Ormerod from RS

Posted by ROBBED666

|

Ormerod from RS December 03, 2013 04:16PM |

Registered: 10 years ago Posts: 2 |

Hi All

This is my first post on the forum, so ......Hello :-)

I've just purchased an Ormerod from RS components. Number 003 of 500 no less!

As no assembly instructions were supplied, I assume the only place to get the instructions is on Reprappro web site. I did find instructions there, but obviously the proof reader had taken a day off, as there are numerous omissions and design changes since these instruction were posted.

So is there another website for assembly instructions for the current/RS model of Ormerod printer or is it a case of just emailing support at Reprappro?

Thanks

Rob

This is my first post on the forum, so ......Hello :-)

I've just purchased an Ormerod from RS components. Number 003 of 500 no less!

As no assembly instructions were supplied, I assume the only place to get the instructions is on Reprappro web site. I did find instructions there, but obviously the proof reader had taken a day off, as there are numerous omissions and design changes since these instruction were posted.

So is there another website for assembly instructions for the current/RS model of Ormerod printer or is it a case of just emailing support at Reprappro?

Thanks

Rob

|

Re: Ormerod from RS December 03, 2013 06:41PM |

Registered: 10 years ago Posts: 22 |

|

Re: Ormerod from RS December 03, 2013 08:00PM |

Registered: 12 years ago Posts: 1,611 |

Hi Rob

This is a brand new printer, and we're still improving the documentation at the moment. There is no other place for documentation, other than [www.reprappro.com]

We are working hard to make sure you have as painless a build process as possible. As you probably realise, you're one of the first to receive one! Please bear with us, we'll improve things over the next couple of days.

Email me on the reprappro support email address for any specific problems.

Ian

RepRapPro tech support

This is a brand new printer, and we're still improving the documentation at the moment. There is no other place for documentation, other than [www.reprappro.com]

We are working hard to make sure you have as painless a build process as possible. As you probably realise, you're one of the first to receive one! Please bear with us, we'll improve things over the next couple of days.

Email me on the reprappro support email address for any specific problems.

Ian

RepRapPro tech support

|

Re: Ormerod from RS December 04, 2013 01:43AM |

Registered: 10 years ago Posts: 191 |

www.reprappro.com

Error 521 Ray ID: d7679ddbfd706ee

Web server is down

I hope the web site will be up and the instructions will be complete when I receive my Ormerod today. In my opinion if you sell a 700 Euro 3D printer via a major distributor there have to be complete and adequate instructions included - online or offline.

Error 521 Ray ID: d7679ddbfd706ee

Web server is down

I hope the web site will be up and the instructions will be complete when I receive my Ormerod today. In my opinion if you sell a 700 Euro 3D printer via a major distributor there have to be complete and adequate instructions included - online or offline.

|

Re: Ormerod from RS December 04, 2013 02:30AM |

Registered: 10 years ago Posts: 992 |

|

Re: Ormerod from RS December 04, 2013 02:45AM |

Registered: 10 years ago Posts: 2 |

Thanks Ian,

It's mainly listing and identifying parts for the various sub assembly stages and from what bagged set it is in (mainly bearings and fasteners).

Some of the fasteners are different length to the ones specified in the instructions.

No dimension for positioning the Z axis column on the X base, I just stuck it in the centre..... ;-)

Hopefully I'll have this up and running tonight.....

Rob

It's mainly listing and identifying parts for the various sub assembly stages and from what bagged set it is in (mainly bearings and fasteners).

Some of the fasteners are different length to the ones specified in the instructions.

No dimension for positioning the Z axis column on the X base, I just stuck it in the centre..... ;-)

Hopefully I'll have this up and running tonight.....

Rob

|

Re: Ormerod from RS December 07, 2013 09:14AM |

Registered: 12 years ago Posts: 1,611 |

@markbee: Not sure why you're having trouble accessing the website, but then we've had x10 the number of usual visitors in the last week! As far as I can tell it hasn't actually been down.

@Robbed666: Instructions have been updated a lot in the past couple of days. All the parts lists should say which bag the parts are in. Also, the position for the Z axis on the Y is now listed; it's not central:

"On the Y axis motor side, the face of the Z axis aluminium extrusion should be 205mm from the end of the Y axis aluminium extrusion.

