Frustrating lack of a fan duct: "Sturdy" + E3D-V6

Posted by Rich K.

|

Frustrating lack of a fan duct: "Sturdy" + E3D-V6 March 31, 2015 08:28PM |

Registered: 9 years ago Posts: 254 |

I really like my E3D-V6 hotend. It produces some of the best ABS prints I have ever made, and does not seem to have the problems I had with my J-head Mk. V-BV.

Only problem is, I lack a fan duct for cooling PLA prints.

The problem is, I built the "Sturdy" version of the Mendel90, and there is a dearth of accessories available. The LM10UU bearings mean that (1) the slots/holes for mounting any ducts to the X carriage need to be 20mm apart (center to center), and (2) the duct needs to be longer in order for the hotend to be centered properly in the opening of the duct, so that it does not get too close and melt the duct. Tried this one:

E3D-V6 fan duct for 60mm fan

The designer made the holes the right distance apart (though I had to cut one corner out to clear the belt tensioner), but he said it would be hard to move the opening 7mm further back.

I also tried this one:

Flexible "hose" fan duct

Can't get the "hose" sections to snap together and articulate properly without breaking, though.

I don't know how to use any CAD software - been beating my head against a wall with OpenSCAD, 123D Design, and FreeCAD - so I can't design my own.

I am REALLY getting frustrated.

Anybody have any helpful suggestions???

Edited 2 time(s). Last edit at 03/31/2015 08:31PM by Rich K..

Only problem is, I lack a fan duct for cooling PLA prints.

The problem is, I built the "Sturdy" version of the Mendel90, and there is a dearth of accessories available. The LM10UU bearings mean that (1) the slots/holes for mounting any ducts to the X carriage need to be 20mm apart (center to center), and (2) the duct needs to be longer in order for the hotend to be centered properly in the opening of the duct, so that it does not get too close and melt the duct. Tried this one:

E3D-V6 fan duct for 60mm fan

The designer made the holes the right distance apart (though I had to cut one corner out to clear the belt tensioner), but he said it would be hard to move the opening 7mm further back.

I also tried this one:

Flexible "hose" fan duct

Can't get the "hose" sections to snap together and articulate properly without breaking, though.

I don't know how to use any CAD software - been beating my head against a wall with OpenSCAD, 123D Design, and FreeCAD - so I can't design my own.

I am REALLY getting frustrated.

Anybody have any helpful suggestions???

Edited 2 time(s). Last edit at 03/31/2015 08:31PM by Rich K..

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 01, 2015 07:22AM |

Registered: 10 years ago Posts: 541 |

Hi,

Adding the E3D hotends to a Mendel90 is not trivial and I understand your pain.

In theory it is just a matter of accommodating the hotend and its cooling fan but in practice there is an added complication if you wish to provide cooling for the printed part.

The E3D fan blows across the heasink fins and exhausts opposite the fan itself. I could imagine some clever ducting to move this exhausted air out of the way but you cannot consider using that exhaust flow as cooling because it will be always on.

This dictates the provision of another fan to give the original Mendel90 ducted cooling for the printed object under GCode control.

Two fans and the mounting modifications required for the E3D hotend are not trivial given the amount of space available on the X carriage.

It is an interesting problem and one I would like to tackle myself at some time but I have a desire to keep my Mendel90 in original condition as it prints so well and I would be relying on it to print the parts for any new printer I may build.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Adding the E3D hotends to a Mendel90 is not trivial and I understand your pain.

In theory it is just a matter of accommodating the hotend and its cooling fan but in practice there is an added complication if you wish to provide cooling for the printed part.

The E3D fan blows across the heasink fins and exhausts opposite the fan itself. I could imagine some clever ducting to move this exhausted air out of the way but you cannot consider using that exhaust flow as cooling because it will be always on.

This dictates the provision of another fan to give the original Mendel90 ducted cooling for the printed object under GCode control.

Two fans and the mounting modifications required for the E3D hotend are not trivial given the amount of space available on the X carriage.

It is an interesting problem and one I would like to tackle myself at some time but I have a desire to keep my Mendel90 in original condition as it prints so well and I would be relying on it to print the parts for any new printer I may build.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 01, 2015 10:58AM |

Registered: 10 years ago Posts: 439 |

Openscad does appear a bit daunting at first but I found a good tutorial at

[www.makerbot.com]

[www.makerbot.com]

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 01, 2015 12:19PM |

Registered: 9 years ago Posts: 73 |

Since I am doing my first steps with 3D Modeling myself, I too understand your problems. I had a look at OpenSCAD, FreeCAD too and watched some video tutorial, but at least for now the effort of "programming" models seems to high. That´s why I made my first models with Sketchup, but that is very limited if you want to make shapes with irregular faces. That´s why I tried PTC Creo Elements Direct Modeling. They are both for free (at least there are free versions of it) and there are tons of tutorials to learn them.

