Bed levelling question

Posted by Firefox3D

|

Bed levelling question June 07, 2015 05:08PM |

Registered: 8 years ago Posts: 105 |

Hi, couldn't find a direct answer to this with a search so apologies if it has been answered and I missed it.

If you use the bed levelling (I have an Ormerod 2) and for a simple example the bed is 0.2mm higher on one edge vs the opposite edge, an overall small incline, does the effect of the adjustment mean that the head tracks the bed so the whole print will have a leaning tower of Pisa effect as it trys to print the whole thing in the plane of the bed?

If you use the bed levelling (I have an Ormerod 2) and for a simple example the bed is 0.2mm higher on one edge vs the opposite edge, an overall small incline, does the effect of the adjustment mean that the head tracks the bed so the whole print will have a leaning tower of Pisa effect as it trys to print the whole thing in the plane of the bed?

|

Re: Bed levelling question June 07, 2015 05:38PM |

Registered: 9 years ago Posts: 638 |

|

Re: Bed levelling question June 07, 2015 06:09PM |

Registered: 8 years ago Posts: 105 |

Thanks, I asking because the auto bed levelling seemed to be producing some almost random results in my case.

I have fine tuned the levelling by hand and found the bed rises slowly to about 0.3mm max higher at one of the unsupported corners starting about halfway out from the dead center of the bed, I think maybe this confuses the calculation as it is slightly bent not a straight slope. It's not a big dead, the rest of the bed is ruler flat, I just arrange prints to miss than corner.

Edited 1 time(s). Last edit at 06/07/2015 06:10PM by Firefox3D.

I have fine tuned the levelling by hand and found the bed rises slowly to about 0.3mm max higher at one of the unsupported corners starting about halfway out from the dead center of the bed, I think maybe this confuses the calculation as it is slightly bent not a straight slope. It's not a big dead, the rest of the bed is ruler flat, I just arrange prints to miss than corner.

Edited 1 time(s). Last edit at 06/07/2015 06:10PM by Firefox3D.

|

Re: Bed levelling question June 08, 2015 07:50AM |

Registered: 9 years ago Posts: 638 |

You might have twisted rods:

[forums.reprap.org]

Altho my problem was both broken acrylic and twisted rods.

i still cant completly eliminate it but got it down to 0.2 diference

Edited 1 time(s). Last edit at 06/08/2015 07:52AM by Darathy.

[forums.reprap.org]

Altho my problem was both broken acrylic and twisted rods.

i still cant completly eliminate it but got it down to 0.2 diference

Edited 1 time(s). Last edit at 06/08/2015 07:52AM by Darathy.

|

Re: Bed levelling question June 08, 2015 10:38AM |

Registered: 8 years ago Posts: 105 |

It is pretty minor, if you stay 30mm from the corner it's probably only about 0.2mm max, but gets progressively worse as you go to the corner, like the corner is curled up.

Thanks for the suggestion, but it doesn't seem to be any flex in the printer itself. I did wonder if the printer wasn't sitting on a dead flat surface which might be causing it, but moving it around didn't change the result.

I can nearly eliminate the problem by cable tying the bottom of the bolt on the corner of the bed to the middle support bolt near the heated bed connections, but it looks ugly.

Also I turned the glass over as there seemed to be a bit of extra height on the same corner that was making the problem worse.

I just thought of something to try, thin shims on the other corners under the glass as long as it doesn't reduce the heating effect on the glass too much.

Thanks for the suggestion, but it doesn't seem to be any flex in the printer itself. I did wonder if the printer wasn't sitting on a dead flat surface which might be causing it, but moving it around didn't change the result.

I can nearly eliminate the problem by cable tying the bottom of the bolt on the corner of the bed to the middle support bolt near the heated bed connections, but it looks ugly.

Also I turned the glass over as there seemed to be a bit of extra height on the same corner that was making the problem worse.

I just thought of something to try, thin shims on the other corners under the glass as long as it doesn't reduce the heating effect on the glass too much.

|

Re: Bed levelling question June 08, 2015 11:47AM |

Registered: 10 years ago Posts: 2,472 |

If it is not a straight slope, the apparent height difference is likely to be caused by something other than the flatness of the bed. Common causes are (1) slight twist in the acrylic X-arm, (2) Y ground rods not being exactly parallel or (3) Bowden tube causing the head to tilt slightly near the center (because it has a sharper bend in the center). You can check (3) very easily by unclipping the extruder and putting it in a different slot, then see if your bed readings have changed.

