Help printing e3D fan duct

Posted by demetris

|

Help printing e3D fan duct December 28, 2015 10:32AM |

Registered: 11 years ago Posts: 90 |

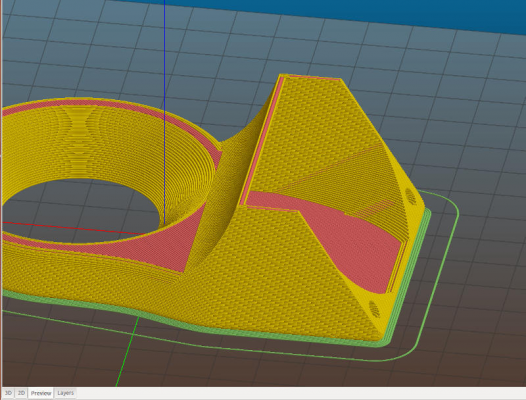

Hello. I am trying to print the fan duct that is compatible with e3D hotend. At some point the part becomes very thin, and the plastic just wont have enough time to cool before the new layer comes.

Do you have any suggestions that might help me print this? Thanks.

Do you have any suggestions that might help me print this? Thanks.

|

Re: Help printing e3D fan duct December 28, 2015 11:39AM |

Registered: 11 years ago Posts: 31 |

|

Re: Help printing e3D fan duct December 28, 2015 12:46PM |

Registered: 11 years ago Posts: 90 |

Hi thanks for the suggestions. I should have already stated that I am using the cooling feature of Slic3r that does slow down the print. But as you can see the area is way too small, so even if you slow it down it does cause problems.

The second solution might work but that means I have to print a dummy object that I don't need and waste plastic. I am sure people here have successfully printed this.

Edited 1 time(s). Last edit at 12/28/2015 12:47PM by demetris.

The second solution might work but that means I have to print a dummy object that I don't need and waste plastic. I am sure people here have successfully printed this.

Edited 1 time(s). Last edit at 12/28/2015 12:47PM by demetris.

|

Re: Help printing e3D fan duct December 28, 2015 01:06PM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes it is a small, but it is long and thin so has a high surface area, so it shouldn't be a problem if you slow down enough.

What plastic are you using?

[www.hydraraptor.blogspot.com]

What plastic are you using?

[www.hydraraptor.blogspot.com]

|

Re: Help printing e3D fan duct December 28, 2015 01:12PM |

Registered: 11 years ago Posts: 90 |

|

Re: Help printing e3D fan duct December 28, 2015 01:18PM |

Admin Registered: 17 years ago Posts: 7,879 |

|

Re: Help printing e3D fan duct December 28, 2015 01:56PM |

Registered: 11 years ago Posts: 31 |

Quote

demetris

The second solution might work but that means I have to print a dummy object that I don't need and waste plastic. I am sure people here have successfully printed this.

I've never had to use a dummy object, but I've never fully understood this logic. Even if I grossly overestimate the cost, a 10 mm x 10 mm x 100 mm column of solid plastic would cost less than $0.50 (USD) in plastic. Your failed print probably cost you more than that already.

That said, I'm with nophead. Slicing in my slicer of choice at 20 second minimum for layers shows the slowest perimeters are still at over 700 mm/s. Increase your minimum print time per layer.

|

Re: Help printing e3D fan duct December 28, 2015 02:19PM |

Registered: 11 years ago Posts: 90 |

Quote

daichiasuka

I've never had to use a dummy object, but I've never fully understood this logic.

I don't want to waste material. The reasons are not only economical. If I am able to pull it off without that then it makes much sense.

Edited 1 time(s). Last edit at 12/28/2015 02:25PM by demetris.

|

Re: Help printing e3D fan duct December 28, 2015 05:06PM |

Admin Registered: 17 years ago Posts: 7,879 |

>slowest perimeters are still at over 700 mm/s

That is way faster than the printer can move!

[www.hydraraptor.blogspot.com]

That is way faster than the printer can move!

[www.hydraraptor.blogspot.com]

|

Re: Help printing e3D fan duct December 28, 2015 05:38PM |

Registered: 11 years ago Posts: 31 |

|

Re: Help printing e3D fan duct December 28, 2015 09:29PM |

Admin Registered: 17 years ago Posts: 7,879 |

So 11.67mm/s, quite slow.

When I print tiny areas my printer slows down so much each step is a tick. I.e. speed goes to almost zero to allow very small areas to take 20s.

[www.hydraraptor.blogspot.com]

When I print tiny areas my printer slows down so much each step is a tick. I.e. speed goes to almost zero to allow very small areas to take 20s.

[www.hydraraptor.blogspot.com]

|

Re: Help printing e3D fan duct December 29, 2015 12:23AM |

Registered: 11 years ago Posts: 90 |

|

Re: Help printing e3D fan duct December 29, 2015 03:17AM |

Registered: 10 years ago Posts: 541 |

Why is the fan mounting not complete? I only see two mounting holes at the bottom and it is open at the top. How can that make an airtight chamber?

I think I could print that object at 220C with a minimum layer time of 5 seconds and minimum print speed of 10mm/s and I would have the fan enabled for layer times of 5 seconds or less (even for ABS). The Reprappertech ABS I use can cope with these conditions.

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 12/29/2015 03:19AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

I think I could print that object at 220C with a minimum layer time of 5 seconds and minimum print speed of 10mm/s and I would have the fan enabled for layer times of 5 seconds or less (even for ABS). The Reprappertech ABS I use can cope with these conditions.