On the Y axis idler side, the face of the Z axis aluminium extrusion should be 125mm from the end of the Y axis aluminium extrusion."

Hope that helps.

Ian

RepRapPro tech support

@Robbed666: Instructions have been updated a lot in the past couple of days. All the parts lists should say which bag the parts are in. Also, the position for the Z axis on the Y is now listed; it's not central:

"On the Y axis motor side, the face of the Z axis aluminium extrusion should be 205mm from the end of the Y axis aluminium extrusion.

On the Y axis idler side, the face of the Z axis aluminium extrusion should be 125mm from the end of the Y axis aluminium extrusion."

Hope that helps.

Ian

RepRapPro tech support

|

Re: Ormerod from RS December 07, 2013 09:31AM |

Registered: 10 years ago Posts: 24 |

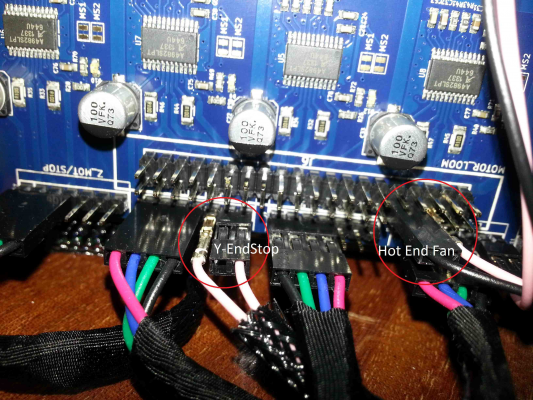

I've had great difficulty constructing the Ormerod myself as it's a case of hunting for the part that matches the picture and ignoring the text. Though the build instructions are a lot better in the last few days. The real issue I've had at the moment is wiring it up, the loom is premade and the connector configurations on the supplied loom are not the same as those in the pictures so I can't plug and play with the duet.

|

Re: Ormerod from RS December 07, 2013 09:45AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Ormerod from RS December 07, 2013 10:27AM |

Registered: 10 years ago Posts: 24 |

The hot end fan needed one of the pins taking out so it could be plugged in. The wiring picture and diagram differ however, the diagram says the row below and the picture shows it on the row above (I went with the wiring diagram). The Y-EndStop in the wiring picture has a three connector (the middle is left empty), but mine was a two connector, so I had to pop a pin out again).

|

Re: Ormerod from RS December 07, 2013 11:41AM |

Registered: 12 years ago Posts: 1,611 |

@Carnivalius: You are quite correct, and it's an oversight on our part; the Y endstop and hot end fan connections should be in a 3-way housing, using just the outer two connections. All looms shipped so far have a 2-way housing (due to a just-discovered mistake when we ordered them) so popping one connector out of the housing will work. The wiring diagram and picture in the instructions are correct; there is a difference between the hot end fan connections between the picture and wiring diagram, but either works.

I will update the instructions to reflect this. Contact us and we can send you the correct housings, if you wish. All kits shipped from now on will have 3-way housings on these wires.

Sorry for the inconvenience, and many thanks for the feedback!

Ian

RepRapPro tech support

Edited 1 time(s). Last edit at 12/07/2013 11:41AM by droftarts.

I will update the instructions to reflect this. Contact us and we can send you the correct housings, if you wish. All kits shipped from now on will have 3-way housings on these wires.

Sorry for the inconvenience, and many thanks for the feedback!

Ian

RepRapPro tech support

Edited 1 time(s). Last edit at 12/07/2013 11:41AM by droftarts.

|

Re: Ormerod from RS December 07, 2013 12:14PM |

Registered: 10 years ago Posts: 191 |

@Ian: Could you pls check the X-Axis documentation (http://www.reprappro.com/documentation/ormerod/x-axis-assembly/) ?

I have no M3x30mm cap head screw at all, which are used for the x-motor-bracket and the z-runner-mount. Also the amount of nuts/ washers/ screws for some of the assemblies (in the lists) seem to be incorrect.

I did not actually build it, but by reading through the instructions I think the assembling of the z-axis-motor gears is not described in the documentation.

