Help with a few printing issues

Posted by tracyj

|

Help with a few printing issues April 27, 2014 06:12PM |

Registered: 10 years ago Posts: 10 |

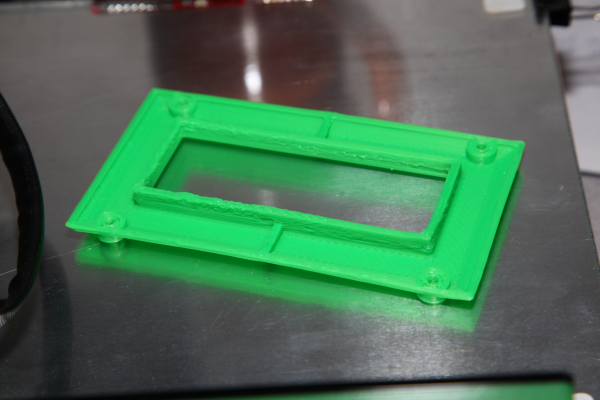

I am attempting to print a bezel for an LCD display that I created in Sketchup, and I am getting some bad printing artifacts. The first image shows that the first half of the inside of the bezel printing decently, but then on the upper half it starts to look like cottage cheese.

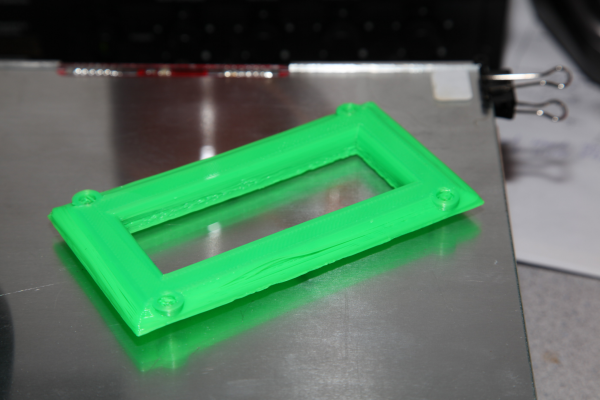

The problem with the second image is a bridging issue. The part is printed face down, so the second image is looking at the part that was contacting the bed. The beveled overhang prints with some of the filaments sagging. I know that there are several people who have come up with better air ducts to help improve bridging, but is there something I can change in the settings to help without printing a new air duct. I would also like suggestions about the best air duct without getting too complicated like Kim Brown's big blue. I was hoping that I wouldn't have the bridging issue with this since it is beveled, and not a straight across bridge. It sags in the screw holes as well.

Thanks for any help

Tracy

The problem with the second image is a bridging issue. The part is printed face down, so the second image is looking at the part that was contacting the bed. The beveled overhang prints with some of the filaments sagging. I know that there are several people who have come up with better air ducts to help improve bridging, but is there something I can change in the settings to help without printing a new air duct. I would also like suggestions about the best air duct without getting too complicated like Kim Brown's big blue. I was hoping that I wouldn't have the bridging issue with this since it is beveled, and not a straight across bridge. It sags in the screw holes as well.

Thanks for any help

Tracy

|

Re: Help with a few printing issues April 27, 2014 07:08PM |

Registered: 10 years ago Posts: 10 |

|

Re: Help with a few printing issues April 27, 2014 08:19PM |

Registered: 10 years ago Posts: 14,672 |

I suggest a lower hotend temperature to start with, because 205 is much too high for standard PLA. Try 195 for the first layer and between 180 and 190 for the remainder.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Help with a few printing issues April 27, 2014 08:25PM |

Registered: 10 years ago Posts: 859 |

Hi Traceyj, Welcome... Sorry if you've posted before and I've missed it, but it seems like a fresh name to me.

OK, here's my suggestions.

Use a Big Blue, because it will help with more than the bridging.

It's not complicated, I put allot of time in to making easy. But you do have to turn the Ally block with the heater in through 90' because it was going to

be a major event trying to get the cooling ducts to accomodate the heater wires.