It is best to get the bed as level as possible using the corner bolts and not use bed compensation at all.

Dave

It is best to get the bed as level as possible using the corner bolts and not use bed compensation at all.

Dave

|

Re: Bed levelling question June 08, 2015 09:07PM |

Registered: 8 years ago Posts: 105 |

Thanks for that Dave makes sense, I think the front black acrylic piece might be off square so the outer rod is that bit too high causing the head to move towards the bed as Y goes from positive to zero with X at max which is the effected corner. Will adjust it tomorrow and report back.

Yeah I had read to not use bed compensation if you could avoid it which is what I was trying to do, as I said the compensation result seemed to vary, also the extra corner pads waste bed real estate.

I glued the acrylic pieces of the x-arm together with EMA plastic weld, clamped it for a couple of hours while setting and it's totally rigid, if you push hard in the y axis direction you can just get it to move.

Jon

Edited 2 time(s). Last edit at 06/08/2015 09:10PM by Firefox3D.

Yeah I had read to not use bed compensation if you could avoid it which is what I was trying to do, as I said the compensation result seemed to vary, also the extra corner pads waste bed real estate.

I glued the acrylic pieces of the x-arm together with EMA plastic weld, clamped it for a couple of hours while setting and it's totally rigid, if you push hard in the y axis direction you can just get it to move.

Jon

Edited 2 time(s). Last edit at 06/08/2015 09:10PM by Firefox3D.

|

Re: Bed levelling question June 09, 2015 09:25AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Firefox3D

I glued the acrylic pieces of the x-arm together with EMA plastic weld, clamped it for a couple of hours while setting and it's totally rigid, if you push hard in the y axis direction you can just get it to move.

Jon

The problem is not in the rigidity, but that some X arms have a slight twist - the front (floating) vertical edge is not parallel to the rear (Z pillar) vertical edge. This causes the head to tilt as the X position changes due to it being supported by the X arm via the X runner bearing. Easy to fix - slacken X-idler bracket (the part at the end of the X-arm that holds the X-belt idle pulley and also mounts the X-arm to the ground rod), twist the X-arm straight and re-tighten.

A bow in the X arm would have a similar effect, but I have not seen any reports of that issue.

Dave

|

Re: Bed levelling question June 09, 2015 11:13AM |

Registered: 8 years ago Posts: 105 |

|

Re: Bed levelling question June 09, 2015 01:40PM |

Registered: 9 years ago Posts: 1,699 |

I hope I can join this discussion. I have nearly the same problem. I have an Ormerod MK1 it had not that manually level support until I bought a new bed support made from aluminium. I still have leveling issues like you have. Luckily my auto bed leveling works like a charm. I do not know how you prepared your bed. In the moment I am trying to print PLA directly on glass. This information is important because I put some blue painters tape directly on the aluminium plate. Four big squares. These squares does not reflect as much light as white paper or directly the mirroring aluminium surface but it is still enough to repeat the leveling securely and I can achieve this even with the original sensor.

I am thinking of disassembling the whole printer and reassemble it and care intensive that all is angled. But I am afraid that would not help.

Darathy what did you do about your acrylic problem?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I am thinking of disassembling the whole printer and reassemble it and care intensive that all is angled. But I am afraid that would not help.

Darathy what did you do about your acrylic problem?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Bed levelling question June 09, 2015 02:00PM |

Registered: 9 years ago Posts: 638 |

As i mentioned before i could not eliminate the rod twist, either it moved too much with slightest twist of the scew or it went on the other side(mybe my lack of patiance but i am fine with 0.1-.2mm diference). For the acrylic Y-Idlers i had a friend waterjet me a pair from Aluminum and also bought Daves Alu X-arm(so i dont have any acrylic part on the printer other then the spacer for the hotend atm(planing to upgrade to E3D v6).

Now i just have to figure out how to make a new Y belt clamps ,the original Ormerod 2 are always sliping

Edited 2 time(s). Last edit at 06/09/2015 02:04PM by Darathy.

Now i just have to figure out how to make a new Y belt clamps ,the original Ormerod 2 are always sliping

Edited 2 time(s). Last edit at 06/09/2015 02:04PM by Darathy.

|

Re: Bed levelling question June 10, 2015 09:22AM |

Registered: 8 years ago Posts: 105 |

Working on fixing the problem now, now I know what I am looking for I can see the front arm is high and the rear arm is probably fractionally low. Gave it one small tweak which has already helped, but I need to move the acrylic part more than the printed end Y parts will allow. So need to disassemble and file a little off the printed parts. Once they are correct looks I will drill a hole for another bolt nearer the front and then glue the green printed part to the acrylic.