The instructions up to the x-axis assembly are very precise, keep on the good work!

I have some suugestions:

* On the y-axis assembly you could propose sanding the wooden lasercut parts, but that's just for the look.

* On the z-axis assembly I would tell the horizontal distance of the z-axis extrusion earlier, maybe before "The Z axis assembly can now be attached to the Y axis assembly." You are then not fixing it too early on the wrong position.

* My y axis drive belt is way too long with 990 mm

* The Duet-enclosure-lid with the RS logo is somehow not so nice Are there .svg-files available? I would then lasercut a neutral lid by myself.

Are there .svg-files available? I would then lasercut a neutral lid by myself.

Anyway the whole packing in the bags and the documentation are very well done.

Markus

I have no M3x30mm cap head screw at all, which are used for the x-motor-bracket and the z-runner-mount. Also the amount of nuts/ washers/ screws for some of the assemblies (in the lists) seem to be incorrect.

I did not actually build it, but by reading through the instructions I think the assembling of the z-axis-motor gears is not described in the documentation.

The instructions up to the x-axis assembly are very precise, keep on the good work!

I have some suugestions:

* On the y-axis assembly you could propose sanding the wooden lasercut parts, but that's just for the look.

* On the z-axis assembly I would tell the horizontal distance of the z-axis extrusion earlier, maybe before "The Z axis assembly can now be attached to the Y axis assembly." You are then not fixing it too early on the wrong position.

* My y axis drive belt is way too long with 990 mm

* The Duet-enclosure-lid with the RS logo is somehow not so nice

Are there .svg-files available? I would then lasercut a neutral lid by myself.

Are there .svg-files available? I would then lasercut a neutral lid by myself.Anyway the whole packing in the bags and the documentation are very well done.

Markus

|

Re: Ormerod from RS December 07, 2013 01:23PM |

Registered: 12 years ago Posts: 1,611 |

Hi Markus

Thanks for the feedback! Keep it coming...

Should be M3x35mm cap head screws x 4 for the x motor bracket ... updated. The z-runner-mount uses a countersunk screw, I can't remember the length... might be a 25mm, judging by the picture. I'll check and update tomorrow.

Z axis gears - It's there, but not very clear. I've updated the words, and take a picture tomorrow.

Lasercut parts - sanding is nice. We trying to keep the instructions free from too many extra comments, though. I'll ask the higher-ups if they think we should add it!

Z axis placement dimensions - moved to a little earlier.

Y axis belt - it's the X axis belt length, at 710mm, that is really important that you don't cut too short. We supply more belt than you actually need, so you can trim the Y axis belt after it has been fitted.

Laser cut part dxfs are here: [github.com]

SolidWorks versions here: [github.com]

Hope that helps!

Ian

RepRapPro tech support

Thanks for the feedback! Keep it coming...

Should be M3x35mm cap head screws x 4 for the x motor bracket ... updated. The z-runner-mount uses a countersunk screw, I can't remember the length... might be a 25mm, judging by the picture. I'll check and update tomorrow.

Z axis gears - It's there, but not very clear. I've updated the words, and take a picture tomorrow.

Lasercut parts - sanding is nice. We trying to keep the instructions free from too many extra comments, though. I'll ask the higher-ups if they think we should add it!

Z axis placement dimensions - moved to a little earlier.

Y axis belt - it's the X axis belt length, at 710mm, that is really important that you don't cut too short. We supply more belt than you actually need, so you can trim the Y axis belt after it has been fitted.

Laser cut part dxfs are here: [github.com]

SolidWorks versions here: [github.com]

Hope that helps!

Ian

RepRapPro tech support

|

Re: Ormerod from RS December 07, 2013 02:21PM |

Registered: 15 years ago Posts: 84 |

Slightly OT but Ian or anyone else from RepRapPro, any time frame guesstimate of when you'll be officially adding support for the two extra heads i.e. the trihead / tricolour option? I'm hoping it'll at least be sooner than for the Mendel where IIRC your page was saying it would be "coming soon" for over a year or more before you made it available ;-) Also able to offer any info on when you'll be selling the Ormerod via your site? The markup for RS in NZ is rather steep as it always is so even adding shipping from you it could end up cheaper.

