[HELP] Rust on the bearings and z-rod issues..

Posted by V4z

[HELP] Rust on the bearings and z-rod issues..  August 24, 2014 06:55PM |

Registered: 9 years ago Posts: 3 |

Hi guys, I'm V4z from Italy and this is my first 3D-Printing related post.

I own the Ormerod-1 kit since July, and finally today I saw the beast moving for the first time! I'm so happy for that!

Please, check this video of the CIRCLE.G Test: [youtu.be]

I have modified a few parts of my Ormerod:

- Bed plate: removed the MDF part and used an Aluminium replacement.

- X-axis arm: removed the Acrylic part and used an Aluminium replacement.

I really need a few tips from you, because some things are struggling me.. :/

First.

I noticed a premature manifestation of rust in the external surface of the linear bearings, where they are exposed to the air.

I have placed the Ormerod in my garage-lab where in this season the humidity sets between 60% to 70%, with an average temperature of 20°C.

Have you ever faced this rust issue? How to prevent the proliferation over other parts (the spheres inside the bearings, the rods, maybe the motors..)?

Any suggestion will be appreciated. I've uploaded a few pics, please have a look:

Second.

My z-rod have an issue while moving the arm down, especially with the extruder block not in the home position. The hexagonal nut doesn't keep the position and sometimes it jumps out from the nut-trap, and is not a good thing. I was thinking if CA glue will help to fix the nut in the nut-trap. What do you think about this solution?

Third.

The z-rod have not a perfect movement (as you see in the video), while it rotate around its axis, it creates a "cone", the rotation is not linear. Probably, it is due to a lack of roundness in the z-gear-driven. Could it be a problem in the long term?

Could be this issue the cause of the previous question?

Fourth.

The CIRCLE.G Test execution that I have recorded, is acceptable in you opinion? Is it correct that the circle reaches the bed side or is it wrong?

Really glad to be a RepRapPro Ormerod owner.

Thank you all, regards.

V4z

Edited 1 time(s). Last edit at 08/24/2014 06:55PM by V4z.

I own the Ormerod-1 kit since July, and finally today I saw the beast moving for the first time! I'm so happy for that!

Please, check this video of the CIRCLE.G Test: [youtu.be]

I have modified a few parts of my Ormerod:

- Bed plate: removed the MDF part and used an Aluminium replacement.

- X-axis arm: removed the Acrylic part and used an Aluminium replacement.

I really need a few tips from you, because some things are struggling me.. :/

First.

I noticed a premature manifestation of rust in the external surface of the linear bearings, where they are exposed to the air.

I have placed the Ormerod in my garage-lab where in this season the humidity sets between 60% to 70%, with an average temperature of 20°C.

Have you ever faced this rust issue? How to prevent the proliferation over other parts (the spheres inside the bearings, the rods, maybe the motors..)?

Any suggestion will be appreciated. I've uploaded a few pics, please have a look:

- Bed bearings [oi62.tinypic.com]

- X-axis bearings [oi62.tinypic.com]

Second.

My z-rod have an issue while moving the arm down, especially with the extruder block not in the home position. The hexagonal nut doesn't keep the position and sometimes it jumps out from the nut-trap, and is not a good thing. I was thinking if CA glue will help to fix the nut in the nut-trap. What do you think about this solution?

Third.

The z-rod have not a perfect movement (as you see in the video), while it rotate around its axis, it creates a "cone", the rotation is not linear. Probably, it is due to a lack of roundness in the z-gear-driven. Could it be a problem in the long term?

Could be this issue the cause of the previous question?

Fourth.

The CIRCLE.G Test execution that I have recorded, is acceptable in you opinion? Is it correct that the circle reaches the bed side or is it wrong?

Really glad to be a RepRapPro Ormerod owner.

Thank you all, regards.

V4z

Edited 1 time(s). Last edit at 08/24/2014 06:55PM by V4z.

Re: [HELP] Rust on the bearings and z-rod issues..  August 25, 2014 01:51AM |

Registered: 10 years ago Posts: 378 |

1. I have also seen some rust on the outside of the linear bearings, and also on the steel rods for the Y axis outside of the travel of the carriage. Unless you buy much more expensive steel, even "stainless" steel can get a little bit of rust. It is only on the surface and you can clean it off very easily if you think it looks bad. The outside of the linear bearings do not need to be very smooth and are probably low-grade steel, the balls inside it are probably of some harder steel. I would not worry about it. Worst case, you might need to replace the linear bearings in a few years if they stop moving smoothly. The steel rods will probably last centuries.

2. My z nut was moving a little bit back and forth (just a tiny amount and not enough to really have an effect on printing). Still, I used a little bit of hot glue to keep it in place. CA would probably do well, just take care not to get any on the threads.

I have since replaced the Z nut trap with this one, which had a bit more grip on the nut (and also got a longer nut, but that's a different matter).

3. A lot of people have that, and it can be caused by the nut in the Z gear being a little bit off-center or the rod being not perfectly straight. From what little can be seen in the video I don't think it's too bad, but it might be related to the Z nut popping out. You should at least be able to start printing, and you could try printing a new Z gear. You can also take the Z rod out and roll it along a flat surface to see if it is straight. If it is noticeably curved you can just bend it to straighten it out, or replace it. It is a plain M5 threaded rod, which is cheap.

4. Looks good to me. It is supposed to just move in a circle over the whole print area.

2. My z nut was moving a little bit back and forth (just a tiny amount and not enough to really have an effect on printing). Still, I used a little bit of hot glue to keep it in place. CA would probably do well, just take care not to get any on the threads.

I have since replaced the Z nut trap with this one, which had a bit more grip on the nut (and also got a longer nut, but that's a different matter).

