Modulated Z probe inconsistent

Posted by mynamesriz

|

Modulated Z probe inconsistent July 25, 2015 04:42AM |

Registered: 9 years ago Posts: 22 |

Hi,

I hope someone can give me some advice, I've check the forums and troubleshooting pages but can't find anything.

I recently bought a modulated Z brobe from the Reprap Pro website in order to get auto levelling working on my reprap printer but I find it very in consistent, I have white insulation tape on each corner of my heated print bed as I'm using BuildTak, I tried aluminium tape but it was really unreliable.

The main problem I am facing is that I will calibrate the printer and save the config file and then a few prints down the line I'll have problems with the hotend being too close to the bed and then I'll have to recalibrate it and save the new value to the config file.

Is this a common issue?

I'm currently using DC42's 1.09c Reprap firmware. I've also attached my config file just in case.

A good example of the issue I'm facing is the G31 Z0 P400 line in the config file was G31 Z0 P525 yesterday! big difference, my Z probe is securely screwed on to the printhead. there isn't any IR interference that I'm aware of either.

Thanks in advance

Riz

I hope someone can give me some advice, I've check the forums and troubleshooting pages but can't find anything.

I recently bought a modulated Z brobe from the Reprap Pro website in order to get auto levelling working on my reprap printer but I find it very in consistent, I have white insulation tape on each corner of my heated print bed as I'm using BuildTak, I tried aluminium tape but it was really unreliable.

The main problem I am facing is that I will calibrate the printer and save the config file and then a few prints down the line I'll have problems with the hotend being too close to the bed and then I'll have to recalibrate it and save the new value to the config file.

Is this a common issue?

I'm currently using DC42's 1.09c Reprap firmware. I've also attached my config file just in case.

A good example of the issue I'm facing is the G31 Z0 P400 line in the config file was G31 Z0 P525 yesterday! big difference, my Z probe is securely screwed on to the printhead. there isn't any IR interference that I'm aware of either.

Thanks in advance

Riz

|

Re: Modulated Z probe inconsistent July 25, 2015 06:28AM |

Registered: 10 years ago Posts: 14,672 |

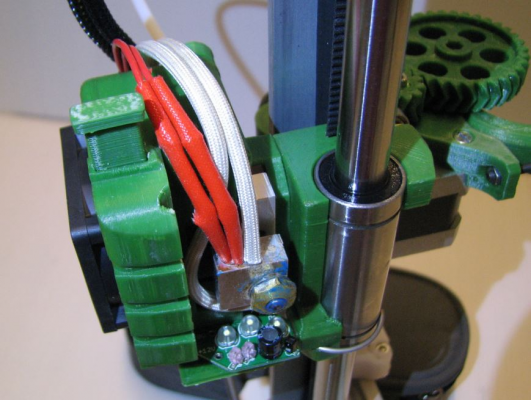

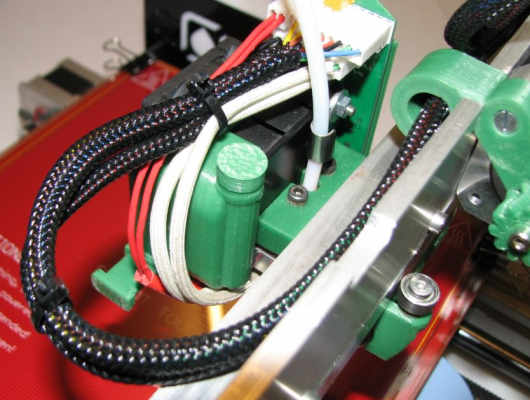

If you buy one of my differential IR probes (either the Ormerod one that also controls the hot end fan and integrates the connectors, or my new mini board), it works on BuildTak as well as most other surfaces, so you will be able to use it anywhere on the bed without needing white tapes. But here are my suggestions for getting the RRP modulated probe working better:

1. Make sure it really is running in modulated mode. You have M558 P2 in your config.g file, which is correct. However, the RRP homing files switch it to P1 for X homing (which is not necessary using my firmware fork), Make sure it is switched back to P2 at the end of the X homing sequence, in both homex.g and homeall.g. You can send M558 with no parameters to see what mode it is in.

