My Mendel90 project

Posted by Rich K.

|

My Mendel90 project October 26, 2014 09:40PM |

Registered: 9 years ago Posts: 254 |

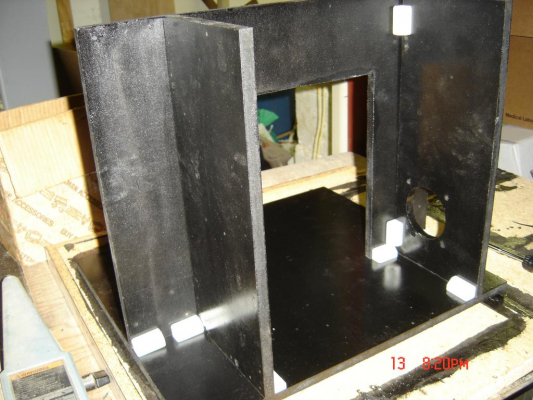

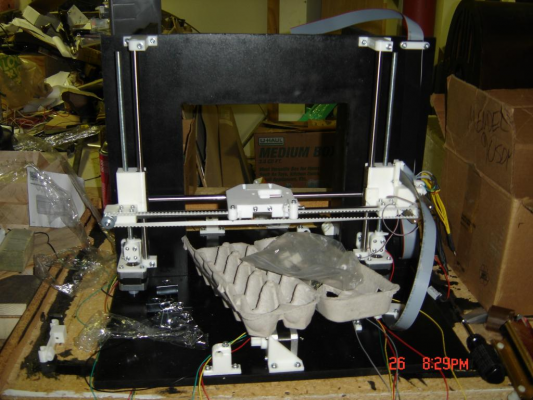

Thought I'd post a few pics of my Mendel 90 "Sturdy" as it is thus far. Will post more as things progress. I just assembled the X and Z axes this evening. Adjusted the voltages on my Melzi last night. I'm not going to attach my extruder until the machine is leveled (no point in putting the extruder on if I have to remove it to put my indicator in its place). I'm waiting for my limit switches to arrive from Nophead (hopefuly tomorrow or Tuesday, depending on when they got sent out; it generally takes a week or so for things to arrive here via Royal Mail).

|

Re: My Mendel90 project October 27, 2014 10:06AM |

Registered: 9 years ago Posts: 66 |

|

Re: My Mendel90 project October 28, 2014 09:46PM |

Registered: 9 years ago Posts: 254 |

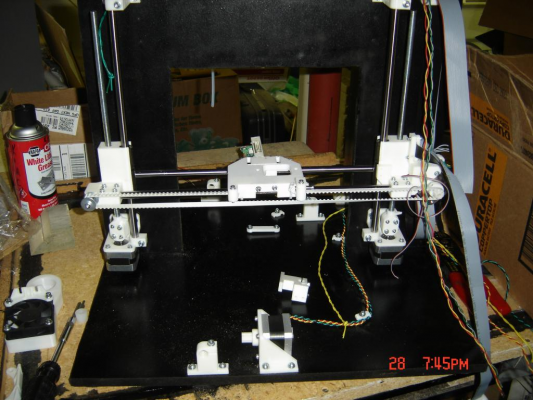

Ran most of the wiring this evening, and installed the spool brackets (had to open the notches a bit wider with a knife to allow for my 1/2" MDF, which is ~.03" thicker than 12mm. End stops still have not arrived, but I ran the wires for them anyway. My motors have a different color code than the ones Nophead supplies in his kits, and are lower torque, but I am hoping they will still work (maybe at a lower speed). The torque on my motors is still rated higher than the ones originally specified for the Mendel reprap, so I am keeping my fingers crossed.

|

Re: My Mendel90 project October 29, 2014 08:57PM |

Registered: 10 years ago Posts: 363 |

|

Re: My Mendel90 project November 02, 2014 05:58PM |

Registered: 9 years ago Posts: 254 |

Well, it is 99% finished. Only problem is, I have to replace my z and extruder motors. In my ignorance, I bought 3 12-volt motors (I had bought the two motors I used in the X and Y axes earlier - they're rated at around 5v). I had wired the X ribbon cable backwards, leading to a great deal of frustration as to figuring out what the problem was. Fixed that, at least. My much-maligned Mk2b heated bed with the through-plated holes WILL get up to the full 110 degrees specified in the "ABS preheat" settings built into my Panelolu2, and the hot-end (a Chinese J-head clone) also heats up nicely. Won't know how well it prints until I replace those three motors, though, and get the bed leveled and the machine calibrated. Might be a couple more weeks, folks...

Re: My Mendel90 project - IT'S ALIIIIIVE!!!!!!   November 14, 2014 09:02PM |

Registered: 9 years ago Posts: 254 |

WOOO HOOOO - IT WORKS!!!

Mendel90 video 1

Mendel90 video 2

My first attempt last night was made with bare (cleaned with acetone) glass. Started to work, but then my Melzi shut down - I think I may have had the motor voltage turned up too high. Fixed that problem. Subsequent attempts would not stick to the glass, no matter how clean I got it. Put blue tape on it, and the print came out fine (except that the finished print didn't want to come off the tape...).

Thanks for all the help, Chris, Neil, and all the other forum members who offered help and advice. Chris, you designed a great machine. I know I am happy with it!

