Filament gets stuck all over the nozzle

Posted by Sardi

|

Filament gets stuck all over the nozzle May 07, 2014 03:27PM |

Registered: 10 years ago Posts: 466 |

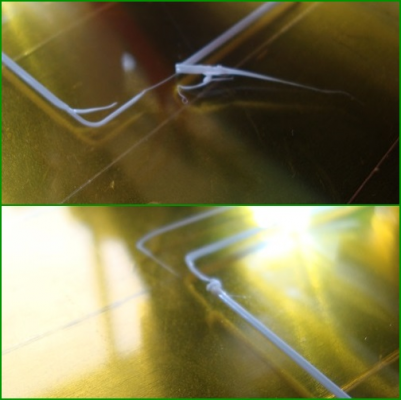

This started happening out of nowhere and nothing. Havent changed any setting in slicer or anywhere, havent done any modifications to the printer etc etc.

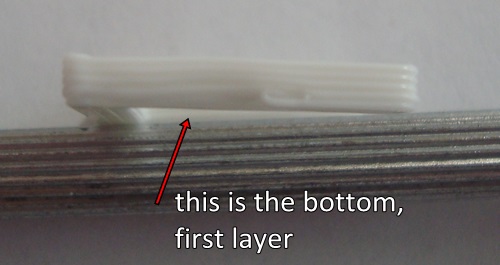

When it was just like this, I could bring my print to an end, but I had to stop my last 8 prints at the beginning of the first layer..

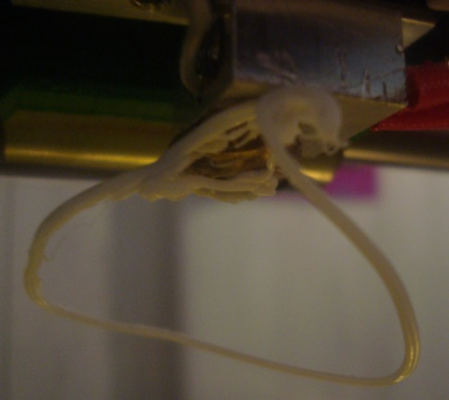

Just out of a sudden, the filament, as soon as it gets out of the nozzle and touches the bed, it kind of swirls and gets back to the side of the nozzle so that the head is draging it along destroying everything, because on return to the first positions, almost all of the filament gets scrambled, displaced, draged with the nozzle, then the new filament that comes out just starts sticking to the side of the nozzle with the other filament creating a total mess...

In the last 2 hrs I have cleaned the nozzle 20 times, each time I start with a clean nozzle, and must stop the print after the skrit is done (or whats left of it).

I have absolutely no ide howcome this happened. Ive been printing at ext. 185/180 and bed 80/75, and was in the middle of trying out the ormerod0-5 slic3r settings with 0.24 layer height.

Any ideas?

Antonio

Edited 1 time(s). Last edit at 05/07/2014 03:37PM by Sardi.

When it was just like this, I could bring my print to an end, but I had to stop my last 8 prints at the beginning of the first layer..

Just out of a sudden, the filament, as soon as it gets out of the nozzle and touches the bed, it kind of swirls and gets back to the side of the nozzle so that the head is draging it along destroying everything, because on return to the first positions, almost all of the filament gets scrambled, displaced, draged with the nozzle, then the new filament that comes out just starts sticking to the side of the nozzle with the other filament creating a total mess...

In the last 2 hrs I have cleaned the nozzle 20 times, each time I start with a clean nozzle, and must stop the print after the skrit is done (or whats left of it).

I have absolutely no ide howcome this happened. Ive been printing at ext. 185/180 and bed 80/75, and was in the middle of trying out the ormerod0-5 slic3r settings with 0.24 layer height.

Any ideas?

Antonio

Edited 1 time(s). Last edit at 05/07/2014 03:37PM by Sardi.

|

Re: Filament gets stuck all over the nozzle May 07, 2014 04:45PM |

Registered: 10 years ago Posts: 157 |

|

Re: Filament gets stuck all over the nozzle May 07, 2014 05:38PM |

Registered: 10 years ago Posts: 466 |

Nothing helps... cleaning, washing, changing temperatures, switching the printing side from glass to kapton....

