x carriage fan duct for E3D-V6

Posted by wgaona

|

x carriage fan duct for E3D-V6 March 31, 2016 01:39AM |

Registered: 11 years ago Posts: 32 |

Recently I read the post of NopHeadt: A bridge too far about printing the fan duct for the E3D hot end. He concluded that

Slic3r gives the better slicing for this part in particular.

Nevertheless I have been using Skeinforge for a while and I prefer it by its accuracy.

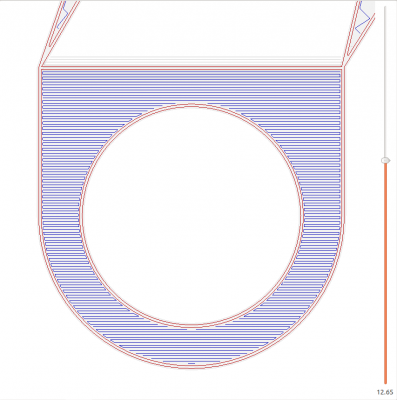

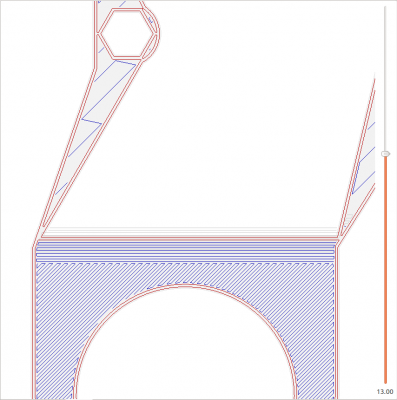

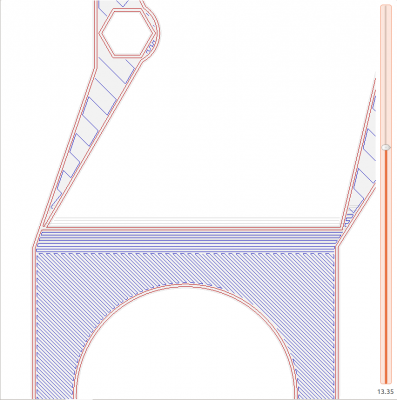

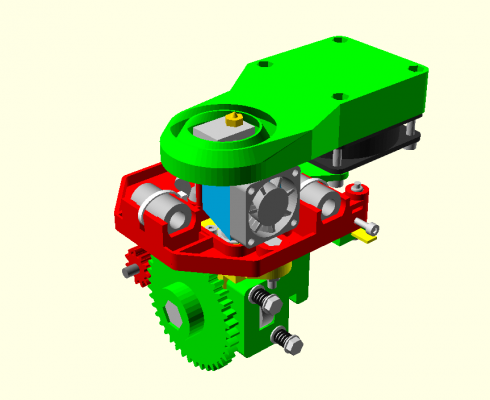

The printed x carriage fan duct can be seen in the attached pictures.

It was good, despite a little error filling in 2 layers the holes where the screws are inserted.

In the pictures can be observed too, the bridge is almost perfect in the sense that there is no a hanging thread.

The main parameters that I used are: Infill Begin Rotation to 0 degrees and Infill odd Layer Extra Rotation to 0 too.

I now that this values decrease the mechanical resistance of the part, but in this case, the fan duct is not under load or under a fluctuating load.

Edited 1 time(s). Last edit at 03/31/2016 01:40AM by wgaona.

Slic3r gives the better slicing for this part in particular.

Nevertheless I have been using Skeinforge for a while and I prefer it by its accuracy.

The printed x carriage fan duct can be seen in the attached pictures.

It was good, despite a little error filling in 2 layers the holes where the screws are inserted.

In the pictures can be observed too, the bridge is almost perfect in the sense that there is no a hanging thread.

The main parameters that I used are: Infill Begin Rotation to 0 degrees and Infill odd Layer Extra Rotation to 0 too.

I now that this values decrease the mechanical resistance of the part, but in this case, the fan duct is not under load or under a fluctuating load.