Treito - I am printing onto the kapton tape, I thought it could be a difference in the glass thickness on one corner so turned the glass over and tried the glass side no tape, adhesion was probably about 50% of kapton max. I have printed parts that literally fill the bed, had a small amount or edge warp partly because the heat doesn't "wrap around" the part at the edges and one part overhung the cut-out in the heat plate at the front. On other parts I have printed if I suspect there will be a chance or lifting/warping I build a brim or supports onto the model to create extra contact area outside the part, have found you need around 2cm squared contact or more to keep things flat.

In looking at printing with other materials found this info on putting PEI sheet on the bed which sounds like the best answer to stop warping [reprap.org]

Pic of the print that warped a bit here [www.dropbox.com] front right corner

Edited 3 time(s). Last edit at 06/10/2015 09:25AM by Firefox3D.

Treito - I am printing onto the kapton tape, I thought it could be a difference in the glass thickness on one corner so turned the glass over and tried the glass side no tape, adhesion was probably about 50% of kapton max. I have printed parts that literally fill the bed, had a small amount or edge warp partly because the heat doesn't "wrap around" the part at the edges and one part overhung the cut-out in the heat plate at the front. On other parts I have printed if I suspect there will be a chance or lifting/warping I build a brim or supports onto the model to create extra contact area outside the part, have found you need around 2cm squared contact or more to keep things flat.

In looking at printing with other materials found this info on putting PEI sheet on the bed which sounds like the best answer to stop warping [reprap.org]

Pic of the print that warped a bit here [www.dropbox.com] front right corner

Edited 3 time(s). Last edit at 06/10/2015 09:25AM by Firefox3D.

|

Re: Bed levelling question June 10, 2015 02:58PM |

Registered: 9 years ago Posts: 1,699 |

Hello,

I ordered BuildTak because I have also HIPS and somebody told me that PEI is not compatible with HIPS. But as long as my bed is not leveled yet I will not use it or otherwise I risk a damage.

The strange thing about glass is that my original glass is covered with blue tape and I use this blue tape also to level my bed. I am able to level the bed by the screws. I have also ordered to other piece of glass (both same type but slightly different to the original one). With these glasses I get strange levels.

I have also an idea where my fault could be located. I was unhappy to get an Ormerod 1 where the production series changed of the metal bars. There were slightly too long and the parts were changed later. No I have the problem that these bars does not make the whole way through the acrylic parts at the front. Maybe the hole is too small or the bar is too thick. This ends in that the left acyrlc part is not angled to the frame (at the front) but slightly bend to the outside. The backside slipped in easily. I do not know if that could be the cause but I saw this yesterday. I do not think so because at the beginning I extended the aluminum profile with some big washers to compensate the problem in length of the bars and I had had the same problems until the spare parts arrived.

I have ordered some new bars and we will see.

I ordered BuildTak because I have also HIPS and somebody told me that PEI is not compatible with HIPS. But as long as my bed is not leveled yet I will not use it or otherwise I risk a damage.

The strange thing about glass is that my original glass is covered with blue tape and I use this blue tape also to level my bed. I am able to level the bed by the screws. I have also ordered to other piece of glass (both same type but slightly different to the original one). With these glasses I get strange levels.

Bed equation fits points [50.0, 30.0, 0.173] [50.0, 190.0, 0.515] [180.0, 190.0, -0.082] [180.0, 30.0, -0.246]The strange thing about this is that it is equal if I use Kapton tape or not and also the direction does not matter I always get the same differences in height (the absolute values may vary). Without autobed leveling I am not able to print. The only idea I have is that the weight differs and that is maybe the reason.

I have also an idea where my fault could be located. I was unhappy to get an Ormerod 1 where the production series changed of the metal bars. There were slightly too long and the parts were changed later. No I have the problem that these bars does not make the whole way through the acrylic parts at the front. Maybe the hole is too small or the bar is too thick. This ends in that the left acyrlc part is not angled to the frame (at the front) but slightly bend to the outside. The backside slipped in easily. I do not know if that could be the cause but I saw this yesterday. I do not think so because at the beginning I extended the aluminum profile with some big washers to compensate the problem in length of the bars and I had had the same problems until the spare parts arrived.

