts: 541 |

Quote

nophead

I think the main reason for the droop is not the lack of cooling. It is because it slows down so much that the die swell is much less, so the filament tension is less. You could try not slowing down and turning the fan on for just those layers instead. I have never tried a fan on ABS with a heated bed. I don't even fit the fan on my production machines.

With the following Cool values -

Activate Cool: Checked Full Fan Speed (0 - 255): 255 Do Not Use Fan Before Layer (integer): 1 Maximum Layer Time for Fan use (seconds): 5.0 Full Fan Speed Below Layer Time (seconds): 5.0 Maximum Cool (Celcius): 0 Minumum Layer Time (seconds): 5.0I have produced a very good result but fan-only is not quite the solution, you do need to set a minimum layer time and 5 seconds appears to be acceptable.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Printing small areas in ABS without droop? October 17, 2014 06:16AM |

Registered: 10 years ago Posts: 541 |

Here are some photographs of the finished part.

Technical details -

I think that is not bad considering I am breaking the rules regarding layer height and am printing without any form of chamber to stabilise temperature.

Edited 2 time(s). Last edit at 10/17/2014 06:27AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Technical details -

Material: 3dfilaprint White ABS 3mm Print speed: 40mm/s, 20mm/s first layer Layer height: 0.4mm Line width: 0.6mm Infill: 90% Extruder temperature: 220C Heated Bed temperature: 125C (for 110C at glass surface) Build surface: 2mm plain glass with ABS Juice Slicer: skeinforge Special processing: Filament oversized by 0.055mm in slicer, X-carriage Fan on for Ribbon Cable post last 1cm

I think that is not bad considering I am breaking the rules regarding layer height and am printing without any form of chamber to stabilise temperature.

Edited 2 time(s). Last edit at 10/17/2014 06:27AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: [SOLVED] Printing small areas in ABS without droop? October 17, 2014 06:41AM |

Registered: 12 years ago Posts: 212 |

|

Re: [SOLVED] Printing small areas in ABS without droop? October 17, 2014 07:08AM |

Registered: 10 years ago Posts: 541 |

@Alzibiff: Attached

This zipfile contains my start_ABS.gcode and a Skeinforge profile named ABS0.4 which was used to print the above part. Read the Technical details above regarding Filament Diameter oversizing (e.g. 2.96mm --> 3.015mm).

Results may be highly dependant on your ABS filament properties. My impression is that 3dfilaprint White ABS is very forgiving and I am very interested in receiving feedback on use of this profile with other materials.

ABS0.4.zip

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

This zipfile contains my start_ABS.gcode and a Skeinforge profile named ABS0.4 which was used to print the above part. Read the Technical details above regarding Filament Diameter oversizing (e.g. 2.96mm --> 3.015mm).

Results may be highly dependant on your ABS filament properties. My impression is that 3dfilaprint White ABS is very forgiving and I am very interested in receiving feedback on use of this profile with other materials.

ABS0.4.zip

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Printing small areas in ABS without droop? October 17, 2014 08:22AM |

Admin Registered: 17 years ago Posts: 7,879 |

Interesting. I used to be able to print 0.4 by 0.6 with a 0.4mm nozzle with ABS from reprapsource.com but when they switched suppliers I had to ream all my nozzles to 0.45mm to use the same g-code. It is good that Mendel90 with a 0.4mm nozzle can print its own parts again.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: [SOLVED] Printing small areas in ABS without droop? October 17, 2014 08:46AM |

Registered: 12 years ago Posts: 212 |

Quote

neildarlow

Read the Technical details above regarding Filament Diameter oversizing (e.g. 2.96mm --> 3.015mm).

Yes, I saw that and had to smile - RichGain employed a similar fudge factor when using Slic3r two or more years ago, (for an EMaker Huxley if I remember correctly). Did you spend a lot of time twiddling and experimenting with this setting as I would never have plucked the figure of 0.055mm out of the air.

I will have a go with this over the weekend as I want to print out another part cooling fan mount. I'll get back to let you know how I got on.

Alan

Edited 1 time(s). Last edit at 10/17/2014 08:54AM by Alzibiff.

|

Re: [SOLVED] Printing small areas in ABS without droop? October 17, 2014 09:18AM |

Registered: 10 years ago Posts: 541 |

nophead piqued my interest when he said that he employed a filament stretching technique to handle bridges.