(I'm guessing main reasons you launched it without three heads being an officially available option is you needed to get it out to meet obligations with RS etc and perhaps in time for Christmas. And maybe also hoping for some publicity when you annouce the three head support. Since this time nearly all the work must be done. I assume main areas you may need to work on is making 3 heads work using the DUET + expansion rather than the old master + slave Melzis config if this hasn't been done yet. And other testing and general set up to make it work properly with the different printer. )

Edited 1 time(s). Last edit at 12/07/2013 02:29PM by Nil Einne.

(I'm guessing main reasons you launched it without three heads being an officially available option is you needed to get it out to meet obligations with RS etc and perhaps in time for Christmas. And maybe also hoping for some publicity when you annouce the three head support. Since this time nearly all the work must be done. I assume main areas you may need to work on is making 3 heads work using the DUET + expansion rather than the old master + slave Melzis config if this hasn't been done yet. And other testing and general set up to make it work properly with the different printer. )

Edited 1 time(s). Last edit at 12/07/2013 02:29PM by Nil Einne.

|

Re: Ormerod from RS December 07, 2013 02:41PM |

Registered: 10 years ago Posts: 191 |

Thanks Ian!

Regarding the M3x35mm cap head screws there are only 3 supplied and 1 is used for the z-upper-mount, so there are only 2 left

35mm looks too long for the motor mount screws. I guess it means 2 M3x25 and 2 M3x20 cap head screws. that would fit.

For the z-runner-mount there is no M3x30mm countersunk socket screw in the fastener bags. Pleas check all screws for the z-runner mount. The sizes seem to be wrong.

Markus

Edited 5 time(s). Last edit at 12/07/2013 03:14PM by markbee.

Regarding the M3x35mm cap head screws there are only 3 supplied and 1 is used for the z-upper-mount, so there are only 2 left

35mm looks too long for the motor mount screws. I guess it means 2 M3x25 and 2 M3x20 cap head screws. that would fit.

For the z-runner-mount there is no M3x30mm countersunk socket screw in the fastener bags. Pleas check all screws for the z-runner mount. The sizes seem to be wrong.

Markus

Edited 5 time(s). Last edit at 12/07/2013 03:14PM by markbee.

|

Re: Ormerod from RS December 07, 2013 03:03PM |

Registered: 10 years ago Posts: 7 |

Hi Ian,

I have so far only completed the assembly of the mechanical aspects of the Ormorod, but I have encountered a challenging problem relating to the thickness of the black acrylic X-axis main guide with it's rib.

I have found the thickness varies, its thinner towards the back. As a result the print head assembly is firmly held with the single 9mm dia. ball bearing, but only when in the front/near position. As it moves backwards towards the vertical extruded aluminium support end there is play allowing the print head to tip downwards slightly. I was a bit surprised to see this slack so measured the black acrylic sheet thickness at the front, and compared it to the thickness at the back where I found it gets just slightly thinner!

Is it possible to receive a replacement panel, and when replaced I would be happy to send you the problem piece for your inspection. Embarrasingly, I would also ask what is involved in obtaining a replacement X-rib acrylic piece as I carelessly broke the small nib of the open hex-hole when fitting the nut on the threaded Z-axis.

So far I am very pleased with the kit, I have spent three evenings getting the basic mechanics assembled and recognise the issues re. instructions, but have pretty much got around the problems. Although I did end up using a couple of incorrect screws, re. the screw head types. I have still to fit the electronics and will at least experiment despite the head play problems until they are resolved.

Graham.

I have so far only completed the assembly of the mechanical aspects of the Ormorod, but I have encountered a challenging problem relating to the thickness of the black acrylic X-axis main guide with it's rib.

I have found the thickness varies, its thinner towards the back. As a result the print head assembly is firmly held with the single 9mm dia. ball bearing, but only when in the front/near position. As it moves backwards towards the vertical extruded aluminium support end there is play allowing the print head to tip downwards slightly. I was a bit surprised to see this slack so measured the black acrylic sheet thickness at the front, and compared it to the thickness at the back where I found it gets just slightly thinner!

