E3D Hotend Fitting

Posted by 3ddude

|

E3D Hotend Fitting January 28, 2015 03:34AM |

Registered: 11 years ago Posts: 106 |

Hi Guys

I managed to kill my hot end so I've decided I have two options to replace it, either a straight swap for the same J Head or change to an E3D all metal one. Could someone tell me what I need to do to install the E3D? As it stands I'm aware of a few things:-

1. The hotend cooling fan needs to be on all the time with the hotend (Is there a spare pin out on the melzi which I could control via G Code?)

2. I presume I'd need to run additional wiring for thi sfan to keep seperate from the build area cooling

3. The E3D's come with a thermocouple so not sure if my electronics are compatible, or any idea what to change (if anything?)

4. Z height will need adjusting but that's straight forward

5. Presumably I'll need a different fan duct for the build area?

Did I miss anything?

Is it worth messing around with or is the standard J Head fine?

Thank you for any guidance/opinions!

PS I did try searching but for some reason I didn't get any hits for E3D under Mendel90 despite seeing E3D a few times in posts!

Ross

I managed to kill my hot end so I've decided I have two options to replace it, either a straight swap for the same J Head or change to an E3D all metal one. Could someone tell me what I need to do to install the E3D? As it stands I'm aware of a few things:-

1. The hotend cooling fan needs to be on all the time with the hotend (Is there a spare pin out on the melzi which I could control via G Code?)

2. I presume I'd need to run additional wiring for thi sfan to keep seperate from the build area cooling

3. The E3D's come with a thermocouple so not sure if my electronics are compatible, or any idea what to change (if anything?)

4. Z height will need adjusting but that's straight forward

5. Presumably I'll need a different fan duct for the build area?

Did I miss anything?

Is it worth messing around with or is the standard J Head fine?

Thank you for any guidance/opinions!

PS I did try searching but for some reason I didn't get any hits for E3D under Mendel90 despite seeing E3D a few times in posts!

Ross

|

Re: E3D Hotend Fitting January 28, 2015 01:01PM |

Registered: 10 years ago Posts: 541 |

Hi,

1. and 2. Most people use the spare wire on the ribbon cable to provide a ground for the fan. A permanent +12V feed is already available at the hotend heater terminal. The fan can be wired between the correct hotend terminal and the correct "P" pin on the two-way connector of the extruder PCB.

3. No, the E3D hotends ship with a thermistor as standard. Fitting an E3D hotend to a standard Mendel90 would be more complicated if a thermocouple was used.

4. The available Z height will be reduced but you will need to recalibrate after changing the hotend anyway.

5. Yes, a different cooling fan scheme will be needed.

My personal opinion is that, provided it is adequately looked after, the standard J-Heaf is a fine piece of equipment for general ABS and PLA printing. Mis-use can shorten its lifetime but that also applies to any hotend. I have been using my J-Head for nearly 15 months now without any issues whatsoever.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

1. and 2. Most people use the spare wire on the ribbon cable to provide a ground for the fan. A permanent +12V feed is already available at the hotend heater terminal. The fan can be wired between the correct hotend terminal and the correct "P" pin on the two-way connector of the extruder PCB.

3. No, the E3D hotends ship with a thermistor as standard. Fitting an E3D hotend to a standard Mendel90 would be more complicated if a thermocouple was used.

4. The available Z height will be reduced but you will need to recalibrate after changing the hotend anyway.

5. Yes, a different cooling fan scheme will be needed.

My personal opinion is that, provided it is adequately looked after, the standard J-Heaf is a fine piece of equipment for general ABS and PLA printing. Mis-use can shorten its lifetime but that also applies to any hotend. I have been using my J-Head for nearly 15 months now without any issues whatsoever.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: E3D Hotend Fitting January 28, 2015 01:27PM |

Registered: 11 years ago Posts: 106 |

Hi Neil, thanks for your help. I think I'm going to try the E3D as it seems fairly straight forward to install. I like the idea that it's all metal, in my head it would be easier to clean out a jam if I can take it all apart etc

Would it be worth switching to 1.75mm while I'm at it? I have loads of different filaments etc already. I imagine that the thinner filament may be more accurate in the volume calculation the slicers make.

Would it be worth switching to 1.75mm while I'm at it? I have loads of different filaments etc already. I imagine that the thinner filament may be more accurate in the volume calculation the slicers make.

|

Re: E3D Hotend Fitting January 28, 2015 01:44PM |

Registered: 10 years ago Posts: 541 |

Hi,

Bear in mind that the Wades block is designed for 3mm filament. In particular, the hobbed bolt might require replacement with one designed for 1.75mm filament. Also the feed channels would need to be reduced in diameter.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Bear in mind that the Wades block is designed for 3mm filament. In particular, the hobbed bolt might require replacement with one designed for 1.75mm filament. Also the feed channels would need to be reduced in diameter.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: E3D Hotend Fitting January 28, 2015 02:38PM |

Registered: 10 years ago Posts: 48 |

I have been running a E3D for some time now and are really happy with it.

Look at this thread.

[forums.reprap.org]

Edited 1 time(s). Last edit at 01/28/2015 02:39PM by amr_dwarf.

Look at this thread.

[forums.reprap.org]

Edited 1 time(s). Last edit at 01/28/2015 02:39PM by amr_dwarf.

|

Re: E3D Hotend Fitting January 28, 2015 03:59PM |

Registered: 10 years ago Posts: 439 |

An E3D Mendel90 mounting here:

[www.thingiverse.com]

The hotend cooling fan needs to be on until the hotend cools after printing.