I guessed that the easiest way to achieve that would be to tell the slicer the filament diameter is larger than reality. I also noticed that, despite having my E_STEPS_PER_MM accurately set, there still seemed to be a lot of plastic being laid down.

I spent a little time estimating what a particular percentage of increase in filament diameter would mean at the extruder and I got somewhere near with +0.055mm. A few experiments above and below this value confirmed that I was somewhere near right but I suspect it could all be highly material and conditions dependent.

As far as being able to print at 0.4mm layer height, I suspected this might be something to do with taking advantage of the effect of die-swell. I have since debunked my own theory on this because I also have a PLA0.4 profile, which does not need any filament stretching, that prints identically.

I had some problems recently with a lot of my Mendel90 plastics cracking (I will admit they could have been overtightened although the cracks were yellowish compared to surrounding material). I reprinted these using my PLA0.4 profile and they fitted extremely well. These were the Y-rail clamps, Z-rail clamps, left Z-Motor bracket, X-Idler block (which had delaminated) and the left Z-coupler.

nophead prints the fan duct with a 0.35mm layer height so you will need to adjust for that and the perimeter flow rate ratio. They are small value changes and I would very much like to hear how you get on with that. I will take a look at an ABS0.35 profile too.

Regards,

Neil Darlow

Edited 3 time(s). Last edit at 10/17/2014 01:47PM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

I guessed that the easiest way to achieve that would be to tell the slicer the filament diameter is larger than reality. I also noticed that, despite having my E_STEPS_PER_MM accurately set, there still seemed to be a lot of plastic being laid down.

I spent a little time estimating what a particular percentage of increase in filament diameter would mean at the extruder and I got somewhere near with +0.055mm. A few experiments above and below this value confirmed that I was somewhere near right but I suspect it could all be highly material and conditions dependent.

As far as being able to print at 0.4mm layer height, I suspected this might be something to do with taking advantage of the effect of die-swell. I have since debunked my own theory on this because I also have a PLA0.4 profile, which does not need any filament stretching, that prints identically.

I had some problems recently with a lot of my Mendel90 plastics cracking (I will admit they could have been overtightened although the cracks were yellowish compared to surrounding material). I reprinted these using my PLA0.4 profile and they fitted extremely well. These were the Y-rail clamps, Z-rail clamps, left Z-Motor bracket, X-Idler block (which had delaminated) and the left Z-coupler.

nophead prints the fan duct with a 0.35mm layer height so you will need to adjust for that and the perimeter flow rate ratio. They are small value changes and I would very much like to hear how you get on with that. I will take a look at an ABS0.35 profile too.

Regards,

Neil Darlow

Edited 3 time(s). Last edit at 10/17/2014 01:47PM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: [SOLVED] Printing small areas in ABS without droop? October 17, 2014 11:16AM |

Admin Registered: 17 years ago Posts: 7,879 |

I don't know how you can print 0.4 by 0.6 in PLA with a 0.4 nozzle. It doesn't have enough die swell. Are you sure you haven't accidentally increased the nozzle aperture?

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: [SOLVED] Printing small areas in ABS without droop? October 17, 2014 01:55PM |

Registered: 10 years ago Posts: 541 |

Quote

nophead

I don't know how you can print 0.4 by 0.6 in PLA with a 0.4 nozzle. It doesn't have enough die swell. Are you sure you haven't accidentally increased the nozzle aperture?

My J-Head has been well-behaved and has never needed attention and I can't believe that the material I have put through it in 11 months would have enlarged it significantly. Is there a chance that I was supplied with a nozzle larger than 0.4mm?

The PLA parts printed superbly at 0.4mm layer height using the measured filament diameter. There may be wizardry involved but I don't know what it might be.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: [SOLVED] Printing small areas in ABS without droop? October 17, 2014 02:23PM |

Admin Registered: 17 years ago Posts: 7,879 |

It should be 0.4mm as that is what I order. They have 4 stamped on the heater block but that will be covered by the silicone tape.

What diameter does PLA come out at when extruded into free space? In my experience is it is not much more that 0.4mm, so the area is smaller than 0.4x0.6, which means it comes out longer than intended and so droops when spanning gaps.

[www.hydraraptor.blogspot.com]

What diameter does PLA come out at when extruded into free space? In my experience is it is not much more that 0.4mm, so the area is smaller than 0.4x0.6, which means it comes out longer than intended and so droops when spanning gaps.

