New Ormerod, some issues

Posted by ein

|

New Ormerod, some issues March 12, 2018 09:35PM |

Registered: 6 years ago Posts: 17 |

Greetings, I recently acquired an Ormerod 1 that had never been turned on, let alone used for printing. David has kindly helped me work though the myriad of issues I've had with the firmware and now I'm trying to nail down some other bugs.

First, it seems to home the X axis wherever it happens to be, so that seems to be an issue. If I either send the command or use the web interface the extruder head will move slightly to the right and be at 'home'. Per David's suggestion, I'll be checking the proximity sensor out when I get back to it. If anyone has any other ideas, the info would be great.

Second, I've seen is that the bed temperature sensor seems to lose connection. It goes from room temp to 2000 degrees. I touched the sensor wiring a couple of times and it will go in and out, so I'm guessing the connection to the bed is at fault. I'm going to disassemble the bed to investigate.

Lastly and what I think is the most significant issue, when the Z axis moves, the gear that is connected to the threaded rod is very, very wobbly. I've even seen it bind a time or two when I'm running it up and down at a higher feed rate. I've asked a friend to reprint the gears, but it looks like the opening on the bottom is too large for the bearing. Is it possible the previous owner put the wrong size bearing there? I found this modified Z axis gears that I thought I'd give a try. Annoyingly that requires having access to a printer... so I might have to phone a friend on that one.

Thanks in advance.

First, it seems to home the X axis wherever it happens to be, so that seems to be an issue. If I either send the command or use the web interface the extruder head will move slightly to the right and be at 'home'. Per David's suggestion, I'll be checking the proximity sensor out when I get back to it. If anyone has any other ideas, the info would be great.

Second, I've seen is that the bed temperature sensor seems to lose connection. It goes from room temp to 2000 degrees. I touched the sensor wiring a couple of times and it will go in and out, so I'm guessing the connection to the bed is at fault. I'm going to disassemble the bed to investigate.

Lastly and what I think is the most significant issue, when the Z axis moves, the gear that is connected to the threaded rod is very, very wobbly. I've even seen it bind a time or two when I'm running it up and down at a higher feed rate. I've asked a friend to reprint the gears, but it looks like the opening on the bottom is too large for the bearing. Is it possible the previous owner put the wrong size bearing there? I found this modified Z axis gears that I thought I'd give a try. Annoyingly that requires having access to a printer... so I might have to phone a friend on that one.

Thanks in advance.

|

Re: New Ormerod, some issues March 14, 2018 10:18AM |

Registered: 8 years ago Posts: 123 |

Sounds right, I'd buzz the wires with a multimeter to ensure they are all connected properly.Quote

First, it seems to home the X axis wherever it happens to be, so that seems to be an issue. If I either send the command or use the web interface the extruder head will move slightly to the right and be at 'home'. Per David's suggestion, I'll be checking the proximity sensor out when I get back to it. If anyone has any other ideas, the info would be great.

Yep, remove, test and reconnect wires securely.Quote

Second, I've seen is that the bed temperature sensor seems to lose connection. It goes from room temp to 2000 degrees. I touched the sensor wiring a couple of times and it will go in and out, so I'm guessing the connection to the bed is at fault. I'm going to disassemble the bed to investigate.

Quote

Lastly and what I think is the most significant issue, when the Z axis moves, the gear that is connected to the threaded rod is very, very wobbly. I've even seen it bind a time or two when I'm running it up and down at a higher feed rate. I've asked a friend to reprint the gears, but it looks like the opening on the bottom is too large for the bearing. Is it possible the previous owner put the wrong size bearing there? I found this modified Z axis gears that I thought I'd give a try. Annoyingly that requires having access to a printer... so I might have to phone a friend on that one.

Can you measure the bearing with some calipers? [reprappro.com] indicates that it is a "623 bearing (10mm diameter)"

|

Re: New Ormerod, some issues March 22, 2018 02:42PM |

Registered: 6 years ago Posts: 17 |

I've managed to get a couple of prints, but they are not of very good quality.