I am thinking that I messed something up in Slic3r settings, because its the first contact of the filament with the bed that makes all the problems. Even if the skirt does its loop, when it retracts and shoots the filament out again to start the first layer - same problems occur.

I am thinking that I messed something up in Slic3r settings, because its the first contact of the filament with the bed that makes all the problems. Even if the skirt does its loop, when it retracts and shoots the filament out again to start the first layer - same problems occur.

|

Re: Filament gets stuck all over the nozzle May 07, 2014 06:19PM |

Registered: 10 years ago Posts: 859 |

Hi Sardi, 3D is right I think, but check your bed is level as well. I don't run compensation here... It's simpler to run a level bed.

I improved the bed to make it more rigid, and the printer travels around the country and clocks up 1200 miles a month.

So it get's knocked about in it's box, even thou I try to protect it.

For cleaning the nozzle my friend, use a Leather gardening glove.

Heat the HotEnd, put the glove on, and give it a good rub. It's gentle, and brings it up as new. Just don't hold your finger still to long.

I normaly do a fast 5mm retract before hand, then it's good for a while before printing.

Also see my automated cleaner... It drags alot of rubbish off. I try to remember to do a pass throu the clean before every print.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I improved the bed to make it more rigid, and the printer travels around the country and clocks up 1200 miles a month.

So it get's knocked about in it's box, even thou I try to protect it.

For cleaning the nozzle my friend, use a Leather gardening glove.

Heat the HotEnd, put the glove on, and give it a good rub. It's gentle, and brings it up as new. Just don't hold your finger still to long.

I normaly do a fast 5mm retract before hand, then it's good for a while before printing.

Also see my automated cleaner... It drags alot of rubbish off. I try to remember to do a pass throu the clean before every print.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Filament gets stuck all over the nozzle May 07, 2014 07:16PM |

Registered: 10 years ago Posts: 466 |

|

Re: Filament gets stuck all over the nozzle May 07, 2014 07:32PM |

Registered: 10 years ago Posts: 378 |

|

Re: Filament gets stuck all over the nozzle May 07, 2014 10:15PM |

Registered: 10 years ago Posts: 780 |

It looks as if your nozzle is too high. How are you setting your Z0?

I heat the bed and nozzle up to temperature, run bed compensation, go to X100, Y100, lower nozzle so that a piece of normal copy paper just slides in and out under the nozzle, issue G92 Z0 (I think that's right, I'm away from my machine). Then start your print.

Hope that helps

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I heat the bed and nozzle up to temperature, run bed compensation, go to X100, Y100, lower nozzle so that a piece of normal copy paper just slides in and out under the nozzle, issue G92 Z0 (I think that's right, I'm away from my machine). Then start your print.

Hope that helps

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Filament gets stuck all over the nozzle May 08, 2014 01:08AM |

Registered: 10 years ago Posts: 859 |

Hi Sardi, thanks for that.....

I've corrected it.... I best check the others later.

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I've corrected it.... I best check the others later.

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Filament gets stuck all over the nozzle May 08, 2014 02:16AM |

Registered: 10 years ago Posts: 1,230 |

Quote

appjaws1

.. lower nozzle so that a piece of normal copy paper just slides in and out under the nozzle, issue G92 Z0..

As the slicer program expect zero to be absolute it would be more appropriate to zero on nothing, but nothing is hard to handle and find in the toolbox when needed (the upside here is that nothing is lost) the only findable close to nothing-thing I can think of is household aluminum foil at 0.011 mm - and fingerspitzgefühl, lots of it

Erik

|

Re: Filament gets stuck all over the nozzle May 08, 2014 02:42AM |

Registered: 10 years ago Posts: 14,672 |

I had a similar problem when I was a few tens of metres into a new reel of filament. Eventually I switched to another reel from a different supplier and the problem went away.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Filament gets stuck all over the nozzle May 08, 2014 04:07AM |

Registered: 10 years ago Posts: 466 |

New day, new try.

The nozzle is spottles clean, the bed was washed with soapy water and later cleaned with white vinegar (Im printing on glass).

