Problems with hotend

Posted by demetris

|

Problems with hotend December 10, 2015 03:29PM |

Registered: 11 years ago Posts: 90 |

Hello all,

So my printer was working fine, printing both PLA and ABS since 2013. Yesterday I tried printing a new brand PLA and got into problems.

After loading the filament and checking that is extruding at 195 C, I started the print and after a while no filament was coming out of the nozzle. I reversed the flow and pulled the filament out of the hotend and tried again. The same thing happened. After a couple of failed tries, no filament was going in or out. So I took the hotend apart. The plastic was stuck at the top of the hotend, inside the PTFE tube. I pulled it out cut a small part of the PTFE tube, and put it back.

Now the hotend is leaking from the sides of the PEEK compartment! Some plastic comes out of the nozzle but most of it goes out from the side. I don't understand why this happens because when I am manually extruding the filament seems to come out just fine in a straight line as it always have. The hotend doesn't seem clogged and yet when I try to print the pastic comes out from the side.

Is my hotend completely destroyed?

Any advice is welcome!

So my printer was working fine, printing both PLA and ABS since 2013. Yesterday I tried printing a new brand PLA and got into problems.

After loading the filament and checking that is extruding at 195 C, I started the print and after a while no filament was coming out of the nozzle. I reversed the flow and pulled the filament out of the hotend and tried again. The same thing happened. After a couple of failed tries, no filament was going in or out. So I took the hotend apart. The plastic was stuck at the top of the hotend, inside the PTFE tube. I pulled it out cut a small part of the PTFE tube, and put it back.

Now the hotend is leaking from the sides of the PEEK compartment! Some plastic comes out of the nozzle but most of it goes out from the side. I don't understand why this happens because when I am manually extruding the filament seems to come out just fine in a straight line as it always have. The hotend doesn't seem clogged and yet when I try to print the pastic comes out from the side.

Is my hotend completely destroyed?

Any advice is welcome!

|

Re: Problems with hotend December 10, 2015 07:18PM |

Admin Registered: 17 years ago Posts: 7,879 |

My advice is never disassemble a hot end. It isn't necessary to fix any jamb and it is difficult to reassemble correctly.

For jambs at the cold end: heat the cold end with a hot air gun or in a glass of boiling water, then nip the filament with needle nosed pliers and pull it out of the hex socket of the grub screw. That is the only place it can jamb. Anything below the cavity will slide through the PTFE tube.

For jambs at the nozzle do this [hydraraptor.blogspot.co.uk].

If you removed some of the PTFE tube then it might need to be replaced.

To re-assemble you need to clean the top edge of the brass tube and the threads. Then you need to wrap it with a few turns of plumber's PTFE tape (in the right direction so it tightens when screwed in). Then screw it into the PEEK and tighten it.

Then you inert the PTFE tube from the top and clamp it down with the brass washer and the M8x3 grub screw until it gets hard to turn. Not too tight or it will crush the PTFE.

Seems like the new brand of PLA needs a higher temperature, or has contaminants that have blocked the nozzle. Try pushing it manually and increasing the temperature until it extrudes easily.

The problem with PLA is if it isn't moving at a reasonable speed then heat creeps up it and softens it when it reaches the glass transition, which is only about 55C. The Achilles heel of the J-Head is the grub screw because it forms a cavity bigger than the filament path. If PLA gets hot enough to expand into the gap it won't move in either direction.

Edited 2 time(s). Last edit at 12/10/2015 07:51PM by nophead.

[www.hydraraptor.blogspot.com]

For jambs at the cold end: heat the cold end with a hot air gun or in a glass of boiling water, then nip the filament with needle nosed pliers and pull it out of the hex socket of the grub screw. That is the only place it can jamb. Anything below the cavity will slide through the PTFE tube.

For jambs at the nozzle do this [hydraraptor.blogspot.co.uk].

If you removed some of the PTFE tube then it might need to be replaced.

To re-assemble you need to clean the top edge of the brass tube and the threads. Then you need to wrap it with a few turns of plumber's PTFE tape (in the right direction so it tightens when screwed in). Then screw it into the PEEK and tighten it.

Then you inert the PTFE tube from the top and clamp it down with the brass washer and the M8x3 grub screw until it gets hard to turn. Not too tight or it will crush the PTFE.

Seems like the new brand of PLA needs a higher temperature, or has contaminants that have blocked the nozzle. Try pushing it manually and increasing the temperature until it extrudes easily.

The problem with PLA is if it isn't moving at a reasonable speed then heat creeps up it and softens it when it reaches the glass transition, which is only about 55C. The Achilles heel of the J-Head is the grub screw because it forms a cavity bigger than the filament path. If PLA gets hot enough to expand into the gap it won't move in either direction.