I´d recommend PTC Creo for beginners....

Jens

I´d recommend PTC Creo for beginners....

Jens

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 01, 2015 04:51PM |

Registered: 10 years ago Posts: 541 |

Hi,

If you want to work with nophead's design directly then OpenSCAD is the only choice.

Beyond this I use FreeCAD because it provides some usefulness in modifying the Mendel90 component parts by:

These abilities assist in not needing to "go back to square one" which you would need to do in some other CAD applications.

You can start easily in FreeCAD by creating objects using simple shape objects then move on to mapping 2D sketches onto objects to create pockets and extrusions. Finally you can go beyond tweaking object's parameters to scripting FreeCAD using its Python API which is very powerful.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

If you want to work with nophead's design directly then OpenSCAD is the only choice.

Beyond this I use FreeCAD because it provides some usefulness in modifying the Mendel90 component parts by:

- Being able to import OpenSCAD format CSG files

- Being able to import STL files

These abilities assist in not needing to "go back to square one" which you would need to do in some other CAD applications.

You can start easily in FreeCAD by creating objects using simple shape objects then move on to mapping 2D sketches onto objects to create pockets and extrusions. Finally you can go beyond tweaking object's parameters to scripting FreeCAD using its Python API which is very powerful.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 01, 2015 06:20PM |

Registered: 9 years ago Posts: 254 |

I'm the sort of person who learns best when there is someone actually there with me showing me how to do things. I have a book that is about how to use OpenSCAD and another one about how to use 123D Design, and I still can't make heads or tails out of either one. Unfortunately, I don't know anyone near me who knows how to use any of the free 3D CAD software available...

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 01, 2015 07:44PM |

Admin Registered: 17 years ago Posts: 7,879 |

There is an un-merged pull request for an OpenScad E3D fan duct. That should adjust itself for the sturdy. If you fork Mendel90 on github and merge it then it might give you what you want, but github is not the most straightforward thing to use, else I would have merged it myself but I know that will cause me grief because it clashes with un-merged changes of my own.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 01, 2015 07:53PM |

Registered: 9 years ago Posts: 254 |

Ummm...sounds good, but the process sounds like Greek to meQuote

nophead

There is an un-merged pull request for an OpenScad E3D fan duct. That should adjust itself for the sturdy. If you fork Mendel90 on github and merge it then it might give you what you want, but github is not the most straightforward thing to use, else I would have merged it myself but I know that will cause me grief because it clashes with un-merged changes of my own.

. I can do computers well enough to navigate the web, send emails, and download files. ANy way you can break that down into easy steps, explanation-wise?

. I can do computers well enough to navigate the web, send emails, and download files. ANy way you can break that down into easy steps, explanation-wise?

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 02, 2015 04:20AM |

Registered: 9 years ago Posts: 73 |

Hehe,.. thank god it isn´t only me... concerning OpenSCAD, I tried a little as well, but I didn´t even manage to open one of nopheads files in there. I downloaded the whole Mendel90 thing from github and tried to open the wades block... first of all, there is no matching file... there is only wade.scad and if I try to open (render) that, my pc is working for ages and in the end I get the whole assembly.

Is it possible to export parts of that assembly into other formats? (Except STL, those are already available and kinda useless for tweaking).

I found out that it would be possible to export to CSG from OpenSCAD, then import/open in FreeCAD and then Export into STEP Format, which is then usable by PTC Creo.

But that still leaves the question, how do I export parts of an assembly from OpenSCAD? From dabbling with the process I think it is necessary to render first, before you can export into CSG, is that really necessary (takes a very long time for larger assembly)?

Edited 2 time(s). Last edit at 04/02/2015 05:05AM by D4RK1.

Is it possible to export parts of that assembly into other formats? (Except STL, those are already available and kinda useless for tweaking).

I found out that it would be possible to export to CSG from OpenSCAD, then import/open in FreeCAD and then Export into STEP Format, which is then usable by PTC Creo.

