Updating Ormerod 1 Y axis to Ormerod 2

Posted by droftarts

|

Updating Ormerod 1 Y axis to Ormerod 2 September 10, 2014 08:51AM |

Registered: 12 years ago Posts: 1,611 |

A customer emailed us:

I replied:

Yes, it is; fundamentally there's not much difference in the way it works. However, most of the parts have changed, so there is a bit of work! You will need:

Y axis (the spacing between the smooth rods has changed, so you need to change the y-axis ends):

2 x y-axis-end-plate (5mm acrylic, lasercut)

1 x y-motor-bracket (printed part)

1 x y-idler-bracket

Y carriage:

1 x bed-support (6mm ply, lasercut)

1 x y-axis-rib (6mm ply, lasercut)

1 x y-axis-cross-rib (6mm ply, lasercut)

y-bearing-clamp (printed part)

y-bearing-clamp-tagged (printed part)

Heated bed:

1 x MDF bed insulator (3mm MDF, lasercut)

Fasteners, Y axis:

2 x M4x12mm countersunk socket head screw

2 x M4 T-nut

4 x M3x12mm countersunk socket head screw

4 x M3 Nut

1 x M3x12mm cap head screw

4 x M6x16mm countersunk socket head screw

2 x M3x8mm countersunk socket screw

1 x M3x40mm cap head screw

1 x M3 washer

Fasteners, Y carriage:

4 x M3x16mm countersunk socket screw

10 x M3 nut

4 x M3 washer

4 x M3x30mm cap head screw

1 x M3x25mm countersunk socket screw

1 x M3x26mm crosshead screw (removed from NEMA17 motor)

Fasteners, heated bed

3 x M3x25mm cap head screw

2 x M3x12mm cap head screw

7 x M3 washer

7 x M3 nyloc nut

3 x M3 nut

Bed:

4 x Picture frame clips

Also, if you change the end the y-motor is, you may need a longer wiring loom for the y-motor and the endstop.

You will be able to reuse all other parts, eg motors, smooth rod, bearings, microswitch, belt, heated bed, heated bed wiring, thermistor, aluminium heat spreader. There's probably a lot of fasteners you can reuse, but I haven't done a count of what is supplied in the same sections of the Ormerod 1. See the Ormerod 2 instructions here for details and assembly:

[reprappro.com]

[reprappro.com]

[reprappro.com]

All of the parts are available, just not listed in our webshop. Contact Sally for a quote on the above. If you want to laser cut and print the parts yourself, they are available in the github repository, which is up to date with the Ormerod 2 parts: [github.com]

We may yet release a kit including all of the above parts, but not in the next few weeks! If you do update the axis, you'll need to change the homing behaviour of the Y axis, so it homes to the correct end, as per the Ormerod 2. You'll need to update the homey.g and homeall.g, replacing:

with

I hope that helps.

Ian

RepRapPro tech support

edit: I'll add a link to this thread on the Ormerod improvements page.

Edited 1 time(s). Last edit at 09/10/2014 08:57AM by droftarts.

Quote

Hi, Is it possible to retro fit an Ormerod 2 Y axis to an Ormerod machine, if yes are the parts available.

I replied:

Yes, it is; fundamentally there's not much difference in the way it works. However, most of the parts have changed, so there is a bit of work! You will need:

Y axis (the spacing between the smooth rods has changed, so you need to change the y-axis ends):

2 x y-axis-end-plate (5mm acrylic, lasercut)

1 x y-motor-bracket (printed part)

1 x y-idler-bracket

Y carriage:

1 x bed-support (6mm ply, lasercut)

1 x y-axis-rib (6mm ply, lasercut)

1 x y-axis-cross-rib (6mm ply, lasercut)

y-bearing-clamp (printed part)

y-bearing-clamp-tagged (printed part)

Heated bed:

1 x MDF bed insulator (3mm MDF, lasercut)

Fasteners, Y axis:

2 x M4x12mm countersunk socket head screw

2 x M4 T-nut

4 x M3x12mm countersunk socket head screw

4 x M3 Nut

1 x M3x12mm cap head screw

4 x M6x16mm countersunk socket head screw

2 x M3x8mm countersunk socket screw

1 x M3x40mm cap head screw

1 x M3 washer

Fasteners, Y carriage:

4 x M3x16mm countersunk socket screw

10 x M3 nut

4 x M3 washer

4 x M3x30mm cap head screw

1 x M3x25mm countersunk socket screw

1 x M3x26mm crosshead screw (removed from NEMA17 motor)

Fasteners, heated bed

3 x M3x25mm cap head screw

2 x M3x12mm cap head screw

7 x M3 washer

7 x M3 nyloc nut

3 x M3 nut

Bed:

4 x Picture frame clips

Also, if you change the end the y-motor is, you may need a longer wiring loom for the y-motor and the endstop.

You will be able to reuse all other parts, eg motors, smooth rod, bearings, microswitch, belt, heated bed, heated bed wiring, thermistor, aluminium heat spreader. There's probably a lot of fasteners you can reuse, but I haven't done a count of what is supplied in the same sections of the Ormerod 1. See the Ormerod 2 instructions here for details and assembly:

[reprappro.com]

[reprappro.com]

[reprappro.com]

All of the parts are available, just not listed in our webshop. Contact Sally for a quote on the above. If you want to laser cut and print the parts yourself, they are available in the github repository, which is up to date with the Ormerod 2 parts: [github.com]

We may yet release a kit including all of the above parts, but not in the next few weeks! If you do update the axis, you'll need to change the homing behaviour of the Y axis, so it homes to the correct end, as per the Ormerod 2. You'll need to update the homey.g and homeall.g, replacing:

... G92 Y0 G1 Y250 F2000 S1 G92 Y200 G1 Y197 F200 G1 Y250 S1 G92 Y200 G1 Y0 F2000 ...

with

... G92 Y0 G1 Y-250 F2000 S1 G92 Y0 G1 Y3 F200 G1 Y-30 F200 S1 G92 Y0 ...

I hope that helps.

Ian

RepRapPro tech support

edit: I'll add a link to this thread on the Ormerod improvements page.

Edited 1 time(s). Last edit at 09/10/2014 08:57AM by droftarts.

|

Re: Updating Ormerod 1 Y axis to Ormerod 2 September 22, 2014 01:49PM |

Registered: 10 years ago Posts: 378 |

If I just want to change the position of the Y motor (to the other end of the Y axis) on my "Mk I", is it sufficient to just swap out the Y motor bracket and Y idler bracket (as well as obviously extending cables to motor and microswitch)? It looks to me like the inner of the two 12mm steel rods is still in the same position, in which case I guess it should fit with the old acrylic end-plates.

Doing this mostly for cosmetic reasons, and just want to make sure I don't need to print anything else before taking the Y axis apart.

Doing this mostly for cosmetic reasons, and just want to make sure I don't need to print anything else before taking the Y axis apart.

|

Re: Updating Ormerod 1 Y axis to Ormerod 2 September 23, 2014 04:58AM |

Registered: 12 years ago Posts: 1,611 |

Hi jstck

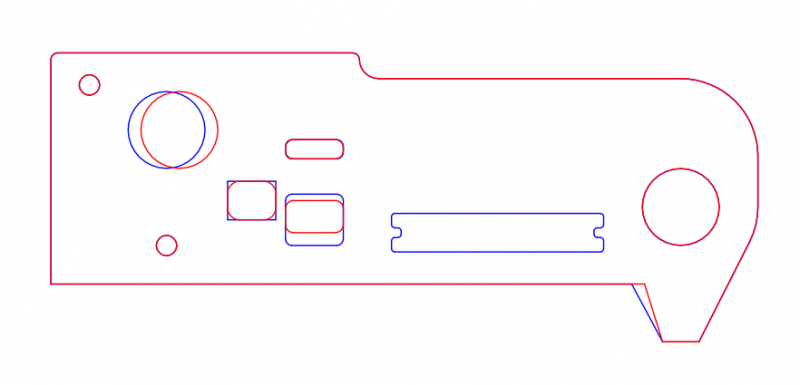

It's actually the inner 12mm rod that has moved, by 2mm away from the y-axis aluminium extrusion. It would probably be safest to take the Ormerod 1 y-ends and 'mirror' them (you can do this in Netfabb Basic), as the pocket in the idler end will then be in the right place. I don't think anything else has moved. I've attached a picture of the difference between the y-axis-end-plates; Ormerod 1 is in blue, Ormerod 2 in red.