Edited 1 time(s). Last edit at 03/31/2016 01:40AM by wgaona.

|

Re: x carriage fan duct for E3D-V6 March 31, 2016 03:54AM |

Admin Registered: 17 years ago Posts: 7,879 |

What layer height and width are you using?

The bridges over the holes are deliberate. That is where it transitions from a hex nut trap to a round hole, so the outline of the hole would be printed in mid air without the support membrane. I drilled them out for the kits. If I was designing it again I would probably use this technique but it is very slicer setting dependent.

[www.hydraraptor.blogspot.com]

The bridges over the holes are deliberate. That is where it transitions from a hex nut trap to a round hole, so the outline of the hole would be printed in mid air without the support membrane. I drilled them out for the kits. If I was designing it again I would probably use this technique but it is very slicer setting dependent.

[www.hydraraptor.blogspot.com]

|

Re: x carriage fan duct for E3D-V6 March 31, 2016 09:44AM |

Registered: 11 years ago Posts: 32 |

|

Re: x carriage fan duct for E3D-V6 March 31, 2016 02:51PM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes all the parts are designed to be printable without support material, so no outlines in mid air. In practice the ribbon clamps need support because the bridges are so close to the bed they droop. I removed all the support membranes before sending them out.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: x carriage fan duct for E3D-V6 May 02, 2016 01:47AM |

Registered: 11 years ago Posts: 90 |

Sorry for jumping in, I tried the latest version of Slic3r (1.3.0-dev 510ca9f) and bridges seem to work fine.

I am currently printing this, so I could update you on the results once finished.

I am currently printing this, so I could update you on the results once finished.

|

Re: x carriage fan duct for E3D-V6 May 02, 2016 04:40AM |

Registered: 11 years ago Posts: 90 |

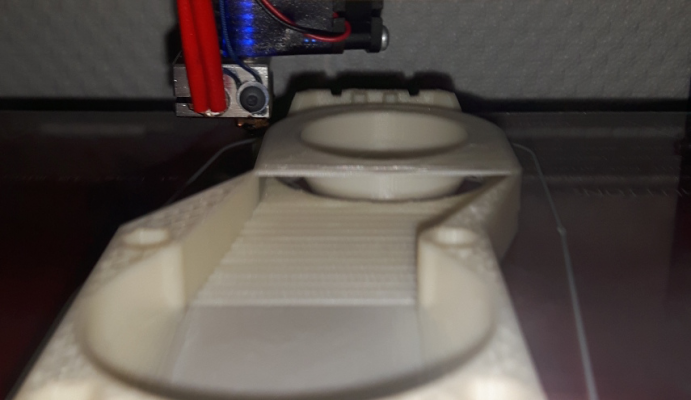

I think the bridge turned out well. The photo shows printing of the layers after the bridge

@nophead: The distance between the bracket mounting slots seems much smaller than it should and does not fit my printer (bought it March 2013). Is there another version of the x-axis carriage? Also, how do you orient the e3d hotend in order to fit the duct?

Thanks.

Edited 1 time(s). Last edit at 05/02/2016 04:42AM by demetris.

@nophead: The distance between the bracket mounting slots seems much smaller than it should and does not fit my printer (bought it March 2013). Is there another version of the x-axis carriage? Also, how do you orient the e3d hotend in order to fit the duct?

Thanks.

Edited 1 time(s). Last edit at 05/02/2016 04:42AM by demetris.

|

Re: x carriage fan duct for E3D-V6 May 02, 2016 05:55AM |

Admin Registered: 17 years ago Posts: 7,879 |

Looks like you are trying to fit the parts for the sturdy version to a dibond machine.

The assembly looks like this:

[www.hydraraptor.blogspot.com]

The assembly looks like this:

[www.hydraraptor.blogspot.com]

|

Re: x carriage fan duct for E3D-V6 May 03, 2016 08:04AM |

Registered: 11 years ago Posts: 90 |

Sorry, only registered users may post in this forum.