3. A lot of people have that, and it can be caused by the nut in the Z gear being a little bit off-center or the rod being not perfectly straight. From what little can be seen in the video I don't think it's too bad, but it might be related to the Z nut popping out. You should at least be able to start printing, and you could try printing a new Z gear. You can also take the Z rod out and roll it along a flat surface to see if it is straight. If it is noticeably curved you can just bend it to straighten it out, or replace it. It is a plain M5 threaded rod, which is cheap.

4. Looks good to me. It is supposed to just move in a circle over the whole print area.

Re: [HELP] Rust on the bearings and z-rod issues..  August 25, 2014 05:03AM |

Registered: 10 years ago Posts: 776 |

Keep the rods lightly oiled, your conditions are not too good for metal - high humidity, low temp.

I would not use CA to glue to z nut into the housing, it is meant to allow the x-arm to lift off if it gets jammed on a downward motion, or gets rammed into the bed glass when zeroing, fixing it will likely end in broken glass and mangled hot ends or heads and arms.

Keep the threaded rod lightly oiled too and fit a longer brass nut from eBay, they only cost pennies.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

I would not use CA to glue to z nut into the housing, it is meant to allow the x-arm to lift off if it gets jammed on a downward motion, or gets rammed into the bed glass when zeroing, fixing it will likely end in broken glass and mangled hot ends or heads and arms.

Keep the threaded rod lightly oiled too and fit a longer brass nut from eBay, they only cost pennies.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Re: [HELP] Rust on the bearings and z-rod issues..  August 25, 2014 05:32AM |

Registered: 10 years ago Posts: 378 |

Re: [HELP] Rust on the bearings and z-rod issues..  August 26, 2014 10:52AM |

Registered: 10 years ago Posts: 2,472 |

Always keep unprotected metal oiled unless you are certain it is a good quality stainless (such as 316) or other type of metal that will not corrode. As a very basic rule of thumb - if the metal is even slightly attracted to a magnet it needs protection (though the reverse is not necessarily the case).

Dave

(#106)

Dave

(#106)

Re: [HELP] Rust on the bearings and z-rod issues..  August 27, 2014 05:53PM |

Registered: 9 years ago Posts: 3 |

Thank you all!

As prevention, which oil do you suggest to use over all the metal parts?

Temporarely, I have fixed the issue using some CA glue to hold the x-rod gear into the nut, then I have placed a few Kapton strips to reduce the play in the x-arm nut trap. And it works better...

Next, I'll hold better the x-rod gear, rarely it pops out a little (it does not go outside the trap but simply moves a little, until the arm weight re-pulls it in place..) but only when the arm is moving down.. Probably it is caused by the aluminum x-arm, which add weight and maybe needs balancing (when it pops I apply pressure on the x-arm motor side)...

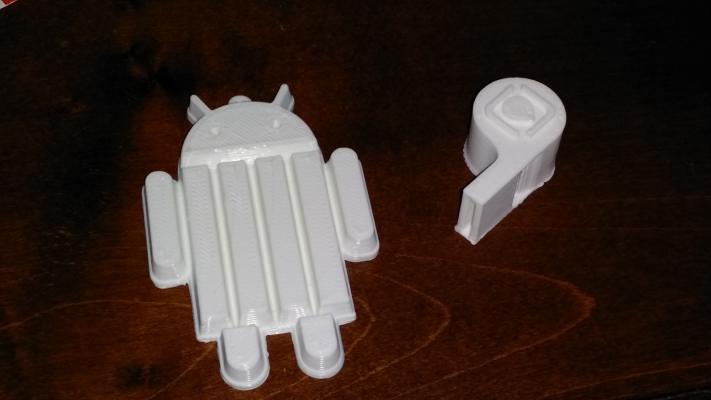

Finally, due to curiosity, I've printed a few objects..

And, without having already done the orthogonal calibration, I'm so happy with the result!

Have a look:

Thanks, regards.

V4z

Edited 1 time(s). Last edit at 08/27/2014 06:00PM by V4z.

As prevention, which oil do you suggest to use over all the metal parts?

Temporarely, I have fixed the issue using some CA glue to hold the x-rod gear into the nut, then I have placed a few Kapton strips to reduce the play in the x-arm nut trap. And it works better...

Next, I'll hold better the x-rod gear, rarely it pops out a little (it does not go outside the trap but simply moves a little, until the arm weight re-pulls it in place..) but only when the arm is moving down.. Probably it is caused by the aluminum x-arm, which add weight and maybe needs balancing (when it pops I apply pressure on the x-arm motor side)...

Finally, due to curiosity, I've printed a few objects..

And, without having already done the orthogonal calibration, I'm so happy with the result!

Have a look:

Thanks, regards.

V4z

Edited 1 time(s). Last edit at 08/27/2014 06:00PM by V4z.

Re: [HELP] Rust on the bearings and z-rod issues..  August 28, 2014 01:11PM |

Registered: 10 years ago Posts: 776 |

It sounds like if the x arm sticks on the way down, you may have the z axis runner bearing a bit too tight?

It only needs the lightest tension on the z support beam.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

It only needs the lightest tension on the z support beam.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Re: [HELP] Rust on the bearings and z-rod issues..  September 02, 2014 03:20AM |

Registered: 9 years ago Posts: 3 |

Re: [HELP] Rust on the bearings and z-rod issues..  September 02, 2014 03:52AM |

Registered: 10 years ago Posts: 1,230 |

do both z-bearings move with out resistance on the smooth rod?- also when mounted?

[reprappro.com]

Erik

Quote

documentation

Now tighten the bearing mount screws. The holes in the bearing clamps are clearance for the M3 screws, so keep moving the axis up and down between turns of each screw. This will let the bearings settle in the right place, and ensure the axis runs smoothly.

[reprappro.com]

Erik

Sorry, only registered users may post in this forum.