Regards,

Neil Darlow

Edited 1 time(s). Last edit at 12/29/2015 03:19AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Help printing e3D fan duct December 29, 2015 03:20AM |

Registered: 11 years ago Posts: 90 |

|

Re: Help printing e3D fan duct December 29, 2015 02:47PM |

Registered: 10 years ago Posts: 541 |

|

Re: Help printing e3D fan duct December 30, 2015 05:02AM |

Registered: 9 years ago Posts: 64 |

|

Re: Help printing e3D fan duct December 30, 2015 06:39AM |

Registered: 10 years ago Posts: 541 |

@danielis:

There is a lot of myth in the 3D printing community relating to many things that should, and should not, be done. There is much advice that is not appropriate to modern materials or hardware and you need to make determinations for yourself.

Yes, using a fan with ABS can be a potential cause of de-lamination but if you are in a situation where there is excess heat in the deposition of the material and removing some of that heat, by using a fan, helps then there is no reason not to. You need to assess, for yourself, whether doing so is detrimental to the object you are printing.

There are rules that say you cannot print layer heights greater than 80% of your nozzle diameter or that layer Width/Height should be close to 1.5. These are all rules that I break because I know that I can do so safely.

The original Wade's block for my Mendel90 kit which nophead printed at 240C+ and 0.4mm layer height (using a nozzle diameter bigger than 0.4mm) failed within 6 months. I replaced that with one printed at 220C and 0.4mm layer height using the standard Mendel90 0.4mm J-Head and that Wade's block is still in service two years later.

When you are given a rule to follow, you should asses the logic behind that rule but do not blindly follow the rule if the logic is not sound.

Regards,

Neil Darlow

Edited 2 time(s). Last edit at 12/30/2015 06:42AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

There is a lot of myth in the 3D printing community relating to many things that should, and should not, be done. There is much advice that is not appropriate to modern materials or hardware and you need to make determinations for yourself.

Yes, using a fan with ABS can be a potential cause of de-lamination but if you are in a situation where there is excess heat in the deposition of the material and removing some of that heat, by using a fan, helps then there is no reason not to. You need to assess, for yourself, whether doing so is detrimental to the object you are printing.

There are rules that say you cannot print layer heights greater than 80% of your nozzle diameter or that layer Width/Height should be close to 1.5. These are all rules that I break because I know that I can do so safely.

The original Wade's block for my Mendel90 kit which nophead printed at 240C+ and 0.4mm layer height (using a nozzle diameter bigger than 0.4mm) failed within 6 months. I replaced that with one printed at 220C and 0.4mm layer height using the standard Mendel90 0.4mm J-Head and that Wade's block is still in service two years later.

When you are given a rule to follow, you should asses the logic behind that rule but do not blindly follow the rule if the logic is not sound.

Regards,

Neil Darlow

Edited 2 time(s). Last edit at 12/30/2015 06:42AM by neildarlow.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Help printing e3D fan duct December 30, 2015 01:19PM |

Registered: 11 years ago Posts: 31 |

The rules you refer to are general best practices. There are certainly situations where those guidelines can be bent and altered when it makes sense, but they require some background knowledge of why the guideline exists in the first place.

In this situation and for the part the OP asked about at the start of this thread, I wouldn't recommend a fan for ABS. I would simply print it slower as we have already discussed -- with the problem area of this part at a minimum speed of 10 mm/s, the smallest layer would take over 20 seconds (probably closer to 25). Slic3r will try to satisfy the minimum layer time by lowering the speed until the calculated print time of the layer is less than the minimum print time, but it will never lower the speed below the minimum speed. In this case if you set the minimum speed to 10 mm/s and the minimum layer time to 20 seconds (or even 15), it will print just fine without going down the rabbit hole of a fan with ABS.

In this situation and for the part the OP asked about at the start of this thread, I wouldn't recommend a fan for ABS. I would simply print it slower as we have already discussed -- with the problem area of this part at a minimum speed of 10 mm/s, the smallest layer would take over 20 seconds (probably closer to 25). Slic3r will try to satisfy the minimum layer time by lowering the speed until the calculated print time of the layer is less than the minimum print time, but it will never lower the speed below the minimum speed. In this case if you set the minimum speed to 10 mm/s and the minimum layer time to 20 seconds (or even 15), it will print just fine without going down the rabbit hole of a fan with ABS.

|

Re: Help printing e3D fan duct December 30, 2015 04:12PM |

Admin Registered: 17 years ago Posts: 7,879 |

>but it will never lower the speed below the minimum speed

Perhaps that is problem. I use Skeinforge that has no minimum speed, so never need to use a fan for ABS and can print very small items.

[www.hydraraptor.blogspot.com]

Perhaps that is problem. I use Skeinforge that has no minimum speed, so never need to use a fan for ABS and can print very small items.

[www.hydraraptor.blogspot.com]

|

Re: Help printing e3D fan duct December 31, 2015 05:49AM |

Registered: 10 years ago Posts: 541 |

My only concern about extremely slow speeds and high extrusion temperature is that you may then start to see the effects of ooze.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Help printing e3D fan duct December 31, 2015 07:22AM |

Admin Registered: 17 years ago Posts: 7,879 |

ABS is still pretty viscous at 250C so it doesn't ooze much. I think ooze while extruding would only be an issue if it was faster than the required extrusion rate. I.e. it doesn't really add to the extrusion rate, simply sets a lower limit on it but that is very small indeed.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Help printing e3D fan duct December 31, 2015 07:23AM |

Admin Registered: 17 years ago Posts: 7,879 |

The only issue I get from extreme slowdown is it no longer spans bridges well because the die swell is reduced at low pressure.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.

700 mm/min

700 mm/min