Increasing printing accuracy

Posted by atmark

|

Increasing printing accuracy October 07, 2015 01:43AM |

Registered: 8 years ago Posts: 96 |

Hi there

Finally I got my Mendel90 ready for printing, the bed is level and everything is adjusted, but still I'm not happy with the accuracy on x- and y-dimension. Lets say I print a cube of 10x10x10 mm the outcome results in a 9x9,5x10 mm cube. And if I noticed it correctly the offset increases the bigger the objects are.

Any ideas where to tune the machine?

Finally I got my Mendel90 ready for printing, the bed is level and everything is adjusted, but still I'm not happy with the accuracy on x- and y-dimension. Lets say I print a cube of 10x10x10 mm the outcome results in a 9x9,5x10 mm cube. And if I noticed it correctly the offset increases the bigger the objects are.

Any ideas where to tune the machine?

|

Re: Increasing printing accuracy October 07, 2015 06:23AM |

Admin Registered: 17 years ago Posts: 7,879 |

Try printing bigger cubes, or several at one time. A 10mm cube will not cool fast enough, so the lower layers are not set when the upper layers are being deposited, leading to distortions.

If you slice with the Skeinforge profile provided I would expect a larger object to be accurate within about 0.2mm.

[www.hydraraptor.blogspot.com]

If you slice with the Skeinforge profile provided I would expect a larger object to be accurate within about 0.2mm.

[www.hydraraptor.blogspot.com]

|

Re: Increasing printing accuracy October 07, 2015 06:28AM |

Registered: 10 years ago Posts: 541 |

Hi,

This really is a process of tuning and using good materials.

If your belts are correctly tight there should be no need to adjust the steps/mm value for the axes. There are four things that are essential to getting good prints:

1) Use an accurate slicer

I cannot emphasize enough how important this is. If you want really accurate parts then you should use Skeinforge. Other slicers do not compete with the degree of control you have and the results Skeinforge produces in terms of accuracy.

Using Skeinforge (and my profiles for it) I can slice for either ABS or PLA and produce an identical result with my preferred filaments.

I can be sure that a designed 10mm circular Peg will fit a designed 10mm Hole as an interference fit without having to under or oversize either dimension.

2) Slicer Filament Diameter setting

a) I use a Digital Caliper to measure this value accurate to two decimal places.

b) Use a quality filament that is genuinely round and exhibits a tight tolerance on its diameter (better than +/-0.1mm if you can get it).

3) Extruder steps/mm

a) I use a metal rule and Digital Caliper to measure the filament length for extruder calibration.

b) Cut a small piece of tape and apply this to the rule at 120mm with some overhang into free-space.

c) Raise the teflon tube at the Wade's Block filament entry and place the rule alongside the filament vertically.

d) Wrap the tape around the filament and peel away the rule before wrapping the tape on itself.

e) Heat the extruder to working temperature and extrude 100mm at 60mm/min.

f) Measure the remaining filament after the extrusion of 100mm using a Digital Caliper and factor this into your E_STEPS_PER_MM equation.

4) First layer height

a) I print all layers at the same height including the first layer. It is very important to have your bed level and to set the Z_MAX_POS (Z_HEIGHT_MM in my Marlin version) previously.

b) I set the initial Z_MAX_POS value to 203.0mm and upload the firmware with this setting.

c) I use a 20mm cube (whose dimensions I check with a Digital Caliper before adjusting Z position) placed at the centre-front of the heated bed.

d) Home the printer and then lower the extruder to 21mm (G1 Z21) with the cube not present.

e) Place the cube under the nozzle and jog the extruder downwards until you can just feel some friction between the cube top surface and the extruder nozzle.

f) Issue a M114 GCode command and note the Z position value.

g) Use the: actual cube height minus reported Z position value to adjust the firmware Z_MAX_POS (increase for positive difference and decrease for negative difference) BUT reduce the final value by 0.2mm to allow for extruder nozzle length expansion.

h) Recomile Marlin and upload the result.

Following these procedures I slice a test object and observe the printed first layer in comparison to the GCode displayed in a GCode viewer such as gcode.ws. This is very important because it confirms that your extrusion matches what the slicer generated.

Follwing your first print, with these adjusted parameters, measure the surrounding skirt height with a Digital Caliper and use the deviation from required layer height to tune the firmware Z_MAX_POS value.

Regards,

Neil Darlow

Edited 3 time(s). Last edit at 10/07/2015 06:34AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

This really is a process of tuning and using good materials.

If your belts are correctly tight there should be no need to adjust the steps/mm value for the axes. There are four things that are essential to getting good prints:

1) Use an accurate slicer

I cannot emphasize enough how important this is. If you want really accurate parts then you should use Skeinforge. Other slicers do not compete with the degree of control you have and the results Skeinforge produces in terms of accuracy.