Mendel90 video 1

Mendel90 video 2

My first attempt last night was made with bare (cleaned with acetone) glass. Started to work, but then my Melzi shut down - I think I may have had the motor voltage turned up too high. Fixed that problem. Subsequent attempts would not stick to the glass, no matter how clean I got it. Put blue tape on it, and the print came out fine (except that the finished print didn't want to come off the tape...).

Thanks for all the help, Chris, Neil, and all the other forum members who offered help and advice. Chris, you designed a great machine. I know I am happy with it!

Re: My Mendel90 project - IT'S ALIIIIIVE!!!!!!   November 14, 2014 10:28PM |

Registered: 10 years ago Posts: 363 |

Great job Rich! Your first android looks awesome. If that is your first print I can say you are going to have a lot of fun with your machine!

Some PLA sticks easily to glass; others doesn't stick well at all. I think the colorant or pigment makes the difference. Natural PLA seems easy to print to bare glass. But make sure you have the first layer hot enough or you won't get it to stick to the glass. If the first layer fails keep bumping up the temperature on subsequent attempts. You should find it starts sticking at some point. The glass needs to be hot enough too. I set mine to 80C which most would say is too hot. But it works. And I don't drop the temperature of the bed through the print.

But now I mostly use this method to apply PVA glue (I use LePage Carpenters glue): PVA Glue Application. I don't seem to have any problem with poor quality PLA sticking. You may like to try this.

I am curious if a Mendel90 with such a solid frame like yours is quieter than one with a Dibond frame? But I know you likely haven't been able to compare. Would you say your machine is quiet?

Good luck!

Some PLA sticks easily to glass; others doesn't stick well at all. I think the colorant or pigment makes the difference. Natural PLA seems easy to print to bare glass. But make sure you have the first layer hot enough or you won't get it to stick to the glass. If the first layer fails keep bumping up the temperature on subsequent attempts. You should find it starts sticking at some point. The glass needs to be hot enough too. I set mine to 80C which most would say is too hot. But it works. And I don't drop the temperature of the bed through the print.

But now I mostly use this method to apply PVA glue (I use LePage Carpenters glue): PVA Glue Application. I don't seem to have any problem with poor quality PLA sticking. You may like to try this.

I am curious if a Mendel90 with such a solid frame like yours is quieter than one with a Dibond frame? But I know you likely haven't been able to compare. Would you say your machine is quiet?

Good luck!

Re: My Mendel90 project - IT'S ALIIIIIVE!!!!!!   November 15, 2014 12:22AM |

Registered: 9 years ago Posts: 254 |

Re: My Mendel90 project - IT'S ALIIIIIVE!!!!!!   November 15, 2014 01:30AM |

Registered: 10 years ago Posts: 363 |

Re: My Mendel90 project - IT'S ALIIIIIVE!!!!!!   November 15, 2014 01:35AM |

Registered: 9 years ago Posts: 254 |

Re: My Mendel90 project - IT'S ALIIIIIVE!!!!!!   November 15, 2014 02:01AM |

Registered: 10 years ago Posts: 363 |

I'm guessing. Are you running the fan after the first layer is done? J-heads need cooling or heat will creep up the hot end body and will cause the filament to soften high up in the cool section and it will jam in the hollow hex screw. You would need to take the hot end out of the Wade's block and remove the jam. I did this. Twice.

Re: My Mendel90 project - IT'S ALIIIIIVE!!!!!!   November 15, 2014 02:16AM |

Registered: 9 years ago Posts: 254 |

Even with the fan running, my hotend is getting PLA blobbed all over its end rather than laying it down on the build surface. I also think my splined bolt would do better if it was hobbed instead. The splines are getting clogged easily, and I also think it is flattening the filament out.

Re: My Mendel90 project - IT'S ALIIIIIVE!!!!!!   November 15, 2014 02:33AM |

Registered: 10 years ago Posts: 363 |

Are you printing to bare glass now? If the extruded filament does not stick to the glass it will glob up on the nozzle. Draw a cylinder 40mm in diameter (circles stick easily) and slice that with your extruder set to 205C and bed to 80C. Speed 25mm/sec. Print that and see if the PLA sticks and doesn't gob onto the nozzle.

Re: My Mendel90 project - IT'S ALIIIIIVE!!!!!!   November 15, 2014 02:35AM |

Registered: 9 years ago Posts: 254 |

Re: My Mendel90 project - IT'S ALIIIIIVE!!!!!!   November 15, 2014 03:13AM |

Registered: 10 years ago Posts: 363 |

|

Re: My Mendel90 project November 16, 2014 07:42PM |

Registered: 9 years ago Posts: 254 |

I seem to finally be getting the hang of things. I successfully printed a knob for my Panelolu2. As of this moment it is printing up the back panel for the P2. I tried to print the front panel for it as well, but my Slic3r settings were wrong and the fan shut off, causing the hotend to overheat and jam after the second layer. Re-sliced everything and the printer seems to be going smoothly now. Will post photos when this set of prints is done (P2 case)!

|

Re: My Mendel90 project November 18, 2014 10:15AM |

Registered: 10 years ago Posts: 439 |

|

Re: My Mendel90 project November 18, 2014 07:19PM |

Registered: 9 years ago Posts: 254 |

Sorry, only registered users may post in this forum.