Is it possible to receive a replacement panel, and when replaced I would be happy to send you the problem piece for your inspection. Embarrasingly, I would also ask what is involved in obtaining a replacement X-rib acrylic piece as I carelessly broke the small nib of the open hex-hole when fitting the nut on the threaded Z-axis.

So far I am very pleased with the kit, I have spent three evenings getting the basic mechanics assembled and recognise the issues re. instructions, but have pretty much got around the problems. Although I did end up using a couple of incorrect screws, re. the screw head types. I have still to fit the electronics and will at least experiment despite the head play problems until they are resolved.

Graham.

|

Re: Ormerod from RS December 07, 2013 03:24PM |

Registered: 12 years ago Posts: 1,611 |

@Nil Einne:

We don't have a date set for the multiple head launch, but we'll be using the Duet expansion board that you can see on the Think3DPrint3D site, which is already printing in three colours using the same firmware as we ship on the current Duet board. Also, if you look at the Ormerod instructions, you'll see the X axis has space for three extruders, and the nozzle fan ducts already point at the places where the other nozzles will be. We also have lots of experience with the extra heads, particularly the firmware and software side of things, which we didn't before. So we're a lot further along than when the Mendel was launched! Mostly, we need to spend some time refining the hot end design and layout. I'm not sure about prices, but I think the expansion board will be cheaper than the Duet board, at least.

We have, indeed, been very, very busy with our obligations to RS. We hope to expand our production to offer kits directly early in the New Year. However, remember I'm just a monkey, not the organ grinder, so try not to be too harsh if we don't stick to these (admittedly very vague) timelines!

Ian

RepRapPro tech support

We don't have a date set for the multiple head launch, but we'll be using the Duet expansion board that you can see on the Think3DPrint3D site, which is already printing in three colours using the same firmware as we ship on the current Duet board. Also, if you look at the Ormerod instructions, you'll see the X axis has space for three extruders, and the nozzle fan ducts already point at the places where the other nozzles will be. We also have lots of experience with the extra heads, particularly the firmware and software side of things, which we didn't before. So we're a lot further along than when the Mendel was launched! Mostly, we need to spend some time refining the hot end design and layout. I'm not sure about prices, but I think the expansion board will be cheaper than the Duet board, at least.

We have, indeed, been very, very busy with our obligations to RS. We hope to expand our production to offer kits directly early in the New Year. However, remember I'm just a monkey, not the organ grinder, so try not to be too harsh if we don't stick to these (admittedly very vague) timelines!

Ian

RepRapPro tech support

|

Re: Ormerod from RS December 07, 2013 03:25PM |

Registered: 10 years ago Posts: 191 |

@Graham: I can confirm the varying thickness of both parts.

The x-axis plate measures 4.72mm in thickness near the motor and 5.2mm near the idler.

The x-axis rib measures 4.38mm near the motor and 4.53mm near the idler.

I'm not sure if this is within the specs but it is somehow surprising.

Btw my x-axis rib arrived broken with the little part near the motor likely due to shipping, but these parts anyhow should be handled with care imho.

Markus

Edited 1 time(s). Last edit at 12/07/2013 03:29PM by markbee.

The x-axis plate measures 4.72mm in thickness near the motor and 5.2mm near the idler.

The x-axis rib measures 4.38mm near the motor and 4.53mm near the idler.

I'm not sure if this is within the specs but it is somehow surprising.

Btw my x-axis rib arrived broken with the little part near the motor likely due to shipping, but these parts anyhow should be handled with care imho.

Markus

Edited 1 time(s). Last edit at 12/07/2013 03:29PM by markbee.

|

Re: Ormerod from RS December 07, 2013 03:37PM |

Registered: 12 years ago Posts: 1,611 |

@markbee: Thanks, I'll update the sizes with your suggestions now (I thought 35mm was too long, but I'm at home today, so couldn't check), but will check the sizes for the X motor mount and z runner tomorrow.

@mandeng: The varying thickness of the acrylic lasercut part is very odd. However, this shouldn't be a problem; the compensation should be able to take account of this, as long as the change in thickness is linear. However, if you would like a replacement for this and the broken part, please send me an email to support at reprappro dot com.

Thanks for all your comments; we probably need an Ormerod section in the Machine Variations section of the forum!