Using Skeinforge (and my profiles for it) I can slice for either ABS or PLA and produce an identical result with my preferred filaments.

I can be sure that a designed 10mm circular Peg will fit a designed 10mm Hole as an interference fit without having to under or oversize either dimension.

2) Slicer Filament Diameter setting

a) I use a Digital Caliper to measure this value accurate to two decimal places.

b) Use a quality filament that is genuinely round and exhibits a tight tolerance on its diameter (better than +/-0.1mm if you can get it).

3) Extruder steps/mm

a) I use a metal rule and Digital Caliper to measure the filament length for extruder calibration.

b) Cut a small piece of tape and apply this to the rule at 120mm with some overhang into free-space.

c) Raise the teflon tube at the Wade's Block filament entry and place the rule alongside the filament vertically.

d) Wrap the tape around the filament and peel away the rule before wrapping the tape on itself.

e) Heat the extruder to working temperature and extrude 100mm at 60mm/min.

f) Measure the remaining filament after the extrusion of 100mm using a Digital Caliper and factor this into your E_STEPS_PER_MM equation.

4) First layer height

a) I print all layers at the same height including the first layer. It is very important to have your bed level and to set the Z_MAX_POS (Z_HEIGHT_MM in my Marlin version) previously.

b) I set the initial Z_MAX_POS value to 203.0mm and upload the firmware with this setting.

c) I use a 20mm cube (whose dimensions I check with a Digital Caliper before adjusting Z position) placed at the centre-front of the heated bed.

d) Home the printer and then lower the extruder to 21mm (G1 Z21) with the cube not present.

e) Place the cube under the nozzle and jog the extruder downwards until you can just feel some friction between the cube top surface and the extruder nozzle.

f) Issue a M114 GCode command and note the Z position value.

g) Use the: actual cube height minus reported Z position value to adjust the firmware Z_MAX_POS (increase for positive difference and decrease for negative difference) BUT reduce the final value by 0.2mm to allow for extruder nozzle length expansion.

h) Recomile Marlin and upload the result.

Following these procedures I slice a test object and observe the printed first layer in comparison to the GCode displayed in a GCode viewer such as gcode.ws. This is very important because it confirms that your extrusion matches what the slicer generated.

Follwing your first print, with these adjusted parameters, measure the surrounding skirt height with a Digital Caliper and use the deviation from required layer height to tune the firmware Z_MAX_POS value.

Regards,

Neil Darlow

Edited 3 time(s). Last edit at 10/07/2015 06:34AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Increasing printing accuracy October 07, 2015 07:52AM |

Registered: 8 years ago Posts: 96 |

|

Re: Increasing printing accuracy October 10, 2015 06:56AM |

Registered: 8 years ago Posts: 96 |

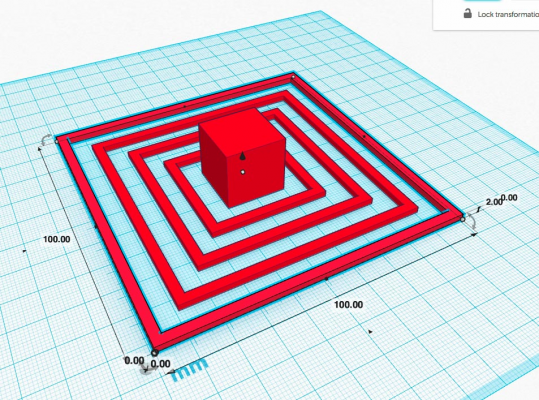

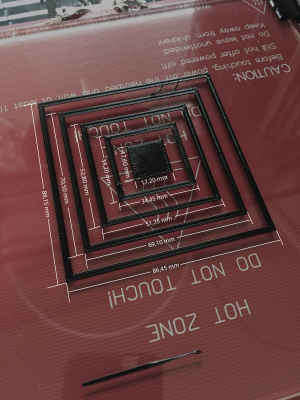

So I did some testing and printed this model of some squares. Starting from 100x100mm going in 20mm-steps down to a 20x20x20mm cube.

As you can see the abbreviations are significant. On the x-axis around 13,5% and on the y-axis around 12%.

This test print was sliced with Neil's skeinforge profiles. Frankly, I don't this is a slicing issue.

I have an e3d-v6 extruder installed and I'm using it for now without the fan. The original fanduct don't fit.

But nevertheless srinking of the PLA can't be causing this as I did stop printing after two layers.

My Mendel90 build is a self sourced dibond version. The only mods are the e3d extruder, RAMPS 1.4 and a LCD controller. As firmware I'm using Neil's version.

