sensor area on X carriage keeps hitting prints

Posted by Amsterdamman

|

sensor area on X carriage keeps hitting prints September 27, 2014 08:05PM |

Registered: 9 years ago Posts: 146 |

Hi Again all, Finally got printing again with the duet from my Ormerod2 kit and the sensor as well (may have burned the other new sensor with the duet) using a new X carriage from Reprap that came with sensor upgrade. Everything seems the same and yet the sensor seems to hang low. I've even added two washers under the mount to push the nozzle lower and it seems well clear and yet I keep having issues printing the Y-idler bracket for the Ormerod2 - but I noticed it was the same part at the same height that started the issues using my original duet and sensor. It appears the corners are curving slightly up and this catches the sensor block. I changed the design to make the area under the angle leading to the Y axis belt bearing a vertical wall straight to the bed and the part printed successfully. Attached are the .stl from the github and my changed Ny-idler-bracket.stl

Since the sensor is being used at approx 2mm or higher to read the Z home - is there any reason it is so close to the printed parts? Was debating printing a X carriage with the sensor raised 1-2mm to make sure it is clear of the work surface. Am I going to cause other problems I'm not aware of? My X-carriage .STL file imports very poorly into sketchup, so the adjustment is difficult to make. Plus changing it on the X-arm is also a task. I'm hoping it makes sense before I spend the effort. But I can't see any reason the sensor can't be higher...

I've checked the X arm level across the travel and adjusted the bed to level. The fan is higher on Z home as is the sensor, but it clearly is catching on the parts. If there is another print issue, the sensor crash prevents it from showing itself clear enough for me to see it. The Ny-idler mod was mainly to see if the unsupported angle was part of the issue and a way to try to get a success after three failures. No other changes were made and the part printed successfully.

Socrates ~ The Amsterdamman

slic3r-1.2.9

Since the sensor is being used at approx 2mm or higher to read the Z home - is there any reason it is so close to the printed parts? Was debating printing a X carriage with the sensor raised 1-2mm to make sure it is clear of the work surface. Am I going to cause other problems I'm not aware of? My X-carriage .STL file imports very poorly into sketchup, so the adjustment is difficult to make. Plus changing it on the X-arm is also a task. I'm hoping it makes sense before I spend the effort. But I can't see any reason the sensor can't be higher...

I've checked the X arm level across the travel and adjusted the bed to level. The fan is higher on Z home as is the sensor, but it clearly is catching on the parts. If there is another print issue, the sensor crash prevents it from showing itself clear enough for me to see it. The Ny-idler mod was mainly to see if the unsupported angle was part of the issue and a way to try to get a success after three failures. No other changes were made and the part printed successfully.

Socrates ~ The Amsterdamman

slic3r-1.2.9

|

Re: sensor area on X carriage keeps hitting prints September 28, 2014 02:33AM |

Registered: 10 years ago Posts: 14,672 |

I have a few suggestions:

1. Look along the x axis to check that the hot end is level and the nozzle vertical. If you have the x runner bearing too close to the x carriage body, this will cause the print head to rise (the opposite of head sag that is a common problem on Ormerod 1) which will place the sensor too close to the bed.

2. Printing a nozzle mount that drops the head a little is easier than printing a new x carriage. I have a nozzle mount design in OpenScad on Thingyverse.

3. If you really want to print a modified x carriage, then

I have an x carriage design in OpenScad too. You would need to add the mounting holes for the sensor board.

4. Or you could do what I did before I made my own sensor boards and mount the RRP board on the hot end. This also makes it much less sensitive to head sag. Johneato did me a modified heatsink duct design with mounting points for the sensor, and I can look for that if you want it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Look along the x axis to check that the hot end is level and the nozzle vertical. If you have the x runner bearing too close to the x carriage body, this will cause the print head to rise (the opposite of head sag that is a common problem on Ormerod 1) which will place the sensor too close to the bed.

2. Printing a nozzle mount that drops the head a little is easier than printing a new x carriage. I have a nozzle mount design in OpenScad on Thingyverse.

3. If you really want to print a modified x carriage, then

I have an x carriage design in OpenScad too. You would need to add the mounting holes for the sensor board.

4. Or you could do what I did before I made my own sensor boards and mount the RRP board on the hot end. This also makes it much less sensitive to head sag. Johneato did me a modified heatsink duct design with mounting points for the sensor, and I can look for that if you want it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: sensor area on X carriage keeps hitting prints September 28, 2014 10:43AM |

Registered: 9 years ago Posts: 146 |

Am I right that there is no reason for the sensor to be in such close tolerance to the work surface? I'm now trying to print the orig Y idler using Slic3r - but the sensor is so close the the current layer that it is a issue waiting to happen. Even 1mm would make a huge difference.

So your saying to rebuild the the nozzle mount with a lower face... OK, that is a much better method!! Do you have links for your OpenScads? I tried to DL the plug in, but was just one more road to fight...