Ian

RepRapPro tech support

@mandeng: The varying thickness of the acrylic lasercut part is very odd. However, this shouldn't be a problem; the compensation should be able to take account of this, as long as the change in thickness is linear. However, if you would like a replacement for this and the broken part, please send me an email to support at reprappro dot com.

Thanks for all your comments; we probably need an Ormerod section in the Machine Variations section of the forum!

Ian

RepRapPro tech support

|

Re: Ormerod from RS December 07, 2013 03:42PM |

Registered: 10 years ago Posts: 7 |

@markbee & @Ian - (for RepRap)

I appreciate your feedback markbee, confirming the varying thickness X-acrylic pieces, I am not alone I do see that only the main X-Carriage acylic plate is of concern re. the print head accuracy. Does the print head depend on its weight to ensure it says in alignment, or should the thickness of the X-carriage acrylic plate matter given the head sits loosly when it's near the ?

I do see that only the main X-Carriage acylic plate is of concern re. the print head accuracy. Does the print head depend on its weight to ensure it says in alignment, or should the thickness of the X-carriage acrylic plate matter given the head sits loosly when it's near the ?

Graham.

I appreciate your feedback markbee, confirming the varying thickness X-acrylic pieces, I am not alone

I do see that only the main X-Carriage acylic plate is of concern re. the print head accuracy. Does the print head depend on its weight to ensure it says in alignment, or should the thickness of the X-carriage acrylic plate matter given the head sits loosly when it's near the ?

I do see that only the main X-Carriage acylic plate is of concern re. the print head accuracy. Does the print head depend on its weight to ensure it says in alignment, or should the thickness of the X-carriage acrylic plate matter given the head sits loosly when it's near the ?Graham.

|

Re: Ormerod from RS December 07, 2013 03:43PM |

Registered: 15 years ago Posts: 84 |

Thanks Ian. Mostly what I expected about triple head support. And yeah also understand given your position and likely even those in charge can't really predict how demand is going to change means, anything now is a real guess but sometime early next year also sounds good for kits direct (was thinking it could be 6 months or so away).

Cheers.

Cheers.

|

Re: Ormerod from RS December 07, 2013 03:43PM |

Registered: 10 years ago Posts: 7 |

@Ian,

Sorry Ian, my message crossed your posting!

Many thanks, I will email you re. the X-carriage bits.

I should add some points I puzzled over for a while whilst building the Ormerod:

1. I only noticed the position of the IR sensor lurking in one of the images, but no details written on it's fitting. At first I thought it required 3mm screws to self tap - only to realise there were 2.5mm screws in a bag.

2. It was a bit fiddly to get the T-nuts to rotate and securely anchor within the extrusions, they often failed to turn correctly when tightening. A note and very big close up to assist could help others.

3. The holes in the big circuit board to secure it to the box with screws that protrude to take the MDF washers and T-nuts, needed to be drilled out - this is not mentioned. But not to do what I did and drill all 4 holes on the RS panel, only the ones to take the long screws for t-nuts, otherwise the top screws holding the PCB will not grip

4. The printed tube that serves as an axle for the bobbins of filament was unclear as there was no mention or image of it, and the V-shaped thin flat peg to hold the bobbin on was a puzzle too - for a short while.

5, The RJ45 plug is a bit high making the lid not fit snugly, with fear it may drop off. Maybe the box would be best a touch deeper - When I get mine commisioned I should print a deeper box.

6. I was uncomfortable with the way the wires wrapped around the motor using the single sockets, pre-fitted to the flying leads, for the thermister. I opted to solder the thermistor ends directly on to the flying wires and used heat shrink (as in your original constructed model) - it was a lot neater and no fear of loose contact that could be imterittent or fall off.

On another point, I cut the adhesive foil into three, as per the first instructions, then taped over them all when taping the glass - does this mean the none taped corner is to be front right as appears in your general view images ? Or was I delusional and it always say cut into four pieces ? -

Graham.

Graham.

Edited 1 time(s). Last edit at 12/07/2013 04:27PM by mandeng.

Sorry Ian, my message crossed your posting!

Many thanks, I will email you re. the X-carriage bits.