If you need help with fitting it, then PM me, I'll do my best to help.

Thinking of which, I must change my X-motor back to the original so I can make an Original Probe mounting bracket for it, which is something I forgot till just now.

The Probe plate I did for mounting the original probe was for the Modified X-axis motor mount, not the original one oops... I'll fix that, and design another mount in the morning.

oops... I'll fix that, and design another mount in the morning.

When you print a Big Blue, you will find an array of 0.25mm walls on the bottom. Just snap them off with your fingers (or pliers), and tidy up the edges if you want to.

If you want to remove the support column half way up BB, you can, but you might not have to, it's there for printing only, and can be removed if you want.

I took allot of time to make it simple, so hopefully just mounting the HeatSink with the fins verticaly, and a few screws and it's done. (You might have to drill a 3.5mm hole in the heatsink to get the fins vertical, then fill the redunt hole with glue)....

Then you can Bridge to your hearts content, and your big prints won't get Warping from over cooling. You should find you can lower your temps, and get a better quality print, to which I'm just about to start another topic on.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

OK, here's my suggestions.

Use a Big Blue, because it will help with more than the bridging.

It's not complicated, I put allot of time in to making easy. But you do have to turn the Ally block with the heater in through 90' because it was going to

be a major event trying to get the cooling ducts to accomodate the heater wires.

If you need help with fitting it, then PM me, I'll do my best to help.

Thinking of which, I must change my X-motor back to the original so I can make an Original Probe mounting bracket for it, which is something I forgot till just now.

The Probe plate I did for mounting the original probe was for the Modified X-axis motor mount, not the original one

oops... I'll fix that, and design another mount in the morning.

oops... I'll fix that, and design another mount in the morning.When you print a Big Blue, you will find an array of 0.25mm walls on the bottom. Just snap them off with your fingers (or pliers), and tidy up the edges if you want to.

If you want to remove the support column half way up BB, you can, but you might not have to, it's there for printing only, and can be removed if you want.

I took allot of time to make it simple, so hopefully just mounting the HeatSink with the fins verticaly, and a few screws and it's done. (You might have to drill a 3.5mm hole in the heatsink to get the fins vertical, then fill the redunt hole with glue)....

Then you can Bridge to your hearts content, and your big prints won't get Warping from over cooling. You should find you can lower your temps, and get a better quality print, to which I'm just about to start another topic on.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Help with a few printing issues April 27, 2014 08:44PM |

Registered: 10 years ago Posts: 859 |

I was going to add a PS there about the temps... But DC has beaten me to it...

However you do have a difficult print there. 195' as DC suggests might be a better choice. With a BB 55' / 60' is real good for PLA as well for the Bed.

I found on some prints with a higher bed temp I get blistering and sometimes the HotEnd actualy picks it up and drags the blister around the print wrecking it.

A lower bed temp fixes that, and with BB you don't have the BackWash cooling the print, so you can safely lower the temp.

I would add one thing, and that is to use his firmware, as well.... I use his 57y at the moment, and it's pretty good, and miles better than the original Rep-Rap one.

It would be interesting to here your progress.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

However you do have a difficult print there. 195' as DC suggests might be a better choice. With a BB 55' / 60' is real good for PLA as well for the Bed.

I found on some prints with a higher bed temp I get blistering and sometimes the HotEnd actualy picks it up and drags the blister around the print wrecking it.

A lower bed temp fixes that, and with BB you don't have the BackWash cooling the print, so you can safely lower the temp.

I would add one thing, and that is to use his firmware, as well.... I use his 57y at the moment, and it's pretty good, and miles better than the original Rep-Rap one.

It would be interesting to here your progress.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Help with a few printing issues April 28, 2014 01:07AM |

Registered: 10 years ago Posts: 378 |

Quote

dc42

I suggest a lower hotend temperature to start with, because 205 is much too high for standard PLA. Try 195 for the first layer and between 180 and 190 for the remainder.

