Nylon print

Posted by jstck

|

Nylon print May 19, 2014 04:49PM |

Registered: 10 years ago Posts: 378 |

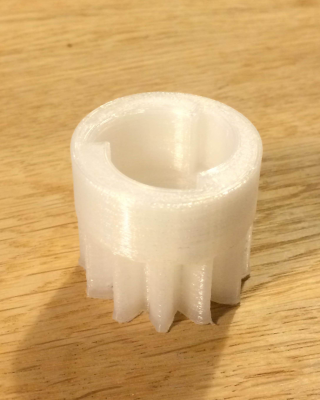

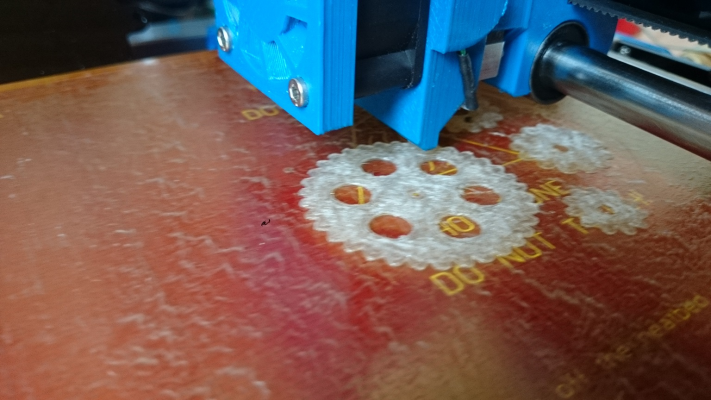

I feel like showing off a bit. I just did my first successful nylon print, using Taulman 645.

I had a couple earlier attempts where it wouldn't stick properly (first not stick at all, then tear itself off due to warping), but eventually it worked well enough. Using basically the settings recommended by Taulman and other reprap users (with other printers).

Hotend at 240, bed at 40. Layer height 0.32mm. Speeds same as I use with PLA/ABS, which are pretty conservative. Using blue painters tape and printing with 5mm brim, which sticks well enough.

The part is a replacement gear for a lawnmower, where the original ones (which I believe are PEEK) are worn down, and spares can't be found anymore. 34mm diameter, 32mm high. Wanted the strongest material possible, and this seems to be it. It flexes a bit, but will hopefully work. I got the same thing printed in PLA too, but I expect that will wear down quickly. I don't expect these to last forever either, but it's easy to print more as needed.

I had a couple earlier attempts where it wouldn't stick properly (first not stick at all, then tear itself off due to warping), but eventually it worked well enough. Using basically the settings recommended by Taulman and other reprap users (with other printers).

Hotend at 240, bed at 40. Layer height 0.32mm. Speeds same as I use with PLA/ABS, which are pretty conservative. Using blue painters tape and printing with 5mm brim, which sticks well enough.

The part is a replacement gear for a lawnmower, where the original ones (which I believe are PEEK) are worn down, and spares can't be found anymore. 34mm diameter, 32mm high. Wanted the strongest material possible, and this seems to be it. It flexes a bit, but will hopefully work. I got the same thing printed in PLA too, but I expect that will wear down quickly. I don't expect these to last forever either, but it's easy to print more as needed.

|

Re: Nylon print May 20, 2014 07:07AM |

Registered: 10 years ago Posts: 665 |

Ha, very nice. At the moment I'm trying to print iamburny's extruder and Z gears with Nylon on a layer of UHU glue stick, I hope these parts won't warp so easily.

|

Re: Nylon print May 20, 2014 07:28AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Nylon print May 20, 2014 07:28AM |

Registered: 10 years ago Posts: 378 |

I tried glue stick on glass (generic brand glue, but same kind of "purple when wet" stuff), and it stuck decently well there too. Would probably have been fine with just a larger brim. One one of the two I printed (the one above and it's mirror image), the brim had let go in a couple of places but the print held up fine.

|

Re: Nylon print May 20, 2014 07:30AM |

Registered: 10 years ago Posts: 378 |

Btw, when I loaded the nylon filament (after printing PLA earlier), I set it to 220°C (high for PLA, low for nylon, but both flow decently well) and slowly extruded for a bit. Then, I increased temp to 240 and extruded a bit more, and I actually got smoke coming from the hotend and some faint strange burning smell. I guess it was just some remnants of PLA not liking the temperature, and it went away pretty quickly.

|

Re: Nylon print May 20, 2014 07:45AM |

Registered: 10 years ago Posts: 665 |

Ian: Were you looking for this and for that thread?

jstck: I know what you mean. The last material I used for printing was ABS, and I can see a few black bubbles in my printed parts. Probably some ABS was stuck inside the nozzle, but nothing I need to worry about I get the same effect you described when I switch from PLA to ABS, especially because it's quite difficult to remove the PLA completely from the nozzle. ABS is much easier to remove IMO (I usually do this at 160°C).

