Wade gear printing trouble

Posted by janoc

|

Wade gear printing trouble January 21, 2015 08:17PM |

Registered: 9 years ago Posts: 6 |

Hello everyone,

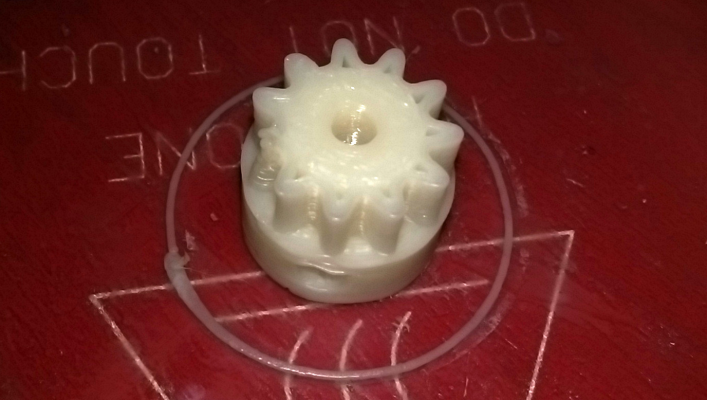

I have managed to build the Mendel90 kit from Nophead (great job on the kit, btw!) and now I am trying to print some spare parts like the extruder gears. I have attempted to make the small extruder gear in ABS, with 100% infill and this what I am getting:

If you look carefully, there is a crooked tooth on the left side. Also the left side seems to be more filled? The right side has holes in the teeth. The round bottom of the gear seems to be also a bit flat right under where the crooked tooth is. I have also noticed that during the printing there was a kind of "horn" of the plastic sticking up on the bad tooth (it is barely visible in the photo).

This is actually the second attempt at printing the gear, the first one had two crooked teeth on the left side. I have tightened the X belt thinking it might be loose and tried again, getting the above.

What is the reason for this? I am still pretty much a total noob at 3D printing, so excuse my stupidity if the problem is obvious.

Also, what are the recommended settings for slicing the extruder gears in Slicr? I have pretty much left everything at default, only changed the temperature to 235C hotend and 100C bed and set 100% infill, using the rectilinear pattern.

I have managed to build the Mendel90 kit from Nophead (great job on the kit, btw!) and now I am trying to print some spare parts like the extruder gears. I have attempted to make the small extruder gear in ABS, with 100% infill and this what I am getting:

If you look carefully, there is a crooked tooth on the left side. Also the left side seems to be more filled? The right side has holes in the teeth. The round bottom of the gear seems to be also a bit flat right under where the crooked tooth is. I have also noticed that during the printing there was a kind of "horn" of the plastic sticking up on the bad tooth (it is barely visible in the photo).

This is actually the second attempt at printing the gear, the first one had two crooked teeth on the left side. I have tightened the X belt thinking it might be loose and tried again, getting the above.

What is the reason for this? I am still pretty much a total noob at 3D printing, so excuse my stupidity if the problem is obvious.

Also, what are the recommended settings for slicing the extruder gears in Slicr? I have pretty much left everything at default, only changed the temperature to 235C hotend and 100C bed and set 100% infill, using the rectilinear pattern.

|

Re: Wade gear printing trouble January 22, 2015 10:45AM |

Admin Registered: 17 years ago Posts: 7,879 |

I suspect the defect tooth is where the layer starts, so perhaps the retraction parameters are not correct. Also you are probably better with a random start point s there is no cumulative effect.

To get solid teeth you need a single perimeter, not two.

If you print one gear on its own it will tend to get too hot. I print 25 at a time but two is probably OK.

[www.hydraraptor.blogspot.com]

To get solid teeth you need a single perimeter, not two.

If you print one gear on its own it will tend to get too hot. I print 25 at a time but two is probably OK.

[www.hydraraptor.blogspot.com]

|

Re: Wade gear printing trouble January 22, 2015 11:11AM |

Registered: 9 years ago Posts: 6 |

Hello Nophead,

Thanks for the tip, I will try that. I was thinking about lowering the bed temperature a bit too.

