Odd print problem

Posted by hsbontop

|

Odd print problem March 31, 2015 03:27AM |

Registered: 9 years ago Posts: 49 |

After a fully successful first android print I updated to the Neil Darlow fw and since only prints in one direction at the time turn out well (like the calibration angle). Bi-directional prints (base of a cube) keeps being printed at a slant. Motor current was turned down a bit before the android print but has not been touched since. Pulleys seem not to slip but still remains to be confirmed (and the angle still comes out fine).

Are there any setting in the need of attention when switching from the nophead to the neil fw (like acceleration values)?

Bed PID is currently active.

Are there any setting in the need of attention when switching from the nophead to the neil fw (like acceleration values)?

Bed PID is currently active.

|

Re: Odd print problem March 31, 2015 05:02AM |

Registered: 10 years ago Posts: 541 |

Hi,

The speed, acceleration and jerk values are the same in my firmware and nophead's.

I think you are saying that prints involving movement in both axes are causing you problems e.g. diagonals, arcs and circles?

The only difference I see between those and a linear print is that two motors are being driven instead of one. This might indicate a problem with missed steps due to a power supply problem or motor cable connection.

You do not say what your hardware specification is i.e. kit or self-sourced build. In the absence of this information I would suggest using a host program to move the head around the bed and assess the motions in X, Y and combined directions. Check for repeatability of the motions by reversing them in order to determine if steps are being missed under certain conditions.

I, obviously, use my firmware and do not observe these problems. Let us see if we can fix things for you.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

The speed, acceleration and jerk values are the same in my firmware and nophead's.

I think you are saying that prints involving movement in both axes are causing you problems e.g. diagonals, arcs and circles?

The only difference I see between those and a linear print is that two motors are being driven instead of one. This might indicate a problem with missed steps due to a power supply problem or motor cable connection.

You do not say what your hardware specification is i.e. kit or self-sourced build. In the absence of this information I would suggest using a host program to move the head around the bed and assess the motions in X, Y and combined directions. Check for repeatability of the motions by reversing them in order to determine if steps are being missed under certain conditions.

I, obviously, use my firmware and do not observe these problems. Let us see if we can fix things for you.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Odd print problem March 31, 2015 05:36AM |

Registered: 9 years ago Posts: 49 |

Thanks for the quick reply.

It is a self sourced printer. The problem only occurs when more than one axle at the time is moving, but not with nophead fw. I plan to go back to nophead's version just to ensure this is not the problem. All connections will be checked and I'll try to print with the bed turned off to see if power consumption is the cause. Next step will be to increase the motor current althoug the current setting worked previously. The motors are running quite cool so there should be room for an increase.

Any other ideas what to test?

It is a self sourced printer. The problem only occurs when more than one axle at the time is moving, but not with nophead fw. I plan to go back to nophead's version just to ensure this is not the problem. All connections will be checked and I'll try to print with the bed turned off to see if power consumption is the cause. Next step will be to increase the motor current althoug the current setting worked previously. The motors are running quite cool so there should be room for an increase.

Any other ideas what to test?

|

Re: Odd print problem March 31, 2015 06:32AM |

Admin Registered: 17 years ago Posts: 7,879 |

Try setting dropsegments = 0 in configuration_adv.h.

By default Marlin ignores very short moves. I think slic3r generates some when slicing a cube and it can cause each layer to offset by that amount.

[www.hydraraptor.blogspot.com]

By default Marlin ignores very short moves. I think slic3r generates some when slicing a cube and it can cause each layer to offset by that amount.

[www.hydraraptor.blogspot.com]

|

Re: Odd print problem March 31, 2015 06:59AM |

Registered: 9 years ago Posts: 49 |

|

Re: Odd print problem March 31, 2015 01:16PM |

Registered: 10 years ago Posts: 541 |

Hi,

Both firmware forks have the same value for dropsegments so I would expect similar behaviour.

The functional settings in my firmare should match those of nophead's (I isolated all of his changes in the Marlin 1.0.0RC branch and applied them to the newer Marlin branch) so any unexpected behaviour would be attributed to new functionality or bugs.

I have printed a modified Mendel90 dust filter, which was sliced with slic3r, and many objects with circular features and have not noticed any problems like this.

