Need help calibrating

Posted by ben2015

|

Need help calibrating October 16, 2015 03:41AM |

Registered: 8 years ago Posts: 2 |

Hello,

I have some trouble calibrating my Mendel90.

Find attached some Images of the Calibration Cube I printed from here:

[www.thingiverse.com]

There are serveral issues:

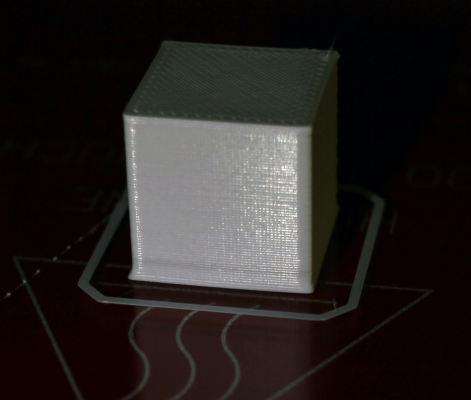

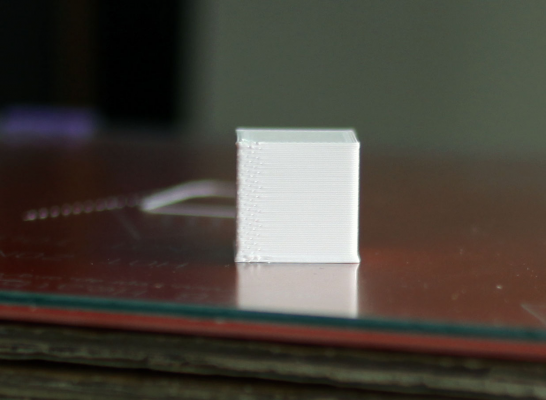

1 one edge has some blobs (IMG_9106.JPG)

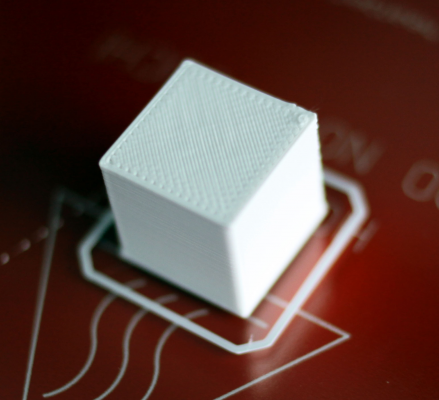

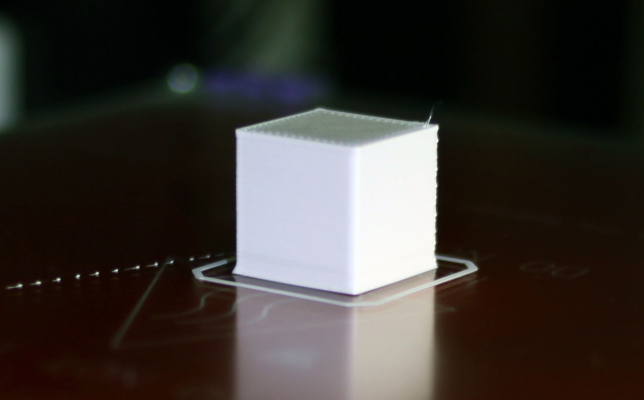

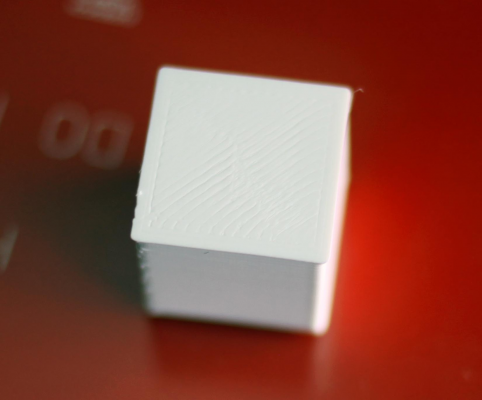

2 the bottom is like melted a little bit (thicker than upper part, IMG_9107.JPG,IMG_9105.JPG )

3 the dimensions are wrong (between 19.13 and 19.50)

4 maybe more please see the images

This is my first 3D printer and I have no idea what to change. I followed the

instructions from the manual.

I am using Skeinforge and Pronterface from the provided USB-Stick.

The cube is sliced with 0.3mm layer height using 185 degree for the hotend

and 75 degree for the bed temp.

Filament (PLS) is the white one from dasfilament.de

I hope someone can help me finding a solution.

Thank you very much in andvance.

I have some trouble calibrating my Mendel90.

Find attached some Images of the Calibration Cube I printed from here:

[www.thingiverse.com]

There are serveral issues:

1 one edge has some blobs (IMG_9106.JPG)

2 the bottom is like melted a little bit (thicker than upper part, IMG_9107.JPG,IMG_9105.JPG )

3 the dimensions are wrong (between 19.13 and 19.50)

4 maybe more please see the images

This is my first 3D printer and I have no idea what to change. I followed the

instructions from the manual.

I am using Skeinforge and Pronterface from the provided USB-Stick.

The cube is sliced with 0.3mm layer height using 185 degree for the hotend

and 75 degree for the bed temp.

Filament (PLS) is the white one from dasfilament.de

I hope someone can help me finding a solution.

Thank you very much in andvance.

|

Re: Need help calibrating October 16, 2015 07:48AM |

Registered: 10 years ago Posts: 541 |

Hi,

There are a number of things that can be addressed in your print. Note that I did not say there are things wrong with your print. Things just need a little understanding and tuning.