2. Make sure your probing positions place the sensor over the centres of the white tapes, and that the X and Y homing positions are consistent enough that this is always the case.

3. The mounting position on the X carriage of the RRP proximity sensor does not place it in line with the nozzle in the X direction. This means that any rotation of the head about the X smooth rod will change the relative heights of the nozzle and the sensor. So make sure the head angle is constant. My Ormerod sensor boards mount on the hot end, with the sensitive area in line with the nozzle in the X direction, in order to minimise this effect.

4. The modulated sensor is still somewhat sensitive to ambient IR (but around 15 times less sensitive than the unmodulated one, from my measurements). In particular, it can be affected by strong sunlight. So if the printer is in a room that gets direct sunlight, on sunny days make sure that you do not have strong sunlight shining directly on the bed.

Edited 1 time(s). Last edit at 07/25/2015 06:28AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Make sure it really is running in modulated mode. You have M558 P2 in your config.g file, which is correct. However, the RRP homing files switch it to P1 for X homing (which is not necessary using my firmware fork), Make sure it is switched back to P2 at the end of the X homing sequence, in both homex.g and homeall.g. You can send M558 with no parameters to see what mode it is in.

2. Make sure your probing positions place the sensor over the centres of the white tapes, and that the X and Y homing positions are consistent enough that this is always the case.

3. The mounting position on the X carriage of the RRP proximity sensor does not place it in line with the nozzle in the X direction. This means that any rotation of the head about the X smooth rod will change the relative heights of the nozzle and the sensor. So make sure the head angle is constant. My Ormerod sensor boards mount on the hot end, with the sensitive area in line with the nozzle in the X direction, in order to minimise this effect.

4. The modulated sensor is still somewhat sensitive to ambient IR (but around 15 times less sensitive than the unmodulated one, from my measurements). In particular, it can be affected by strong sunlight. So if the printer is in a room that gets direct sunlight, on sunny days make sure that you do not have strong sunlight shining directly on the bed.

Edited 1 time(s). Last edit at 07/25/2015 06:28AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Modulated Z probe inconsistent July 25, 2015 07:19AM |

Registered: 9 years ago Posts: 22 |

Thanks Dave,

I actually removed the M558 command from the homex and homeall files as I'm still using a switch for the x axis, for the homeall file I just send the G30 command for the z homing so it should just pickup the settings in the config file.

I will double check the positioning of the tape etc and get back to you. Also your point about mounting position is interesting, I'm going to try to move the sensor so it's more central to the hotend as currently it's offset in the Y direction.

I don't think ambient IR is a problem as the room the printer is in is quite dark and doesn't get that much sunlight.

If I don't get anywhere I would be interested in your mini sensor board, have you got any stock? Also how much are they?***scratch that found the price ***

***

Thanks

Riz

Edited 1 time(s). Last edit at 07/25/2015 07:23AM by mynamesriz.

I actually removed the M558 command from the homex and homeall files as I'm still using a switch for the x axis, for the homeall file I just send the G30 command for the z homing so it should just pickup the settings in the config file.

I will double check the positioning of the tape etc and get back to you. Also your point about mounting position is interesting, I'm going to try to move the sensor so it's more central to the hotend as currently it's offset in the Y direction.

I don't think ambient IR is a problem as the room the printer is in is quite dark and doesn't get that much sunlight.

