Multi Material with one Extruder

Posted by muggi

|

Multi Material with one Extruder June 18, 2014 06:19AM |

Registered: 9 years ago Posts: 138 |

Hi,

in April Reprappro posted a News about multimaterial feeding with one extruder.

https://reprappro.com/2014/04/15/multimaterial-research/

I think it is a cool solution and should be tested by the community.

So place the parts from the posts to git, some basic codes in firmware and i think a few community members and ormerod owner make it working.

I love the reprap community, so my green Ormerod is now 50 % blue with a lot of improved parts from here and thiniverse....

greetings.

in April Reprappro posted a News about multimaterial feeding with one extruder.

https://reprappro.com/2014/04/15/multimaterial-research/

I think it is a cool solution and should be tested by the community.

So place the parts from the posts to git, some basic codes in firmware and i think a few community members and ormerod owner make it working.

I love the reprap community, so my green Ormerod is now 50 % blue with a lot of improved parts from here and thiniverse....

greetings.

|

Re: Multi Material with one Extruder June 18, 2014 06:54AM |

Registered: 10 years ago Posts: 58 |

I'm sure the design will work for printing one material in multicolor, I have serious doubts taking this multi-material, as there are often temperature differences between different materials that would be a b*tch to overcome with this design. Also the large retraction distance might be troublesome (doesn't have to be though). I think that having multiple colors on one nozzle, and a support-filament nozzle close to each other might prove to be more useful

|

Re: Multi Material with one Extruder June 18, 2014 07:03AM |

Registered: 12 years ago Posts: 78 |

Hi, All the details are on the Ormerod Github in the Dev branch. See here: [github.com]

Multicolour Firmware in the test branch here: [github.com]

Best wishes

Sally

RepRapPro Ltd

Multicolour Firmware in the test branch here: [github.com]

Best wishes

Sally

RepRapPro Ltd

|

Re: Multi Material with one Extruder June 18, 2014 07:39AM |

Registered: 13 years ago Posts: 1,611 |

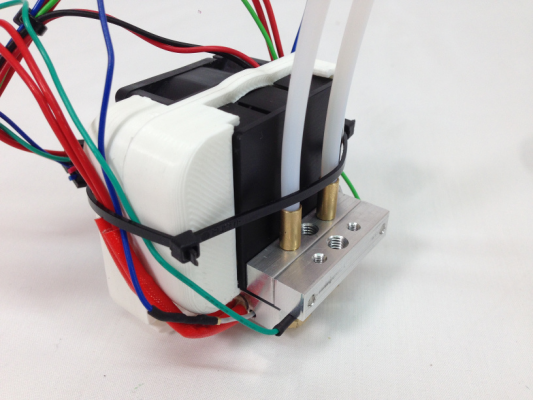

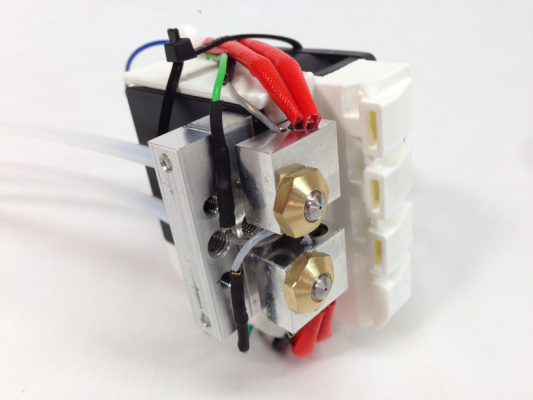

We're working on a number of different multi-extruder approaches - filament changing, multiple nozzles, mixing nozzles. We have done a quick multi-hot-end with existing parts, though it hasn't been tested yet and has it's problems (like to accurately level the nozzles with each other, extra rotational pressure on the x-carriage as it's centre of mass is further out, etc). Here's a couple of pictures:

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: Multi Material with one Extruder June 18, 2014 09:16AM |

Registered: 10 years ago Posts: 58 |

The pictures are close to what I envisioned, and knowing the Ormerod a bit by now, I can see where alignment can go wrong, especially for the impatient ones. Wouldn't changing to a differenct nozzle-type help? The E3D's and J-heads have a sort of alignment indent that might make construction of a multihead phot-end a bit easier, although that would come with quite an overhaul of the hot-end design.