I get the same effect you described when I switch from PLA to ABS, especially because it's quite difficult to remove the PLA completely from the nozzle. ABS is much easier to remove IMO (I usually do this at 160°C).

One thing that seems to be quite different from ABS and PLA is that Nylon appears to throw strings much more frequently, but I'm not using Taulman Nylon here. I hope I can get rid of them once my print has been finished. Also, I can hear my filament "cracking" when it melts - I'd blame humidity for that but I unpacked that spool just an hour ago. Everything is looking good at 5.5mm though.

jstck: I know what you mean. The last material I used for printing was ABS, and I can see a few black bubbles in my printed parts. Probably some ABS was stuck inside the nozzle, but nothing I need to worry about

I get the same effect you described when I switch from PLA to ABS, especially because it's quite difficult to remove the PLA completely from the nozzle. ABS is much easier to remove IMO (I usually do this at 160°C).

I get the same effect you described when I switch from PLA to ABS, especially because it's quite difficult to remove the PLA completely from the nozzle. ABS is much easier to remove IMO (I usually do this at 160°C).One thing that seems to be quite different from ABS and PLA is that Nylon appears to throw strings much more frequently, but I'm not using Taulman Nylon here. I hope I can get rid of them once my print has been finished. Also, I can hear my filament "cracking" when it melts - I'd blame humidity for that but I unpacked that spool just an hour ago. Everything is looking good at 5.5mm though.

|

Re: Nylon print May 20, 2014 07:49AM |

Registered: 10 years ago Posts: 1,230 |

Quote

droftarts

Have you got a link to the thread that talks about the herringbone extruder gears (and the Z gears)? I've added a link to the files on the Ormerod Improvements page, but it's good to link the discussion, too.

Ian

RepRapPro tech support

Double Helix Extruder Gears - iamburny Style

[forums.reprap.org]

Double Helix Z-Gears - iamburny Style

[forums.reprap.org]

Erik

|

Re: Nylon print May 20, 2014 08:12AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Nylon print May 20, 2014 11:09AM |

Registered: 10 years ago Posts: 378 |

Quote

zombiepantslol

jstck: I know what you mean. The last material I used for printing was ABS, and I can see a few black bubbles in my printed parts. Probably some ABS was stuck inside the nozzle, but nothing I need to worry aboutI get the same effect you described when I switch from PLA to ABS, especially because it's quite difficult to remove the PLA completely from the nozzle. ABS is much easier to remove IMO (I usually do this at 160°C).

One thing that seems to be quite different from ABS and PLA is that Nylon appears to throw strings much more frequently, but I'm not using Taulman Nylon here. I hope I can get rid of them once my print has been finished. Also, I can hear my filament "cracking" when it melts - I'd blame humidity for that but I unpacked that spool just an hour ago. Everything is looking good at 5.5mm though.

I don't think I have seen that kind of "smoke" when going from PLA to ABS, but I might just have missed it. No big deal, run some filament through and it should be clean enough for my purposes.

The Taulman 645 nylon is very very stringy. I ran some test prints earlier, and even with a lot of retraction the already-melted stuff in the nozzle is runny enough that it "drools" quite a bit. And the stuff that comes out forms long sticky strings allover the place. Usually easily cleaned off though. In this case, all the travel moves were over infill, so it didn't matter much.

I also hear some "cracking" from the nozzle sometimes, even when I had the spool straight out of the bag. Also some small bubbles could sometimes be visible inside the extruded nylon. However, I have only ever heard it when manually turning the extruder when loading or just feeding some stuff, it never seems to happen when printing (and I've seen no such "bubbles" either). Might be I'm just feeding it a bit faster than it should.

Sorry, only registered users may post in this forum.