all axis calibration issues

Posted by 09zx-6r

|

all axis calibration issues January 20, 2015 06:06PM |

Registered: 9 years ago Posts: 93 |

Ok so I've setup everything per the mendel90 instructions from nophead..iv ran at least 20 test cubes and not one of em are correct in dimensions...the block is 10x10x10..so Iv been adjusting the steps per MM and it doesn't seem to do anything. I started with the prusa calculated suggested steps. X,Y @ 94.12. & Z @ 3200 steps.. I did the extruder calibration as well which is spot on...extruder is working great. I have perfect layers and adhesion...but every time I adjust my X &Y steps it doesn't seem to do anything..my prints are still off either .50mm over or .50mm under...even if I don't change it...I checked belt tension and checked for loose parts..everything is good.. I checked for bearing slop...none found..I don't get it... Any help is appreciated....

|

Re: all axis calibration issues January 20, 2015 06:51PM |

Registered: 9 years ago Posts: 93 |

for those that need more info,

test 1

X 10.38mm @ 94.12 steps

Y 10.36mm @ 94.12 steps

Z 9.88mm @ 1200*8/3 or 3200 steps

test 2

X 10.44mm @ 94.50

Y 10.36mm @ 94.50 <-- stayed the same as previous

Z 10.05mm @ 1199 <-- increased in mm ?

test 3

X 10.43mm @ 94.00 <-- increased with less steps?

Y 10.40mm @ 94.00 <-- increased with less steps?

Z 9.93mm @ 1199.50 <--- increased mm with less steps?

(skips a few tests)

test 8

X 10.02mm @ 88

Y 10.18mm @ 88

Z 10.02mm @ 1200 <-- same steps as test 1 but has alot more mm?

test 9

X 9.90mm @ 87.75

Y 9.92mm @ 88.75

Z 10.03mm @ 1200

test 10

X 9.97mm @ 87.85

Y 10.07mm @ 89.10

skip to test 12

X 9.96mm @ 87.98

Y 10.00 @ 89

Z 10.03 @ 1200

so as you can see, if i lower the steps it drops, but if i raise the steps to fine tune it still drops or goes way over... it dont make any sense...if i dont change the numbers and do 2 or 3 prints with nothing changed, it has different numbers everytime...

Edited 1 time(s). Last edit at 01/20/2015 06:57PM by 09zx-6r.

test 1

X 10.38mm @ 94.12 steps

Y 10.36mm @ 94.12 steps

Z 9.88mm @ 1200*8/3 or 3200 steps

test 2

X 10.44mm @ 94.50

Y 10.36mm @ 94.50 <-- stayed the same as previous

Z 10.05mm @ 1199 <-- increased in mm ?

test 3

X 10.43mm @ 94.00 <-- increased with less steps?

Y 10.40mm @ 94.00 <-- increased with less steps?

Z 9.93mm @ 1199.50 <--- increased mm with less steps?

(skips a few tests)

test 8

X 10.02mm @ 88

Y 10.18mm @ 88

Z 10.02mm @ 1200 <-- same steps as test 1 but has alot more mm?

test 9

X 9.90mm @ 87.75

Y 9.92mm @ 88.75

Z 10.03mm @ 1200

test 10

X 9.97mm @ 87.85

Y 10.07mm @ 89.10

skip to test 12

X 9.96mm @ 87.98

Y 10.00 @ 89

Z 10.03 @ 1200

so as you can see, if i lower the steps it drops, but if i raise the steps to fine tune it still drops or goes way over... it dont make any sense...if i dont change the numbers and do 2 or 3 prints with nothing changed, it has different numbers everytime...