Yeah, all those issues are consistent with temperature being too high. Drop it down a bit and it will probably print fine, no matter which airduct thingy you have.

|

Re: Help with a few printing issues April 28, 2014 01:19AM |

Registered: 10 years ago Posts: 10 |

Hi Kim,

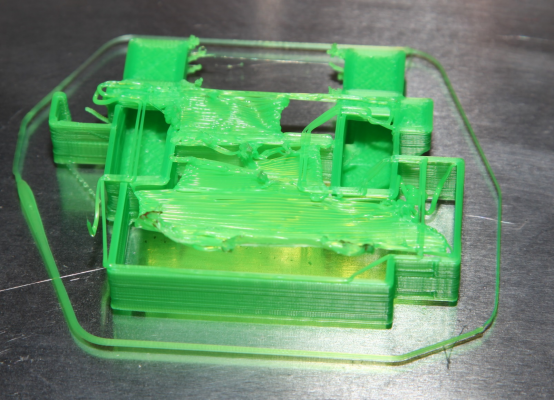

Thanks for the response. I decided to go ahead and print up a Big Blue. I set my bed and extruder temps as you and dc42 had suggested. I also updated my firmware to dc42s 57y. Now I am having problems with the bridging just trying to get the Big Blue printed. It appears that the first large bridged layer that makes up the bottom of the duct at about 1cm high would print okay, however it looks like the y carriage travel isn't far enough to attach the filament to the opposite walls. Below is a picture of what happened. The bottom of the duct printed pretty good, but then curled up because it wasn't attached to each side wall. The curling jammed the print head, and then the y axis slipped. It was all over at that point so I stopped it. Could that be a Slic3r issue? I am running Version 0.9.9, and I know there is a newer version out there.

By the way, I am new to this group. I just got my Ormerod built about a week ago.

Thanks

Tracy

Thanks for the response. I decided to go ahead and print up a Big Blue. I set my bed and extruder temps as you and dc42 had suggested. I also updated my firmware to dc42s 57y. Now I am having problems with the bridging just trying to get the Big Blue printed. It appears that the first large bridged layer that makes up the bottom of the duct at about 1cm high would print okay, however it looks like the y carriage travel isn't far enough to attach the filament to the opposite walls. Below is a picture of what happened. The bottom of the duct printed pretty good, but then curled up because it wasn't attached to each side wall. The curling jammed the print head, and then the y axis slipped. It was all over at that point so I stopped it. Could that be a Slic3r issue? I am running Version 0.9.9, and I know there is a newer version out there.

By the way, I am new to this group. I just got my Ormerod built about a week ago.

Thanks

Tracy

|

Re: Help with a few printing issues April 28, 2014 08:38AM |

Registered: 10 years ago Posts: 2,472 |

The issue with not reaching the ends of the bridge can be caused by the belt being a bit too loose (so there is backlash in the movement). This is more likely with the Y belt (because the X belt is easier to adjust). If this is the problem, you may find your bezel prints OK if you rotate it 90 degrees in Slic3r. I suggest printing one of the alternate Y belt mounts that make the belt attachment much more secure and easier to adjust, though you may have to battle to get the belt tighter in order to make a successful print - it's a bit of a chicken-and-egg situation.

It can also be a result of printing too fast. Slic3r has a separate speed setting for printing bridges. Try setting to 15mm/s. I suggest that you get the settings and adjustments good enough to print your bezel before attempting Kim's design, because the bridging needed for Kim's part is more challenging than your bezel (which looks a great design, btw).

The "cottage cheese" effect was almost certainly a result of a too high extrusion temperature in your case, though it can also occur in my experience if the speed is too fast or the filament has absorbed too much water. If all else fails to improve matters, try a completely different filament (different batch and colour). I have had reels that give a poor result on a machine that works fine with other filaments of the same type.

Dave

(#106)

It can also be a result of printing too fast. Slic3r has a separate speed setting for printing bridges. Try setting to 15mm/s. I suggest that you get the settings and adjustments good enough to print your bezel before attempting Kim's design, because the bridging needed for Kim's part is more challenging than your bezel (which looks a great design, btw).

