Ormerod 2 bed sensor

Posted by Europa

|

Ormerod 2 bed sensor February 04, 2016 05:45PM |

Registered: 9 years ago Posts: 151 |

I seem to be having problems with the sensor used to set the nozzle zero height above the bed.

I recently made a change to the bed configuration in that I have fitted fitted a GeckoTek Build plate instead of the 3mm glass plate. The GeckoTek is a 0.9mm stainless brushed steel plate with lacquer finish. I am still using white labels at the four corners so as far as the sensor is concerned it is the same as before.

The problem is that I have to re-zero the bed almost every print, it is at it's worse with high bed temp when printing ABS. Could it be that the temperature is affecting it or do the sensors need replacing from time to time?

Thank you for any advice you can offer.

Brian

I recently made a change to the bed configuration in that I have fitted fitted a GeckoTek Build plate instead of the 3mm glass plate. The GeckoTek is a 0.9mm stainless brushed steel plate with lacquer finish. I am still using white labels at the four corners so as far as the sensor is concerned it is the same as before.

The problem is that I have to re-zero the bed almost every print, it is at it's worse with high bed temp when printing ABS. Could it be that the temperature is affecting it or do the sensors need replacing from time to time?

Thank you for any advice you can offer.

Brian

|

Re: Ormerod 2 bed sensor February 04, 2016 07:03PM |

Registered: 8 years ago Posts: 164 |

By "re-zero", do you mean rehoming your Z-axis? During the initial calibration of the printer, we're instructed on how to set up the Z-probe using a known height at a known value. If your new build plate is thinner and you have not changed anything, you're going to get a lower Z-value for the same Z-axis height. Maybe you need to re-adjust that? The instructions for doing this are here

Edited 1 time(s). Last edit at 02/04/2016 07:03PM by 0x0000.

Edited 1 time(s). Last edit at 02/04/2016 07:03PM by 0x0000.

|

Re: Ormerod 2 bed sensor February 04, 2016 11:20PM |

Registered: 9 years ago Posts: 1,699 |

With the stock sensor both cases are true. The sensor is a little bit depending from the temperature. If I switch from PLA to ABS I need to use other values for z-homing. Also I watched that from time to time the values changed for what reason ever. Maybe environment light?

The sensor boards from dc42 should show a much better behaviour, but I have not tested it yet. I hope I could do so soon. My Ormerod 2 with an alternative nozzle uses a microswitch now which gives a more precise z-homing and auto-bed leveling. However it may have broken the heater cartridge wiring (I will check this the next days). I hopy my next version reduces the reaction time. As the nozzle touches the bed the bed itself should be able to withstand the temperature. BuildTak for example will be damaged if the nozzle is hot during the touch. You need a hot and clean nozzle to do such a calibration like this and the surface has to be clean. This method may keep some small blobs of filament on the bed at the touching point. I use a PrintBite (modified FR4 surface) so it does not end in a permanent damage.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

The sensor boards from dc42 should show a much better behaviour, but I have not tested it yet. I hope I could do so soon. My Ormerod 2 with an alternative nozzle uses a microswitch now which gives a more precise z-homing and auto-bed leveling. However it may have broken the heater cartridge wiring (I will check this the next days). I hopy my next version reduces the reaction time. As the nozzle touches the bed the bed itself should be able to withstand the temperature. BuildTak for example will be damaged if the nozzle is hot during the touch. You need a hot and clean nozzle to do such a calibration like this and the surface has to be clean. This method may keep some small blobs of filament on the bed at the touching point. I use a PrintBite (modified FR4 surface) so it does not end in a permanent damage.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 2 bed sensor February 05, 2016 02:06AM |

Registered: 9 years ago Posts: 151 |

Yes I do mean homing the z axis and I am quite familiar with how to do it. sometimes I will need to change the values 4 or 5 times during an evening of printing, I naturally write the new values to the config file, it will always need to be done again the next day.

Treito makes an interesting point, calibrate the nozzle height when hot, I will give this a try. ABS does need a different setting as he says.

Has anyone fitted the dc42 sensor board? I was thinking of getting one of them but they look quite complicated to setup and of course are £50!!

Many thanks,

Brian

Treito makes an interesting point, calibrate the nozzle height when hot, I will give this a try. ABS does need a different setting as he says.