Concerning the kit:

The machine works nicely - I was really surprised how rigid and stiff the thing is! It certainly doesn't look like it, but I am used to aluminium and steel machinery, so it was a nice surprise.

However, you really should adopt the revised Y axis idler with the tensioner (e.g. this one: [www.thingiverse.com]) for the future versions. The current design is quite wonky, making it hard to tension the belt and to keep the idler fixed in place as the screw cannot be tightened completely in order to not crush the dibond or crack the plastic. The other issue that I have noticed is the design of the X axis, that makes the left side "jump" when the Z axis is moving down, because the left side is lighter (there is no heavy motor there). I have put a temporary weight there to make it rest on the brass nut and reduce the binding on the rod. That is probably my only peeve with your kit.

I have also a comment about the documentation - it is generally excellent and detailed, but it would be really helpful to have photos of the real machine/parts and not only the rendered parts in the manual - I have never built one of these before and it took me a while to realize how (and which!) things fit together in a few cases. Especially the parts where wires are to be routed - they aren't visible on the renderings.

Edited 1 time(s). Last edit at 01/22/2015 11:15AM by janoc.

Thanks for the tip, I will try that. I was thinking about lowering the bed temperature a bit too.

Concerning the kit:

The machine works nicely - I was really surprised how rigid and stiff the thing is! It certainly doesn't look like it, but I am used to aluminium and steel machinery, so it was a nice surprise.

However, you really should adopt the revised Y axis idler with the tensioner (e.g. this one: [www.thingiverse.com]) for the future versions. The current design is quite wonky, making it hard to tension the belt and to keep the idler fixed in place as the screw cannot be tightened completely in order to not crush the dibond or crack the plastic. The other issue that I have noticed is the design of the X axis, that makes the left side "jump" when the Z axis is moving down, because the left side is lighter (there is no heavy motor there). I have put a temporary weight there to make it rest on the brass nut and reduce the binding on the rod. That is probably my only peeve with your kit.

I have also a comment about the documentation - it is generally excellent and detailed, but it would be really helpful to have photos of the real machine/parts and not only the rendered parts in the manual - I have never built one of these before and it took me a while to realize how (and which!) things fit together in a few cases. Especially the parts where wires are to be routed - they aren't visible on the renderings.

Edited 1 time(s). Last edit at 01/22/2015 11:15AM by janoc.

|

Re: Wade gear printing trouble January 22, 2015 12:44PM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

janoc

Concerning the kit:

The machine works nicely - I was really surprised how rigid and stiff the thing is! It certainly doesn't look like it, but I am used to aluminium and steel machinery, so it was a nice surprise.

3mm DiBond is as stiff as 2.8mm solid aluminium and stiffer than 6mm acrylic.

Quote

However, you really should adopt the revised Y axis idler with the tensioner (e.g. this one: [www.thingiverse.com]) for the future versions. The current design is quite wonky, making it hard to tension the belt and to keep the idler fixed in place as the screw cannot be tightened completely in order to not crush the dibond or crack the plastic.

I don't find this a problem at all on my machines. I simply tension it with my thumb on the idler and my fingers over the edge of the DiBond. I tighten it just enough to hold, then swivel it to get the belt to run in the middle and then I tighten it some more. It never slips after that, even after years of running I don't need to touch it again.

Quote

The other issue that I have noticed is the design of the X axis, that makes the left side "jump" when the Z axis is moving down, because the left side is lighter (there is no heavy motor there). I have put a temporary weight there to make it rest on the brass nut and reduce the binding on the rod. That is probably my only peeve with your kit.

I think you have some misalignment of the Z bars causing binding. Gravity should be enough to keep the both nuts pressed down.

Quote

I have also a comment about the documentation - it is generally excellent and detailed, but it would be really helpful to have photos of the real machine/parts and not only the rendered parts in the manual - I have never built one of these before and it took me a while to realize how (and which!) things fit together in a few cases. Especially the parts where wires are to be routed - they aren't visible on the renderings.