I have ordered some new bars and we will see.

|

Re: Bed levelling question June 10, 2015 03:13PM |

Registered: 9 years ago Posts: 638 |

Quote

Treito

Hello,

I ordered BuildTak because I have also HIPS and somebody told me that PEI is not compatible with HIPS. But as long as my bed is not leveled yet I will not use it or otherwise I risk a damage.

The strange thing about glass is that my original glass is covered with blue tape and I use this blue tape also to level my bed. I am able to level the bed by the screws. I have also ordered to other piece of glass (both same type but slightly different to the original one). With these glasses I get strange levels.

Bed equation fits points [50.0, 30.0, 0.173] [50.0, 190.0, 0.515] [180.0, 190.0, -0.082] [180.0, 30.0, -0.246]The strange thing about this is that it is equal if I use Kapton tape or not and also the direction does not matter I always get the same differences in height (the absolute values may vary). Without autobed leveling I am not able to print. The only idea I have is that the weight differs and that is maybe the reason.

I have also an idea where my fault could be located. I was unhappy to get an Ormerod 1 where the production series changed of the metal bars. There were slightly too long and the parts were changed later. No I have the problem that these bars does not make the whole way through the acrylic parts at the front. Maybe the hole is too small or the bar is too thick. This ends in that the left acyrlc part is not angled to the frame (at the front) but slightly bend to the outside. The backside slipped in easily. I do not know if that could be the cause but I saw this yesterday. I do not think so because at the beginning I extended the aluminum profile with some big washers to compensate the problem in length of the bars and I had had the same problems until the spare parts arrived.

I have ordered some new bars and we will see.

I have noticed my bars had abit of resedue left from cutting them ,i Chamfered them at the tip only abaut 0.5mm. and if that does not work try using some fine sand paper on the acrylic hole(8mm drill and wrap it araund the non cutting part and just turn) but not too much , it should go through the hole bit roughly so it does not slip out when the bed is moving.

For the bed diferences i thin you just need to manualy set the bed(adjusting the 3 scews) the first point is at the 1st scew so lower thatone by 1 turn and 2nd point is at the 2nd scew lower thatone by just a 1/3th of a turn.

The other 2 points i see you have the twisted rod issue suggest getting the adjustable Y idler.

|

Re: Bed levelling question June 10, 2015 03:35PM |

Registered: 9 years ago Posts: 1,699 |

As I descibed above I am at the end of the screws. The inner nut of the front screw labeled with A bearly touches the nut above that fixes the screw to the pcb. The pcb is nearly to get pushed down and bend so I cannot push the screw more downwards. The screws labeled with B and C (The outer screws at near the PCB or the vertical aluminium bar) are completely srewed up so the nuts on the downside nearly get lost because there is no thread anymore. Of course I could replace the screws with longer ones but there must definitely something wrong - really wrong. I am printing the calibration at the moment and if this succeeded then I am going to print a new bed support so I can find out if there is maybe a problem with the plywood or it is caused elsewhere.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Bed levelling question June 10, 2015 04:09PM |

Registered: 10 years ago Posts: 14,672 |

As I understand it:

1. You have the 2 screws at the back of the bed adjusted to make the bed as high as possible, and the one at the front adjusted to make the bed as low as possible.

2. You are already using DaveK's aluminium bed support. So the problem isn't that the back corners of the bed support are sagging, which was a common problem with the original Ormerod 1 MDF bed support.

3. You have already checked that the cutout in the plywood rib that supports the front of the bed is sitting squarely on the linear bearing.

Is that all correct?

If so, have you tried measuring the angle between the Z axis and the X axis, to see whether the X axis is sagging?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. You have the 2 screws at the back of the bed adjusted to make the bed as high as possible, and the one at the front adjusted to make the bed as low as possible.

2. You are already using DaveK's aluminium bed support. So the problem isn't that the back corners of the bed support are sagging, which was a common problem with the original Ormerod 1 MDF bed support.

3. You have already checked that the cutout in the plywood rib that supports the front of the bed is sitting squarely on the linear bearing.

Is that all correct?

If so, have you tried measuring the angle between the Z axis and the X axis, to see whether the X axis is sagging?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Bed levelling question June 10, 2015 05:09PM |

Registered: 9 years ago Posts: 1,699 |

You are nearly right.

1. Yes

2. Yes and also the X-arm kit

3. Yes. Maybe I should try to hit this little notch on one end the rod but it is centered at the moment. No we come to the point you are not completely right. I can not measure angle exactly but I can measure if something is angled. So I even decreased the angle between the top of the X-arm and the Z-axis to help increasing my little bed problem. I have no idea anymore. Okay to be honest I an Electrician but I have to know and I do know some advanced basics about Mechanics but at the moment I have no further idea except for the plywood rib. That is why I want to replace this part.