I should add some points I puzzled over for a while whilst building the Ormerod:

1. I only noticed the position of the IR sensor lurking in one of the images, but no details written on it's fitting. At first I thought it required 3mm screws to self tap - only to realise there were 2.5mm screws in a bag.

2. It was a bit fiddly to get the T-nuts to rotate and securely anchor within the extrusions, they often failed to turn correctly when tightening. A note and very big close up to assist could help others.

3. The holes in the big circuit board to secure it to the box with screws that protrude to take the MDF washers and T-nuts, needed to be drilled out - this is not mentioned. But not to do what I did and drill all 4 holes on the RS panel, only the ones to take the long screws for t-nuts, otherwise the top screws holding the PCB will not grip

4. The printed tube that serves as an axle for the bobbins of filament was unclear as there was no mention or image of it, and the V-shaped thin flat peg to hold the bobbin on was a puzzle too - for a short while.

5, The RJ45 plug is a bit high making the lid not fit snugly, with fear it may drop off. Maybe the box would be best a touch deeper - When I get mine commisioned I should print a deeper box.

6. I was uncomfortable with the way the wires wrapped around the motor using the single sockets, pre-fitted to the flying leads, for the thermister. I opted to solder the thermistor ends directly on to the flying wires and used heat shrink (as in your original constructed model) - it was a lot neater and no fear of loose contact that could be imterittent or fall off.

On another point, I cut the adhesive foil into three, as per the first instructions, then taped over them all when taping the glass - does this mean the none taped corner is to be front right as appears in your general view images ? Or was I delusional and it always say cut into four pieces ? -

Graham.

Graham.

Edited 1 time(s). Last edit at 12/07/2013 04:27PM by mandeng.

|

Re: Ormerod from RS December 07, 2013 03:58PM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Ormerod from RS December 08, 2013 03:11AM |

Registered: 10 years ago Posts: 191 |

Just some more questions/ remarks regarding the instructions:

Little typo with the Extruder drive assembly -> Gear drive assembly:

"MR63ZZ" in the text should be "MR93ZZ".

Suggestion: The "tongue" which is supplied with the Extruder Drive set is used much later in the hot end assembly to fix the bowden tube. I wondered what to do with it until reaching the end of the hot end assembly instructions.

Hot end assembly -> Adding the temperature-measuring thermistor:

No Black polyolefin heatshrink supplied in the bags

Wire colors: Green and blue wires supplied - no red an black as in the pictures

Suggestion with hot air gun: PTFE heatshrink temp ~350-400°C

Hot end assembly -> Final assembly:

No M3 x 16mm countersunk screws left in the supplied bags (for fixing the MDF heat insulator to the nozzle mount)

Nozzle mount to the x-carriage not described yet (and also the proximity sensor missing in instructions?)

One more: Mounting of z-gears not described.

Markus

Edited 3 time(s). Last edit at 12/08/2013 07:16AM by markbee.

Little typo with the Extruder drive assembly -> Gear drive assembly:

"MR63ZZ" in the text should be "MR93ZZ".

Suggestion: The "tongue" which is supplied with the Extruder Drive set is used much later in the hot end assembly to fix the bowden tube. I wondered what to do with it until reaching the end of the hot end assembly instructions.

Hot end assembly -> Adding the temperature-measuring thermistor:

No Black polyolefin heatshrink supplied in the bags

Wire colors: Green and blue wires supplied - no red an black as in the pictures

Suggestion with hot air gun: PTFE heatshrink temp ~350-400°C

Hot end assembly -> Final assembly:

No M3 x 16mm countersunk screws left in the supplied bags (for fixing the MDF heat insulator to the nozzle mount)

Nozzle mount to the x-carriage not described yet (and also the proximity sensor missing in instructions?)

One more: Mounting of z-gears not described.

Markus

Edited 3 time(s). Last edit at 12/08/2013 07:16AM by markbee.

|

Re: Ormerod from RS December 08, 2013 03:32PM |

Registered: 10 years ago Posts: 191 |

I think almost all sizes and amounts of screws in

Electronics (www.reprappro.com/documentation/ormerod/electronics/) are wrong.

Instructions are poor.

It's getting frustrating.

Unfortunately I only now recognized that the Duet-enclosure was broken apart near the LAN opening. That is a weak section in this quite big printed part and fragile to any shipping stress because it is among all the plastic parts in one bag.