The slumping at the bottom of the print is likely due to accumulation of heat during printing of the lower layers (notice how things improve further up the print). This is often caused by the influence of the heated bed and a higher than necessary print speed. If you slow down the print speed the plastic has time to cool a little before the next layer is deposited. Turning on the cooling fan after the first layer also helps.

The top of your print also shows some evidence of the layer being pushed outwards. This might be due to over-extrusion. When you over-extrude the infill will push the perimeter outwards if print speed is high enough othwerwise it will result in a build-up of plastic which the extruder then has to push through at the next layer when the print speed is lower. Ensuring your extruder is well calibrated will prevent this and calibrate your extruder near your working temperature.

The blobs down the side can only be managed by tuning your retraction settings and these depend on many factors including material viscosity. The general rule is that adjusting amount of retraction affects stringing and adjusting speed of retraction affects blobbing. In general, for a geared extruder, you will need between 1.0mm and 2.0mm of retraction and I typically retract at 60mm/s. These are generalities and need experimentation to eliminate blobs.

So, to summarize, for good prints you need:

1) A mechanically sound printer with no sloppy belts and correctly set stepper driver current.

2) Accurately calibrated Z-height and extruder steps/mm.

3) Good quality filament that is round and of a decent tolerance on the diameter (better than +/-0.1mm if you can get it).

4) Temperatures that are within the rated specification for the filament.

Things you can do to improve the quality and accuracy of your prints:

1) Calibrate your extruder near working temperature. The PLA I use is specified for 200C +/-10C and I calibrate the extruder at 200C. I adjust the temperature by 5C for each 10mm/s speed change. Downwards for slower speeds and upwards for higher speeds. This allows me to print at 190C for 20mm/s, 200C for 40mm/s and 210C for 60mm/s which is a useful print speed range for the Mendel90.

2) Spend some time assessing the retraction requirements for your filament. Done well you can eliminate blobs.

3) Do not restrict yourself to one slicer. Skeinforge is great for printing accurate parts but does not handle small areas of infill well. Cura is better at this at the expense of reduced accuracy but that does not always matter. And then there is always Slic3r...

4) Be prepared to adjust printing speed. There is a trade-off between quality and speed. I produce my highest quality prints at a speed of 20mm/s.

Making good prints is an iterative process of printing, assessing and adjusting. It is satisfying to produce high quality results and the Mendel90 is quite capable of doing that.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

There are a number of things that can be addressed in your print. Note that I did not say there are things wrong with your print. Things just need a little understanding and tuning.

The slumping at the bottom of the print is likely due to accumulation of heat during printing of the lower layers (notice how things improve further up the print). This is often caused by the influence of the heated bed and a higher than necessary print speed. If you slow down the print speed the plastic has time to cool a little before the next layer is deposited. Turning on the cooling fan after the first layer also helps.

The top of your print also shows some evidence of the layer being pushed outwards. This might be due to over-extrusion. When you over-extrude the infill will push the perimeter outwards if print speed is high enough othwerwise it will result in a build-up of plastic which the extruder then has to push through at the next layer when the print speed is lower. Ensuring your extruder is well calibrated will prevent this and calibrate your extruder near your working temperature.

The blobs down the side can only be managed by tuning your retraction settings and these depend on many factors including material viscosity. The general rule is that adjusting amount of retraction affects stringing and adjusting speed of retraction affects blobbing. In general, for a geared extruder, you will need between 1.0mm and 2.0mm of retraction and I typically retract at 60mm/s. These are generalities and need experimentation to eliminate blobs.

So, to summarize, for good prints you need:

1) A mechanically sound printer with no sloppy belts and correctly set stepper driver current.

2) Accurately calibrated Z-height and extruder steps/mm.

3) Good quality filament that is round and of a decent tolerance on the diameter (better than +/-0.1mm if you can get it).

4) Temperatures that are within the rated specification for the filament.

Things you can do to improve the quality and accuracy of your prints:

1) Calibrate your extruder near working temperature. The PLA I use is specified for 200C +/-10C and I calibrate the extruder at 200C. I adjust the temperature by 5C for each 10mm/s speed change. Downwards for slower speeds and upwards for higher speeds. This allows me to print at 190C for 20mm/s, 200C for 40mm/s and 210C for 60mm/s which is a useful print speed range for the Mendel90.

2) Spend some time assessing the retraction requirements for your filament. Done well you can eliminate blobs.

3) Do not restrict yourself to one slicer. Skeinforge is great for printing accurate parts but does not handle small areas of infill well. Cura is better at this at the expense of reduced accuracy but that does not always matter. And then there is always Slic3r...

4) Be prepared to adjust printing speed. There is a trade-off between quality and speed. I produce my highest quality prints at a speed of 20mm/s.

Making good prints is an iterative process of printing, assessing and adjusting. It is satisfying to produce high quality results and the Mendel90 is quite capable of doing that.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Need help calibrating October 17, 2015 04:40AM |

Registered: 8 years ago Posts: 2 |

|

Re: Need help calibrating October 17, 2015 09:29PM |

Registered: 8 years ago Posts: 11 |

|

Re: Need help calibrating October 18, 2015 12:18PM |

Registered: 10 years ago Posts: 541 |

@rdomonkey: I was using White PLA from here which I found very good. I have recently discovered this supplier who promises a lot in terms of quality and tolerance although I must admit I am finding it a challenge to use their material.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Need help calibrating October 25, 2015 11:38AM |

Registered: 10 years ago Posts: 94 |

Sorry, only registered users may post in this forum.