BTW I just controlled the angle between the glass surface and the y-axis and the problem is definitely related at this place.

1. Yes

2. Yes and also the X-arm kit

3. Yes. Maybe I should try to hit this little notch on one end the rod but it is centered at the moment. No we come to the point you are not completely right. I can not measure angle exactly but I can measure if something is angled. So I even decreased the angle between the top of the X-arm and the Z-axis to help increasing my little bed problem. I have no idea anymore. Okay to be honest I an Electrician but I have to know and I do know some advanced basics about Mechanics but at the moment I have no further idea except for the plywood rib. That is why I want to replace this part.

BTW I just controlled the angle between the glass surface and the y-axis and the problem is definitely related at this place.

|

Re: Bed levelling question June 10, 2015 05:42PM |

Registered: 9 years ago Posts: 638 |

As i understand ,you can try loosening the 4 bolts that hold the acrylic on the idlers and just lift the front rod up(carefull you pull on both end equaly or you can worsen the Rod Twist problem) and retighten the scews. I think this would make the Front higher so you can lower the bed in the front part making it more pararel to the X axis. and then readjust the bed.

Thats just my thinking , can someone confirm that this would help?

Thats just my thinking , can someone confirm that this would help?

|

Re: Bed levelling question June 10, 2015 05:56PM |

Registered: 9 years ago Posts: 1,699 |

I cannot test this for yet but I have another idea thanks to you right simliar. What about the connection of the y-idler-bracket and y-motor-bracket parts to the aluminium profile? It is hard to measure the angle here and I think there is maybe the problem. Why I did not get this earlier? And now I got the thing what you mean with the twist problem fully.

Nevertheless I still want to get rid off the ply rib.

Many thanks for your help so far I got a hint and probably two problems at the same time.

Nevertheless I still want to get rid off the ply rib.

Many thanks for your help so far I got a hint and probably two problems at the same time.

|

Re: Bed levelling question June 12, 2015 05:24PM |

Registered: 9 years ago Posts: 24 |

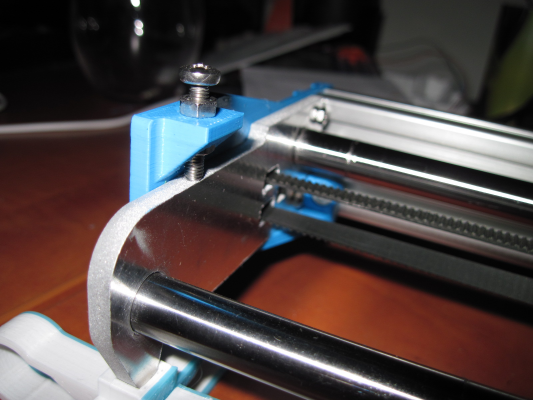

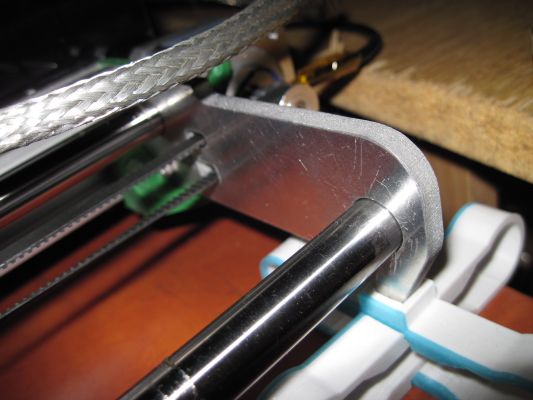

I have been trying to fix my bed level problem for a while now, always had a diffrence at the front of the bed. Was unable to correct it acuratley enogh by twisting the acylic. So i designed this yesterday to replace the acylic part of the y idler on the ormerod 2. The front rod fits into the block which can be moved up and down in a grove to change the angle at the front of the bed. With this I have managed to get the bed level and no longer need to use the compensation. Have not done much printing with it yet but so far so good. Need to tweek the hole sizes for the rods as i needed to open them up slightly with a stanley knife to get the rods to fit.

|

Re: Bed levelling question June 13, 2015 04:12AM |

Registered: 10 years ago Posts: 776 |

|

Re: Bed levelling question June 13, 2015 07:42AM |

Registered: 9 years ago Posts: 1,699 |

There is another good solution on thingiverse. I will test the original for the Ormerod MK1 soon together with the aluminium bed support. And I believe that is a very good solution. This hopefully fix my problem or at least helps to fix it. First I will check all angles (and twists) so that this is not a problem caused by something like this.