But that still leaves the question, how do I export parts of an assembly from OpenSCAD? From dabbling with the process I think it is necessary to render first, before you can export into CSG, is that really necessary (takes a very long time for larger assembly)?

Edited 2 time(s). Last edit at 04/02/2015 05:05AM by D4RK1.

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 02, 2015 08:07AM |

Admin Registered: 17 years ago Posts: 7,879 |

The F5 preview only generates pixels on the screen so all you can export is a picture. You need to change the lines at the bottom of the file to select the part you want and do F6 to actually compute the geometry. You can then export it as an STL or CSG.

Don't do F6 with the assembly selected as it will take ages and possibly use all the memory on your machine and crash. It isn't useful as you would have one part representing the whole assembly.

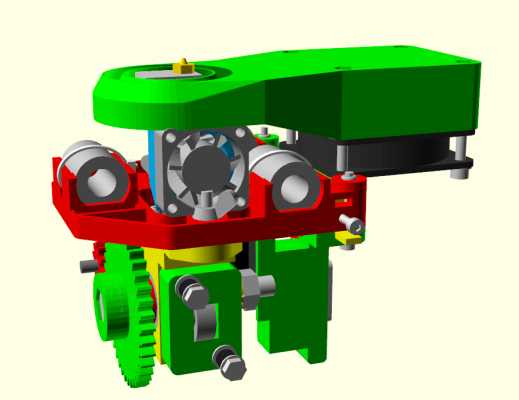

If everybody took the time to learn OpenScad then all the additions to Mendel90 would work on the sturdy or the dibond. When pulled into another CAD system they are fixed to one version. In this case philfifi has kindly done all the work for E3D version of Wade's and fan duct. I just haven't got time at the moment to merge it. [github.com]

I can probably make a branch and merge into that but I will need to read up on it as I find Git and Github very difficult.

[www.hydraraptor.blogspot.com]

Don't do F6 with the assembly selected as it will take ages and possibly use all the memory on your machine and crash. It isn't useful as you would have one part representing the whole assembly.

If everybody took the time to learn OpenScad then all the additions to Mendel90 would work on the sturdy or the dibond. When pulled into another CAD system they are fixed to one version. In this case philfifi has kindly done all the work for E3D version of Wade's and fan duct. I just haven't got time at the moment to merge it. [github.com]

I can probably make a branch and merge into that but I will need to read up on it as I find Git and Github very difficult.

[www.hydraraptor.blogspot.com]

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 02, 2015 10:09AM |

Registered: 9 years ago Posts: 73 |

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 02, 2015 10:55AM |

Registered: 11 years ago Posts: 369 |

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 02, 2015 11:48AM |

Registered: 9 years ago Posts: 73 |

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 02, 2015 01:30PM |

Registered: 9 years ago Posts: 73 |

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 02, 2015 01:37PM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes all the files show assembly views by default. You can explode them by setting $exploded =1; at the top of the file.

There is also a tree of if statements to show the parts laid out for printing in various combinations. To show a single part just add

!part_name_stl(); at the end. E.g.

!wades_block_stl();

will show the block on its own.

[www.hydraraptor.blogspot.com]

There is also a tree of if statements to show the parts laid out for printing in various combinations. To show a single part just add

!part_name_stl(); at the end. E.g.

!wades_block_stl();

will show the block on its own.

[www.hydraraptor.blogspot.com]

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 02, 2015 02:09PM |

Registered: 9 years ago Posts: 73 |

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 02, 2015 03:33PM |

Admin Registered: 17 years ago Posts: 7,879 |

I have successfully merged philfifi's work into an E3D branch in my local repository. There seems to a clash between the fan and the duct but I think that is can probably be resolved in reality by repositioning one or the other. It also looks like the wingnut needs to removed and the screw turned the other way round.

I will upload the branch to github when I have finished generating the STL files.

[www.hydraraptor.blogspot.com]

I will upload the branch to github when I have finished generating the STL files.

[www.hydraraptor.blogspot.com]

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 02, 2015 07:10PM |

Registered: 9 years ago Posts: 254 |

Thanks! Is that version compatible with the "sturdy", then - i.e., is long enough to make up for the added width of the LM10UU bearings?

I'm not having any trouble with my wing nuts/screws working with my E3D fan duct. The screw is long enough that it JUST touches the top of the duct. I have to remove the duct to remove the wing-nut, but that's okay because the duct has to come off to remove the extruder assembly from the X carriage. I'm using a modified Wade's block I found on Thingiverse that has a shallower hole in the bottom than the original Mendel90 version, to allow for the thinner top flange on the E3D.