[www.hydraraptor.blogspot.com]

|

Re: [SOLVED] Printing small areas in ABS without droop? October 17, 2014 06:20PM |

Registered: 10 years ago Posts: 541 |

The nozzle must be 0.4mm because it prints well at my profiled layer heights using standard calibration procedures.

I will measure the extruded PLA diameter when I have completed my present ABS runs. I will be recalibrating then and will be able to see if things continue to print well at 0.4mm layer height.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

I will measure the extruded PLA diameter when I have completed my present ABS runs. I will be recalibrating then and will be able to see if things continue to print well at 0.4mm layer height.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: [SOLVED] Printing small areas in ABS without droop? October 17, 2014 08:26PM |

Admin Registered: 17 years ago Posts: 7,879 |

What size does the ABS come out at?

Nozzle size doesn't really affect calibration it only has secondary affects such as how well it bridges when producing a given filament size.

[www.hydraraptor.blogspot.com]

Nozzle size doesn't really affect calibration it only has secondary affects such as how well it bridges when producing a given filament size.

[www.hydraraptor.blogspot.com]

|

Re: [SOLVED] Printing small areas in ABS without droop? October 19, 2014 05:42AM |

Registered: 12 years ago Posts: 212 |

Quote

Alzibiff

I will have a go with this over the weekend as I want to print out another part cooling fan mount. I'll get back to let you know how I got on.

Sorted! Thank you for the profile Neil - gave me the confidence to have a go printing at a 0.35mm layer height for the X carriage fan duct. I used your ABS0.4 Skeinforge profile as it was but with the layer height changed to 0.35mm. The fan duct is quite a challenge given the distance the filament has to span once it starts to cover over the air duct at around 2mm or so from the final Z height. I got some drooping which needed tidying up but what is important is that I got a good replacement part.

I have printed this piece before in ABS for use on my spare extruder but used a layer height of 0.2mm - took longer to do of course!

Alan

Edited 1 time(s). Last edit at 10/19/2014 11:19AM by Alzibiff.

|

Re: [SOLVED] Printing small areas in ABS without droop? October 19, 2014 10:45AM |

Registered: 10 years ago Posts: 541 |

Quote

nophead

What size does the ABS come out at?

My ABS extruded into free-air is 0.42mm diameter. I also measured the height of my printed X Motor Bracket which should be 75.2mm and it is 75.21mm.

Edited 1 time(s). Last edit at 10/19/2014 11:08AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: [SOLVED] Printing small areas in ABS without droop? October 19, 2014 11:47AM |

Admin Registered: 17 years ago Posts: 7,879 |

I have no idea how you can print 0.4 by 0.6 layers then without droop as when you pass over a gap you get 0.42 round filament which will have an area 1.7 times too small, so its length will be 1.7 times longer than the gap.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: [SOLVED] Printing small areas in ABS without droop? October 19, 2014 12:46PM |

Registered: 10 years ago Posts: 541 |

But the oversize of the filament I have done in the slicer will reduce the amount of filament actually extruded and the resulting stretch reduces the filament diameter. Or am I wrong here?

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: [SOLVED] Printing small areas in ABS without droop? October 19, 2014 02:21PM |

Admin Registered: 17 years ago Posts: 7,879 |

I don't use Sli3r but I would assume if you tell it the filament is bigger than it actually is then the flow rate will be too low. That would stretch the filament more but it would not produce filament runs with the correct cross section, so I would expect gaps between the lines in the solid infill if it was significantly too low.

E.g. to pull the filament tight you would need to reduce the flow rate by about 1.7 so it outputs enough filament to fill a 0.42 circle rather than a 0.4x0.6 rectangle. However, a 0.42 circle squashed to 0.4mm would still be roughly circular and not 0.6mm wide.

[www.hydraraptor.blogspot.com]

E.g. to pull the filament tight you would need to reduce the flow rate by about 1.7 so it outputs enough filament to fill a 0.42 circle rather than a 0.4x0.6 rectangle. However, a 0.42 circle squashed to 0.4mm would still be roughly circular and not 0.6mm wide.

[www.hydraraptor.blogspot.com]

|

Re: [SOLVED] Printing small areas in ABS without droop? October 19, 2014 02:38PM |

Admin Registered: 17 years ago Posts: 7,879 |

Also 0.42mm from a 0.4mm nozzle is very low die swell. I would expect that with PLA but not ABS. I would get more like 0.5mm.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.