xy problem - not regular print, help me please!

Posted by simosartori76

|

xy problem - not regular print, help me please! August 15, 2014 08:01PM |

Registered: 10 years ago Posts: 28 |

Hello everyone!

I attached one photo of the problem!

When I start to print or I print a little object that's all ok, but if I print a medium linear part (see the photo) after +/- 1 hour the problem of misalignment begins.

Do you have a idea, please?

Thanks.

Bye

Simone

I attached one photo of the problem!

When I start to print or I print a little object that's all ok, but if I print a medium linear part (see the photo) after +/- 1 hour the problem of misalignment begins.

Do you have a idea, please?

Thanks.

Bye

Simone

|

Re: xy problem - not regular print, help me please! August 16, 2014 03:24AM |

Registered: 10 years ago Posts: 378 |

Looks like both X and Y axis are skipping steps. Most common is that the Y belt isn't tight enough and teeth are skipping past the pulley. Best way to fix that is to print iamburny's belt clamps. But that would just cause skips in one direction.

Another cause is that the Y and/or X axis isn't moving freely, and the friction is too much for the stepper motor which will start skipping. This usually makes a horrible noise when it happens, and you can usually feel where it happens it if you move the X or Y carriages around by hand (with motors disabled).

Third, and what I would guess based on the picture, you might have an older firmware that has some acceleration bugs; Basically the firmware accelerates things so quickly that the mass of the carriage overcomes the strength of the motor, which will skip steps. To some small extent, this can be improved by increasing motor currents with the M906 command and reducing print speed, but best is to upgrade firmware. The 078-dc42 line of firmware is excellent. Which firmware version are you running?

Another cause is that the Y and/or X axis isn't moving freely, and the friction is too much for the stepper motor which will start skipping. This usually makes a horrible noise when it happens, and you can usually feel where it happens it if you move the X or Y carriages around by hand (with motors disabled).

Third, and what I would guess based on the picture, you might have an older firmware that has some acceleration bugs; Basically the firmware accelerates things so quickly that the mass of the carriage overcomes the strength of the motor, which will skip steps. To some small extent, this can be improved by increasing motor currents with the M906 command and reducing print speed, but best is to upgrade firmware. The 078-dc42 line of firmware is excellent. Which firmware version are you running?

|

Re: xy problem - not regular print, help me please! August 17, 2014 07:14PM |

Registered: 10 years ago Posts: 28 |

|

Re: xy problem - not regular print, help me please! August 18, 2014 02:53AM |

Registered: 9 years ago Posts: 6 |

Hey Simone,

Though I did not find "how-to" pictures of iamburneys y-clamps, I'd like to provide you with this link.

It has a lot more of useful upgrades you might be interested in as well.

As for mounting these y-clamps, the picture provided by jstck seems pretty straight forward. You can probably just mount them with a bolt!

Though I did not find "how-to" pictures of iamburneys y-clamps, I'd like to provide you with this link.

It has a lot more of useful upgrades you might be interested in as well.

As for mounting these y-clamps, the picture provided by jstck seems pretty straight forward. You can probably just mount them with a bolt!

|

Re: xy problem - not regular print, help me please! August 18, 2014 03:33AM |

Registered: 10 years ago Posts: 1,230 |

Quote

simosartori76

..How I could mount this parts on printer?Do you have some photos, please?

Erik

|

Re: xy problem - not regular print, help me please! August 18, 2014 04:50AM |

Registered: 10 years ago Posts: 14,672 |

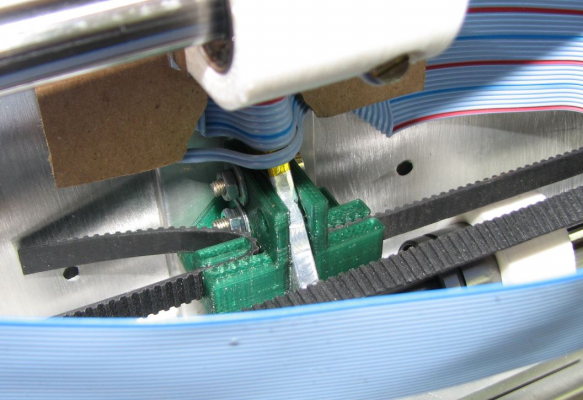

You attach them either side of the rib with two screws. Here are some more photos:

I find it easiest to do the two mounting screws up loosely when putting the belt into the toothed groove. Then tighten the screws to tension the belt. You can adjust the tension by slipping some of these spacers [github.com] between the belt clamps and the rib.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I find it easiest to do the two mounting screws up loosely when putting the belt into the toothed groove. Then tighten the screws to tension the belt. You can adjust the tension by slipping some of these spacers [github.com] between the belt clamps and the rib.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: xy problem - not regular print, help me please! September 05, 2014 01:51AM |

Registered: 10 years ago Posts: 28 |

|

Re: xy problem - not regular print, help me please! September 07, 2014 05:55AM |

Registered: 10 years ago Posts: 859 |

One thing that we all do with the belts in the begining is either get them to tight or to slack.

As the guys have said above, it does look like your missing steps, which can mean it's either to tight or to slack.

To slack and the motor pulley jumps teeth.

To tight and the motor struggles to move the belt.

There isn't a way at the moment to check for the correct tightness.

The way I try to explain it (taking the Y axis belt as an example) is:-

When the printer is running look carefully at the motor pulley and watch the belt.

If you see it humping up on the slack side of the pulley (which ever direction it's moving), then the belt is to slack, and you need to tighten it a LITTLE.

Try it again, and if it still humps up, tighten it a LITTLE more.

Keep repeat the above untill you just start to see the belt hasn't got the HUMP in the slack side.

Then the tension is correct.

It's very difficult to go the other way round from a belt that's to tight to the correct amount.

Once you've got the Y axis belt done, you can do the same to the X-axis, but you'll also be able to feel the spring in the Y belt, and have an idea of the tension.

I use Iamburnys version 7 belt tensioner which has helped allot. After printing them I used a watch makers screw driver to clean out the grooves for the teeth of the belt.

Then when fitting I used large washers as spacers between them and the wooden frame to adjust the tension. I think DC did design some shims to use with them which is a great idea, and would be better than the washers. I keep meaning to print some, but it's on the todo list...

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

As the guys have said above, it does look like your missing steps, which can mean it's either to tight or to slack.

To slack and the motor pulley jumps teeth.

To tight and the motor struggles to move the belt.

There isn't a way at the moment to check for the correct tightness.

The way I try to explain it (taking the Y axis belt as an example) is:-

When the printer is running look carefully at the motor pulley and watch the belt.

If you see it humping up on the slack side of the pulley (which ever direction it's moving), then the belt is to slack, and you need to tighten it a LITTLE.

Try it again, and if it still humps up, tighten it a LITTLE more.

Keep repeat the above untill you just start to see the belt hasn't got the HUMP in the slack side.

Then the tension is correct.

It's very difficult to go the other way round from a belt that's to tight to the correct amount.

Once you've got the Y axis belt done, you can do the same to the X-axis, but you'll also be able to feel the spring in the Y belt, and have an idea of the tension.

I use Iamburnys version 7 belt tensioner which has helped allot. After printing them I used a watch makers screw driver to clean out the grooves for the teeth of the belt.

Then when fitting I used large washers as spacers between them and the wooden frame to adjust the tension. I think DC did design some shims to use with them which is a great idea, and would be better than the washers. I keep meaning to print some, but it's on the todo list...

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: xy problem - not regular print, help me please! October 14, 2014 04:10PM |

Registered: 9 years ago Posts: 2 |

What works for me is to send it home after every layer.

Currently in repetier host this option is only available for slic3r.

just put G28 X0 Y0 in the "Layer change G-code" in printer settings of slic3r. my Y has a max endstop, which made me question about if it would work at all, but it does.

Adds few minutes in total printing time, but reduces reprints by 100% so far.

Currently in repetier host this option is only available for slic3r.

just put G28 X0 Y0 in the "Layer change G-code" in printer settings of slic3r. my Y has a max endstop, which made me question about if it would work at all, but it does.

Adds few minutes in total printing time, but reduces reprints by 100% so far.

|

Re: xy problem - not regular print, help me please! October 21, 2014 02:15AM |

Registered: 9 years ago Posts: 92 |

Hi

Have you checked that the grub screws on your X and Y pulleys are tight and still in correct position. Look at my post here [forums.reprap.org]

James

Have you checked that the grub screws on your X and Y pulleys are tight and still in correct position. Look at my post here [forums.reprap.org]

James

Sorry, only registered users may post in this forum.

uet DATE:2014-05-13.

uet DATE:2014-05-13.