I'm not having any trouble with my wing nuts/screws working with my E3D fan duct. The screw is long enough that it JUST touches the top of the duct. I have to remove the duct to remove the wing-nut, but that's okay because the duct has to come off to remove the extruder assembly from the X carriage. I'm using a modified Wade's block I found on Thingiverse that has a shallower hole in the bottom than the original Mendel90 version, to allow for the thinner top flange on the E3D.

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 03, 2015 04:58AM |

Admin Registered: 17 years ago Posts: 7,879 |

It's written in OpenScad, like the original, so everything is parametric and adjusts itself to suit the rest of the machine. I generates a new Wade's block that doesn't have the extension on the bottom, so it loses less Z height. That means there is no room for the wingnut as you can see above. The carriage has nut traps so you can put the hex screw head in the bottom and a washer and nut on the top.

There are a few bugs I am trying to iron out at the moment.

[www.hydraraptor.blogspot.com]

There are a few bugs I am trying to iron out at the moment.

[www.hydraraptor.blogspot.com]

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 03, 2015 10:10AM |

Registered: 9 years ago Posts: 254 |

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 03, 2015 10:51AM |

Registered: 9 years ago Posts: 73 |

sure... but you were the one who used another Hotend  Feel free to design a more convenient solution ^^

Feel free to design a more convenient solution ^^

But I think it is manageable, you have to access the nut from above so you can use a screwdriver with a matching bit or a wrench... compared to the whole process of bed leveling, the effort to remove the hotend should be negligible.

Edited 1 time(s). Last edit at 04/03/2015 10:55AM by D4RK1.

Feel free to design a more convenient solution ^^

Feel free to design a more convenient solution ^^But I think it is manageable, you have to access the nut from above so you can use a screwdriver with a matching bit or a wrench... compared to the whole process of bed leveling, the effort to remove the hotend should be negligible.

Edited 1 time(s). Last edit at 04/03/2015 10:55AM by D4RK1.

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 03, 2015 02:03PM |

Registered: 9 years ago Posts: 254 |

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 03, 2015 03:58PM |

Registered: 9 years ago Posts: 44 |

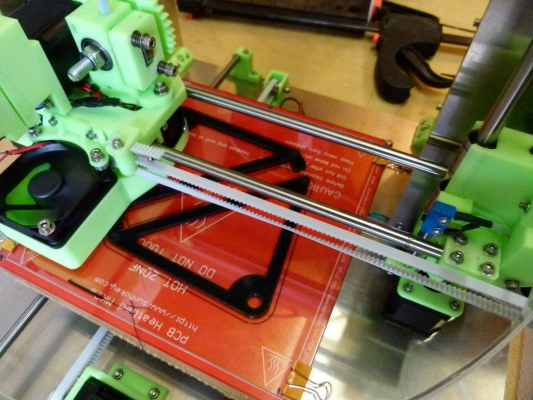

I do have the e3d v6 in use on the Dibond with this: Fan Duct e3d

There are two versions 25mm and 31mm high. Because I did not know before how it would work with the printer my version is the 25mm with some washers to correct the height to 31mm again. This duct is fixed like the new github one on the origin mount. So it should fit on the sturdy version also.

As you can see on the picture there is no chance to continue with the wing nut. In any case the screw has to be mounted upside down and secured due to space with a normal nut. The other side still works with the wing nut.

There are two versions 25mm and 31mm high. Because I did not know before how it would work with the printer my version is the 25mm with some washers to correct the height to 31mm again. This duct is fixed like the new github one on the origin mount. So it should fit on the sturdy version also.

As you can see on the picture there is no chance to continue with the wing nut. In any case the screw has to be mounted upside down and secured due to space with a normal nut. The other side still works with the wing nut.

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 03, 2015 04:11PM |

Registered: 9 years ago Posts: 254 |

Quote

kreidler

I do have the e3d v6 in use on the Dibond with this: Fan Duct e3d

There are two versions 25mm and 31mm high. Because I did not know before how it would work with the printer my version is the 25mm with some washers to correct the height to 31mm again. This duct is fixed like the new github one on the origin mount. So it should fit on the sturdy version also.

As you can see on the picture there is no chance to continue with the wing nut. In any case the screw has to be mounted upside down and secured due to space with a normal nut. The other side still works with the wing nut.