I have done the mechanical bed leveling with a piece of paper (it worked fine till this problem occured) and all 4 corners are within a piece of paper from the bed, and I have Kims hexgears installed.

Also occured to me as a potential problem maker as I have ruled out the bed, temperature, nozzle and slic3r settings. I am still at the PLA reel provided with the kit, and I am almost at the end of it, maybe less than a 100m left.

Edited 1 time(s). Last edit at 05/08/2014 04:09AM by Sardi.

The nozzle is spottles clean, the bed was washed with soapy water and later cleaned with white vinegar (Im printing on glass).

Quote

ormerod168

Quote

appjaws1

.. lower nozzle so that a piece of normal copy paper just slides in and out under the nozzle, issue G92 Z0..

As the slicer program expect zero to be absolute it would be more appropriate to zero on nothing, but nothing is hard to handle and find in the toolbox when needed (the upside here is that nothing is lost) the only findable close to nothing-thing I can think of is household aluminum foil at 0.011 mm - and fingerspitzgefühl, lots of it

Erik

I have done the mechanical bed leveling with a piece of paper (it worked fine till this problem occured) and all 4 corners are within a piece of paper from the bed, and I have Kims hexgears installed.

Quote

dc42

I had a similar problem when I was a few tens of metres into a new reel of filament. Eventually I switched to another reel from a different supplier and the problem went away.

Also occured to me as a potential problem maker as I have ruled out the bed, temperature, nozzle and slic3r settings. I am still at the PLA reel provided with the kit, and I am almost at the end of it, maybe less than a 100m left.

Edited 1 time(s). Last edit at 05/08/2014 04:09AM by Sardi.

|

Re: Filament gets stuck all over the nozzle May 08, 2014 05:43AM |

Registered: 10 years ago Posts: 466 |

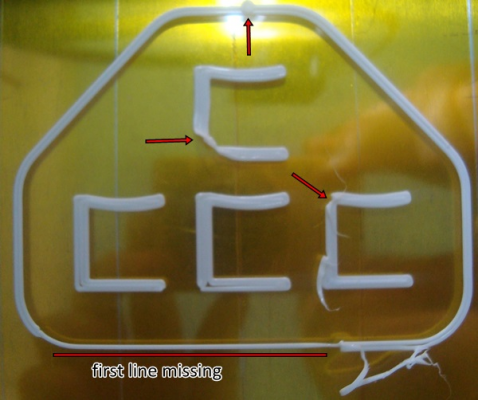

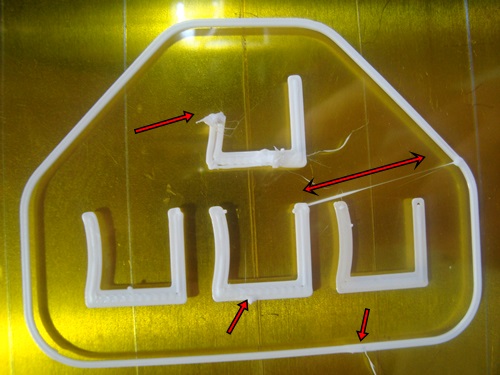

These bed clips are my models for testing if everthing is ok.

As you can see, not everything is ok.

Its as if the filament doesnt want to touch the bed

I am going to see if the hobbed gear is dirty before switching to a new reel of filament.

Edited 1 time(s). Last edit at 05/08/2014 05:51AM by Sardi.

As you can see, not everything is ok.

Its as if the filament doesnt want to touch the bed

I am going to see if the hobbed gear is dirty before switching to a new reel of filament.

Edited 1 time(s). Last edit at 05/08/2014 05:51AM by Sardi.

|

Re: Filament gets stuck all over the nozzle May 08, 2014 05:52AM |

Registered: 10 years ago Posts: 19 |

How "old" is your spool of filament?

I have experienced the same problem toward the end of a 1KG spool, and it was likely due to the PLA having absorbed humidity along time.

Check if you can hear small popping sounds from the nozzle due to the evaporating humidity.

With a new spool the problem was gone.

I have experienced the same problem toward the end of a 1KG spool, and it was likely due to the PLA having absorbed humidity along time.