Edited 1 time(s). Last edit at 01/20/2015 06:57PM by 09zx-6r.

|

Re: all axis calibration issues January 21, 2015 10:20AM |

Admin Registered: 17 years ago Posts: 7,879 |

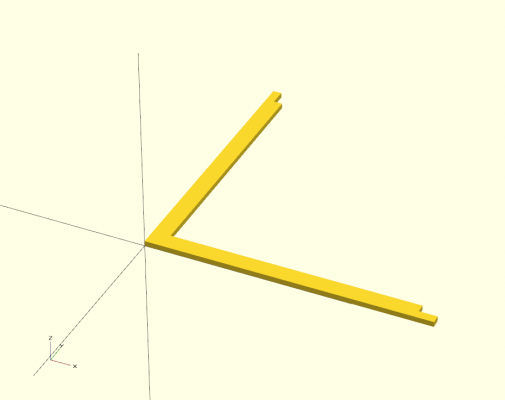

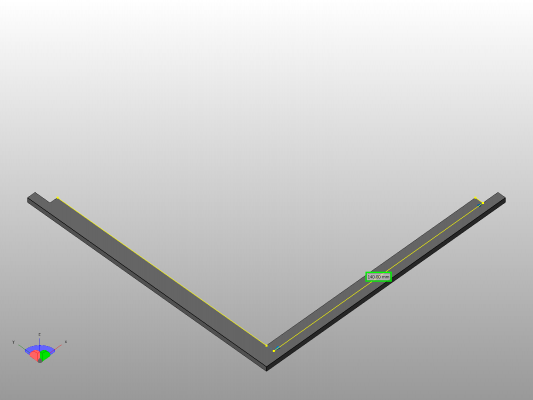

I normally just use the quoted belt pitch as it is far more accurate than measuring a 10mm printed object. To get a more accurate calibration I use this shape:

By measuring between edges reached by moves in the same direction you can separate backlash from steps per mm errors and by measuring long and short section and using simultaneous equations you can separate errors caused by extrusion width.

[www.hydraraptor.blogspot.com]

By measuring between edges reached by moves in the same direction you can separate backlash from steps per mm errors and by measuring long and short section and using simultaneous equations you can separate errors caused by extrusion width.

[www.hydraraptor.blogspot.com]

|

Re: all axis calibration issues January 21, 2015 12:14PM |

Registered: 9 years ago Posts: 93 |

|

Re: all axis calibration issues January 21, 2015 01:05PM |

Admin Registered: 17 years ago Posts: 7,879 |

It is more complicated. If you simply measure the outside dimensions of something it is made up of the distance the axes move minus the backlash plus the filament width. To be able to correct the axis movement you have to separate the other two quantities using maths.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: all axis calibration issues January 21, 2015 02:35PM |

Registered: 9 years ago Posts: 93 |

|

Re: all axis calibration issues January 21, 2015 04:23PM |

Admin Registered: 17 years ago Posts: 7,879 |

To start with measure from the inner corner to the point where it narrows, should be 140mm. That distance is purely a measure of travel because the axis moving hasn't changed direction between those points, so no backlash, and both edges are on the same side so filament width doesn't add to it.

Edited 1 time(s). Last edit at 01/21/2015 04:24PM by nophead.

[www.hydraraptor.blogspot.com]

Edited 1 time(s). Last edit at 01/21/2015 04:24PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: all axis calibration issues January 21, 2015 06:05PM |

Registered: 9 years ago Posts: 93 |

|

Re: all axis calibration issues January 22, 2015 10:53AM |

Admin Registered: 17 years ago Posts: 7,879 |

It looks to be a long way out.

Where you have 130.4 is should be 140. What belt and pulleys are you using? It is normally 80 steps per mm.

Edited 1 time(s). Last edit at 01/22/2015 10:55AM by nophead.

[www.hydraraptor.blogspot.com]

Where you have 130.4 is should be 140. What belt and pulleys are you using? It is normally 80 steps per mm.

Edited 1 time(s). Last edit at 01/22/2015 10:55AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: all axis calibration issues January 22, 2015 06:14PM |

Registered: 9 years ago Posts: 93 |

|

Re: all axis calibration issues January 22, 2015 06:58PM |

Admin Registered: 17 years ago Posts: 7,879 |

Should be 3200.0 / (17 * 2) = 94.117647058823529411764705882353.