Ongoing, causing issues:

1. Z axis driven gear wobbles - The bearing is, indeed, a 10mm outer diameter. I had a friend print a couple of iterations of the herringbone gears, but they are super tight and will lock up a lot. My current setup to compensate for the wobbling is to put some thick packing tape under the driven gear, on the bearing, and it helps a lot. However, once I got to the top 20% of a benchy right below the roof to the cabin, the gears were grinding again so I stopped.

Ongoing, but managable:

1. X axis homeing - The wires going to the proximity sensor are good. I've not noticed any breaks in the sensor readings on the web interface. So far to home X, by hand I move the print head to the X0 position before I start and home X from there. It seems to be ok.

Fixed:

1. Bed temp sensor - I've fixed the bed temp wiring. One of the female pins in the connector had backed out, so I've reattached it with no issues since.

Ongoing, causing issues:

1. Z axis driven gear wobbles - The bearing is, indeed, a 10mm outer diameter. I had a friend print a couple of iterations of the herringbone gears, but they are super tight and will lock up a lot. My current setup to compensate for the wobbling is to put some thick packing tape under the driven gear, on the bearing, and it helps a lot. However, once I got to the top 20% of a benchy right below the roof to the cabin, the gears were grinding again so I stopped.

Ongoing, but managable:

1. X axis homeing - The wires going to the proximity sensor are good. I've not noticed any breaks in the sensor readings on the web interface. So far to home X, by hand I move the print head to the X0 position before I start and home X from there. It seems to be ok.

Fixed:

1. Bed temp sensor - I've fixed the bed temp wiring. One of the female pins in the connector had backed out, so I've reattached it with no issues since.

|

Re: New Ormerod, some issues March 22, 2018 07:45PM |

Registered: 10 years ago Posts: 14,672 |

To fix your X axis homing issue, if it's not stopping during homing try gluing a piece of white card on top of the X homing tab.

Edited 1 time(s). Last edit at 03/22/2018 07:46PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 03/22/2018 07:46PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New Ormerod, some issues March 23, 2018 05:23PM |

Registered: 6 years ago Posts: 17 |

David, I fixed the homing issue yesterday afternoon. I had forgotten about your post suggesting to add another M574 code for the X axis.

I've made a few test prints (bottom 10-12 layers of Benchy and a simple ring) and it seems I'm getting over extrusion at the beginning/end of a layer. So at the one vertical plane in the print, I am getting globbing. I adjusted the global extrusion rate down about 2% and it didn't seem to help. Any thoughts on this one?

I can post a pic if anyone would like.

I've made a few test prints (bottom 10-12 layers of Benchy and a simple ring) and it seems I'm getting over extrusion at the beginning/end of a layer. So at the one vertical plane in the print, I am getting globbing. I adjusted the global extrusion rate down about 2% and it didn't seem to help. Any thoughts on this one?

I can post a pic if anyone would like.

|

Re: New Ormerod, some issues March 24, 2018 03:11AM |

Registered: 10 years ago Posts: 14,672 |

Make sure you have retract on layer change enabled in your slicer. Try enabling pressure advance; see M572 in the GCode wiki page.

Edited 2 time(s). Last edit at 03/24/2018 03:13AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 2 time(s). Last edit at 03/24/2018 03:13AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New Ormerod, some issues March 31, 2018 12:29AM |

Registered: 6 years ago Posts: 17 |

I tried both of those settings with little to no effect on the print. I only set the pressure advance to .1 and then .2.

I did get a lot better results when using the Cura slicer. I'm going to keep using that for now. I printed another ring as a test yesterday and it turned out pretty clean. A few little blobs here and there, but I didn't really take any time to migrate any of the more detailed settings from Slic3r yet.

I noted that the movements from the Slic3r code to the Cura code are radically different. The Slic3r movements are very regular, making each later almost exactly the same, starting and stopping at the same spot. I think maybe what was causing the really huge globs was that it made the same movement between the inner and outer walls at the origin of the layer.

Thanks again for all the help.