Check if you can hear small popping sounds from the nozzle due to the evaporating humidity.

With a new spool the problem was gone.

|

Re: Filament gets stuck all over the nozzle May 08, 2014 06:13AM |

Registered: 10 years ago Posts: 466 |

Cant hear a bloody thing over the sound of the fanQuote

aesuli

Check if you can hear small popping sounds from the nozzle due to the evaporating humidity.

Quote

aesuli

How "old" is your spool of filament?

I have experienced the same problem toward the end of a 1KG spool, and it was likely due to the PLA having absorbed humidity along time.

Check if you can hear small popping sounds from the nozzle due to the evaporating humidity.

With a new spool the problem was gone.

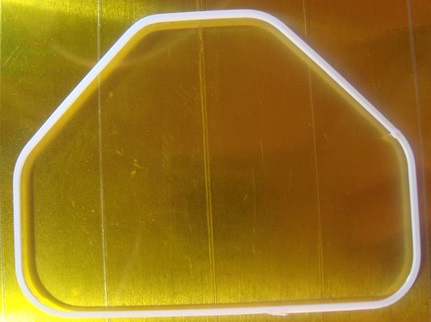

This is whats left of the reel.

Well I think you and DC42 might be on the right track. The spool I am using came with the kit (300m reel) and its almost done now. Its been out in the open for a month now, and Ive been printing for the last 2 weeks or so (give or take).

Altough I did switch rooms a 2 days ago, till then I was in a colder room, with much much less sunlight. The room I am in now heats up pretty nicely, especially in the morning.

Edited 3 time(s). Last edit at 05/08/2014 08:31AM by Sardi.

|

Re: Filament gets stuck all over the nozzle May 08, 2014 08:33AM |

Registered: 10 years ago Posts: 2,472 |

The paper method is pretty good. While the nozzle is about 0.1mm above the bed when it first touches the paper, it must be lower in order to put pressure on the paper to exert the drag you can feel, and that probably just brings it into contact with the bed after the paper is removed. I've become pretty good at estimating the amount of drag that will produce the best first layer, and can probably get the correct height by feel to within 0.05mm or so, which is smaller than the non-linear variations in my bed height so there's no point in getting any more accuracy.

Dave

(#106)

Dave

(#106)

|

Re: Filament gets stuck all over the nozzle May 08, 2014 09:01AM |

Registered: 10 years ago Posts: 466 |

Quote

dmould

While the nozzle is about 0.1mm above the bed when it first touches the paper, it must be lower in order to put pressure on the paper to exert the drag you can feel, and that probably just brings it into contact with the bed after the paper is removed.

Dave

(#106)

Exactly. I level the bed at Z 0.0 and while the paper is under the nozzle, if I press Z-0.1 the nozzle puts pressure on the paper, if I press Z-0.1 again, the paper is pretty hard to get out.

On topic, I have moved back to the cold room and the result is:

So almost the same, altough better, than yesterday

It as if the extrusion of the first few mm of filament is darn slow..

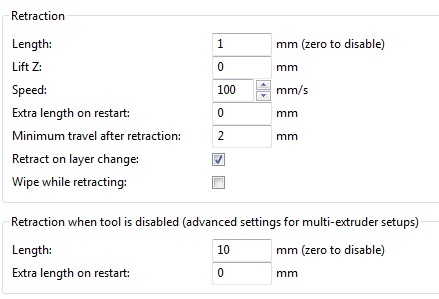

Maybe to add a value to slic3r -> Printer Settings -> Extruder 1 -> Retraction -> Extra lenght on restart? Currently 0.

EDIT:

Third try, this time I rotated the position of the models but some problems occur at the same positions.

The only problems I have is with retraction and extrusion. If anyone else tells me to change the filament reel, Ill do it, but to me this doesnt look like a filament issue since 90% of the model is ok, and the only problem is at "first contact" (as I call it now).

Edited 5 time(s). Last edit at 05/08/2014 09:25AM by Sardi.

|

Re: Filament gets stuck all over the nozzle May 08, 2014 09:37AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Sardi

It as if the extrusion of the first few mm of filament is darn slow..