Not the best choice of pulley as it will be a bit smaller, so the belt will be at an angle. 20 tooth gives 80 steps per mm and is the same diameter as T2.5 16 tooth.

[www.hydraraptor.blogspot.com]

Not the best choice of pulley as it will be a bit smaller, so the belt will be at an angle. 20 tooth gives 80 steps per mm and is the same diameter as T2.5 16 tooth.

[www.hydraraptor.blogspot.com]

|

Re: all axis calibration issues January 22, 2015 07:24PM |

Registered: 9 years ago Posts: 93 |

|

Re: all axis calibration issues January 22, 2015 07:24PM |

Registered: 9 years ago Posts: 93 |

|

Re: all axis calibration issues January 23, 2015 04:49AM |

Admin Registered: 17 years ago Posts: 7,879 |

If you use 3200.0 / (17 * 2) it will be as accurate as a float allows, which will be slightly better than 4 digits.

The outside dimensions of a part are also determined by the filament width, which is determined by the slicer. It is generally only correct with Skeinforge and single outlines. For a 100mm part the filament width is only a small percentage but much more for 10mm part. There is also backlash and shrinkage.

Measuring the inside of the L allows you to separate just the axis movement and the plastic shrinkage. Then you can look at the filament width. The width of the L shape should be 10mm and the thin parts 5mm.

If you print a 10mm cube on its own it will tend to get too hot, which may be why you get inconsistent results. 20mm cubes, 10mm high are better.

[www.hydraraptor.blogspot.com]

The outside dimensions of a part are also determined by the filament width, which is determined by the slicer. It is generally only correct with Skeinforge and single outlines. For a 100mm part the filament width is only a small percentage but much more for 10mm part. There is also backlash and shrinkage.

Measuring the inside of the L allows you to separate just the axis movement and the plastic shrinkage. Then you can look at the filament width. The width of the L shape should be 10mm and the thin parts 5mm.

If you print a 10mm cube on its own it will tend to get too hot, which may be why you get inconsistent results. 20mm cubes, 10mm high are better.

[www.hydraraptor.blogspot.com]

|

Re: all axis calibration issues January 26, 2015 01:21AM |

Registered: 10 years ago Posts: 18 |

What I need to know is where the setting is, prior to compilation, to correct the accuracy of the X, Y, and Z axes. I just scoured the Configuration.h and Configuration_adv.h files and could not find any settings for E Steps per mm for the axes. I found the setting for the extruder, (Configuration_adv.h, Line 330 - #define STEPS_MM_E 459.29), but I also need to make corrections for all axes. And I thank ZennmasterM for his video: [www.youtube.com]. I have done quite a bit of looking, but at some point I get burned out and just need to ask.

On a similar topic, I just finished tightening up the DIY Tech Shop Omega I got running in May 2014. I had noticed the 3D printed parts that held the linear bearings had some wriggle in them. So I designed and printed a half-dozen bearing clamps that worked well. Then I designed and printed a couple of cross-bars with adjustment screws to nudge the Y axis belt to run on (or near) the centers of its pulley and ball bearing. The idea was to reduce friction and vibration. The improvement was dramatic! I have attached a picture of a Make Magazine test robot I printed before and after my clamps were installed (plus a few other tweaks I can detail for you if anyone is interested). The picture includes one of the black bearing clamps I installed on the lower X axis rod. I also attached a picture of the front Y axis bearing adjustment part I made.

I hope these image links to DropBox will work. Inserting the image links seems to be straight forward, but the pre-view showed errors...