Ian

RepRapPro tech support

Edited 2 time(s). Last edit at 09/23/2014 05:01AM by droftarts.

It's actually the inner 12mm rod that has moved, by 2mm away from the y-axis aluminium extrusion. It would probably be safest to take the Ormerod 1 y-ends and 'mirror' them (you can do this in Netfabb Basic), as the pocket in the idler end will then be in the right place. I don't think anything else has moved. I've attached a picture of the difference between the y-axis-end-plates; Ormerod 1 is in blue, Ormerod 2 in red.

Ian

RepRapPro tech support

Edited 2 time(s). Last edit at 09/23/2014 05:01AM by droftarts.

|

Re: Updating Ormerod 1 Y axis to Ormerod 2 September 23, 2014 05:15AM |

Registered: 10 years ago Posts: 14,672 |

Personally, I see no advantage in moving the Y motor and endstop to the other end. To me, the important thing about homing is not to put the bed at XYZ=(0,0,0) but rather to put it at a known position. I find stopping the bed at Y=200 is much more useful than stopping it at Y=0 because I can get at more of the bed for cleaning etc.

Edited 1 time(s). Last edit at 09/23/2014 06:45AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 09/23/2014 06:45AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Updating Ormerod 1 Y axis to Ormerod 2 September 23, 2014 05:18AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Updating Ormerod 1 Y axis to Ormerod 2 September 23, 2014 10:23AM |

Registered: 10 years ago Posts: 378 |

Ah, I thought it was the outer rod that had moved, but that seems to be in the same spot.

Yep, that should work. Mirroring the Ormerod 1 idler bracket, and use together with the Ormerod 2 Y motor bracket.

I don't want to move the rod itself, since I want to keep the stock Ormerod 1-Y carriage (got Davek's aluminium bed support which does the job, together with iamburny's belt thingies). While tensioning the belt with dc42's spacer shims works, it is cumbersome to do and quite difficult to get the tension just right.

(edit: silly me, there is no pocket for the rod on the motor bracket)

It has nothing to do with homing really, mostly looks. I plan on moving the Duet as well to the back of the printer to have easier access to the "front" of the Ormerod (the "low Y" side), make it look neater sitting on my desk, and have more room for strange hotends and cooling setups.

Edited 1 time(s). Last edit at 09/23/2014 10:27AM by jstck.

Quote

droftarts

It would probably be safest to take the Ormerod 1 y-ends and 'mirror' them (you can do this in Netfabb Basic), as the pocket in the idler end will then be in the right place.

Yep, that should work. Mirroring the Ormerod 1 idler bracket, and use together with the Ormerod 2 Y motor bracket.

I don't want to move the rod itself, since I want to keep the stock Ormerod 1-Y carriage (got Davek's aluminium bed support which does the job, together with iamburny's belt thingies). While tensioning the belt with dc42's spacer shims works, it is cumbersome to do and quite difficult to get the tension just right.

(edit: silly me, there is no pocket for the rod on the motor bracket)

Quote

dc42

Personally, I see no advantage in moving the Y motor and endstop to the other end.

It has nothing to do with homing really, mostly looks. I plan on moving the Duet as well to the back of the printer to have easier access to the "front" of the Ormerod (the "low Y" side), make it look neater sitting on my desk, and have more room for strange hotends and cooling setups.