The big problem isn't so much using the original mount with this one, it's the fact that it needs to be longer in the "sturdy" version because the LM10UU bearings are larger in diameter. Otherwise, the hotend isn't centered in the opening front-to-back, and ends up too close to the back of the opening if you try to use a "dibond" length duct with a "sturdy" x-carriage, and the radiated heat makes the edge of the duct sag and eventually touch the heater block of the hotend. I had this problem with a Chinese J-head clone that had a heater block the same size as the one on the E3D.

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 03, 2015 08:39PM |

Admin Registered: 17 years ago Posts: 7,879 |

Just pushed an E3D branch to Github. Select that branch and then either download the zip or navigate to the STLs and download them individually.

The wades block, fan duct and fan bracket are all different. As the machine is built around the extruder the knock on effect is to make it slightly taller, which affects the sheets and the spool holder slightly. Those changes are only relevant if you are building a new machine from scratch with an E3D hot end. Otherwise you lose a few mm from Z. Only 3mm I think with V6 and the new wades block that loses the extension piece that is there for J-Head MK5.

[www.hydraraptor.blogspot.com]

The wades block, fan duct and fan bracket are all different. As the machine is built around the extruder the knock on effect is to make it slightly taller, which affects the sheets and the spool holder slightly. Those changes are only relevant if you are building a new machine from scratch with an E3D hot end. Otherwise you lose a few mm from Z. Only 3mm I think with V6 and the new wades block that loses the extension piece that is there for J-Head MK5.

[www.hydraraptor.blogspot.com]

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 03, 2015 08:58PM |

Registered: 9 years ago Posts: 254 |

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 04, 2015 06:48AM |

Registered: 9 years ago Posts: 44 |

Yepp, I forgot the 4mm more in diameter for the 10mm bearing ... parametric design is very good on one hand but can bring you to real fustration alsoQuote

Rich K.

The big problem isn't so much using the original mount with this one, it's the fact that it needs to be longer in the "sturdy" version because the LM10UU bearings are larger in diameter. Otherwise, the hotend isn't centered in the opening front-to-back, and ends up too close to the back of the opening if you try to use a "dibond" length duct with a "sturdy" x-carriage, and the radiated heat makes the edge of the duct sag and eventually touch the heater block of the hotend. I had this problem with a Chinese J-head clone that had a heater block the same size as the one on the E3D.

I made the heatsink fan wiring deattachable with some small straight grids. The fan will not go through the hole in the x carriage and has to be dismounted first.

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 04, 2015 07:54AM |

Registered: 10 years ago Posts: 541 |

Hi,

You might be interested in what Ivor O'Shea has done with fitting an E3D V6 to a Mendel90 at numbersixreprap.blogspot.co.uk.

He has addressed modifications to Wade's block and X-carriage to permit easy disassembly and convenient fan ducting.

This is not intended to detract from nophead's excellent work in merging changes into his repository. I just came across Ivor's work yesterday.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

You might be interested in what Ivor O'Shea has done with fitting an E3D V6 to a Mendel90 at numbersixreprap.blogspot.co.uk.

He has addressed modifications to Wade's block and X-carriage to permit easy disassembly and convenient fan ducting.

This is not intended to detract from nophead's excellent work in merging changes into his repository. I just came across Ivor's work yesterday.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 04, 2015 12:18PM |

Admin Registered: 17 years ago Posts: 7,879 |

Again it is all not parametric though, so only works for whichever version Ivor built.

OpenScad is the DNA of RepRap. I think anything that doesn't use it is doomed as an evolutionary dead end, however good it might be.

[www.hydraraptor.blogspot.com]

OpenScad is the DNA of RepRap. I think anything that doesn't use it is doomed as an evolutionary dead end, however good it might be.

[www.hydraraptor.blogspot.com]

|

Re: Frustrating lack of a fan duct: "Sturdy" + E3D-V6 April 04, 2015 12:26PM |

Registered: 10 years ago Posts: 541 |

Quote

nophead

Again it is all not parametric though, so only works for whichever version Ivor built.

OpenScad is the DNA of RepRap. I think anything that doesn't use it is doomed as an evolutionary dead end, however good it might be.

Agreed, I was using Ivor's work as an example of an improvement to simple mounting of the E3D hotend into the standard Wade's block viz:

- It uses a clamping arrangement to hold the hotend and reduce height loss.

- The X-carriage is enlarged to allow removal of the hotend with fan attached.

- The use of the wing-nut is retained.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Sorry, only registered users may post in this forum.