Beyond a difference due to firmware (which I do not comprehend) I would expect a mechanical or electronics-related cause.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Both firmware forks have the same value for dropsegments so I would expect similar behaviour.

The functional settings in my firmare should match those of nophead's (I isolated all of his changes in the Marlin 1.0.0RC branch and applied them to the newer Marlin branch) so any unexpected behaviour would be attributed to new functionality or bugs.

I have printed a modified Mendel90 dust filter, which was sliced with slic3r, and many objects with circular features and have not noticed any problems like this.

Beyond a difference due to firmware (which I do not comprehend) I would expect a mechanical or electronics-related cause.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Odd print problem March 31, 2015 04:36PM |

Registered: 9 years ago Posts: 49 |

|

Re: Odd print problem March 31, 2015 05:08PM |

Admin Registered: 17 years ago Posts: 7,879 |

The bug I was thinking off only occurred with slic3r and hardware retraction, see [github.com]

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Odd print problem April 11, 2015 08:11AM |

Registered: 9 years ago Posts: 49 |

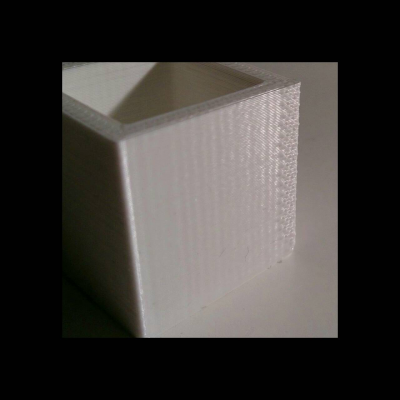

Switched to a e3dv6 and sliced with Skeinforge using nophead's 0.2PLA profile. No slant but some other things to look after:

1. Over shooting, acceleration problem, lose belts?

2. Smal blobs in one corner, to much retract?

3. Uneaven top surface, overextrusion?

Amazing piece of engineering this, thanks nophead!

Edited 1 time(s). Last edit at 04/11/2015 05:27PM by hsbontop.

1. Over shooting, acceleration problem, lose belts?

2. Smal blobs in one corner, to much retract?

3. Uneaven top surface, overextrusion?

Amazing piece of engineering this, thanks nophead!

Edited 1 time(s). Last edit at 04/11/2015 05:27PM by hsbontop.

|

Re: Odd print problem April 11, 2015 04:06PM |

Registered: 10 years ago Posts: 541 |

Hi,

It does appear you have some over-extrusion.

The stippling on the corner is symptomatic of incorrect retraction. Not so much quantity but speed. I typically retract 0.5mm at a speed of 80mm/s.

The varying position of the stipples is caused by Skeinforge's Jitter setting which randomly positions layer endings within a set distance and defaults to 2mm.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

It does appear you have some over-extrusion.

The stippling on the corner is symptomatic of incorrect retraction. Not so much quantity but speed. I typically retract 0.5mm at a speed of 80mm/s.

The varying position of the stipples is caused by Skeinforge's Jitter setting which randomly positions layer endings within a set distance and defaults to 2mm.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Odd print problem April 12, 2015 06:06AM |

Admin Registered: 17 years ago Posts: 7,879 |

Hi Neil,

I don't think Marlin can do 80mm/s on the extruder as it would be about 48kHz. What acceleration and jerk values do you use because I also don't think it will reach that speed in 0.5mm?

I do agree it looks like it would be better done faster. I am just not sure Marlin can go that fast. I am about the attach a logic analyser to see what speed it actually achieves.

[www.hydraraptor.blogspot.com]

I don't think Marlin can do 80mm/s on the extruder as it would be about 48kHz. What acceleration and jerk values do you use because I also don't think it will reach that speed in 0.5mm?

I do agree it looks like it would be better done faster. I am just not sure Marlin can go that fast. I am about the attach a logic analyser to see what speed it actually achieves.

[www.hydraraptor.blogspot.com]

|

Re: Odd print problem April 13, 2015 08:59AM |

Registered: 10 years ago Posts: 541 |

Hi,

Extrude and retract acceleration are both 5000 and extruder Jerk is 10.

I settled on 80mm/s recently in attempting to reduce the layer-end stippling effect with Brassfill. I increased retraction speed by 20mm/s increments until the effect was reduced to negligible levels.

