Z lead screw mounting?

Posted by dawa

|

Z lead screw mounting? June 07, 2015 11:47AM |

Registered: 10 years ago Posts: 68 |

Hi,

I got my mendel90 kit from nophead in Nov 2013.

Now I am beginning to wonder if I did not mount the Z lead screws good enough.

I think I have some Z wobble, although I may have confused it with extruder/temperature problems.

Anyway, I have some unwanted waves along the Z axis on my prints, about 1 mm periodicity (haven't checked this carefully).

Here is a picture: (sliced with skeinforge, ryan marks profile 0.3mm, 100% infill, 50mm/sec, 195 celcius, esun white PLA, maybe bad quality?)

As I understand it, the idea with the rubber tubes in the Z couplings is to prevent vibrations from being transmitted from the Z lead screws to the Z smooth rods. Right?

But in the intructions manual nothing is mentioned about how hard one should tighten the couplings, as far as I can see.

I tightened them as much as possible (without breaking the couplings), but later I have observed that the z lead screws aren't really aligned/centered with respect to the motor shafts.

And I dont see that the construction helps to make them centered.

But, if they were more loosely connected via the rubber tubes, they should kind of "adapt" so that the z threaded rod x-y movement doesnt apply any harmful force on the Z smooth rods.

And so, Z wobble is avoided.

Yesterday I tried to loosen the coupling screws a bit, but nothing changed. Maybe I'll have to disassemble them and put together again.

Have I understood it right?

Maybe this should be explained in future versions of the manual, so people get an idea what to pay attention to during the assembly?

Another (less likely) hypothesis is that my X/Y belts are too loose. They "should play a low note when plucked", but how low? What frequency? Is there any other way to estimate it? Sorry if I take things too literally ...

Best regards,

David

I got my mendel90 kit from nophead in Nov 2013.

Now I am beginning to wonder if I did not mount the Z lead screws good enough.

I think I have some Z wobble, although I may have confused it with extruder/temperature problems.

Anyway, I have some unwanted waves along the Z axis on my prints, about 1 mm periodicity (haven't checked this carefully).

Here is a picture: (sliced with skeinforge, ryan marks profile 0.3mm, 100% infill, 50mm/sec, 195 celcius, esun white PLA, maybe bad quality?)

As I understand it, the idea with the rubber tubes in the Z couplings is to prevent vibrations from being transmitted from the Z lead screws to the Z smooth rods. Right?

But in the intructions manual nothing is mentioned about how hard one should tighten the couplings, as far as I can see.

I tightened them as much as possible (without breaking the couplings), but later I have observed that the z lead screws aren't really aligned/centered with respect to the motor shafts.

And I dont see that the construction helps to make them centered.

But, if they were more loosely connected via the rubber tubes, they should kind of "adapt" so that the z threaded rod x-y movement doesnt apply any harmful force on the Z smooth rods.

And so, Z wobble is avoided.

Yesterday I tried to loosen the coupling screws a bit, but nothing changed. Maybe I'll have to disassemble them and put together again.

Have I understood it right?

Maybe this should be explained in future versions of the manual, so people get an idea what to pay attention to during the assembly?

Another (less likely) hypothesis is that my X/Y belts are too loose. They "should play a low note when plucked", but how low? What frequency? Is there any other way to estimate it? Sorry if I take things too literally ...

Best regards,

David

|

Re: Z lead screw mounting? June 07, 2015 02:18PM |

Admin Registered: 17 years ago Posts: 7,879 |

The screws should be fully tightened to fully close the z couplings. That should give the correct amount of squeeze on the neoprene tubes and grip on the screw. It is important that they well centred though, which they should be as they are symmetrical and the neoprene bore is well centred.

Perhaps you could try loosening them and re-tightening them to get them centred better.

A belt problem would not give periodic Z errors at 1mm intervals.

[www.hydraraptor.blogspot.com]

Perhaps you could try loosening them and re-tightening them to get them centred better.

A belt problem would not give periodic Z errors at 1mm intervals.

[www.hydraraptor.blogspot.com]

|

Re: Z lead screw mounting? June 21, 2015 10:14AM |

Registered: 10 years ago Posts: 68 |

Hi, thank for your reply, nophead.

I read in some forum that there was an intention behind the rubber tubes and that the brass nuts should not be too tight (similar for prusa i3), and there I got the impression that the "slack" should prevent the wobble to propagate to the print result. But you didnt comment on this, and I guess from that, you dont find it important, or maybe even not true. If the source of wobble is eliminated, then of course that question loses its significance.

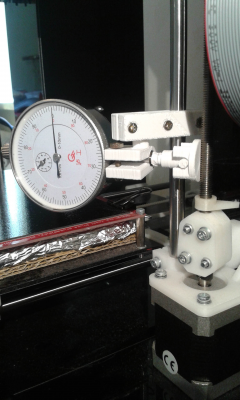

Anyway, I printed (and designed :-) ) this holder to measure the wobble:

The gauge shows a deviation of 0.125 mm between max and min, so it is not centered.