Has anyone fitted the dc42 sensor board? I was thinking of getting one of them but they look quite complicated to setup and of course are £50!!

Many thanks,

Brian

|

Re: Ormerod 2 bed sensor February 05, 2016 03:46AM |

Registered: 9 years ago Posts: 1,699 |

The price is the reason why I did not order a board by myself. However I have the parts at home except for the IR-LEDs (slightly different type) and I designed a PCB board which is about 50% bigger than the original board (I cannot make single-layer-boards).

I ran some pre-tests to test the principle of the sensor boards and I was astonished. It seems to work really good, but that was only a testing environment. No connection to the printer or to a bed surface. I only used paper, skin, spool surfaces and so on. Different surfaces and only slightly differences in height. I hope to finish a board soon, but unfortunately I have many other things to do at the moment. For example my Ormerod 2 needs to get complete disassembled and reassembled with parts exchanged.

However if you calculate the time needed for finishing and testing the board as how dc42 offers it you will come to the conclusion that his price is okay. If you can do the mounting of the parts by yourself you can safe some money.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I ran some pre-tests to test the principle of the sensor boards and I was astonished. It seems to work really good, but that was only a testing environment. No connection to the printer or to a bed surface. I only used paper, skin, spool surfaces and so on. Different surfaces and only slightly differences in height. I hope to finish a board soon, but unfortunately I have many other things to do at the moment. For example my Ormerod 2 needs to get complete disassembled and reassembled with parts exchanged.

However if you calculate the time needed for finishing and testing the board as how dc42 offers it you will come to the conclusion that his price is okay. If you can do the mounting of the parts by yourself you can safe some money.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 2 bed sensor February 05, 2016 01:02PM |

Registered: 9 years ago Posts: 638 |

Quote

Europa

Yes I do mean homing the z axis and I am quite familiar with how to do it. sometimes I will need to change the values 4 or 5 times during an evening of printing, I naturally write the new values to the config file, it will always need to be done again the next day.

Treito makes an interesting point, calibrate the nozzle height when hot, I will give this a try. ABS does need a different setting as he says.

Has anyone fitted the dc42 sensor board? I was thinking of getting one of them but they look quite complicated to setup and of course are £50!!

Many thanks,

Brian

I have a dual board and they do seem to be more reliable then the stock sensor ,i still have to test the Z=0 before each print with a peice of paper ,but the auto bed compensation works flowlessly with it ,when it gave me lots of troubles when i was using stock sensor.

|

Re: Ormerod 2 bed sensor February 05, 2016 01:16PM |

Registered: 9 years ago Posts: 151 |

|

Re: Ormerod 2 bed sensor February 05, 2016 01:52PM |

Registered: 9 years ago Posts: 638 |

[forums.reprap.org]

but if you are gona order one ,he will have to get a few orders for the big sensors ,i think he still makes the mini sensor(it is withought fan controll ,just the sensor)

The big one : [miscsolutions.wordpress.com]

Mini: [miscsolutions.wordpress.com]

Edited 1 time(s). Last edit at 02/05/2016 01:53PM by Darathy.

but if you are gona order one ,he will have to get a few orders for the big sensors ,i think he still makes the mini sensor(it is withought fan controll ,just the sensor)

The big one : [miscsolutions.wordpress.com]

Mini: [miscsolutions.wordpress.com]

Edited 1 time(s). Last edit at 02/05/2016 01:53PM by Darathy.

|

Re: Ormerod 2 bed sensor February 05, 2016 04:48PM |

Registered: 10 years ago Posts: 14,672 |

Yes I make the Ormerod-specific boards when I have enough orders to justify the time it takes to make a batch. I carry the mini board in stock because it is much more popular and is included by T3P3 and E3D in their 3D printer kits.

To use the mini board on an Ormerod 2, somebody would need to design a printed or easily-fabricated mount to fit it on the Ormerod hot end. I don't have an Ormerod 2 so I can't do this.

You can order the mini board from my site escher3d.com.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

To use the mini board on an Ormerod 2, somebody would need to design a printed or easily-fabricated mount to fit it on the Ormerod hot end. I don't have an Ormerod 2 so I can't do this.