Edited 1 time(s). Last edit at 09/23/2014 10:27AM by jstck.

|

Re: Updating Ormerod 1 Y axis to Ormerod 2 September 23, 2014 06:08PM |

Registered: 10 years ago Posts: 378 |

While doing the swap I did find the following:

- On my Ormerod the two steel rods are flush with the acrylic end plates, so it doesn't matter that the pocket for the rod is in the wrong place as it isn't really needed. While a mirrored ormerod-1 part is "better", I was fine with the ormerod-2 one.

- If you are using iamburnys belt clamps, those need to be mirrored as well since the belt now twists the opposite way. I didn't print any beforehand, so I had to tighten the belt the old-fashioned way.

- The Y-axis rib needs to be rotated so the "endstop trigger" is on the other side. Just remember to do it the first time you have the belt off.

|

Re: Updating Ormerod 1 Y axis to Ormerod 2 September 24, 2014 04:51AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Updating Ormerod 1 Y axis to Ormerod 2 September 24, 2014 03:35PM |

Registered: 10 years ago Posts: 378 |

|

Re: Updating Ormerod 1 Y axis to Ormerod 2 July 11, 2015 05:47AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

as there is a link on the Ormerod improvement site I have one question:

Are there any CAD-files outside that I can open with free software? DXF? DWG?

Edited 1 time(s). Last edit at 07/11/2015 05:47AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

as there is a link on the Ormerod improvement site I have one question:

Quote

droftarts

Y carriage:

1 x bed-support (6mm ply, lasercut)

1 x y-axis-rib (6mm ply, lasercut)

1 x y-axis-cross-rib (6mm ply, lasercut)

Heated bed:

1 x MDF bed insulator (3mm MDF, lasercut)

Are there any CAD-files outside that I can open with free software? DXF? DWG?

Edited 1 time(s). Last edit at 07/11/2015 05:47AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Updating Ormerod 1 Y axis to Ormerod 2 July 13, 2015 07:41AM |

Registered: 12 years ago Posts: 1,611 |

Hi Treito

I think you want the lasercut dxf files? The easiest versions to get hold of are here, which is the 'release' or 'tag' in the Github repository for the '528.0 to 528.4' version of Ormerod: [github.com]

These aren't the MOST up to date versions, but we haven't finished of exporting the dxfs from the latest version (528.5), which is the current repository: [github.com]

We use SolidWorks 2015 to design our printers, which is not open source, but our design files are open source. You can open the exported STL files, and convert them to STEP files, in FreeCAD ( [northernhope.blogspot.co.uk] ) (FreeCAD is open source and free) and then import it into any other CAD program. The dxf files can be opened in Inkscape, a free vector drawing program.

Ian

RepRapPro tech support

I think you want the lasercut dxf files? The easiest versions to get hold of are here, which is the 'release' or 'tag' in the Github repository for the '528.0 to 528.4' version of Ormerod: [github.com]

These aren't the MOST up to date versions, but we haven't finished of exporting the dxfs from the latest version (528.5), which is the current repository: [github.com]

We use SolidWorks 2015 to design our printers, which is not open source, but our design files are open source. You can open the exported STL files, and convert them to STEP files, in FreeCAD ( [northernhope.blogspot.co.uk] ) (FreeCAD is open source and free) and then import it into any other CAD program. The dxf files can be opened in Inkscape, a free vector drawing program.

Ian

RepRapPro tech support

|

Re: Updating Ormerod 1 Y axis to Ormerod 2 July 13, 2015 07:53AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

thanks Ian. I already downloaded the Github-files. I am using FreeCAD (as I learned Inventor and the usage is nearly similiar) and LibreCAD so that is why I am asking for the files. I need the DXF-Files to design some new parts for thingiverse.

Many thanks so far, I should have click on "tags", but I did not knew that I have to use an older branch.

Regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

thanks Ian. I already downloaded the Github-files. I am using FreeCAD (as I learned Inventor and the usage is nearly similiar) and LibreCAD so that is why I am asking for the files. I need the DXF-Files to design some new parts for thingiverse.

Many thanks so far, I should have click on "tags", but I did not knew that I have to use an older branch.

Regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.