More spare parts (with pictures)

Posted by neildarlow

|

More spare parts (with pictures) November 05, 2014 05:54AM |

Registered: 10 years ago Posts: 541 |

Hi,

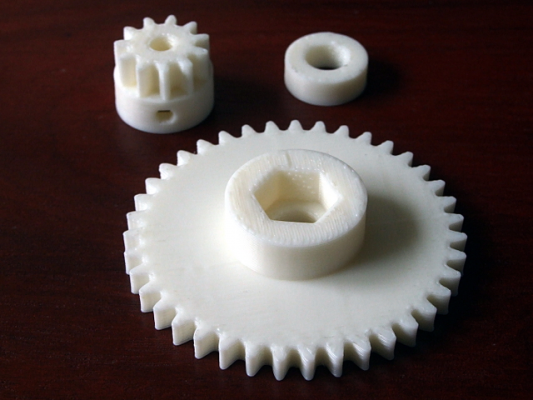

As a final chapter in my first efforts with ABS I have printed the Wades gears and spacer.

My aim, in these recent prints with ABS, was to determine whether I could print replacement parts with minimal additional effort over printing with PLA. This meant no enclosing chamber and no use of tape on the heated bed.

Key to achieving this seems to be a thick layer height, i.e. 0.4mm, otherwise there is a tendency for parts to warp. Also, the use of ABS juice with a good viscosity helps.

A particular difficulty encountered in printing these gears is ensuring a good infill of the teeth. For this I used a linear infill and while you might see gaps on one layer they are not present on the following layer. All 3 objects were sliced, and printed, together.

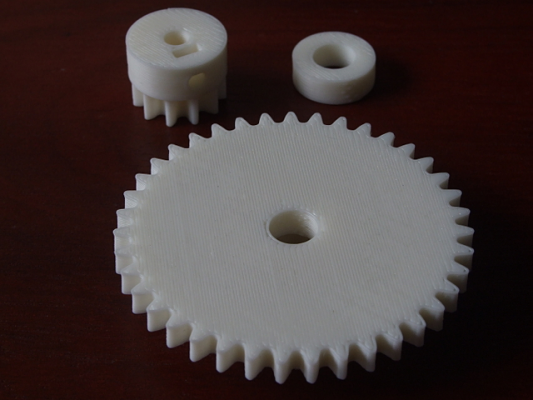

Here are photographs of the finished parts and their associated printing parameters:

Technical details -

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

As a final chapter in my first efforts with ABS I have printed the Wades gears and spacer.

My aim, in these recent prints with ABS, was to determine whether I could print replacement parts with minimal additional effort over printing with PLA. This meant no enclosing chamber and no use of tape on the heated bed.

Key to achieving this seems to be a thick layer height, i.e. 0.4mm, otherwise there is a tendency for parts to warp. Also, the use of ABS juice with a good viscosity helps.

A particular difficulty encountered in printing these gears is ensuring a good infill of the teeth. For this I used a linear infill and while you might see gaps on one layer they are not present on the following layer. All 3 objects were sliced, and printed, together.

Here are photographs of the finished parts and their associated printing parameters:

Technical details -

Material: 3dfilaprint White ABS 3mm Print speed: 40mm/s, 20mm/s first layer Layer height: 0.4mm Line width: 0.5mm Infill: 98% - linear Extruder temperature: 220C Heated Bed temperature: 125C (for 110C at glass surface) Build surface: 2mm plain glass with ABS Juice Slicer: skeinforge Special processing: Filament oversized by 0.055mm in skeinforge, all 3 items plated in Slic3r and re-exported as STL for slicing

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: More spare parts (with pictures) November 05, 2014 06:08AM |

Registered: 12 years ago Posts: 212 |

Good job NeilDarlow! Thank you for the very detailed settings and methodology.

Reducing the tendency of parts to warp by increasing layer height to 0.4mm - what I suspect is the absolute maximum - is interesting. Any ideas why this is? Anything to do with the reduced time to complete the print I wonder, compared to say 0.2mm?

The extrusion temperature of 220C for ABS is 25C less than I have used, I assume that you did not get any delamination problems. Have you used similar settings on other parts with similar results?

Alan

Edited 1 time(s). Last edit at 11/05/2014 06:38AM by Alzibiff.

Reducing the tendency of parts to warp by increasing layer height to 0.4mm - what I suspect is the absolute maximum - is interesting. Any ideas why this is? Anything to do with the reduced time to complete the print I wonder, compared to say 0.2mm?

The extrusion temperature of 220C for ABS is 25C less than I have used, I assume that you did not get any delamination problems. Have you used similar settings on other parts with similar results?