If I don't get anywhere I would be interested in your mini sensor board, have you got any stock? Also how much are they?***scratch that found the price

***

***Thanks

Riz

Edited 1 time(s). Last edit at 07/25/2015 07:23AM by mynamesriz.

|

Re: Modulated Z probe inconsistent July 25, 2015 07:58AM |

Registered: 10 years ago Posts: 1,230 |

Quote

mynamesriz

..Also your point about mounting position is interesting, I'm going to try to move the sensor so it's more central to the hotend as currently it's offset in the Y direction...

yes the original position is leveraged about 1:2 compared to the nozzle, David's probe is in line and pure plug, play and forget, I highly recommend the full blown edition with temperature control of the hotend, I love to be able to switch of the printer just after the print, take out the SD-card and turn on the printer again and know the hot end will keep on cooling - and ad to that the solid connectors that makes for a nice and tidy cabling and easy change of hotends

Erik

|

Re: Modulated Z probe inconsistent July 25, 2015 08:16AM |

Registered: 10 years ago Posts: 14,672 |

Quote

mynamesriz

If I don't get anywhere I would be interested in your mini sensor board, have you got any stock? Also how much are they?***scratch that found the price***

Yes I have mini boards in stock, and latest prices are here [forums.reprap.org]. I have not designed a printed part to fit one to the Ormerod, so you would have to do that yourself. I recommend you fit it on the hot end with the sensitive area in line with the nozzle in the X direction.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Modulated Z probe inconsistent July 26, 2015 03:31PM |

Registered: 9 years ago Posts: 22 |

|

Re: Modulated Z probe inconsistent July 26, 2015 03:49PM |

Registered: 9 years ago Posts: 1,699 |

I am using BlueTak with the stock sensor and without white tape. It works. You only have to change the P value at the G31 command to a lower value. I use P120 for example. however I have a white advertising print in the middle. During homing the nozzle should not move over it at a low high or at homing it can react on the white wires if homing the x-axis. Even auto-levelling is working. But I will change my sensor soon, too - to a mini-board based sensor.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Modulated Z probe inconsistent July 26, 2015 04:42PM |

Registered: 12 years ago Posts: 1,611 |

dc42 - does your firmware fork use bed.g for bed levelling, or M557?

Riz - the RRP v1.09 uses bed.g for homing, see: [reprappro.com]

I'd also advise to use paper (self-adhesive address labels are easiest), rather than silver tape or white insulation tape; we've tried all of these, and paper is best. You can put these in the corners, under the Kapton tape, and they'll rarely get in the way of any print.

Also see the troubleshooting guide, that has a specific section for G32 problems: [reprappro.com]

Ian

RepRapPro tech support

Riz - the RRP v1.09 uses bed.g for homing, see: [reprappro.com]

I'd also advise to use paper (self-adhesive address labels are easiest), rather than silver tape or white insulation tape; we've tried all of these, and paper is best. You can put these in the corners, under the Kapton tape, and they'll rarely get in the way of any print.

Also see the troubleshooting guide, that has a specific section for G32 problems: [reprappro.com]

Ian

RepRapPro tech support

|

Re: Modulated Z probe inconsistent July 26, 2015 04:47PM |

Registered: 10 years ago Posts: 14,672 |

Quote

droftarts

dc42 - does your firmware fork use bed.g for bed levelling, or M557?

It uses bed.g if it exists, and falls back to M557 if it doesn't.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Modulated Z probe inconsistent July 26, 2015 04:51PM |

Registered: 9 years ago Posts: 22 |

|

Re: Modulated Z probe inconsistent July 26, 2015 06:02PM |

Registered: 9 years ago Posts: 1,699 |

Quote

droftarts

You can put these in the corners, under the Kapton tape, and they'll rarely get in the way of any print.

How should this work if he is using BlueTak like me? But for using Kapton tape (on some kind of prints I am afraid that the print gets stucks on BlueTak) I put some white strips under the glass plate directly on the aluminium heat spreader and it works also very well, Maybe it can make trouble if you are using cheap glass but I have three glass plates and it works with all of them with the non-modulated sensor.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Modulated Z probe inconsistent July 26, 2015 08:37PM |

Registered: 8 years ago Posts: 443 |

I was getting some inconsistencies with my RRP Z probe, but found that what was happening was sometimes a print would fail and the debris would get caught between the bed and the Z probe knocking it out of line, so I've printed a protector block that holds the probe head in position better and protects it from getting knocked.