I tried to loosen the clamps a bit, and tried to twist it with hand force, but yet sith no success.

Ill try to open them more and tighten only some srews and see how the gauge reacts ...

Maybe a clamp with x-y adjustment screws would be an improvment?

One could just drill holes near the top the clamps orthogonally to each other, and screw in , like, m2 screws until it is centered. Maybe I'll try...

BR,

David

I read in some forum that there was an intention behind the rubber tubes and that the brass nuts should not be too tight (similar for prusa i3), and there I got the impression that the "slack" should prevent the wobble to propagate to the print result. But you didnt comment on this, and I guess from that, you dont find it important, or maybe even not true. If the source of wobble is eliminated, then of course that question loses its significance.

Anyway, I printed (and designed :-) ) this holder to measure the wobble:

The gauge shows a deviation of 0.125 mm between max and min, so it is not centered.

I tried to loosen the clamps a bit, and tried to twist it with hand force, but yet sith no success.

Ill try to open them more and tighten only some srews and see how the gauge reacts ...

Maybe a clamp with x-y adjustment screws would be an improvment?

One could just drill holes near the top the clamps orthogonally to each other, and screw in , like, m2 screws until it is centered. Maybe I'll try...

BR,

David

|

Re: Z lead screw mounting? June 21, 2015 11:13AM |

Registered: 10 years ago Posts: 68 |

|

Re: Z lead screw mounting? June 21, 2015 12:09PM |

Admin Registered: 17 years ago Posts: 7,879 |

With the clamp fully closed the rubber still allows the studding to lean a little if it needs to if it is slightly bent and constrained at the nut. I.e. it can't put much sideways force on the nut so the Z rod will hold the X axis steady.

0.125mm eccentricity is tiny as the change in angle of the studding when constrained by the nut about 80mm away will be tiny. I don't think it needs to be centred better than that. The machine that I print a lot of the parts on has several mm of wobble at the top and still prints fine.

Edited 1 time(s). Last edit at 06/21/2015 12:10PM by nophead.

[www.hydraraptor.blogspot.com]

0.125mm eccentricity is tiny as the change in angle of the studding when constrained by the nut about 80mm away will be tiny. I don't think it needs to be centred better than that. The machine that I print a lot of the parts on has several mm of wobble at the top and still prints fine.

Edited 1 time(s). Last edit at 06/21/2015 12:10PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Z lead screw mounting? June 21, 2015 01:33PM |

Registered: 10 years ago Posts: 541 |

Hi,

I found my Z-screws were wobbling at the top and devised the following method to reduce/eliminate this when I had to replace my Z-couplers:

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

I found my Z-screws were wobbling at the top and devised the following method to reduce/eliminate this when I had to replace my Z-couplers:

- Move the Z-axis so that the nuts are at half the vertical height

- Loosen/replace the Z-couplers but do not full tighten the screws

- Loosen the Z-motor mount screws

- Loosen the Z-rod upper clamp screws

- Tighten the Z-couplers after checking orientation of the shaft slot

- Tighten the Z-motor mount screws carefully in a diagonal manner e.g. top-left, bottom-right, top-right, bottom-left

- Tighten the Z-rod upper clamp screws carefully to avoid twisting the clamp

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Z lead screw mounting? June 21, 2015 05:24PM |

Registered: 10 years ago Posts: 68 |

Hi, thanks!

Ok, it is good to know that my 0.125 mm eccentricity is not an issue. I actually reduced it to 0.09 mm.

So, maybe either I have inconcistent extrusion, or I have too tightly fitted brass nuts.

The defect in my prints is visible in the picture I attached here.

I might try to remount my Z couplings later...

BR,

David

Ok, it is good to know that my 0.125 mm eccentricity is not an issue. I actually reduced it to 0.09 mm.

So, maybe either I have inconcistent extrusion, or I have too tightly fitted brass nuts.

The defect in my prints is visible in the picture I attached here.

I might try to remount my Z couplings later...

BR,

David

|

Re: Z lead screw mounting? June 21, 2015 06:33PM |

Admin Registered: 17 years ago Posts: 7,879 |

The brass nuts should be a tight fit in the sockets. If not put some tape around them. I think if they are loose they tilt as the studding rotates and that does cause banding. However, yours is the worst case I have seen on a Mendel90 so something is very wrong.

Make sure both ends are resting on their nuts. Sometimes people level the bed and leave one end floating. The solution to getting it level but still resting on both nuts is to re-align the z bars.

[www.hydraraptor.blogspot.com]

Make sure both ends are resting on their nuts. Sometimes people level the bed and leave one end floating. The solution to getting it level but still resting on both nuts is to re-align the z bars.

[www.hydraraptor.blogspot.com]

|

Re: Z lead screw mounting? June 21, 2015 07:05PM |

Registered: 10 years ago Posts: 68 |

Sorry, the English fails me:

I don't understand exactly what you mean by

"the studding rotates".

The brass nuts have some tape around them, but I don't know if it is enough.

I don't think I left any end "floating" when I levelled the bed.

I tried to follow the manual as close as possible. (It was over a year ago)

Realign the Z bars--you mean the smooth z rods?