Alan

Edited 1 time(s). Last edit at 11/05/2014 06:38AM by Alzibiff.

|

Re: More spare parts (with pictures) November 05, 2014 06:42AM |

Registered: 11 years ago Posts: 369 |

Wow, good work Neil!

I've had it on my to-do list for a while now to go through and try your settings as I am noticing more fractures and general wear on my stock parts so it’s only a matter of time before I will need to replace them.

Out of curiosity (ok, maybe a sprinkling of laziness), is there anything specific about the way you've tricked Skeinforge into stretching the filament by specifying a larger extrusion diameter that means I shouldn't even bother trying to replicate in Slic3r?

I am aware of the dimensional accuracy debate, as well as Slic3r’s inability to overcome the OpenSCAD normals bug for internal cavities (as used in the floating nut traps in the X-ends) but the convenience factor of having all my different filament colours/mirror plates and various other printer settings saved in easy to access profiles that I can mix and match for a particular job still outweighs the shortcomings for me.

I vaguely remember reading that Slic3r tries to do something clever with bridges but isn’t 100% successful all of the time – I can’t find the references or explanations now. Is this why you've done this using Skeinforge?

I've had it on my to-do list for a while now to go through and try your settings as I am noticing more fractures and general wear on my stock parts so it’s only a matter of time before I will need to replace them.

Out of curiosity (ok, maybe a sprinkling of laziness), is there anything specific about the way you've tricked Skeinforge into stretching the filament by specifying a larger extrusion diameter that means I shouldn't even bother trying to replicate in Slic3r?

I am aware of the dimensional accuracy debate, as well as Slic3r’s inability to overcome the OpenSCAD normals bug for internal cavities (as used in the floating nut traps in the X-ends) but the convenience factor of having all my different filament colours/mirror plates and various other printer settings saved in easy to access profiles that I can mix and match for a particular job still outweighs the shortcomings for me.

I vaguely remember reading that Slic3r tries to do something clever with bridges but isn’t 100% successful all of the time – I can’t find the references or explanations now. Is this why you've done this using Skeinforge?

|

Re: More spare parts (with pictures) November 05, 2014 07:47AM |

Registered: 10 years ago Posts: 541 |

@QuackingPlums: I primarily use Skeinforge because of the flexibility it offers. I have tried Slic3r but I find it does peculiar things sometimes and I can't seem to replicate the degree of control I have in Skeinforge.

In Slic3r you can make use of the Extrusion Multiplier to achieve what I have done in Skeinforge. We are talking a small reduction here, say 1.8% of filament width, and the intention is to compensate for die swell and stretch the filament a little over gaps to assist in spanning them.

If Slic3r can do this for you without any extrusion multiplier then go with it. I will have a look at emulating my results under Slic3r sometime but it is a low priority for me.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

In Slic3r you can make use of the Extrusion Multiplier to achieve what I have done in Skeinforge. We are talking a small reduction here, say 1.8% of filament width, and the intention is to compensate for die swell and stretch the filament a little over gaps to assist in spanning them.

If Slic3r can do this for you without any extrusion multiplier then go with it. I will have a look at emulating my results under Slic3r sometime but it is a low priority for me.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: More spare parts (with pictures) November 05, 2014 08:58AM |

Registered: 10 years ago Posts: 541 |

Quote

Alzibiff

Reducing the tendency of parts to warp by increasing layer height to 0.4mm - what I suspect is the absolute maximum - is interesting. Any ideas why this is? Anything to do with the reduced time to complete the print I wonder, compared to say 0.2mm?

I doubt it would be possible to have layer heights greater than 0.4mm. I think it is only die swell that permits it. Possibly, I am no materials expert, the thicker layers exhibit a cooling gradient from top-to-bottom which aids stability while thinner layers are more likely to deform because they cool faster on the top surface causing shrinkage that pulls against the lower part of the layer.

Quote

Alzibiff

The extrusion temperature of 220C for ABS is 25C less than I have used, I assume that you did not get any delamination problems. Have you used similar settings on other parts with similar results?

The 3dfilaprint ABS has a specified printing temperature range of 210C to 260C. I found at 230C, and above, there was significant ooze from the nozzle when left at operating temperature. I do not want to print at temperatures above 240C to allow a safe operating margin for my J-Head and results look good down to 220C so I went with that. All my recently printed parts have been done at 220C and I have used parts of failed prints to make my ABS Juice. I really needed to put a lot of effort into breaking them apart using pliers so I think durability should not be a problem. My Wade's block is performing well so far and I am keeping a close watch on it for any fractures that might develop.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: More spare parts (with pictures) November 06, 2014 01:15PM |

Registered: 10 years ago Posts: 22 |

Sorry, only registered users may post in this forum.