I did get a lot better results when using the Cura slicer. I'm going to keep using that for now. I printed another ring as a test yesterday and it turned out pretty clean. A few little blobs here and there, but I didn't really take any time to migrate any of the more detailed settings from Slic3r yet.

I noted that the movements from the Slic3r code to the Cura code are radically different. The Slic3r movements are very regular, making each later almost exactly the same, starting and stopping at the same spot. I think maybe what was causing the really huge globs was that it made the same movement between the inner and outer walls at the origin of the layer.

Thanks again for all the help.

|

Re: New Ormerod, some issues March 31, 2018 06:31AM |

Registered: 10 years ago Posts: 1,230 |

Quote

ein

..I noted that the movements from the Slic3r code to the Cura code are radically different. The Slic3r movements are very regular, making each later almost exactly the same, starting and stopping at the same spot....

So your setting in Slic3r is "Alligned", change it to "Random"

Slic3r\Print Setting\Layers and perimeters\Seam position (Alligned - Random - Nearest)

Erik

|

Re: New Ormerod, some issues March 31, 2018 10:08PM |

Registered: 6 years ago Posts: 17 |

I didn't try that setting, but I suspect I should have. There has to be some difference in addition to that though.

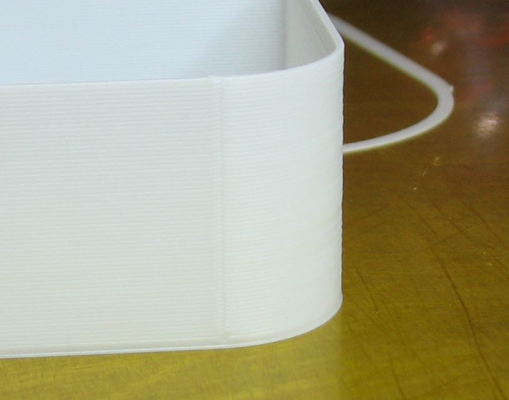

This a couple of the results from the Slic3r code.

Do you think that changing that single setting (after me trying a lot of other things including temp, extrusion multiplier, etc that would indicate that I'm getting too much filament) would do the trick?

This a couple of the results from the Slic3r code.

Do you think that changing that single setting (after me trying a lot of other things including temp, extrusion multiplier, etc that would indicate that I'm getting too much filament) would do the trick?

|

Re: New Ormerod, some issues April 01, 2018 01:21PM |

Registered: 10 years ago Posts: 1,230 |

Quote

ein

Do you think that changing that single setting (after me trying a lot of other things including temp, extrusion multiplier, etc that would indicate that I'm getting too much filament) would do the trick?

The faults would be randomized instead of added on top but still be there

I think you should start from scratch with a clean install of your slicer and the default settings, then slice and print a small single wall model e.g. this from thingiverse:

Single Wall Alignment Test

[www.thingiverse.com]

Stop the print or cut the top of the model, 20mm is more than enough to check the print quality

Start by measuring the single wall width, should be same as your extrusion width setting, if not adjust your extrusion multiplier setting

Print slow, keep your eye on where the excessive extrusion happens, either at layer stop or new layer start, then adjust your slicer accordingly and make another test

Erik

|

Re: New Ormerod, some issues April 02, 2018 09:42PM |

Registered: 6 years ago Posts: 17 |

Quote

ormerod168

I think you should start from scratch with a clean install of your slicer and the default settings, then slice and print a small single wall model e.g. this from thingiverse:

Single Wall Alignment Test

[www.thingiverse.com]

Stop the print or cut the top of the model, 20mm is more than enough to check the print quality

Start by measuring the single wall width, should be same as your extrusion width setting, if not adjust your extrusion multiplier setting

Print slow, keep your eye on where the excessive extrusion happens, either at layer stop or new layer start, then adjust your slicer accordingly and make another test

Erik

Great ideas. I'll try that as soon as I can. Thanks!

|

Re: New Ormerod, some issues April 05, 2018 07:47AM |

Registered: 9 years ago Posts: 31 |

If you are using Cura - beware that is uses Absolute extrusion, and without the right M instruction, the Duet controller defaults to Relative extrusion. I wasn't aware of this until I had a few odd issues:

* Lots of blobbing

* What appeared to be consistent over extrusion.