Edited 2 time(s). Last edit at 12/10/2015 07:51PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Problems with hotend December 11, 2015 02:59AM |

Registered: 11 years ago Posts: 90 |

Thank you Chris for the informational reply.

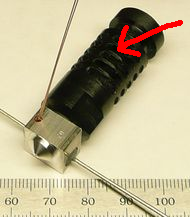

I will try to fix it but first a couple of more questions. It worries me that the plastic is coming out from the side fo the cold end indicated by the arrow in the image (I am not at home to take a picture, so I used a stock picture of the jhead).

Is this happening because the PTFE tube is not tightly connected to the hotend? Or some else i broken?

Do you have any reliable source (ebay preferably) to buy the PTFE tube and the brass washer? Unfortunately it broke when I removed the tube.

Edited 1 time(s). Last edit at 12/11/2015 02:59AM by demetris.

I will try to fix it but first a couple of more questions. It worries me that the plastic is coming out from the side fo the cold end indicated by the arrow in the image (I am not at home to take a picture, so I used a stock picture of the jhead).

Is this happening because the PTFE tube is not tightly connected to the hotend? Or some else i broken?

Do you have any reliable source (ebay preferably) to buy the PTFE tube and the brass washer? Unfortunately it broke when I removed the tube.

Edited 1 time(s). Last edit at 12/11/2015 02:59AM by demetris.

|

Re: Problems with hotend December 11, 2015 06:09AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes the PTFE liner should form a seal against the brass, however the PEEK should not have any holes in it to allow it to escape where you indicated.

I think Brian machines the PTFE liner (it has a chamfer on one end). He sells spares @ [www.hotends.com]. No sign of the washers but I am sure he could include one if you ask.

There are some on eBay as well: [www.ebay.co.uk] but I have no experience of those.

[www.hydraraptor.blogspot.com]

I think Brian machines the PTFE liner (it has a chamfer on one end). He sells spares @ [www.hotends.com]. No sign of the washers but I am sure he could include one if you ask.

There are some on eBay as well: [www.ebay.co.uk] but I have no experience of those.

[www.hydraraptor.blogspot.com]

|

Re: Problems with hotend December 11, 2015 07:12AM |

Registered: 11 years ago Posts: 90 |

|

Re: Problems with hotend December 11, 2015 09:27AM |

Admin Registered: 17 years ago Posts: 7,879 |

If the PTFE makes a good seal then it should prevent plastic getting to the hole in the PEEK. I am not sure because I have never encountered that before.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Problems with hotend December 13, 2015 05:13AM |

Registered: 11 years ago Posts: 90 |

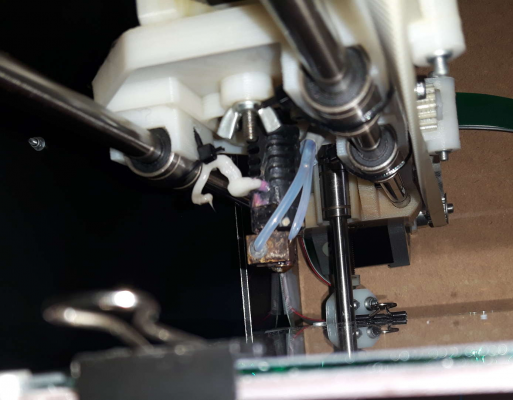

I took it apart again and again in an effort to understand and fix the problem. The plastic keeps coming out from the side; take a look at the picture

I tightened the set screw all the way in in order to compensate for the missing PTFE liner part I cut away, and the missing bronze spacer. What is strange is that when I manually extrude everything seems to work fine. Plastic coming out of the nozzle and no plastic from the sides. I extrude multiple times to ensure that everything is OK. Then I load a gcode I printed at least 10 times before and know it produced excellent results, and problems start immediately after starting the print. It seems that plastic has difficulty coming out from the nozzle, causing a mess. After a while I notice the plastic coming out from the sides.

The fact that the PEEK is broken makes me unsure whether I can repair it without spending considerable amount of money. Also the fact that they ship from US it takes long time to reach me, and I planned to play around with the 3d printer during the holidays. I went ahead and bought an e3d v6 that I was planning to have as a secondary hotend anyway. I know it was not the best choice since I wanted a smooth replacement transition and get back to printing since spare time unfortunately is really short. I studied the Mendel90 forums so hopefully I will be able to install it without much trouble.

I will update the post if I manage to fix the j-head in the future.

Edited 1 time(s). Last edit at 12/13/2015 05:15AM by demetris.