[www.thingiverse.com]

The idea of Putting targets under the glass is questionable the probe accurate sense range is about 2-3 mm and the glass is 3mm thick, paper under Kapton works very well, but its a little tricky to apply, sticky address labels are much easier.

[www.thingiverse.com]

The idea of Putting targets under the glass is questionable the probe accurate sense range is about 2-3 mm and the glass is 3mm thick, paper under Kapton works very well, but its a little tricky to apply, sticky address labels are much easier.

|

Re: Modulated Z probe inconsistent July 27, 2015 01:58AM |

Registered: 9 years ago Posts: 1,699 |

I also tested it with Blue Painters Tape on top of the glass but at my printer I got the best readings to put it under the glass. The result was more stable and repeatable readings. There is a dead zone where the value does not change any more if you are too far to the glass and in my case this one is eliminated so the measured value can be directly converted in a height - in theory. But I had no influence regarding heat or ambient light. Okay I have to say that my printer cannot be hit by direct sun light but I am using a high effective LED light to light the room. It is even slightly a little bit too strong but it has all no influence.

Regarding the BuildTak it is a little bit tricky of course as I use a P-value of only 120 so here I have slightly influence of ambient light or heat or whatever.

My problem with the paper under Kapton tape is simply and easy: You have a difference in height and it costs building volume. You may put it to the outer side but then you risk that the print head hits the clamps and you will never be able to use 5-point-calibration.

But I am knowing it too good that sometimes or even often the z-probe ruins a first or second layer of a printing especially if you are using auto-bed-leveling.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Regarding the BuildTak it is a little bit tricky of course as I use a P-value of only 120 so here I have slightly influence of ambient light or heat or whatever.

My problem with the paper under Kapton tape is simply and easy: You have a difference in height and it costs building volume. You may put it to the outer side but then you risk that the print head hits the clamps and you will never be able to use 5-point-calibration.

But I am knowing it too good that sometimes or even often the z-probe ruins a first or second layer of a printing especially if you are using auto-bed-leveling.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Modulated Z probe inconsistent July 27, 2015 02:44AM |

Registered: 8 years ago Posts: 443 |

Maybe for large builds you can have a second piece of glass.

Keep the glass with targets on for smaller builds, but when you need the extra build volume take the targeted glass out and put your large build volume glass in.

If two pieces of glass is extravagant maybe use both sides of the same piece.

Alternatively try homing with targets on the aluminium and compensate for the glass thickness.

No Aardvarks were harmed in the making of this statement!

Keep the glass with targets on for smaller builds, but when you need the extra build volume take the targeted glass out and put your large build volume glass in.

If two pieces of glass is extravagant maybe use both sides of the same piece.

Alternatively try homing with targets on the aluminium and compensate for the glass thickness.

No Aardvarks were harmed in the making of this statement!

|

Re: Modulated Z probe inconsistent July 27, 2015 06:37AM |

Registered: 9 years ago Posts: 1,699 |

No I have 3pcs for serperate and different usage: one with BuildTak, one with Kapton and one with Blue Painter Tape. But the third one will go to my new Ormerod. BuildTak will be adhered so you cannot switch back that is why I have three different glasses. I do not use them at the same time.

I am homing when all is heated so I cannot remove the glass easily and it may happen that I home more often. But as I told: I have no problems with homing if the paper is under the glass -> for me I even got better results in doing so. And with Blue Tape I only use the Blue Tape as the signal with white paper is too strong (Kapton damps the signal). and it works nearly perfect. Only BuildTak is a little bit tricky and so I will change the sensor by time.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I am homing when all is heated so I cannot remove the glass easily and it may happen that I home more often. But as I told: I have no problems with homing if the paper is under the glass -> for me I even got better results in doing so. And with Blue Tape I only use the Blue Tape as the signal with white paper is too strong (Kapton damps the signal). and it works nearly perfect. Only BuildTak is a little bit tricky and so I will change the sensor by time.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.