Maybe to add a value to slic3r -> Printer Settings -> Extruder 1 -> Retraction -> Extra lenght on restart? Currently 0.

No need - that's the main function of the skirt - it gives the filament a chance to get flowing. It's normal that the start of the first loop of the skirt doesn't print. I have set the loop count to one and the minimum extrusion length to 15mm in Slic3r "skirt & brim" settings. Then, if the part is so small that the skirt length is insufficient to get the plastic flowing before it starts printing the part, Slicer will add more loops until the total loop length is at least 15mm (by which time the plastic should definitely be flowing steadily). It doesn't matter that your print will not be surrounded by a full skirt, but if you don't like it, set the loop count higher.

If you set Slic3r to extrude filament before the start as you suggest, you'll be dragging a length of extrusion around, which could get tangled in the print. The dribble that comes out when the extruder heats is bad enough without adding more!

The lifting of the part is definitely poor bed adhesion, caused either by bad bed preparation/temperature or Z zero height too high (which in turn can be caused by incorrect bed compensation so the nozzle is too high in some places but not others). The MDF bed support is unstable, so you really need to re-do your bed compensation figures before every print because they will change. I found solvent cement (pipe joining glue) painted on plain glass to work a treat, but others have their own pet bed preparations. Try a few alternatives to see which one works best for you. It's likely you will need to try something different if you change material (e.g. to ABS).

Dave

(#106)

|

Re: Filament gets stuck all over the nozzle May 08, 2014 10:02AM |

Registered: 10 years ago Posts: 466 |

Thanks dmould. I have re-checked the bed level again with a sheet of paper and it is level at Z0.0 at all 4 corners.

Also, when the skirt goes ok, sometimes the start of the first layer of my models goes wrong.

I am much confused here I must tell you. This started happening yesterday out of nowhere.

But what troubles me at the moment is what you clearly explained

BUT .. I didnt set the Slic3r to extrude filament before the start! The Gcode sets the hot head at the start position and starts heating the head to 185C, but the PLA starts dripping as soon as the temperature hits 150C. So in those 35C I have about 1cm of filament hanging from the nozzle.

I also always pre-heat the bed (85 first layer, 80 other) otherwise a lot more filament would drip out.

It would be only logical that the filament is a bit retracted untill all temperatures are reached, and once the head starts to move to the position the extruder starts to work. Is this possible to set in Slic3r?

Is it also possible to set the speed of the extrusion for the skirt?

Edited 2 time(s). Last edit at 05/08/2014 10:35AM by Sardi.

Altough that is something I can live with, that also sometimes creates a wreck of my print, because on return, the ball of filament sticks to the hot head and starts sticking to all other filament like its collecting coins in a game.Quote

dmould

It's normal that the start of the first loop of the skirt doesn't print.

Also, when the skirt goes ok, sometimes the start of the first layer of my models goes wrong.

I am much confused here I must tell you. This started happening yesterday out of nowhere.

But what troubles me at the moment is what you clearly explained

Quote

dmould

If you set Slic3r to extrude filament before the start as you suggest, you'll be dragging a length of extrusion around, which could get tangled in the print. The dribble that comes out when the extruder heats is bad enough without adding more!

BUT .. I didnt set the Slic3r to extrude filament before the start! The Gcode sets the hot head at the start position and starts heating the head to 185C, but the PLA starts dripping as soon as the temperature hits 150C. So in those 35C I have about 1cm of filament hanging from the nozzle.

I also always pre-heat the bed (85 first layer, 80 other) otherwise a lot more filament would drip out.

It would be only logical that the filament is a bit retracted untill all temperatures are reached, and once the head starts to move to the position the extruder starts to work. Is this possible to set in Slic3r?

Is it also possible to set the speed of the extrusion for the skirt?

Edited 2 time(s). Last edit at 05/08/2014 10:35AM by Sardi.

|

Re: Filament gets stuck all over the nozzle May 08, 2014 10:37AM |

Registered: 10 years ago Posts: 14,672 |

Two suggestions, apart from trying different filament:

1. Try a slightly lower z=0 height. I use the web interface set to half z steps so that I can set the height to within 0.05mm.