I did not push the speed as high as 100mm/s but the visual improvement increased with each step up to 80mm/s. It may be that I have not fully achieved that speed and it would be good to know the achievable figure.

N.B.: Would have responded sooner but just returned from Norfolk to stable broadband.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Extrude and retract acceleration are both 5000 and extruder Jerk is 10.

I settled on 80mm/s recently in attempting to reduce the layer-end stippling effect with Brassfill. I increased retraction speed by 20mm/s increments until the effect was reduced to negligible levels.

I did not push the speed as high as 100mm/s but the visual improvement increased with each step up to 80mm/s. It may be that I have not fully achieved that speed and it would be good to know the achievable figure.

N.B.: Would have responded sooner but just returned from Norfolk to stable broadband.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Odd print problem April 13, 2015 10:46AM |

Admin Registered: 17 years ago Posts: 7,879 |

I think the max step rate is 40kHz which is around 66mm/s with normal E_STEPS_PER_MM.

However the distance to get to that from 10 at 5000 mm/s^2 would be (66^2 - 10^2) / (2 * 5000) = 0.43mm. Since it also has to stop it would take twice that distance.

I did some experiments with different accelerations and jerks and they did not seem to make sense. For example jerk has no effect and some lower acceleration values were less smooth than higher ones. I suspect there are bugs in the planner code, so I need to have a look at what the pulse waveforms look like.

[www.hydraraptor.blogspot.com]

However the distance to get to that from 10 at 5000 mm/s^2 would be (66^2 - 10^2) / (2 * 5000) = 0.43mm. Since it also has to stop it would take twice that distance.

I did some experiments with different accelerations and jerks and they did not seem to make sense. For example jerk has no effect and some lower acceleration values were less smooth than higher ones. I suspect there are bugs in the planner code, so I need to have a look at what the pulse waveforms look like.

[www.hydraraptor.blogspot.com]

|

Re: Odd print problem April 15, 2015 05:25AM |

Registered: 9 years ago Posts: 49 |

Decreased extruder e-steps from 501 to 495, 470, 450, 440 and 430

. Figured 440 was the value to use and printed a new cube.

Much better result but still ridges at the edges and the blobs remains despite changing retract acceleration to 50 and distance to 0.5. Skeinforge decided not to have the fan on during the print (this has now been fixed), could this be the reason?

Much better result but still ridges at the edges and the blobs remains despite changing retract acceleration to 50 and distance to 0.5. Skeinforge decided not to have the fan on during the print (this has now been fixed), could this be the reason?

|

Re: Odd print problem April 15, 2015 05:34AM |

Registered: 10 years ago Posts: 541 |

Hi,

Use nophead's 100mm of filament extrude method from the build manual to calibrate your E_STEPS_PER_MM value. It will get you to where you need to be in terms of extrusion.

Also, ensure your slicer has an accurate filament diameter configured. Small errors here can produce significant over or under extrusion.

I am guessing that you meant Retract Speed rather than Retract Acceleration. The difference between 40 mm/s and 50mm/s is small. I went as far as 80 mm/s which nophead is evaluating now to see if Marlin can actually achieve that speed.

For me it works but, like a lot of things 3D printing related, individual conditions may vary and produce different results.

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 04/15/2015 05:36AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Use nophead's 100mm of filament extrude method from the build manual to calibrate your E_STEPS_PER_MM value. It will get you to where you need to be in terms of extrusion.

Also, ensure your slicer has an accurate filament diameter configured. Small errors here can produce significant over or under extrusion.

I am guessing that you meant Retract Speed rather than Retract Acceleration. The difference between 40 mm/s and 50mm/s is small. I went as far as 80 mm/s which nophead is evaluating now to see if Marlin can actually achieve that speed.

For me it works but, like a lot of things 3D printing related, individual conditions may vary and produce different results.

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 04/15/2015 05:36AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Odd print problem April 15, 2015 06:06AM |

Registered: 9 years ago Posts: 49 |

The initial cube is printed with the 100 mm calibration and the correct diameter, the result is however massive overextrusion. I will measure what lenght is extruded at 440 but there seem to be a rather large discrepancy. Retract speed ofcourse , sorry.

Edited 1 time(s). Last edit at 04/15/2015 06:55AM by hsbontop.