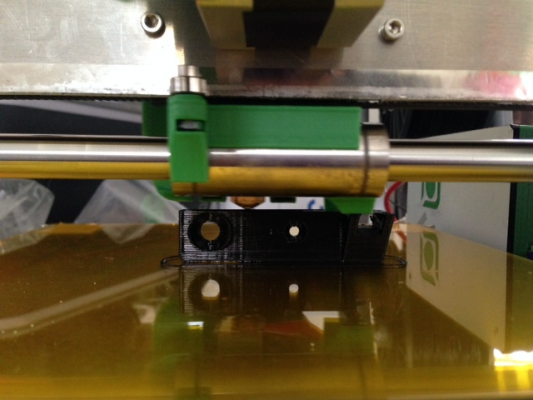

Seems most use Slic3r since its open source, Slic3r says I should use Expert settings, but I can't find anyway to access those expert settings. Where are they found? Are you using 1.2 or the 1.1.7 Slic3r? What speeds do you use in Slic3r? Mine is on 45 Perimeter, 60 infill and 130 travel. Those were the defaults when I loaded it. It prints slower than KISSlicer, but so far it is also printing more accurately and has passed the previous fail point on the y-idler print. So my KISSlicer settings are part of the problem (using Sli3r is a easy solution). The photo is during the print and just a few layers after it failed three times already. I think the nozzle is vertical but the sensor seems very very low, just a hair's breath above the active surface. Thanks Dave!!

Socrates ~ The Amsterdamman

slic3r-1.2.9

So your saying to rebuild the the nozzle mount with a lower face... OK, that is a much better method!! Do you have links for your OpenScads? I tried to DL the plug in, but was just one more road to fight...

Seems most use Slic3r since its open source, Slic3r says I should use Expert settings, but I can't find anyway to access those expert settings. Where are they found? Are you using 1.2 or the 1.1.7 Slic3r? What speeds do you use in Slic3r? Mine is on 45 Perimeter, 60 infill and 130 travel. Those were the defaults when I loaded it. It prints slower than KISSlicer, but so far it is also printing more accurately and has passed the previous fail point on the y-idler print. So my KISSlicer settings are part of the problem (using Sli3r is a easy solution). The photo is during the print and just a few layers after it failed three times already. I think the nozzle is vertical but the sensor seems very very low, just a hair's breath above the active surface. Thanks Dave!!

Socrates ~ The Amsterdamman

slic3r-1.2.9

|

Re: sensor area on X carriage keeps hitting prints September 28, 2014 10:49AM |

Registered: 10 years ago Posts: 776 |

That lump that stick out below is the same on mine, probably just half a mm clearance, I need to lower my nozzle a bit too.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: sensor area on X carriage keeps hitting prints September 28, 2014 12:14PM |

Registered: 9 years ago Posts: 146 |

15mnozzle-mount.stlJust made a 1.5mm longer adjusted nozzle with sketchup. Going with Slic3r as it printed much better. Will print it later tonight. The flange is 2mm longer, but the mount faces are 1.5mm longer. This seem ok?

Socrates ~ The Amsterdamman

slic3r-1.2.9

Socrates ~ The Amsterdamman

slic3r-1.2.9

|

Re: sensor area on X carriage keeps hitting prints September 28, 2014 12:26PM |

Registered: 9 years ago Posts: 146 |

|

Re: sensor area on X carriage keeps hitting prints September 28, 2014 12:38PM |

Registered: 9 years ago Posts: 146 |

15mnozzle-mount.stl I pushed the top down the same 1.5mm now so the bolt has the same part thickness to travel through.

Socrates ~ The Amsterdamman

slic3r-1.2.9

Socrates ~ The Amsterdamman

slic3r-1.2.9

|

Re: sensor area on X carriage keeps hitting prints September 28, 2014 02:35PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Amsterdamman

[attachment 41158 15mnozzle-mount.stl]Just made a 1.5mm longer adjusted nozzle with sketchup. Going with Slic3r as it printed much better. Will print it later tonight. The flange is 2mm longer, but the mount faces are 1.5mm longer. This seem ok?

Nice moddeling! - slot vs holes in the nozzle mount, see this thread:

Head sagging again:

[forums.reprap.org]

Erik

|

Re: sensor area on X carriage keeps hitting prints September 28, 2014 02:35PM |

Registered: 10 years ago Posts: 14,672 |

You can find my OpenScad files for the nozzle mount and x carriage if you still need them at [github.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: sensor area on X carriage keeps hitting prints September 28, 2014 05:42PM |

Registered: 9 years ago Posts: 146 |

2mnozzle-mount.stl ok, one more take on the lowered nozzle, KISSlicer does a better job at a fast visual inspection for model errors. Maybe Slic3r fixes them perfectly, but I'd prefer a error free model. The importing into sketchup can leave small gaps around curves, one reason I model at 100x size especially if cutting / interacting faces. This one had missing faces inside the mounting holes. I fixed them and used the cleanup plugin and its 99% error free. KISSlicer shows something minor on the top mounting but I can't find it in sketchup and no errors fixed in Slic3r. This is also now down to 2mm since I remembered I already have 2 washers in there. It printed fine and is working well. The sensor is clear of the work area and still gave a good Z home. Thanks again Dave, much easier method than changing the carriage!!

Socrates ~ The Amsterdamman

slic3r-1.2.9

Socrates ~ The Amsterdamman

slic3r-1.2.9

|

Re: sensor area on X carriage keeps hitting prints September 29, 2014 02:37AM |

Registered: 10 years ago Posts: 378 |

If you have problems with any slicer software understanding STL files from Sketchup (or OpenSCAD for that matter), netfabb usually makes them 100% error free after a simple automatic repair.

And if you don't want to bother with netfabb basic (which does require some clicking around even for automatic repair), there is an online version that is dead simple and usually does the trick just as well.

Edited 1 time(s). Last edit at 09/29/2014 02:39AM by jstck.

And if you don't want to bother with netfabb basic (which does require some clicking around even for automatic repair), there is an online version that is dead simple and usually does the trick just as well.

Edited 1 time(s). Last edit at 09/29/2014 02:39AM by jstck.

Sorry, only registered users may post in this forum.