[www.thingiverse.com]

The hotend cooling fan needs to be on until the hotend cools after printing.

|

Re: E3D Hotend Fitting January 28, 2015 06:42PM |

Registered: 11 years ago Posts: 106 |

|

Re: E3D Hotend Fitting January 28, 2015 07:26PM |

Admin Registered: 17 years ago Posts: 7,879 |

Note there is an un-merged pull request on my Github for an E3D hot end. It modifies the Wades block to get a bit more height back and modifies the fan duct to fit. I think the STLs for it are on Thingiverse as well.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: E3D Hotend Fitting January 29, 2015 08:25AM |

Registered: 11 years ago Posts: 106 |

|

Re: E3D Hotend Fitting January 30, 2015 02:00PM |

Registered: 11 years ago Posts: 106 |

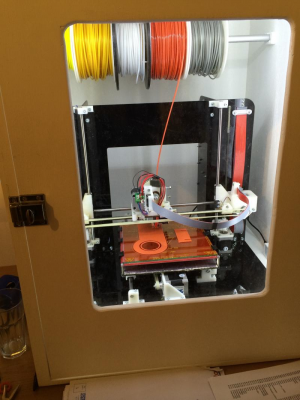

Well, my new hot end has arrived and is now working away printing the revised fan duct and bracket (courtesy of RalphHilton, thanks). I can confirm that the v6 fits the M90 and you can retain the E3D fan and blue duct which comes with it. I'm not sure if it will work with the revised fan duct that's printing now but I'll find out in a few hours!

Thanks to everyone who helped with my queries in this thread.

Ross

Thanks to everyone who helped with my queries in this thread.

Ross

|

Re: E3D Hotend Fitting January 30, 2015 08:12PM |

Registered: 10 years ago Posts: 439 |

I didn't like the supplied fan and holder - I put in a larger fan and modified the wade block to fit it in more easily:

[www.thingiverse.com]

[www.thingiverse.com]

|

Re: E3D Hotend Fitting January 31, 2015 05:57AM |

Registered: 9 years ago Posts: 56 |

hey guys, i managed to assemble the e3d and fitted it, everything fits

but i´m confused about the wiring. is it correct, that i can

- connect the 2 wires from the heater cartridge to the TTHH terminals? to which?

- the black and red wire for the always on hotend fan can also plugged there?

and where do the cables from the thermistor connect? i think also in the TTHH?

but i´m confused about the wiring. is it correct, that i can

- connect the 2 wires from the heater cartridge to the TTHH terminals? to which?

- the black and red wire for the always on hotend fan can also plugged there?

and where do the cables from the thermistor connect? i think also in the TTHH?

|

Re: E3D Hotend Fitting January 31, 2015 03:50PM |

Registered: 10 years ago Posts: 439 |

|

Re: E3D Hotend Fitting February 01, 2015 04:03AM |

Registered: 9 years ago Posts: 56 |

|

Re: E3D Hotend Fitting February 01, 2015 05:08AM |

Registered: 9 years ago Posts: 56 |

|

Re: E3D Hotend Fitting February 02, 2015 02:47AM |

Registered: 10 years ago Posts: 439 |

|

Re: E3D Hotend Fitting February 02, 2015 03:04AM |

Registered: 9 years ago Posts: 56 |

|

Re: E3D Hotend Fitting February 02, 2015 02:41PM |

Registered: 11 years ago Posts: 106 |

|

Re: E3D Hotend Fitting February 02, 2015 04:03PM |

Registered: 9 years ago Posts: 56 |

|

Re: E3D Hotend Fitting February 04, 2015 12:05PM |

Registered: 11 years ago Posts: 32 |

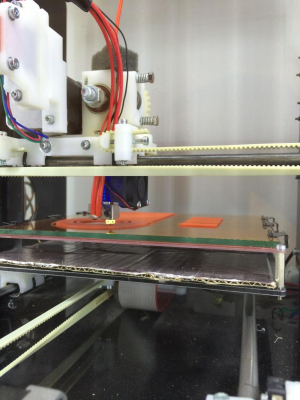

These are the steps that I done to get working the e3dv6 hot end on my Mendel90.

0. I follow the instructions and Marlin configuration from e3d-v6 Assembly

1. I done the connections according to the attached diagramm (using the ribbon 5).

2. I printed the fan duct from e3d-v6 fan duct for Mendel90, but I have to sand the cornes to fit the heater block (see attached images)

3. I change the Hex screw and the wing nut by a M4 cap screw plus a washer and nut. Affortunately nophead left a cavity for the nut. (see last image)

Edited 1 time(s). Last edit at 02/04/2015 12:06PM by wgaona.

0. I follow the instructions and Marlin configuration from e3d-v6 Assembly

1. I done the connections according to the attached diagramm (using the ribbon 5).

2. I printed the fan duct from e3d-v6 fan duct for Mendel90, but I have to sand the cornes to fit the heater block (see attached images)

3. I change the Hex screw and the wing nut by a M4 cap screw plus a washer and nut. Affortunately nophead left a cavity for the nut. (see last image)

Edited 1 time(s). Last edit at 02/04/2015 12:06PM by wgaona.

|

Re: E3D Hotend Fitting February 04, 2015 01:49PM |

Registered: 9 years ago Posts: 56 |

Sorry, only registered users may post in this forum.