I tightened the set screw all the way in in order to compensate for the missing PTFE liner part I cut away, and the missing bronze spacer. What is strange is that when I manually extrude everything seems to work fine. Plastic coming out of the nozzle and no plastic from the sides. I extrude multiple times to ensure that everything is OK. Then I load a gcode I printed at least 10 times before and know it produced excellent results, and problems start immediately after starting the print. It seems that plastic has difficulty coming out from the nozzle, causing a mess. After a while I notice the plastic coming out from the sides.

The fact that the PEEK is broken makes me unsure whether I can repair it without spending considerable amount of money. Also the fact that they ship from US it takes long time to reach me, and I planned to play around with the 3d printer during the holidays. I went ahead and bought an e3d v6 that I was planning to have as a secondary hotend anyway. I know it was not the best choice since I wanted a smooth replacement transition and get back to printing since spare time unfortunately is really short. I studied the Mendel90 forums so hopefully I will be able to install it without much trouble.

I will update the post if I manage to fix the j-head in the future.

Edited 1 time(s). Last edit at 12/13/2015 05:15AM by demetris.

|

Re: Problems with hotend December 13, 2015 07:30AM |

Admin Registered: 17 years ago Posts: 7,879 |

There is more pressure involved when building an object than extruding at the same rate into thin air but it seems odd it would make so much difference.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Problems with hotend December 19, 2015 02:37PM |

Registered: 11 years ago Posts: 90 |

Just an update.

The e3d arrived and I installed it on my Mendel90. I plan to make a post to summarize the procedure that others might find useful.

One thing that I did not anticipate was that the hotend was not fitting well in the socket of the base. It seems that the groove is shorter than the socket and as a result even after tightening the screws, the hotend was not firmly secured. This seems a bit odd because I didn't encounter any post mentioning this. I chose to put a washer between the hotend and the socket which raised the groove outside of the socket, and this allowed my to firmly secure it. Of course I made sure that the washer was correctly aligned so that it wouldn't touch on the filament passing through. Unfortunately, I overtightened a screw and damaged the extruder block. I will have to get a replacement sometime soon.

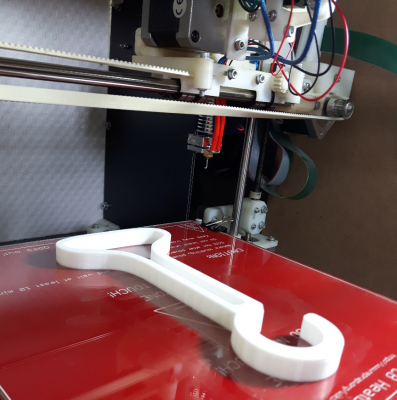

Anyway, the important thing is that I am back to printing I already have two successful (one hour) prints, PLA and ABS!

I already have two successful (one hour) prints, PLA and ABS!

In case you are wondering this an extension I designed to allow my wife and I to open a window placed a bit too high.

The e3d arrived and I installed it on my Mendel90. I plan to make a post to summarize the procedure that others might find useful.

One thing that I did not anticipate was that the hotend was not fitting well in the socket of the base. It seems that the groove is shorter than the socket and as a result even after tightening the screws, the hotend was not firmly secured. This seems a bit odd because I didn't encounter any post mentioning this. I chose to put a washer between the hotend and the socket which raised the groove outside of the socket, and this allowed my to firmly secure it. Of course I made sure that the washer was correctly aligned so that it wouldn't touch on the filament passing through. Unfortunately, I overtightened a screw and damaged the extruder block. I will have to get a replacement sometime soon.

Anyway, the important thing is that I am back to printing

I already have two successful (one hour) prints, PLA and ABS!

I already have two successful (one hour) prints, PLA and ABS!In case you are wondering this an extension I designed to allow my wife and I to open a window placed a bit too high.

|

Re: Problems with hotend December 20, 2015 08:59AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes it standard practice to put an M8 washer in the socket.

If you are re-printing it there is a version specifically for E3D here: [github.com]. It will get you back some of the Z height you lost. Also there is a fan duct and bracket in the same branch.

[www.hydraraptor.blogspot.com]

If you are re-printing it there is a version specifically for E3D here: [github.com]. It will get you back some of the Z height you lost. Also there is a fan duct and bracket in the same branch.

[www.hydraraptor.blogspot.com]

|

Re: Problems with hotend December 21, 2015 03:19PM |

Registered: 11 years ago Posts: 31 |

Quote

nophead

Yes it standard practice to put an M8 washer in the socket.

If you are re-printing it there is a version specifically for E3D here: [github.com]. It will get you back some of the Z height you lost. Also there is a fan duct and bracket in the same branch.