You can order the mini board from my site escher3d.com.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ormerod 2 bed sensor February 06, 2016 03:58AM |

Registered: 9 years ago Posts: 151 |

|

Re: Ormerod 2 bed sensor February 06, 2016 09:02AM |

Registered: 10 years ago Posts: 14,672 |

How bright is the coated steel? Shiny aluminium doesn't work well, but stainless steel may be ok especially if the coating makes it less shiny.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ormerod 2 bed sensor February 06, 2016 12:56PM |

Registered: 9 years ago Posts: 151 |

|

Re: Ormerod 2 bed sensor February 06, 2016 04:26PM |

Registered: 10 years ago Posts: 14,672 |

A dull sheen will probably be OK, especially if you wait for my new batch of mini IR sensors due in less than 2 weeks, which have slightly reduced sensitivity.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ormerod 2 bed sensor February 06, 2016 05:31PM |

Registered: 9 years ago Posts: 189 |

Quote

dc42

Yes I make the Ormerod-specific boards when I have enough orders to justify the time it takes to make a batch. I carry the mini board in stock because it is much more popular and is included by T3P3 and E3D in their 3D printer kits.

To use the mini board on an Ormerod 2, somebody would need to design a printed or easily-fabricated mount to fit it on the Ormerod hot end. I don't have an Ormerod 2 so I can't do this.

You can order the mini board from my site escher3d.com.

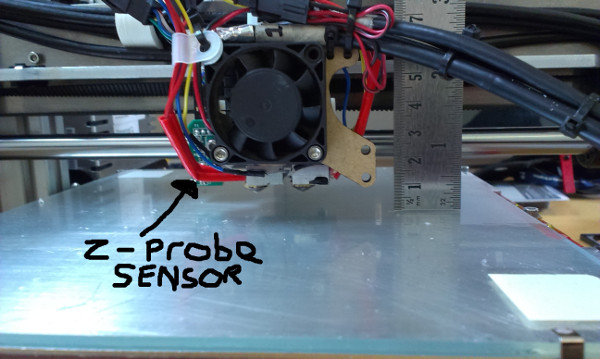

Here is photo of the location of the z-probe upon a ormerod 2

After looking at your website, the PCB is mounted using the fan spacer/duct file, whereas on the Ormerod 2 it mounts into the x-carriage to the left of the hot-end assembly.

This probe also functions as the x-carriage end stop. Does your sensor perform this function?

The white sticky labels, seen at the corners improve the readings from the stock sensor.

Supporting 3D Printers with Parts and Build services.

Printer: Ormerod 2 (528.4) Duel extruder set-up with Aluminium X-Rib, RRPro Firmware v1.11-ch (2016-04-08)

|

Re: Ormerod 2 bed sensor February 06, 2016 05:35PM |

Registered: 9 years ago Posts: 151 |

|

Re: Ormerod 2 bed sensor February 06, 2016 10:37PM |

Registered: 9 years ago Posts: 1,699 |

Quote

orictosh

Here is photo of the location of the z-probe upon a ormerod 2

[attachment 71965 Om2_probe_location.jpg]

After looking at your website, the PCB is mounted using the fan spacer/duct file, whereas on the Ormerod 2 it mounts into the x-carriage to the left of the hot-end assembly.

This probe also functions as the x-carriage end stop. Does your sensor perform this function?

The white sticky labels, seen at the corners improve the readings from the stock sensor.

I would attach the mini-board to the side of the nozzle. But like dc42 said you will need some sort of mounting device.

@Brian The sensor boards from dc42 are indeed IR-based but the measuring is done using a complete different and genius measuring principle to compensate most of the unwanted environment conditions like ambient light and even different bed surfaces. One method you may compare with the IR-remote of your TV. It is also IR-based and hopefully works like a charme. The TV knows which button you pressed. To give a much easier explanation this method was transferred to the sensor board for example.

My own printer design will count on the sensor board or maybe on a modified version.

@dc42 I would take three Mini-boards but only if there is a very very good price for that amount.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 2 bed sensor February 07, 2016 02:22AM |

Registered: 10 years ago Posts: 14,672 |

The Ormerod hot end is designed to pivot about the X axis. It relies on the X arm being and remaining flat and straight so that the head remains vertical when the X runner bearing is correctly adjusted. With the acrylic X arm, I found that it was impossible to avoid a slight twist because of the force exerted by the weight of the head. So the head rolls a little as it moves along the X axis.

The original proximity sensor position on the X carriage has the sensor offset from the nozzle in the Y direction. This means that as the head rolls, the relative heights of the sensor and the nozzle change.