I will report later or tomorrow.

Edit: I am afraid that I had all causes at once and they added themselves. The acrylic plate "A" was bended to the outer side because it did not grab the rod completely. The Y-motor bracket was broken at some points as also one Y-bearing-clamp. There was a slight twist according to the rods (I am not sure how to ensure to remove this by 100% I think only 98% are possible) and maybe the x-arm was indeed hanging even though it did not look so. Nevermind I think I have to replace more and so I will replace some parts of the z-axis. It was not planned for now but I could finish it and start happy printing again.

Edited 1 time(s). Last edit at 06/13/2015 10:20AM by Treito.

I will report later or tomorrow.

Edit: I am afraid that I had all causes at once and they added themselves. The acrylic plate "A" was bended to the outer side because it did not grab the rod completely. The Y-motor bracket was broken at some points as also one Y-bearing-clamp. There was a slight twist according to the rods (I am not sure how to ensure to remove this by 100% I think only 98% are possible) and maybe the x-arm was indeed hanging even though it did not look so. Nevermind I think I have to replace more and so I will replace some parts of the z-axis. It was not planned for now but I could finish it and start happy printing again.

Edited 1 time(s). Last edit at 06/13/2015 10:20AM by Treito.

|

Re: Bed levelling question June 13, 2015 03:55PM |

Registered: 10 years ago Posts: 665 |

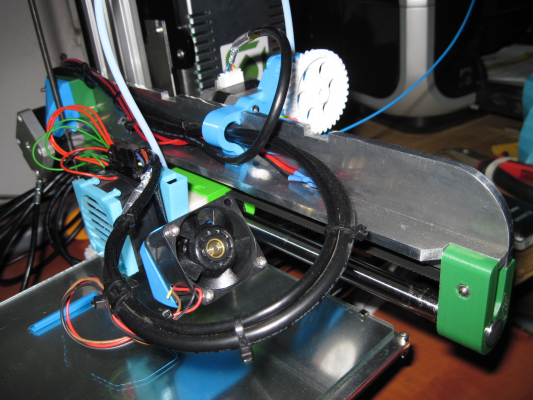

I must admit I was facing the same issue, but I finally found the solution:

I replaced the printed Y parts (y idler bracket and y motor bracket) when I got my Ormerod 2, but the front left corner was always off by 0.4mm - 1.0mm. So I reprinted these parts again (if using ABS you definitely need a brim), mounted them once more and checked my bed level. Again, the bed was off by a fraction. So I took some pliers and pushed against the Y idler bracket from beneath, tightened the M3 countersunk screws once more and voila, my bed is level again:

Maybe that helps a few other users, it's worth a try!

I replaced the printed Y parts (y idler bracket and y motor bracket) when I got my Ormerod 2, but the front left corner was always off by 0.4mm - 1.0mm. So I reprinted these parts again (if using ABS you definitely need a brim), mounted them once more and checked my bed level. Again, the bed was off by a fraction. So I took some pliers and pushed against the Y idler bracket from beneath, tightened the M3 countersunk screws once more and voila, my bed is level again:

Bed equation fits points [40.0, 10.0, 0.009] [40.0, 185.0, 0.006] [204.0, 185.0, 0.020] [204.0, 10.0, 0.040]

Maybe that helps a few other users, it's worth a try!

|

Re: Bed levelling question June 13, 2015 04:03PM |

Registered: 9 years ago Posts: 1,699 |

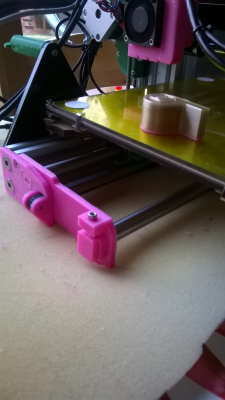

So my idler bracket was broken what can I expect?  I am adding the new bed carriage, It allows you to level the bed around the y-axis (from the view of Simplify3D.

I am adding the new bed carriage, It allows you to level the bed around the y-axis (from the view of Simplify3D.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I am adding the new bed carriage, It allows you to level the bed around the y-axis (from the view of Simplify3D.

I am adding the new bed carriage, It allows you to level the bed around the y-axis (from the view of Simplify3D.Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.