I don't use photos because they can only be taken when building a new machine to the latest specification. When I change the model all the diagrams change automatically and I don't need to build a new machine.

Edited 1 time(s). Last edit at 01/22/2015 12:45PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Wade gear printing trouble January 22, 2015 02:12PM |

Registered: 9 years ago Posts: 6 |

Quote

nophead

3mm DiBond is as stiff as 2.8mm solid aluminium and stiffer than 6mm acrylic.

Aha, ok. I have never worked with DiBond before, so it was surprising, considering that it is quite "foamy".

Quote

nophead

I don't find this a problem at all on my machines. I simply tension it with my thumb on the idler and my fingers over the edge of the DiBond. I tighten it just enough to hold, then swivel it to get the belt to run in the middle and then I tighten it some more. It never slips after that, even after years of running I don't need to touch it again.

That is how I did it too, but then when I swivel it, the screw usually gets loose and the tension is off again, so I need to retention it, then swivel again, etc. The screw tensioner like on the X axis is less hassle once the belt is running straight.

Quote

nophead

I think you have some misalignment of the Z bars causing binding. Gravity should be enough to keep the both nuts pressed down.

That is possible, but still the design of the X axis with the motor on one side is going to make it bind no matter what - the idler end is light, so when the nut goes down, the plastic stays stuck on the rod due to the rotational force around the motor end. The minuscule amount of play that there is is enough to twist the entire X axis like that, which makes the idler side suddenly "jump" down when the difference starts to be too large.

I am certainly not blaming you for it, the design seems to be coming from the Prusas which use the same configuration. I have seen someone actually put a real weight on the idler side in order to get it to move smoothly.

Or did I assemble it wrong? I have the X axis plastic ends resting freely on top of the nuts, they are not attached to them and only gravity pulls it down when the Z axis is moving down.

Quote

I don't use photos because they can only be taken when building a new machine to the latest specification. When I change the model all the diagrams change automatically and I don't need to build a new machine.

I see, makes sense. Even then a few close up photos of existing (even assembled and not exactly identical to the CAD/current kit) machines would be helpful to have - I was looking at various videos on Youtube to see how some of the bits fit together on other people's machines when I wasn't sure about something.

|

Re: Wade gear printing trouble January 22, 2015 02:36PM |

Registered: 10 years ago Posts: 541 |

I found it convenient to print both Wades gears and the spacer together at the same time.

Regarding the X-axis, I assembled my kit very carefully and it has been printing excellently but I recently looked at the top of the threaded rods during a homing operation and noticed they were drawing circles instead of running true.

I devised a method of placing the X-carriage halfway up the rods and loosened the threaded rod clamps, couplers and Z motor mounts then tightening them in a sequence that distributed any rod errors between top and bottom of the Z-axis. The threaded rods now rotate nice and true at both top and bottom. It eliminated a small squeak that sometimes occurred during homing and I experience no problems whatsoever with vertical motion. The fact that one end has a motor while the other does not has no influence on my machine's operation.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Regarding the X-axis, I assembled my kit very carefully and it has been printing excellently but I recently looked at the top of the threaded rods during a homing operation and noticed they were drawing circles instead of running true.

I devised a method of placing the X-carriage halfway up the rods and loosened the threaded rod clamps, couplers and Z motor mounts then tightening them in a sequence that distributed any rod errors between top and bottom of the Z-axis. The threaded rods now rotate nice and true at both top and bottom. It eliminated a small squeak that sometimes occurred during homing and I experience no problems whatsoever with vertical motion. The fact that one end has a motor while the other does not has no influence on my machine's operation.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Wade gear printing trouble January 22, 2015 04:30PM |

Registered: 9 years ago Posts: 6 |

Quote

neildarlow

I found it convenient to print both Wades gears and the spacer together at the same time.

That's maybe a good idea. I haven't dared to launch into larger print jobs yet, because I am still learning how to operate the thing and various small issues that cause failed prints are still being ironed out.

Quote

Regarding the X-axis, I assembled my kit very carefully and it has been printing excellently but I recently looked at the top of the threaded rods during a homing operation and noticed they were drawing circles instead of running true.