I designed my hot end board to place the sensor in line with the nozzle in the X direction, so that rotation of the head about the X axis does not affect the relative heights. If you want to use my mini IR board on an Ormerod, I suggest you do likewise.

To use my Ormerod board for X homing, you need to print a small homing pad to attach to the X motor mount. This is covered in the fitting instructions for the Ormerod board.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The original proximity sensor position on the X carriage has the sensor offset from the nozzle in the Y direction. This means that as the head rolls, the relative heights of the sensor and the nozzle change.

I designed my hot end board to place the sensor in line with the nozzle in the X direction, so that rotation of the head about the X axis does not affect the relative heights. If you want to use my mini IR board on an Ormerod, I suggest you do likewise.

To use my Ormerod board for X homing, you need to print a small homing pad to attach to the X motor mount. This is covered in the fitting instructions for the Ormerod board.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ormerod 2 bed sensor February 07, 2016 05:28AM |

Registered: 9 years ago Posts: 1,699 |

Quote

dc42

To use my Ormerod board for X homing, you need to print a small homing pad to attach to the X motor mount. This is covered in the fitting instructions for the Ormerod board.

Funnily I need this part also for the stock sensor. It seems that there is a small designing issue as the sensor board is a little bit displaced according the y-axis and so it misses the original sensor field by 2mm. It is triggered by the small diagonal area next to the original sensor area which means that the given value is only very small and the sensor is not fully triggered.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 2 bed sensor February 07, 2016 07:14AM |

Registered: 9 years ago Posts: 189 |

Quote

Treito

Quote

dc42

To use my Ormerod board for X homing, you need to print a small homing pad to attach to the X motor mount. This is covered in the fitting instructions for the Ormerod board.

Funnily I need this part also for the stock sensor. It seems that there is a small designing issue as the sensor board is a little bit displaced according the y-axis and so it misses the original sensor field by 2mm. It is triggered by the small diagonal area next to the original sensor area which means that the given value is only very small and the sensor is not fully triggered.

Upon the x-motor mount printed part, the little black sensor on the stock sensor meets up with a lug, just below it. The sensor didn't get enough IR Light reflected back from that lug, so I need to place a white label upon it. The stock sensor's good spot is a value of 600 +- 20. It has a low value (~10) when far from the bed and higher value when near a white surface.

Supporting 3D Printers with Parts and Build services.

Printer: Ormerod 2 (528.4) Duel extruder set-up with Aluminium X-Rib, RRPro Firmware v1.11-ch (2016-04-08)

|

Re: Ormerod 2 bed sensor February 07, 2016 07:36AM |

Registered: 9 years ago Posts: 189 |

Quote

dc42

The Ormerod hot end is designed to pivot about the X axis. It relies on the X arm being and remaining flat and straight so that the head remains vertical when the X runner bearing is correctly adjusted. With the acrylic X arm, I found that it was impossible to avoid a slight twist because of the force exerted by the weight of the head. So the head rolls a little as it moves along the X axis.

I lost a lot of time and had failed prints due to this x-axis roll becoming excessive. This was my reason for upgrading to Dave0974 Aluminium X-rib as I also needed the extra support for duel extruder's, also found that using the x-carriage with the bearing running along the back edge worked better than being underneath.

Saw reports upon here about a grove being put in the arm from the bearing. Looking at the printed part there is a slight ramp away from the x-rib which would place the edge of the bearing upon the surface; which might cut into the aluminium. So I filed the ramp it flat and placed some washers under the bearing so that the face is in contact with the rib.

I then placed a spirit level upon the fan housing and make sure that it's 90 degrees to the bed as it moves up and down the x-axis.

It would be nice to have some fine adjustment, maybe in the form of a bolt pushing the bearing towards the rib but it's seems fine as long as the slot is clear and you can tighten the bolt holding the bearing well enough; Just thought maybe place a shake-proof washer between the printed part and the washer/bearing so it can bite into the printed part and stay put.

Edited 1 time(s). Last edit at 02/07/2016 07:36AM by orictosh.

Supporting 3D Printers with Parts and Build services.