Edited 1 time(s). Last edit at 04/15/2015 06:55AM by hsbontop.

|

Re: Odd print problem April 15, 2015 08:35AM |

Registered: 10 years ago Posts: 541 |

Hi,

How does your extruder compare to a standard Dibond Mendel90 kit in terms of the gears?

I can imagine that if they differ from the standard 11:39 ratio, and you apply nophead's formula unmodified, there will be an extrusion discrepancy.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

How does your extruder compare to a standard Dibond Mendel90 kit in terms of the gears?

I can imagine that if they differ from the standard 11:39 ratio, and you apply nophead's formula unmodified, there will be an extrusion discrepancy.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Odd print problem April 15, 2015 01:58PM |

Registered: 9 years ago Posts: 49 |

|

Re: Odd print problem April 15, 2015 02:18PM |

Registered: 10 years ago Posts: 541 |

Hi,

If calibration by extruding 100mm of filament gives accurate feed then I can only conclude that the error is being introduced by slicer settings.

I think that regardless of whether you are using 1.75mm or 2.85mm filament, for an extruder calibrated using the 100mm of filament extrude method the different filament diameters should print the same provided the slicer is configured correctly (nophead will correct me if I am wrong).

I would check your slicer settings for a non-unity extrusion multiplier or flowrate multiplier. I cannot believe that for an identical input of filament an E3D hotend puts out more material than a J-Head.

One other possibility, I guess, is that your nozzle diameter is not accurate or is incorrectly set in the slicer. That would account for some discrepancy.

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 04/15/2015 02:25PM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

If calibration by extruding 100mm of filament gives accurate feed then I can only conclude that the error is being introduced by slicer settings.

I think that regardless of whether you are using 1.75mm or 2.85mm filament, for an extruder calibrated using the 100mm of filament extrude method the different filament diameters should print the same provided the slicer is configured correctly (nophead will correct me if I am wrong).

I would check your slicer settings for a non-unity extrusion multiplier or flowrate multiplier. I cannot believe that for an identical input of filament an E3D hotend puts out more material than a J-Head.

One other possibility, I guess, is that your nozzle diameter is not accurate or is incorrectly set in the slicer. That would account for some discrepancy.

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 04/15/2015 02:25PM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Odd print problem April 15, 2015 04:07PM |

Registered: 9 years ago Posts: 49 |

The strange behaviour appears with Slic3r and Skeinforge, Slic3r settings found below.

Noticed Slic3r was running absolute so this was changed to relative and a new print started at E501. Again massive overextrusion...

Thought of the Swedish decimal "," might confuse but I can see no errors in the GCODE generated.

; filament used = 133.7mm (0.3cm3)

; avoid_crossing_perimeters = 0

; bed_size = 200,200

; bed_temperature = 70

; bridge_acceleration = 0

; bridge_fan_speed = 100

; bridge_flow_ratio = 1

; brim_width = 0

; complete_objects = 0

; cooling = 1

; default_acceleration = 0

; disable_fan_first_layers = 1

; duplicate_distance = 6

; end_gcode = M104 S0 ; turn off extruder\nM140 S0 ; bed off\nM107 ; carriage fan off\nG1 X0 Y0 F9000 ; go to back\nG1 Z180 F9000 ; go to top\nM84 ; disable motors\n