Are the updates for this in the scad files as well? I'm asking because I just redesigned the extruder block, X carriage, and the printed fan pieces to accommodate the E3D v6. (I've seen others, but not your official one.)

|

Re: Problems with hotend December 21, 2015 03:35PM |

Registered: 11 years ago Posts: 90 |

Quote

nophead

If you are re-printing it there is a version specifically for E3D here: [github.com]. It will get you back some of the Z height you lost. Also there is a fan duct and bracket in the same branch.

Thank you Chris. Do you have any general guidelines for slicing? For example, fill percentage, layer height etc?

Edited 1 time(s). Last edit at 12/21/2015 03:35PM by demetris.

|

Re: Problems with hotend December 22, 2015 05:19AM |

Registered: 10 years ago Posts: 541 |

@demetris:

Most parts for the Mendel90 kit are sliced at 0.4mm layer height and 0.6mm line width. Some parts with fine detail are sliced at 0.35mm layer height and 0.525mm line width. nophead generally follows the 1.5 W/H rule.

For the 0.4mm layer height parts you can, obviously, slice at 0.2mm but the print time will be longer. I recently printed an X-carriage for GT2 belts using 0.4mm layer height and 0.5mm line width (which provides the required GT2 tooth spacing) in ABS and it came out fine when sliced with Skeinforge. I print the Wade's block at 0.4mm layer height and 0.6mm line width. The X-carriage was printed at 50% infill and Wade's block at 75% infill (to keep the infill voids relatively small).

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Most parts for the Mendel90 kit are sliced at 0.4mm layer height and 0.6mm line width. Some parts with fine detail are sliced at 0.35mm layer height and 0.525mm line width. nophead generally follows the 1.5 W/H rule.

For the 0.4mm layer height parts you can, obviously, slice at 0.2mm but the print time will be longer. I recently printed an X-carriage for GT2 belts using 0.4mm layer height and 0.5mm line width (which provides the required GT2 tooth spacing) in ABS and it came out fine when sliced with Skeinforge. I print the Wade's block at 0.4mm layer height and 0.6mm line width. The X-carriage was printed at 50% infill and Wade's block at 75% infill (to keep the infill voids relatively small).

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Problems with hotend December 22, 2015 05:42AM |

Registered: 11 years ago Posts: 90 |

Thanks Neil, you were very informative.

In my case speed is really important as I cannot use the printer for long periods (because we live in a small apartment). However, I don't think I can go with 0.4mm layer height since the nozzle diameter is 0.4mm. I would have to go with 0.35mm. What nozzle size do you use?

In my case speed is really important as I cannot use the printer for long periods (because we live in a small apartment). However, I don't think I can go with 0.4mm layer height since the nozzle diameter is 0.4mm. I would have to go with 0.35mm. What nozzle size do you use?

|

Re: Problems with hotend December 22, 2015 10:29AM |

Admin Registered: 17 years ago Posts: 7,879 |

@daichiasuka, yes the E3D branch of Mendel90 has scad files that correspond to the STLs in it.

@demetris,

I print the Wade's block with 95% fill, 0.4mm layers by 0.6mm. Sometimes I can do that with a 0.4mm nozzle, sometimes I ream it to 0.45, it depends on the ABS die swell.

[www.hydraraptor.blogspot.com]

@demetris,

I print the Wade's block with 95% fill, 0.4mm layers by 0.6mm. Sometimes I can do that with a 0.4mm nozzle, sometimes I ream it to 0.45, it depends on the ABS die swell.

[www.hydraraptor.blogspot.com]

|

Re: Problems with hotend December 22, 2015 01:55PM |

Registered: 10 years ago Posts: 541 |

@demerits:

My nozzle is a standard Mendel90 kit 0.4mm one. I print 0.4mm layers with it often in both ABS and PLA.

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 12/22/2015 01:56PM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

My nozzle is a standard Mendel90 kit 0.4mm one. I print 0.4mm layers with it often in both ABS and PLA.

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 12/22/2015 01:56PM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Problems with hotend December 22, 2015 05:01PM |

Registered: 11 years ago Posts: 31 |

@nophead Ahh, damn. I didn't realize you branched it. Looking at yours, we did very similar things. The biggest difference is I made the fan bracket longer, made the fan duct thinner, and removed the hole from the fan duct all to keep the stock fan for the E3D v6. I also changed the X carriage and wades block a bit to flip the connecting bolts and remove the wing nuts. I'll dump it up on github later if anyone is interested.

I'm also considering replacing the gears with a herringbone pattern printed in nylon, but I haven't gotten that far yet.

I'm also considering replacing the gears with a herringbone pattern printed in nylon, but I haven't gotten that far yet.

Sorry, only registered users may post in this forum.