Printer: Ormerod 2 (528.4) Duel extruder set-up with Aluminium X-Rib, RRPro Firmware v1.11-ch (2016-04-08)

|

Re: Ormerod 2 bed sensor February 07, 2016 09:59AM |

Registered: 9 years ago Posts: 151 |

Am I correct in thinking that i will need to make a new nozzle mount that has the mini sensor on the left hand side so that it can still be used to home the X axis. I assume the X axis printed bit that the old sensor moves across will need to be extended as well as the mini sensor is a wider board with the critical part in the middle.

I am just about to fit my Chinese E3D V6 type hot end which I have printed a mount for but will now need to modify that if I am going with Davids mini sensor.

Many thanks,

Brian

I am just about to fit my Chinese E3D V6 type hot end which I have printed a mount for but will now need to modify that if I am going with Davids mini sensor.

Many thanks,

Brian

|

Re: Ormerod 2 bed sensor February 07, 2016 10:20AM |

Registered: 9 years ago Posts: 638 |

|

Re: Ormerod 2 bed sensor February 07, 2016 10:21AM |

Registered: 9 years ago Posts: 1,699 |

I just placed my order for at least 3 sensor boards. Two for my existing ones and one for the coming one. I hope that wasn't a bad idea.

As the person with the probably biggest damage of the X-arm.

If you use the original X-carriage and the slot is printed well so you can freely move the bolt with the bearing you should be able to align the nozzle. First of all it is very important that the nozzle is perferctly angled. Then you have to watch for the bearing and that was my big fault. I did not take enough care. The bearing surface should be in full touch with the X-arm (I ignored it as it seemed to work). Aluminium is weaker than the stainless steel of the bearing so the bearing can make its way into the aluminium.

If the bearing cannot get in foul touch even though the slot is free accessible you have to options: You can exchange the bearing with a bigger one with an outer diameter of 10mm instead of 9mm. However this did not work for me as the nozzle was not angled anymore. Option two: You can add a sort of shim made of stainless steel. In my case I took a metal ruler. The width should not exceed 13mm. For my second Ormerod which will be soon changed Dave was that nice to add some sort of a shim band. I will test and comprae it with my metal ruler. For the damaged X-arm this was the only option as I needed a stable part to cover the groove. The band would not be stable enough for that case.

However meanwhile I have printed some more parts or some more meters of material. I mainly print at the center of the bed. Eventhough the bearing is perfectly in touch with the metal ruler you can see traces of the movement especially at the center. But it looks more like if somebody had washed or cleaned this are. There is no trace of a groove. But it keeps me alarmed. I will never try to run a stainless steel bearing directly on an aluminium X-arm.

Unfortunately my Ormerod 2 died mechanically and electrically before I could finished printing all parts I would like to exchange at the commisioning. It is not needed to replace much parts but I will have to disassemble the printer completly so I would like to exchange the optional parts, too.

My Ormerod 1 is not easy to handle without the sensor boards of dc42. That printer was a hardly task, but it may be nearly finished. Maybe not.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

As the person with the probably biggest damage of the X-arm.

If you use the original X-carriage and the slot is printed well so you can freely move the bolt with the bearing you should be able to align the nozzle. First of all it is very important that the nozzle is perferctly angled. Then you have to watch for the bearing and that was my big fault. I did not take enough care. The bearing surface should be in full touch with the X-arm (I ignored it as it seemed to work). Aluminium is weaker than the stainless steel of the bearing so the bearing can make its way into the aluminium.

If the bearing cannot get in foul touch even though the slot is free accessible you have to options: You can exchange the bearing with a bigger one with an outer diameter of 10mm instead of 9mm. However this did not work for me as the nozzle was not angled anymore. Option two: You can add a sort of shim made of stainless steel. In my case I took a metal ruler. The width should not exceed 13mm. For my second Ormerod which will be soon changed Dave was that nice to add some sort of a shim band. I will test and comprae it with my metal ruler. For the damaged X-arm this was the only option as I needed a stable part to cover the groove. The band would not be stable enough for that case.

However meanwhile I have printed some more parts or some more meters of material. I mainly print at the center of the bed. Eventhough the bearing is perfectly in touch with the metal ruler you can see traces of the movement especially at the center. But it looks more like if somebody had washed or cleaned this are. There is no trace of a groove. But it keeps me alarmed. I will never try to run a stainless steel bearing directly on an aluminium X-arm.