2. Try printing on glass coated with solvent pipe cement. I have never has adhesion problems this way.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Try a slightly lower z=0 height. I use the web interface set to half z steps so that I can set the height to within 0.05mm.

2. Try printing on glass coated with solvent pipe cement. I have never has adhesion problems this way.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Filament gets stuck all over the nozzle May 08, 2014 10:46AM |

Registered: 10 years ago Posts: 859 |

Hi Sardi, 80/85' is to hi for PLA.... I've found allot of time that anything more than 60/65' causes the plastic on the first layer to blister and lift, which causes your problem. It then tangles around the IR probe, and eventualy around the HotEnd...

Now I use 57' and it seems good. The first layer temp seems dependant of the filament I use.... Normaly I use 195/215', and found it quite critical.

If it still doesn't stick I lower the head by 0.1mm till is does, provided the bed is level.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Now I use 57' and it seems good. The first layer temp seems dependant of the filament I use.... Normaly I use 195/215', and found it quite critical.

If it still doesn't stick I lower the head by 0.1mm till is does, provided the bed is level.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Filament gets stuck all over the nozzle May 08, 2014 10:52AM |

Registered: 10 years ago Posts: 466 |

I am leaving that for last, dont want to open a new reel only to find out its not the filaments fault.Quote

dc42

Two suggestions, apart from trying different filament:

If I lower it by 0.1 it will just grasp the paper I use for bed leveling, any lower than that and its in the bed.Quote

dc42

1. Try a slightly lower z=0 height. I use the web interface set to half z steps so that I can set the height to within 0.05mm.

Dont have it, will go and buy it.Quote

dc42

2. Try printing on glass coated with solvent pipe cement. I have never has adhesion problems this way.

Quote

KimBrown

Hi Sardi, 80/85' is to hi for PLA.... I've found allot of time that anything more than 60/65' causes the plastic on the first layer to blister and lift, which causes your problem. It then tangles around the IR probe, and eventualy around the HotEnd...

Now I use 57' and it seems good. The first layer temp seems dependant of the filament I use.... Normaly I use 195/215', and found it quite critical.

If it still doesn't stick I lower the head by 0.1mm till is does, provided the bed is level.

Kim..

The bed is level.

Regarding temperatures, I am printing directly on glass, so I was advised to set the bed to 75C, and extruder is at 195/190 now.

I can try a lot of things, but what dazzles me is that till yesterday afternoon everything was ok, and as of yesterday afternoon its not. I find it very hard to belive that suddenly the temperature is wrong, the bed is wrong, the z height iz wrong.. It couldnt all go wrong at the same time :/

Ill try a couple of prints more with different temperatures and see what happens. If nothing, will change the reel.

Edited 1 time(s). Last edit at 05/08/2014 10:55AM by Sardi.

|

Re: Filament gets stuck all over the nozzle May 08, 2014 11:35AM |

Registered: 12 years ago Posts: 1,611 |

Hi Sardi

We print on Kapton, we find it's the most reliable, and least maintenance once set up. Having the bed clean is imperative, as is the first layer height. Also, bed temperature should not be higher than around 66C maximum, or PLA will be too soft and pull back off. Here's our advice: [reprappro.com]

Who told you to set the bed temperature to 75C?!

Ian

RepRapPro tech support

Edited 1 time(s). Last edit at 05/08/2014 11:35AM by droftarts.

We print on Kapton, we find it's the most reliable, and least maintenance once set up. Having the bed clean is imperative, as is the first layer height. Also, bed temperature should not be higher than around 66C maximum, or PLA will be too soft and pull back off. Here's our advice: [reprappro.com]

Who told you to set the bed temperature to 75C?!

Ian

RepRapPro tech support

Edited 1 time(s). Last edit at 05/08/2014 11:35AM by droftarts.

|

Re: Filament gets stuck all over the nozzle May 08, 2014 11:54AM |

Registered: 10 years ago Posts: 859 |

PS

I print directly on to glass....

I just have to scrub it clean with neat (no water) Washing Up Liquid, until it is all white and foamy... Then Hot water rinse...

The back of the glass I use a regular towel, the top I use a fresh clean paper towel.

If I see a rainbow, I wash again, and rinse.