* Horrid grinding noises from the extruder as pressure built up.

Reprappro Ormerod2 (528.2, Duet 0.6, firmware 1.18.1 (2017-04-09), web interface Christian Hammacher 1.15a, Cura) & CNC 3020 (GRBL)

* Lots of blobbing

* What appeared to be consistent over extrusion.

* Horrid grinding noises from the extruder as pressure built up.

Reprappro Ormerod2 (528.2, Duet 0.6, firmware 1.18.1 (2017-04-09), web interface Christian Hammacher 1.15a, Cura) & CNC 3020 (GRBL)

|

Re: New Ormerod, some issues April 05, 2018 08:10AM |

Registered: 10 years ago Posts: 14,672 |

The latest version of Cura defaults to relative extrusion if you set the GCode type to reprapfirmware - except that at the beginning of the start and end scripts it still defaults to absolute. It also has a plugin to upload the output directly to a Duet.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New Ormerod, some issues April 05, 2018 08:34AM |

Registered: 9 years ago Posts: 31 |

|

Re: New Ormerod, some issues April 09, 2018 10:04AM |

Registered: 6 years ago Posts: 17 |

Quote

ormerod168

Quote

ein

Do you think that changing that single setting (after me trying a lot of other things including temp, extrusion multiplier, etc that would indicate that I'm getting too much filament) would do the trick?

The faults would be randomized instead of added on top but still be there

I think you should start from scratch with a clean install of your slicer and the default settings, then slice and print a small single wall model e.g. this from thingiverse:

Single Wall Alignment Test

[www.thingiverse.com]

Stop the print or cut the top of the model, 20mm is more than enough to check the print quality

Start by measuring the single wall width, should be same as your extrusion width setting, if not adjust your extrusion multiplier setting

Print slow, keep your eye on where the excessive extrusion happens, either at layer stop or new layer start, then adjust your slicer accordingly and make another test

Erik

Finally had some time to give it another go. Went back to slic3r with the original settings from reprappro's github.

Here are the results: [imgur.com]

I am still getting a small amount of extra material at the start of the layer. I stopped the print in the middle of one of the layers. In the top pic, you can see that the blob is there on the top layer.

After about halfway, I started messing with the extrusion rate and dropped it 10% every few layers. The top 10-ish layers are done at 70% extrusion rate.

Walls are 0.6mm at the bottom and 0.5 mm at the top of the print.

What setting would help with the blob at the start of the layer?

|

Re: New Ormerod, some issues April 10, 2018 01:40PM |

Registered: 10 years ago Posts: 1,230 |

Quote

ein

What setting would help with the blob at the start of the layer?

That would be a negative value of "extra length on restart" under "printer settings\extruder1"

But first get your extrusion spot on

slice and print the thin_wall_test.stl, don't mess with the extrusion rate while printing

measure the walls with a micrometer and compare with the sliced perimeter width, if you open the sliced file in a viewer or editor you will find the numbers in the beginning of the file e.g.

; external perimeters extrusion width = 0.60mm

adjust your extrusion multiplier according to the difference between sliced and measured wall thickness

e.g. if your sliced perimeter setting was 0.60mm

and walls was measured 0.65mm

then your printer is over extruding and the extrusion should be reduced by a factor of 0.60/0.65 to 0.923

put that number in "Filament Settings\Filament\Extrusion Multiplier"

this was printed with perimeter width 0.6 and measured out spot on with extrusion multiplier 0.98

Erik

|

Re: New Ormerod, some issues April 12, 2018 03:08PM |

Registered: 6 years ago Posts: 17 |

I've printed the thin wall test several times, sliced by Slic3r with the config from the reprap github. Turns out I am getting extra filament at the beginning AND the end of the layer. Funny, right?? No.