What dou you think? What's wrong?

As you can see the abbreviations are significant. On the x-axis around 13,5% and on the y-axis around 12%.

This test print was sliced with Neil's skeinforge profiles. Frankly, I don't this is a slicing issue.

I have an e3d-v6 extruder installed and I'm using it for now without the fan. The original fanduct don't fit.

But nevertheless srinking of the PLA can't be causing this as I did stop printing after two layers.

My Mendel90 build is a self sourced dibond version. The only mods are the e3d extruder, RAMPS 1.4 and a LCD controller. As firmware I'm using Neil's version.

What dou you think? What's wrong?

|

Re: Increasing printing accuracy October 10, 2015 10:54AM |

Registered: 10 years ago Posts: 541 |

Hi,

What belts and pulleys are you using? Are your X any Y steps/mm in Marlin set to 80?

I know it is silly but just check that you have not inadvertently activated Skeinforge's scaling feature.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

What belts and pulleys are you using? Are your X any Y steps/mm in Marlin set to 80?

I know it is silly but just check that you have not inadvertently activated Skeinforge's scaling feature.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Increasing printing accuracy October 10, 2015 11:21AM |

Registered: 8 years ago Posts: 96 |

|

Re: Increasing printing accuracy October 10, 2015 01:54PM |

Admin Registered: 17 years ago Posts: 7,879 |

The only way I can think of to get that much error and different on each axis with the print looking otherwise OK is for the steps per mm to be wrong.

One possibility is you have different steps per mm stored in EEPROM. What does M503 report on the M92 line?

[www.hydraraptor.blogspot.com]

One possibility is you have different steps per mm stored in EEPROM. What does M503 report on the M92 line?

[www.hydraraptor.blogspot.com]

|

Re: Increasing printing accuracy October 12, 2015 12:13PM |

Registered: 8 years ago Posts: 96 |

It reports following:

echo: M92 X80.00 Y80.00 Z3200.00 E543.65

I tweaked the settings as followed 92 X96.00 Y94.00 Z3200.00 E543.65 and now I'm getting almost correct dimensions...

While printing I noticed that the belt doesn't glide smooth over the pulley. At one point it lifts up a little bit so the pulley might be china quality. Also I didn't order the belt and the pulleys from the same supplier.

Did I read correctly somewhere that the suggested pulleys would now be GT2? If correct, which number of tooths would you recommend?

echo: M92 X80.00 Y80.00 Z3200.00 E543.65

I tweaked the settings as followed 92 X96.00 Y94.00 Z3200.00 E543.65 and now I'm getting almost correct dimensions...

While printing I noticed that the belt doesn't glide smooth over the pulley. At one point it lifts up a little bit so the pulley might be china quality. Also I didn't order the belt and the pulleys from the same supplier.

Did I read correctly somewhere that the suggested pulleys would now be GT2? If correct, which number of tooths would you recommend?

|

Re: Increasing printing accuracy October 12, 2015 02:03PM |

Admin Registered: 17 years ago Posts: 7,879 |

The later kits shipped with 20 tooth GT2 which also gives 80 steps per mm.

The distance travelled is defined by the belt pitch and the number of teeth on the pulley. I can't see how it can be so far out unless your belts are elastic and stretch, rather than fixed pitch timing belts with steel or kevlar cables to keep the pitch constant regardless of tension.

[www.hydraraptor.blogspot.com]

The distance travelled is defined by the belt pitch and the number of teeth on the pulley. I can't see how it can be so far out unless your belts are elastic and stretch, rather than fixed pitch timing belts with steel or kevlar cables to keep the pitch constant regardless of tension.

[www.hydraraptor.blogspot.com]

|

Re: Increasing printing accuracy October 16, 2015 06:51AM |

Registered: 10 years ago Posts: 541 |

Hi,

You have to be careful with eBaY-sourced pulleys. Some of them are really poor quality.

I recently purchased a combined 2m belt and pulley set from eBaY but I was very careful to study the photographs to assess the manufactured quality. Of course, a photograph is no indication of what you get these days but I think I was lucky.

My pulleys and belt, along with some fresh bearings and X-carriage fan, are waiting for a minor refurbishment of my machine which is due after 2 years of use.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

You have to be careful with eBaY-sourced pulleys. Some of them are really poor quality.

I recently purchased a combined 2m belt and pulley set from eBaY but I was very careful to study the photographs to assess the manufactured quality. Of course, a photograph is no indication of what you get these days but I think I was lucky.

My pulleys and belt, along with some fresh bearings and X-carriage fan, are waiting for a minor refurbishment of my machine which is due after 2 years of use.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Sorry, only registered users may post in this forum.