After mounting the glass, I heat to 60/65', then rub with Vinager on a paper towel. It drys very quickly and start to grip the paper normally.

I then print using a 10mm brim on most things. The plastic normally grips the glass very hard doing it this way.

To remove the print I take the hot glass and print to the sink, and rinse under the cold tap... The print then floats off with no effort.

Sometimes I let it cool normally,and when the temp drops to around 35/40' the print can be lifted off.

Allot of the time I can just wipe the glass when hot with vinager and carry on printing.

When it gets the problem you have, I then know I have to wash it again.

In Slic3r I have the first layer set to 200%, but am thinking of reducing that now, as with a brim it's fine normaly....

I have one sculpture that I keep trying to print that is being very difficult, because the base platform is thin, and when the thick top layer is layed down, it causes the base to warp badly, even with a brim.... I'm thinking of trying to convert the STL and add a thicker base which will stop it warping.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I print directly on to glass....

I just have to scrub it clean with neat (no water) Washing Up Liquid, until it is all white and foamy... Then Hot water rinse...

The back of the glass I use a regular towel, the top I use a fresh clean paper towel.

If I see a rainbow, I wash again, and rinse.

After mounting the glass, I heat to 60/65', then rub with Vinager on a paper towel. It drys very quickly and start to grip the paper normally.

I then print using a 10mm brim on most things. The plastic normally grips the glass very hard doing it this way.

To remove the print I take the hot glass and print to the sink, and rinse under the cold tap... The print then floats off with no effort.

Sometimes I let it cool normally,and when the temp drops to around 35/40' the print can be lifted off.

Allot of the time I can just wipe the glass when hot with vinager and carry on printing.

When it gets the problem you have, I then know I have to wash it again.

In Slic3r I have the first layer set to 200%, but am thinking of reducing that now, as with a brim it's fine normaly....

I have one sculpture that I keep trying to print that is being very difficult, because the base platform is thin, and when the thick top layer is layed down, it causes the base to warp badly, even with a brim.... I'm thinking of trying to convert the STL and add a thicker base which will stop it warping.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Filament gets stuck all over the nozzle May 08, 2014 11:59AM |

Registered: 10 years ago Posts: 859 |

PS As for damp filament.... I place mine in a plastic bag with silicon gel, seal, then put some where very warm, like on top of a radiator, or now the summer is nearly here, In the conservatory that can get to 55'c.... Storing this way draws the moisture out of the filament.

If I hear the filament popping, I know I have to change reels and recondition the reel I've been using.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

If I hear the filament popping, I know I have to change reels and recondition the reel I've been using.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Filament gets stuck all over the nozzle May 08, 2014 11:59AM |

Registered: 10 years ago Posts: 466 |

Quote

droftarts

We print on Kapton, we find it's the most reliable, and least maintenance once set up. Having the bed clean is imperative, as is the first layer height. Also, bed temperature should not be higher than around 66C maximum, or PLA will be too soft and pull back off.

I print on glass because I dont have the nerves to make kapton as perfect as it should be. This is a job for a woman

Now, joke aside, the kapton looks ok, but I dont like the way it feels under the finger, there are some gaps between the tapes and that, so I decided on the glass. I am cleaning it after every print with white vinegar, and till yesterday had absolutely no problems with that.

Now, joke aside, the kapton looks ok, but I dont like the way it feels under the finger, there are some gaps between the tapes and that, so I decided on the glass. I am cleaning it after every print with white vinegar, and till yesterday had absolutely no problems with that.Quote

droftarts

Who told you to set the bed temperature to 75C?!

My friend, kill me if I know. Tried to remeber who did it, but just cant. But again, its been 75/70 for a couple of days and everything was ok till yesterday.

Will try a couple of prints with 65/60 now.

|

Re: Filament gets stuck all over the nozzle May 08, 2014 12:10PM |

Registered: 10 years ago Posts: 65 |

|

Re: Filament gets stuck all over the nozzle May 08, 2014 12:55PM |

Registered: 10 years ago Posts: 76 |

I got the same problem once. I asked in this thread [forums.reprap.org]

I'm now having a print glass with kapton tape on and a newly cut print glass without kapton.