I've managed to reduce the amount of filament at beginning by putting -0.5mm extra filament at restart.

I've reduced the amount of filament at the end of the layer by upping the retraction speed to 100mm/s.

The odd thing is that I can't get it any better. Now I did try to adjust the pressure advance using the M572 command. Now I did this on the fly and then printed another test. According to the RepRapWiki, a value of 0.1 to 0.2 should be good for a bowden setup. I noticed no changes until at least 0.5. Even then there was still extra oozing/blob at the end of the layer. I set the pressure advance to 0.8 . (M572 D0 S0.8) and I got a very slow print, but I managed to get the end of layer blob down, but not eliminated. At this point the beginning of layer extrusion was too much so I set it back to 0.0.

I can't imagine that this is the correct way of doing it. The print is agonizingly slow for the thin wall test piece. I did try to print another of the rings which I had been trying to make and it looked worse than when I started this exercise.

I've managed to reduce the amount of filament at beginning by putting -0.5mm extra filament at restart.

I've reduced the amount of filament at the end of the layer by upping the retraction speed to 100mm/s.

The odd thing is that I can't get it any better. Now I did try to adjust the pressure advance using the M572 command. Now I did this on the fly and then printed another test. According to the RepRapWiki, a value of 0.1 to 0.2 should be good for a bowden setup. I noticed no changes until at least 0.5. Even then there was still extra oozing/blob at the end of the layer. I set the pressure advance to 0.8 . (M572 D0 S0.8) and I got a very slow print, but I managed to get the end of layer blob down, but not eliminated. At this point the beginning of layer extrusion was too much so I set it back to 0.0.

I can't imagine that this is the correct way of doing it. The print is agonizingly slow for the thin wall test piece. I did try to print another of the rings which I had been trying to make and it looked worse than when I started this exercise.

|

Re: New Ormerod, some issues April 13, 2018 11:56AM |

Registered: 10 years ago Posts: 1,230 |

Quote

ein

I've reduced the amount of filament at the end of the layer by upping the retraction speed to 100mm/s.

30mm/s should be the ideal setting for PLA, so I'm told, but I find 60 to print better on my printer

..but the speed and distance of retraction also depends of you stepper current, acceleration and jerk setting

your could try to ad my settings to your config and then print the attached gcode

Please note:

No homing in the file, remember to home your printer before start

Sliced with 200C nozzle temp. and 100% cooling so you may want to lower the temperature a bit

M906 X1000 Y1200 Z800 E1200 ; Set motor currents (mA)

M201 X1200 Y1200 Z20 E3600 ; set accelerations (mm/s^2)

M566 X1800 Y1800 Z30 E600 ; maximum jerk speed mm/minute

Erik

|

Re: New Ormerod, some issues April 27, 2018 02:50PM |

Registered: 6 years ago Posts: 17 |

|

Re: New Ormerod, some issues April 27, 2018 03:38PM |

Registered: 6 years ago Posts: 17 |

Erik,

It gave me very similar results on the walls as when I used the greatly increased retraction speed and a negative extra filament on restart.

However the bottom layer was amazingly better.

I tried a benchy, but it didn't go well. I'll need to do some additional tuning. Thanks!

Edited 1 time(s). Last edit at 04/27/2018 03:40PM by ein.

It gave me very similar results on the walls as when I used the greatly increased retraction speed and a negative extra filament on restart.

However the bottom layer was amazingly better.

I tried a benchy, but it didn't go well. I'll need to do some additional tuning. Thanks!

Edited 1 time(s). Last edit at 04/27/2018 03:40PM by ein.

|

Re: New Ormerod, some issues December 05, 2018 05:59AM |

Registered: 6 years ago Posts: 174 |

Quote

ein

Erik,

It gave me very similar results on the walls as when I used the greatly increased retraction speed and a negative extra filament on restart.

However the bottom layer was amazingly better.

I tried a benchy, but it didn't go well. I'll need to do some additional tuning. Thanks!

Did you manage to resolve your problem?

Sorry, only registered users may post in this forum.