; external_perimeters_first = 0

; extruder_clearance_height = 20

; extruder_clearance_radius = 20

; extruder_offset = 0x0

; extrusion_axis = E

; extrusion_multiplier = 1

; fan_always_on = 0

; fan_below_layer_time = 60

; filament_diameter = 1.74

; first_layer_acceleration = 0

; first_layer_bed_temperature = 70

; first_layer_extrusion_width = 200%

; first_layer_speed = 30%

; first_layer_temperature = 190

; g0 = 0

; gcode_arcs = 0

; gcode_comments = 0

; gcode_flavor = reprap

; infill_acceleration = 0

; infill_first = 0

; layer_gcode =

; max_fan_speed = 100

; min_fan_speed = 35

; min_print_speed = 10

; min_skirt_length = 0

; notes =

; nozzle_diameter = 0.4

; only_retract_when_crossing_perimeters = 1

; ooze_prevention = 0

; output_filename_format = [input_filename_base].gcode

; perimeter_acceleration = 0

; post_process =

; print_center = 100,100

; resolution = 0

; retract_before_travel = 2

; retract_layer_change = 1

; retract_length = 0

; retract_length_toolchange = 10

; retract_lift = 0

; retract_restart_extra = 0

; retract_restart_extra_toolchange = 0

; retract_speed = 50

; skirt_distance = 6

; skirt_height = 1

; skirts = 1

; slowdown_below_layer_time = 30

; spiral_vase = 0

; standby_temperature_delta = -5

; start_gcode = M83 ; use relative distances for extrusion\nG28 ; home\nG1 X100 Y10 F9000 ; Go to the middle of the front\nG1 Z0.05 ; close to the bed\nM104 S185 ; set extruder temp\nM190 S70 ; set bed temp & wait\nM109 S185 ; wait for extruder temp\nG92 E0;\nG1 X50 E5 F200 ; make a thick line to prime extruder\nG1 E-1 F1200\nG1Z0.3 ;lift Z

; temperature = 185

; threads = 2

; toolchange_gcode =

; travel_speed = 130

; use_firmware_retraction = 0

; use_relative_e_distances = 1

; vibration_limit = 0

; wipe = 0

; z_offset = 0

; dont_support_bridges = 1

; extrusion_width = 0

; first_layer_height = 0.2

; infill_only_where_needed = 0

; interface_shells = 0

; layer_height = 0.2

; raft_layers = 0

; seam_position = aligned

; support_material = 0

; support_material_angle = 0

; support_material_enforce_layers = 0

; support_material_extruder = 1

; support_material_extrusion_width = 0

; support_material_interface_extruder = 1

; support_material_interface_layers = 3

; support_material_interface_spacing = 0

; support_material_interface_speed = 100%

; support_material_pattern = pillars

; support_material_spacing = 2.5

; support_material_speed = 60

; support_material_threshold = 0

; bottom_solid_layers = 3

; bridge_speed = 60

; external_perimeter_speed = 70%

; extra_perimeters = 1

; fill_angle = 45

; fill_density = 25%

; fill_pattern = honeycomb

; gap_fill_speed = 20

; infill_every_layers = 1

; infill_extruder = 1

; infill_extrusion_width = 0

; infill_speed = 60

; overhangs = 1

; perimeter_extruder = 1

; perimeter_extrusion_width = 0

; perimeter_speed = 30

; perimeters = 3

; small_perimeter_speed = 30

; solid_fill_pattern = rectilinear

; solid_infill_below_area = 70

; solid_infill_every_layers = 0

; solid_infill_extrusion_width = 0

; solid_infill_speed = 60

; thin_walls = 1

; top_infill_extrusion_width = 0

; top_solid_infill_speed = 50

; top_solid_layers = 3

Noticed Slic3r was running absolute so this was changed to relative and a new print started at E501. Again massive overextrusion...

Thought of the Swedish decimal "," might confuse but I can see no errors in the GCODE generated.

; filament used = 133.7mm (0.3cm3)

; avoid_crossing_perimeters = 0

; bed_size = 200,200

; bed_temperature = 70

; bridge_acceleration = 0

; bridge_fan_speed = 100

; bridge_flow_ratio = 1

; brim_width = 0

; complete_objects = 0

; cooling = 1

; default_acceleration = 0

; disable_fan_first_layers = 1

; duplicate_distance = 6

; end_gcode = M104 S0 ; turn off extruder\nM140 S0 ; bed off\nM107 ; carriage fan off\nG1 X0 Y0 F9000 ; go to back\nG1 Z180 F9000 ; go to top\nM84 ; disable motors\n