Best regards,

David

Edited 1 time(s). Last edit at 06/21/2015 07:08PM by dawa.

I don't understand exactly what you mean by

"the studding rotates".

The brass nuts have some tape around them, but I don't know if it is enough.

I don't think I left any end "floating" when I levelled the bed.

I tried to follow the manual as close as possible. (It was over a year ago)

Realign the Z bars--you mean the smooth z rods?

Best regards,

David

Edited 1 time(s). Last edit at 06/21/2015 07:08PM by dawa.

|

Re: Z lead screw mounting? June 22, 2015 03:46AM |

Admin Registered: 17 years ago Posts: 7,879 |

Sorry "studding" is another name for threaded rod and yes the "z bars" are the smooth rods.

Has the machine always printed like this or did it develop the fault?

[www.hydraraptor.blogspot.com]

Has the machine always printed like this or did it develop the fault?

[www.hydraraptor.blogspot.com]

|

Re: Z lead screw mounting? June 22, 2015 05:51AM |

Registered: 10 years ago Posts: 68 |

Hi,

Ok, I see.

I think it has developed. I have seen it more or less when I

printed tall straight things like tubes and cylinders.

But it became worse. I thought for a while it was because I hadn't tuned

the printer for the new filament.

Now I tried to tighten the extruder idler clamp so

that the clamp screws are 1 mm on the other side of the wades block.

and I raised the temp to 200.

I'll see if this makes any difference ...

BY

David

Ok, I see.

I think it has developed. I have seen it more or less when I

printed tall straight things like tubes and cylinders.

But it became worse. I thought for a while it was because I hadn't tuned

the printer for the new filament.

Now I tried to tighten the extruder idler clamp so

that the clamp screws are 1 mm on the other side of the wades block.

and I raised the temp to 200.

I'll see if this makes any difference ...

BY

David

|

Re: Z lead screw mounting? June 22, 2015 08:54AM |

Registered: 10 years ago Posts: 68 |

Hello,

I printed a hollow cube and cylinder with 2mm walls, 30 mm high, after having tightened the extruder clamp and recalibrated e_steps_per_mm.

The print in the pictures is sliced with skeinforge, ryan marks profile 0.3 mm PLA, 200 celcius, 50mm/s. 0.07 infill perimeter overlap, 100% infill solidity (grid rectangular).

In banding1, banding3, and banding4, one can see that the plastic is unevenly distributed w.r.t. the Z axis. The "banding" is perhaps a bit less than before.

In banding2 I see that filament is kind of missing here and there. This is relatively new, and I have no idea what it somes from. Perhaps extrusion problems.

A while ago I had a jammed hotend that I cleaned. I htought I got ris of the obstacles, but this may be an indication that something is wrong.

It is hard to be methodical, there are so many parameters that seem to have impact on the output.

Sorry if I learn too slowly...

(but I still enjoy the printer very much, and have a lot of fun with it .. my 3d printing tweaking time quota is limited, unfortunately)

BR,

David

I printed a hollow cube and cylinder with 2mm walls, 30 mm high, after having tightened the extruder clamp and recalibrated e_steps_per_mm.

The print in the pictures is sliced with skeinforge, ryan marks profile 0.3 mm PLA, 200 celcius, 50mm/s. 0.07 infill perimeter overlap, 100% infill solidity (grid rectangular).

In banding1, banding3, and banding4, one can see that the plastic is unevenly distributed w.r.t. the Z axis. The "banding" is perhaps a bit less than before.

In banding2 I see that filament is kind of missing here and there. This is relatively new, and I have no idea what it somes from. Perhaps extrusion problems.

A while ago I had a jammed hotend that I cleaned. I htought I got ris of the obstacles, but this may be an indication that something is wrong.

It is hard to be methodical, there are so many parameters that seem to have impact on the output.

Sorry if I learn too slowly...

(but I still enjoy the printer very much, and have a lot of fun with it .. my 3d printing tweaking time quota is limited, unfortunately)

BR,

David

|

Re: Z lead screw mounting? June 22, 2015 10:45AM |

Registered: 10 years ago Posts: 68 |

I have another observation:

I printed one of the parts of my gauge holer again, the same gcode. (the first picture in this thread, the clamp holding the dial gauge)

The banding was exactly the same, w.r.t the Z axis.

So it is deterministic and reproucible.

Then I have hard to believe it is the extruder. Am I right?

/David

I printed one of the parts of my gauge holer again, the same gcode. (the first picture in this thread, the clamp holding the dial gauge)

The banding was exactly the same, w.r.t the Z axis.

So it is deterministic and reproucible.

Then I have hard to believe it is the extruder. Am I right?

/David

|

Re: Z lead screw mounting? June 22, 2015 11:33AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes it looks like the Z axis moves very unevenly so some layers hardly touch. I can't think why that would be unless it wasn't resting on the nuts all the time. Maybe the axis sticks and slips.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Z lead screw mounting? June 22, 2015 11:58AM |

Registered: 10 years ago Posts: 68 |

Sorry, only registered users may post in this forum.