Yep, mine do that too. On the other hand, if the threaded rods are not running completely straight, it is not that big deal - they are not precision rods, could be sligthly bent, the couplers may loosen over time, etc. That's also why the tops are free and not fixed, as you would normally see on an industrial machine using a precision leadscrew.

Quote

I devised a method of placing the X-carriage halfway up the rods and loosened the threaded rod clamps, couplers and Z motor mounts then tightening them in a sequence that distributed any rod errors between top and bottom of the Z-axis. The threaded rods now rotate nice and true at both top and bottom. It eliminated a small squeak that sometimes occurred during homing and I experience no problems whatsoever with vertical motion. The fact that one end has a motor while the other does not has no influence on my machine's operation.

That sounds like a good method. I have tried to align the smooth rods while installing the X axis as in the manual, passing the carriage over few times and only then tightening them, but it probably could use touching up. I am planning to replace the top clamps because I think I have overstressed them while tightening the rods, so I will do it then - I will have to realign the Z axis anyway.

The issue with the Z axis has no visible impact on printing on my Mendel so far neither because during printing the head is moving only in small increments and mostly up. I see the binding only when I am moving down after homing - i.e. traversing the entire length of the rods.

Regards,

Jan

|

Re: Wade gear printing trouble January 22, 2015 04:49PM |

Admin Registered: 17 years ago Posts: 7,879 |

There shouldn't be any binding and the axis should move smoothly in both directions without needing extra weight.

Try loosening all the motor brackets and bar clamps and push the left pair as far left as they will go to accurately make that bar vertical. Then tighten the left brackets, move the axis to the top and tighten the right bar clamp and to the bottom to tighten the motor. That should line everything up perfectly vertical and parallel.

What can happen is if the Z bars are not exactly vertical (due to screw hole clearances) when you level the axis to the bed it causes all the weight to be on one nut.

If the lead screws wobble at the top when the axis is at the bottom it usually indicates the couplings are not perfectly centred, rather than the studding being bent. While the studding is never perfectly straight I reject any that deviate more than a fraction of a mm when rolled on a flat surface.

[www.hydraraptor.blogspot.com]

Try loosening all the motor brackets and bar clamps and push the left pair as far left as they will go to accurately make that bar vertical. Then tighten the left brackets, move the axis to the top and tighten the right bar clamp and to the bottom to tighten the motor. That should line everything up perfectly vertical and parallel.

What can happen is if the Z bars are not exactly vertical (due to screw hole clearances) when you level the axis to the bed it causes all the weight to be on one nut.

If the lead screws wobble at the top when the axis is at the bottom it usually indicates the couplings are not perfectly centred, rather than the studding being bent. While the studding is never perfectly straight I reject any that deviate more than a fraction of a mm when rolled on a flat surface.

[www.hydraraptor.blogspot.com]

|

Re: Wade gear printing trouble January 22, 2015 04:53PM |

Registered: 9 years ago Posts: 6 |

|

Re: Wade gear printing trouble January 22, 2015 06:16PM |

Registered: 9 years ago Posts: 6 |

Follow up - I have tried to quickly adjust the Z axis, it didn't help much with the axis binding. I guess I will need to take the machine quite a bit apart to realign things properly.

However, I have tried printing 2 gears, with perimeter set to 1 and randomized seam position, as suggested by Nophead and voila, this is the result:

There is a tiny bit of stringing here and there (hard to see in the photo), but I think I can live with that. I will try to lower the temperature from the 235C a little next time.

I will try to lower the temperature from the 235C a little next time.

Thanks a lot for the help!

Jan

However, I have tried printing 2 gears, with perimeter set to 1 and randomized seam position, as suggested by Nophead and voila, this is the result:

There is a tiny bit of stringing here and there (hard to see in the photo), but I think I can live with that.

I will try to lower the temperature from the 235C a little next time.

I will try to lower the temperature from the 235C a little next time.Thanks a lot for the help!

Jan

Sorry, only registered users may post in this forum.