; external_perimeters_first = 0

; extruder_clearance_height = 20

; extruder_clearance_radius = 20

; extruder_offset = 0x0

; extrusion_axis = E

; extrusion_multiplier = 1

; fan_always_on = 0

; fan_below_layer_time = 60

; filament_diameter = 1.74

; first_layer_acceleration = 0

; first_layer_bed_temperature = 70

; first_layer_extrusion_width = 200%

; first_layer_speed = 30%

; first_layer_temperature = 190

; g0 = 0

; gcode_arcs = 0

; gcode_comments = 0

; gcode_flavor = reprap

; infill_acceleration = 0

; infill_first = 0

; layer_gcode =

; max_fan_speed = 100

; min_fan_speed = 35

; min_print_speed = 10

; min_skirt_length = 0

; notes =

; nozzle_diameter = 0.4

; only_retract_when_crossing_perimeters = 1

; ooze_prevention = 0

; output_filename_format = [input_filename_base].gcode

; perimeter_acceleration = 0

; post_process =

; print_center = 100,100

; resolution = 0

; retract_before_travel = 2

; retract_layer_change = 1

; retract_length = 0

; retract_length_toolchange = 10

; retract_lift = 0

; retract_restart_extra = 0

; retract_restart_extra_toolchange = 0

; retract_speed = 50

; skirt_distance = 6

; skirt_height = 1

; skirts = 1

; slowdown_below_layer_time = 30

; spiral_vase = 0

; standby_temperature_delta = -5

; start_gcode = M83 ; use relative distances for extrusion\nG28 ; home\nG1 X100 Y10 F9000 ; Go to the middle of the front\nG1 Z0.05 ; close to the bed\nM104 S185 ; set extruder temp\nM190 S70 ; set bed temp & wait\nM109 S185 ; wait for extruder temp\nG92 E0;\nG1 X50 E5 F200 ; make a thick line to prime extruder\nG1 E-1 F1200\nG1Z0.3 ;lift Z

; temperature = 185

; threads = 2

; toolchange_gcode =

; travel_speed = 130

; use_firmware_retraction = 0

; use_relative_e_distances = 1

; vibration_limit = 0

; wipe = 0

; z_offset = 0

; dont_support_bridges = 1

; extrusion_width = 0

; first_layer_height = 0.2

; infill_only_where_needed = 0

; interface_shells = 0

; layer_height = 0.2

; raft_layers = 0

; seam_position = aligned

; support_material = 0

; support_material_angle = 0

; support_material_enforce_layers = 0

; support_material_extruder = 1

; support_material_extrusion_width = 0

; support_material_interface_extruder = 1

; support_material_interface_layers = 3

; support_material_interface_spacing = 0

; support_material_interface_speed = 100%

; support_material_pattern = pillars

; support_material_spacing = 2.5

; support_material_speed = 60

; support_material_threshold = 0

; bottom_solid_layers = 3

; bridge_speed = 60

; external_perimeter_speed = 70%

; extra_perimeters = 1

; fill_angle = 45

; fill_density = 25%

; fill_pattern = honeycomb

; gap_fill_speed = 20

; infill_every_layers = 1

; infill_extruder = 1

; infill_extrusion_width = 0

; infill_speed = 60

; overhangs = 1

; perimeter_extruder = 1

; perimeter_extrusion_width = 0

; perimeter_speed = 30

; perimeters = 3

; small_perimeter_speed = 30

; solid_fill_pattern = rectilinear

; solid_infill_below_area = 70

; solid_infill_every_layers = 0

; solid_infill_extrusion_width = 0

; solid_infill_speed = 60

; thin_walls = 1

; top_infill_extrusion_width = 0

; top_solid_infill_speed = 50

; top_solid_layers = 3

|

Re: Odd print problem April 15, 2015 04:15PM |

Registered: 9 years ago Posts: 49 |

|

Re: Odd print problem April 16, 2015 05:02PM |

Registered: 9 years ago Posts: 49 |

|

Re: Odd print problem April 16, 2015 07:20PM |

Admin Registered: 17 years ago Posts: 7,879 |

You can reduce the acceleration to reduce the overshoot at a corner but you shouldn't need to. Perhaps your belts are not tight enough.

In the previous post you said didn't have corner blobs with Slic3r?

The problem is due to the fact that you are using 1.75 filament in an extruder designed for 3mm. It needs to be fed three times faster with 1/3 of the force so you don't need the gears. With them your retraction speed is limited. A direct drive extruder is better with 1.75mm.

As I suspected there was a bug in Marlin that limits the maximum extruder acceleration that works properly to 3500, see [github.com]. I just fixed that and it does allow a faster retract but I also found the jerk setting for the extruder is ignored if the XY jerk is smaller I will fix that tomorrow and find some better retract settings that might help.