I lack the tools and space for precision metal work, but it seems to me that the aluminium block would allow three extruder/nozzle holes without changing the alignment to the nozzleholder on the x-carriage.

I lack the tools and space for precision metal work, but it seems to me that the aluminium block would allow three extruder/nozzle holes without changing the alignment to the nozzleholder on the x-carriage.

|

Re: Multi Material with one Extruder July 17, 2014 12:35PM |

Registered: 10 years ago Posts: 14,672 |

Ian, can you confirm that the merging block design in the STL files at [github.com] fits 4 of the same brass Bowden ends as fit in the extruder drive assembly? And that you use a short length of PTFE filament guide to connect the merging block to the threaded brass Bowden insert in the hot end?

I'm thinking of trying one of these out, so I would be grateful for any tips on what does and doesn't work.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I'm thinking of trying one of these out, so I would be grateful for any tips on what does and doesn't work.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Multi Material with one Extruder July 17, 2014 12:58PM |

Registered: 12 years ago Posts: 78 |

Hi David,

The three top brass connections are exactly the same as the standard ones that go into our normal extruder drives, the Bowden start - [reprappro.com].

The bottom one that connects to the hot end is a special one that has a slotted top like the Bowden starts mentioned above and an M5 external thread at the bottom like the Bowden end [reprappro.com]

The inside of the threaded end of this is drilled out to 3mm to accommodate an extended PTFE tube like the ones that go in our standard hot end - 3mm OD 2mm ID.

We have run the design successfully, but the major problem we have found with it is the filament stringing out when it is retracted and thus jamming the path for the next filament that is pushed forwards. This problem can be reduced by lowering the temperature before retraction, but it is difficult to eliminate it altogether.

Best wishes

Sally

RepRapPro Ltd

The three top brass connections are exactly the same as the standard ones that go into our normal extruder drives, the Bowden start - [reprappro.com].

The bottom one that connects to the hot end is a special one that has a slotted top like the Bowden starts mentioned above and an M5 external thread at the bottom like the Bowden end [reprappro.com]

The inside of the threaded end of this is drilled out to 3mm to accommodate an extended PTFE tube like the ones that go in our standard hot end - 3mm OD 2mm ID.

We have run the design successfully, but the major problem we have found with it is the filament stringing out when it is retracted and thus jamming the path for the next filament that is pushed forwards. This problem can be reduced by lowering the temperature before retraction, but it is difficult to eliminate it altogether.

Best wishes

Sally

RepRapPro Ltd

|

Re: Multi Material with one Extruder July 17, 2014 01:23PM |

Registered: 10 years ago Posts: 14,672 |

Thanks Sally, that's what I needed to know. I guess I'll carry on improving my dual-nozzle system until you get on top of the stringing issue.

The other idea I had was to modify a nozzle to accept 2 or 3 filaments directly, perhaps by drilling it out and inserting a machined PTFE mixing block. Then the area shared by filaments would be hot and less susceptible to blockage. However, that would require the use of precision machine tools to make it, and I don't have access to those.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The other idea I had was to modify a nozzle to accept 2 or 3 filaments directly, perhaps by drilling it out and inserting a machined PTFE mixing block. Then the area shared by filaments would be hot and less susceptible to blockage. However, that would require the use of precision machine tools to make it, and I don't have access to those.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Multi Material with one Extruder July 17, 2014 01:27PM |

Registered: 12 years ago Posts: 78 |

Quote

dc42

The other idea I had was to modify a nozzle to accept 2 or 3 filaments directly, perhaps by drilling it out and inserting a machined PTFE mixing block. Then the area shared by filaments would be hot and less susceptible to blockage. However, that would require the use of precision machine tools to make it, and I don't have access to those.

Bit of a teaser.... There will hopefully be some more news on this soon... :-)

Sorry, only registered users may post in this forum.