I found that printing on kapton tape may having problem from time to time but resolving it by cleaning with IPA works every time.

I'm now having a print glass with kapton tape on and a newly cut print glass without kapton.

I found that printing on kapton tape may having problem from time to time but resolving it by cleaning with IPA works every time.

|

Re: Filament gets stuck all over the nozzle May 08, 2014 01:38PM |

Registered: 10 years ago Posts: 14,672 |

I use 70C when printing direct on glass if I think adhesion may be a problem. The temperature at the top of the glass remains around 10C lower than the readout from the bed thermistor.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Filament gets stuck all over the nozzle May 08, 2014 01:41PM |

Registered: 10 years ago Posts: 466 |

Ive read about that people who print on glass consider themselves lucky, but Ive been printing on glass since day 1, no problems. For me it was the logical choice as it was completely flat, as to kapton side wasnt all that much.

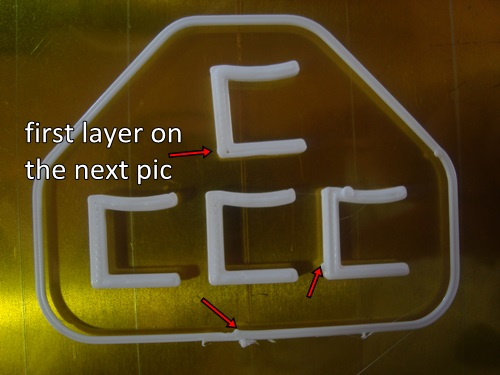

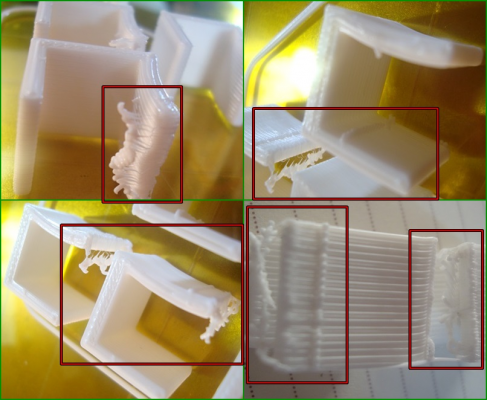

So, after 3 prints, this is what I came up with

Before every print I would heat up the head to 200C and let all the filament to drip out on its own, once it stops dripping and gets cold, I simply move it away - not pulling sideways but down!

That resulted in a perfect skirt

ET 185/180C BT 65/60C LH 0.4/0.4m

I am satisfied with the walls and all. These remains you see in the red squares are the result of the extruder NOT retracting the filament - again, I have no idea why he decided all of a sudden not to retract the filament.

I guess if he had been a good boy and had retracted when I told him to, I would have an excellent print on my hands now.

And its not as I havent told him over our mutual friend the Slic3r to retract the filament

Bad extruder, bad bad.

But to extruders defence, it did retract on all other places, just not on these that you see.

Edited 2 time(s). Last edit at 05/08/2014 01:55PM by Sardi.

So, after 3 prints, this is what I came up with

Before every print I would heat up the head to 200C and let all the filament to drip out on its own, once it stops dripping and gets cold, I simply move it away - not pulling sideways but down!

That resulted in a perfect skirt

ET 185/180C BT 65/60C LH 0.4/0.4m

I am satisfied with the walls and all. These remains you see in the red squares are the result of the extruder NOT retracting the filament - again, I have no idea why he decided all of a sudden not to retract the filament.

I guess if he had been a good boy and had retracted when I told him to, I would have an excellent print on my hands now.

And its not as I havent told him over our mutual friend the Slic3r to retract the filament

Bad extruder, bad bad.

But to extruders defence, it did retract on all other places, just not on these that you see.

Edited 2 time(s). Last edit at 05/08/2014 01:55PM by Sardi.

|

Re: Filament gets stuck all over the nozzle May 08, 2014 02:59PM |

Registered: 10 years ago Posts: 14,672 |

1mm is not enough retraction for the Ormerod's bowden-style extruder. Try 4mm.

Edited 1 time(s). Last edit at 05/08/2014 03:00PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 05/08/2014 03:00PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.