[www.hydraraptor.blogspot.com]

In the previous post you said didn't have corner blobs with Slic3r?

The problem is due to the fact that you are using 1.75 filament in an extruder designed for 3mm. It needs to be fed three times faster with 1/3 of the force so you don't need the gears. With them your retraction speed is limited. A direct drive extruder is better with 1.75mm.

As I suspected there was a bug in Marlin that limits the maximum extruder acceleration that works properly to 3500, see [github.com]. I just fixed that and it does allow a faster retract but I also found the jerk setting for the extruder is ignored if the XY jerk is smaller I will fix that tomorrow and find some better retract settings that might help.

[www.hydraraptor.blogspot.com]

|

Re: Odd print problem April 17, 2015 04:36AM |

Registered: 9 years ago Posts: 49 |

The belts are like piano wire, so I do not think this is the problem (result was not improved when tightened), slic3r were running at lower speed and when lowering in Skeinforge the result improved. Visually there seem to be a slight twitch in the wrong direction when accelerating from zero on XY, I'll see if this can be caught on camera. It is almost as if the printer tries to create a sharp corner by going a few microns the wrong way (but there is nothing supporting this in the gcode).

I'll have a look on replacing the extruder, but for now the quality is astonishing! The small blobs at the start of each layer is less of a problem in Slic3r.

I'll have a look on replacing the extruder, but for now the quality is astonishing! The small blobs at the start of each layer is less of a problem in Slic3r.

|

Re: Odd print problem April 17, 2015 07:44AM |

Admin Registered: 17 years ago Posts: 7,879 |

If you do infill faster than the outline you will get a blob unless the retraction distance is made proportional to speed. To keep things simple I do infill and outlines at the same speed.

Also the faster you extrude, the higher the pressure needs to be at the end of the fast forward. As it ramps up from zero to that pressure the amount of material extruded on the spot should be just enough to make a cylinder with diameter equal to the width. That is constant regardless of speed so the for higher speeds the fast forward needs to faster to allow it to get to a higher pressure without extruding any more.

[www.hydraraptor.blogspot.com]

Also the faster you extrude, the higher the pressure needs to be at the end of the fast forward. As it ramps up from zero to that pressure the amount of material extruded on the spot should be just enough to make a cylinder with diameter equal to the width. That is constant regardless of speed so the for higher speeds the fast forward needs to faster to allow it to get to a higher pressure without extruding any more.

[www.hydraraptor.blogspot.com]

|

Re: Odd print problem April 17, 2015 03:08PM |

Registered: 9 years ago Posts: 49 |

Looked at the last print again and realised the problem now is not blobs but dimples on this single wall print.

Another look at the original flow single wall print and this also had dimples not blobs. The infill prints has blobs so a new go with the infill print with the dimple setting is the next step.

Another look at the original flow single wall print and this also had dimples not blobs. The infill prints has blobs so a new go with the infill print with the dimple setting is the next step.

|

Re: Odd print problem April 24, 2015 05:30AM |

Registered: 9 years ago Posts: 49 |

I have tried changing speed,acceleration and jerk but still the overshot persists. There seem to be no play in the system, might this be due to the low gearing on the extruder when using 1.75mm filament? Figured this might be worth a try so I have configured a set of 1.17 ratio gears to match the 3=>1.75mm change. Also the nophead stepper update forced lower retraction distance as single wall otherwise showed gaps at layer change.

|

Re: Odd print problem April 24, 2015 08:16AM |

Admin Registered: 17 years ago Posts: 7,879 |

Is it overshoot, or is it too much plastic at the corner due to the axis slowing down and the filament flow rate lagging behind?

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Odd print problem April 24, 2015 08:32AM |

Admin Registered: 17 years ago Posts: 7,879 |

The retraction distance should be just enough to stop ooze on long travels. You can have the retract speed too fast though, so it doesn't have time to flow from the nozzle at the start.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Odd print problem April 24, 2015 08:52AM |

Registered: 9 years ago Posts: 49 |

The second is my main theory as slowing down and deaccelerating does not solve the problem, I am a novice at gitfu but should this not be something that can be changed in the fw?Quote

nophead

Is it overshoot, or is it too much plastic at the corner due to the axis slowing down and the filament flow rate lagging behind?

Sorry, only registered users may post in this forum.