Unfortunately my Ormerod 2 died mechanically and electrically before I could finished printing all parts I would like to exchange at the commisioning. It is not needed to replace much parts but I will have to disassemble the printer completly so I would like to exchange the optional parts, too.

My Ormerod 1 is not easy to handle without the sensor boards of dc42. That printer was a hardly task, but it may be nearly finished. Maybe not.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 2 bed sensor February 07, 2016 10:22AM |

Registered: 9 years ago Posts: 1,699 |

Quote

Europa

Am I correct in thinking that i will need to make a new nozzle mount that has the mini sensor on the left hand side so that it can still be used to home the X axis. I assume the X axis printed bit that the old sensor moves across will need to be extended as well as the mini sensor is a wider board with the critical part in the middle.

I am just about to fit my Chinese E3D V6 type hot end which I have printed a mount for but will now need to modify that if I am going with Davids mini sensor.

Which design do you use?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 2 bed sensor February 07, 2016 01:31PM |

Registered: 9 years ago Posts: 151 |

Hi Treito, your design. it is a perfect fit for my E3D type hotend. It does have mounting holes for dc42's sensor board but not the mini unfortunately,

I don't suppose you happened to make it with 123D Design, in which case I would love to have the source file so that I could modify it. Alternatively do you have a STEP file of the mount.

Brian

I don't suppose you happened to make it with 123D Design, in which case I would love to have the source file so that I could modify it. Alternatively do you have a STEP file of the mount.

Brian

|

Re: Ormerod 2 bed sensor February 07, 2016 04:07PM |

Registered: 9 years ago Posts: 1,699 |

Do you know why I have asked? I just ordered the sensor board by myself. So I will provide a mounting option as soon as I have the sensor board.

Maybe there is a 3D-Step-file available of the Mini-sensor board? In that case I could do such an adapter within a week. it shouldn't be a big deal that is why I added the mounting holes at one side.

I used FreeCAD to design this part, I could offer s atep-file but I have no given dimensions of the sensor-board.

I prefer FreeCAD as it is free and for many platforms available, but unfortunately the assembly2 workbench does not fulfill my needs so I design my own printer with Fusion 360. It is like 123 but it offers more functions like a very good assembly-tool.

So what file format do you need?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Maybe there is a 3D-Step-file available of the Mini-sensor board? In that case I could do such an adapter within a week. it shouldn't be a big deal that is why I added the mounting holes at one side.

I used FreeCAD to design this part, I could offer s atep-file but I have no given dimensions of the sensor-board.

I prefer FreeCAD as it is free and for many platforms available, but unfortunately the assembly2 workbench does not fulfill my needs so I design my own printer with Fusion 360. It is like 123 but it offers more functions like a very good assembly-tool.

So what file format do you need?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 2 bed sensor February 07, 2016 05:29PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Europa

Am I correct in thinking that i will need to make a new nozzle mount that has the mini sensor on the left hand side so that it can still be used to home the X axis. I assume the X axis printed bit that the old sensor moves across will need to be extended as well as the mini sensor is a wider board with the critical part in the middle.

I am just about to fit my Chinese E3D V6 type hot end which I have printed a mount for but will now need to modify that if I am going with Davids mini sensor.

Many thanks,

Brian

Brian, check out the fitting instructions for the Ormerod hot end board at miscsolutions.wordpress.com. It includes a link to the printable sensor pad for X homing. You should be able to use that or a similar design for the mini board, if you mount the mini board in the same place relative to the nozzle as the Ormerod board would be.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ormerod 2 bed sensor February 07, 2016 06:16PM |

Registered: 9 years ago Posts: 151 |

|

Re: Ormerod 2 bed sensor February 07, 2016 06:18PM |

Registered: 9 years ago Posts: 151 |

|

Re: Ormerod 2 bed sensor February 07, 2016 06:18PM |

Registered: 9 years ago Posts: 1,699 |

As long as the position of the Mini_IR_board is correct it will work.

Brian, you can be sure after equipping my printers with that board I will make it work Unfortunately I have no detailed dimensions for the board to do a suitable mounting bracket.

Unfortunately I have no detailed dimensions for the board to do a suitable mounting bracket.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Brian, you can be sure after equipping my printers with that board I will make it work

Unfortunately I have no detailed dimensions for the board to do a suitable mounting bracket.

Unfortunately I have no detailed dimensions for the board to do a suitable mounting bracket.Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.