On a similar topic, I just finished tightening up the DIY Tech Shop Omega I got running in May 2014. I had noticed the 3D printed parts that held the linear bearings had some wriggle in them. So I designed and printed a half-dozen bearing clamps that worked well. Then I designed and printed a couple of cross-bars with adjustment screws to nudge the Y axis belt to run on (or near) the centers of its pulley and ball bearing. The idea was to reduce friction and vibration. The improvement was dramatic! I have attached a picture of a Make Magazine test robot I printed before and after my clamps were installed (plus a few other tweaks I can detail for you if anyone is interested). The picture includes one of the black bearing clamps I installed on the lower X axis rod. I also attached a picture of the front Y axis bearing adjustment part I made.

I hope these image links to DropBox will work. Inserting the image links seems to be straight forward, but the pre-view showed errors...

|

Re: all axis calibration issues January 26, 2015 01:25AM |

Registered: 9 years ago Posts: 93 |

what version of marlin are you using?

your images didnt load...but the URL works

Edited 1 time(s). Last edit at 01/26/2015 01:26AM by 09zx-6r.

Nophead Mendel90 Remixed in aluminum

Marlin v2.0

Matterhacker Control (latest)

Ramps 1.4

Sainsmart LCD

MK2B heatbed

E3dV6 hotend .4mm tip

1.75mm filaments

dedicated 12v33a psu

dedicated 12v5a laptop psu mod

your images didnt load...but the URL works

Edited 1 time(s). Last edit at 01/26/2015 01:26AM by 09zx-6r.

Nophead Mendel90 Remixed in aluminum

Marlin v2.0

Matterhacker Control (latest)

Ramps 1.4

Sainsmart LCD

MK2B heatbed

E3dV6 hotend .4mm tip

1.75mm filaments

dedicated 12v33a psu

dedicated 12v5a laptop psu mod

|

Re: all axis calibration issues January 27, 2015 08:42PM |

Registered: 10 years ago Posts: 18 |

Thanks for the response. I am using Marlin 7 and Ramps 1.4. But, finally, I found a YouTube video that showed what I think my answer is:

3DPrintronics - Prusa i3 Build Tutorial : Part 11 - Calibrating the X, Y, Z axis

[www.youtube.com]

Configuration.h

Line 389 - #define DEFAULT_AXIS_STEPS_PER_UNIT {80,78.80,4000,760*1.1} // default steps per unit for Ultimaker

I'm guessing that the settings will work for my Prusa i3 XL (DIY TechShop, Omega) even though they refer to the Ultimaker. I'm just going to change the settings by the percentage of error I am getting and see if that improves my accuracy. I've already found the setting for the E steps per mm for the extruder.

Configuration_adv.h

Line 330 #define STEPS_MM_E 643 (Will change to 459.29, January 2015)

Annnnd, the last thing I think I need to do to get Repetier Host working with my 3D printer is to define the hot bed thermisters as "0" so Rep Host will not get stuck indefinitely trying to head a hot bed I don't have:

Configuration.h

Line 126 - #define TEMP_SENSOR_BED 7 (need to change to 0?)

Thanks, Dale

Dale

3DPrintronics - Prusa i3 Build Tutorial : Part 11 - Calibrating the X, Y, Z axis

[www.youtube.com]

Configuration.h

Line 389 - #define DEFAULT_AXIS_STEPS_PER_UNIT {80,78.80,4000,760*1.1} // default steps per unit for Ultimaker

I'm guessing that the settings will work for my Prusa i3 XL (DIY TechShop, Omega) even though they refer to the Ultimaker. I'm just going to change the settings by the percentage of error I am getting and see if that improves my accuracy. I've already found the setting for the E steps per mm for the extruder.

Configuration_adv.h

Line 330 #define STEPS_MM_E 643 (Will change to 459.29, January 2015)

Annnnd, the last thing I think I need to do to get Repetier Host working with my 3D printer is to define the hot bed thermisters as "0" so Rep Host will not get stuck indefinitely trying to head a hot bed I don't have:

Configuration.h

Line 126 - #define TEMP_SENSOR_BED 7 (need to change to 0?)

Thanks, Dale

Dale

Sorry, only registered users may post in this forum.