The "cottage cheese" effect was almost certainly a result of a too high extrusion temperature in your case, though it can also occur in my experience if the speed is too fast or the filament has absorbed too much water. If all else fails to improve matters, try a completely different filament (different batch and colour). I have had reels that give a poor result on a machine that works fine with other filaments of the same type.

Dave

(#106)

|

Re: Help with a few printing issues April 28, 2014 09:13AM |

Registered: 10 years ago Posts: 859 |

Dave has said most of it. I did have a similar issue with Slic3r, when the first layer of a bridge didn't quite reach, but I also found my nozzle was tilted at a slight angle. So one direction it would reach one end, the other direction it wouldn't. I replaced the Nozzle mount with one of my mod ones, and upgrade Slic3r....

From your picture the bottom wall in the picture looks abit thick. It should be 0.25mm so it's thick enough to support the print, but thin enough to snap off afterwards. In Slic3r there's a setting for the filament thickness. I'd suggest you look at the setting and maybe raise it a little. If you have it set to 1.74mm try 1.8mm and it should decrease the flow a little.

(BTW Look at the failed prints bottom side, the glass side.... The squiggles of filament should be the same thickness in both directions. If they aren't then the filament is rolling off the nozzle instead of being pushed on to the glass meaning your nozzle is tilted).

It could well be your Y belt is to tight as Dave says. Look around the Y-idler end, and see if you have any black dust.

When the belt is to tight it pulls the printed frame over, and tilts the bearing, so the belt rubs on the printed frame.

Iamburnys Y-belt tensioner is really good. I use his version 7 here that I like. After printing you can clean out the belt slots with a watch makers screwdriver.

I had to put spacers behind mine to reduce the tention, but you can use solid cardboard, plasticard, or anything for that....

Seems your having abit of a trial with all this... Stick with it, you'll get there... and the machine will be allot better afterwards....

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

From your picture the bottom wall in the picture looks abit thick. It should be 0.25mm so it's thick enough to support the print, but thin enough to snap off afterwards. In Slic3r there's a setting for the filament thickness. I'd suggest you look at the setting and maybe raise it a little. If you have it set to 1.74mm try 1.8mm and it should decrease the flow a little.

(BTW Look at the failed prints bottom side, the glass side.... The squiggles of filament should be the same thickness in both directions. If they aren't then the filament is rolling off the nozzle instead of being pushed on to the glass meaning your nozzle is tilted).

It could well be your Y belt is to tight as Dave says. Look around the Y-idler end, and see if you have any black dust.

When the belt is to tight it pulls the printed frame over, and tilts the bearing, so the belt rubs on the printed frame.

Iamburnys Y-belt tensioner is really good. I use his version 7 here that I like. After printing you can clean out the belt slots with a watch makers screwdriver.

I had to put spacers behind mine to reduce the tention, but you can use solid cardboard, plasticard, or anything for that....

Seems your having abit of a trial with all this... Stick with it, you'll get there... and the machine will be allot better afterwards....

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Help with a few printing issues April 28, 2014 03:08PM |

Registered: 10 years ago Posts: 10 |

I tightened up the x and y belts, I set the bridging speed to 15mm/s and I set the filament size to 1.8mm. It didn't make a bit of difference when printing Big Blue when it got to doing the bridges. Even the small bridges that print first did the same thing. I carefully watched to see where the nozzle stopped moving and reversed. To me it looked like the nozzle wasn't even getting close to the side wall on either side. If the nozzle were tilted, I would expect it to maybe hit one side, but not the other. I don't understand how there would be a prayer of the bridge working if the nozzle doesn't even come into contact with the side walls. What version of Slice3r is everyone using? Is there a setting in Slice3r that tells it how much overlap it should have on bridges? It appears to fill in just fine when it isn't doing bridges, but in that case it has something beneath it to squash against as it comes out of the nozzle which would make it spread out a little.

Thanks

Tracy

Thanks

Tracy

|

Re: Help with a few printing issues April 28, 2014 03:27PM |

Registered: 10 years ago Posts: 780 |

Hi,

update the following to the latest versions:- slic3r, firmware and interface, you should see a big difference.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

update the following to the latest versions:- slic3r, firmware and interface, you should see a big difference.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Help with a few printing issues April 29, 2014 07:43AM |

Registered: 10 years ago Posts: 2,472 |

What may be happening is that the walls that the bridge is supposed to attach to are not printing thick enough, so they are slightly further apart than they should be, meaning the bridges don't touch them.

Hopefully you have calibrated your extruder as in the RRP instructions by measuring the filament extruded, but have you done a thin wall test to calibrate the extruder ratio? Calibrating the length of filament is only one aspect of extruder calibration - you also need to print a single-wall box and measure the wall thickness, then adjust your extrusion multiplier in Slic3r to produce the correct wall thickness.

Set your filament to the correct size in Slic3r (1.75mm). Changing that size is a frig used when the software does not have any other way of adjusting the extrusion amount. Slic3r has an "extrusion multiplier" variable that you should use instead (though it achieves the same thing - just easier to calculate). Initially set the extrusion multiplier to 1.000 and print a single wall box - just slice an STL of a simple cube (say 20mm per side or so) with perimeters set to 1 and infill set to 0, bottom solid layers 2 or 3 and top layers 0. You can stop it as soon as the walls are high enough to measure. Don't forget to save the settings before slicing (otherwise they don't take effect), and check after saving that the values you entered have not reverted back - some versions of Slic3r have a bug in that respect.

Open the G code with a text editor and see what the perimeter thickness is in the comments at the start (usually 0.5mm).

Measure the 4 walls of your test box with vernier or digital calipers and see what the actual thickness is - take the average of the 4 walls.

Now calculate the extrusion multiplier by dividing the G file thickness by your measured thickness, and plug that value into the "extrusion multiplier" field.

If you print another thin wall box it should then have the correct wall thickness.

Dave

(#106)

Hopefully you have calibrated your extruder as in the RRP instructions by measuring the filament extruded, but have you done a thin wall test to calibrate the extruder ratio? Calibrating the length of filament is only one aspect of extruder calibration - you also need to print a single-wall box and measure the wall thickness, then adjust your extrusion multiplier in Slic3r to produce the correct wall thickness.

Set your filament to the correct size in Slic3r (1.75mm). Changing that size is a frig used when the software does not have any other way of adjusting the extrusion amount. Slic3r has an "extrusion multiplier" variable that you should use instead (though it achieves the same thing - just easier to calculate). Initially set the extrusion multiplier to 1.000 and print a single wall box - just slice an STL of a simple cube (say 20mm per side or so) with perimeters set to 1 and infill set to 0, bottom solid layers 2 or 3 and top layers 0. You can stop it as soon as the walls are high enough to measure. Don't forget to save the settings before slicing (otherwise they don't take effect), and check after saving that the values you entered have not reverted back - some versions of Slic3r have a bug in that respect.

Open the G code with a text editor and see what the perimeter thickness is in the comments at the start (usually 0.5mm).

Measure the 4 walls of your test box with vernier or digital calipers and see what the actual thickness is - take the average of the 4 walls.

Now calculate the extrusion multiplier by dividing the G file thickness by your measured thickness, and plug that value into the "extrusion multiplier" field.

If you print another thin wall box it should then have the correct wall thickness.

Dave

(#106)

|

Re: Help with a few printing issues April 29, 2014 10:27AM |

Registered: 10 years ago Posts: 14,672 |

I had the same bridging issue althought the bridge (a short one) did work, see [forums.reprap.org]. I checked the gcode and it was putting the head 0.25mm over the edge of each wall at the ends of the bridge, which is correct for the configured 0.5mm filament width. What I think was happening is that the print head was turning round so fast at each end of the bridge that the filament hadn't solidified before the nozzle was pulling it away from the wall.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.