Markus

Electronics (www.reprappro.com/documentation/ormerod/electronics/) are wrong.

Instructions are poor.

It's getting frustrating.

Unfortunately I only now recognized that the Duet-enclosure was broken apart near the LAN opening. That is a weak section in this quite big printed part and fragile to any shipping stress because it is among all the plastic parts in one bag.

Markus

|

Re: Ormerod from RS December 08, 2013 04:26PM |

Registered: 12 years ago Posts: 1,611 |

Markus

When was the last time you checked the instructions online? I've updated a lot of these errors yesterday and today - the Extruder drive assembly bearings typo, many other things checked. The hot end instructions have the following note:

"NOTE: We now supply the thermistor wiring with a crimp housing, or with heatshrink already on it. The black heatshrink shown in the picture is not supplied. The thermistor wiring may be another colour, usually blue and/or green."

There should be the correct number of fasteners; I'm checking through the entire instructions that this is still true. I'm updating the electronics mounting at the moment.

The wiring page shows the mounting of the proximity sensor. Fitting of the Z axis gears are described (waiting for new pictures) on the x axis mounting page. Nozzle mount to carriage is at the end of the Hot end assembly page.

We appreciate the feedback, and are doing our best to banish errors and omissions from the instructions.

Please email support at reprappro dot com for warranty replacement of parts.

Ian

RepRapPro tech support

When was the last time you checked the instructions online? I've updated a lot of these errors yesterday and today - the Extruder drive assembly bearings typo, many other things checked. The hot end instructions have the following note:

"NOTE: We now supply the thermistor wiring with a crimp housing, or with heatshrink already on it. The black heatshrink shown in the picture is not supplied. The thermistor wiring may be another colour, usually blue and/or green."

There should be the correct number of fasteners; I'm checking through the entire instructions that this is still true. I'm updating the electronics mounting at the moment.

The wiring page shows the mounting of the proximity sensor. Fitting of the Z axis gears are described (waiting for new pictures) on the x axis mounting page. Nozzle mount to carriage is at the end of the Hot end assembly page.

We appreciate the feedback, and are doing our best to banish errors and omissions from the instructions.

Please email support at reprappro dot com for warranty replacement of parts.

Ian

RepRapPro tech support

|

Re: Ormerod from RS December 08, 2013 04:54PM |

Registered: 12 years ago Posts: 1,236 |

On the subject of errors, the wiki page [www.reprappro.com] has a link to Thingiverse, but it is for Huxley and I don't think Ormerod is even on Thingiverse. The wiki page How to Print RepRapPro Ormerod actually has instructions for Huxley.

It all has a very "Beta" feel about it. Par for the course for Open Source I suppose, I don't know if RS customers are expecting that.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

It all has a very "Beta" feel about it. Par for the course for Open Source I suppose, I don't know if RS customers are expecting that.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

|

Re: Ormerod from RS December 08, 2013 05:17PM |

Registered: 12 years ago Posts: 1,611 |

Thanks, bobc, guess I've got another couple of things for tomorrow's to do list! The open source mantra does tend to be "release early, release often", which does mean documentation is the last thing that gets done... The other part is "And listen to your customers", which I hope we're doing.

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: Ormerod from RS December 08, 2013 05:42PM |

Registered: 10 years ago Posts: 191 |

@Ian

I checked the instructions again, but if I would closely follow them, some screws would obviously miss (maybe this is due to my low #004?). So I'm procceeding with the screws available and checking where they fit best

I fixed the Duet-enclosure with glue - no need to replace.

One more observation: the heater cartridge seems to be very loose in the heater block.

Thanks for your effort and keep up the good work!

Markus

I checked the instructions again, but if I would closely follow them, some screws would obviously miss (maybe this is due to my low #004?). So I'm procceeding with the screws available and checking where they fit best

I fixed the Duet-enclosure with glue - no need to replace.

One more observation: the heater cartridge seems to be very loose in the heater block.

Thanks for your effort and keep up the good work!

Markus

|

Re: Ormerod from RS December 08, 2013 06:09PM |

Registered: 12 years ago Posts: 1,611 |

Hi Markus

We haven't changed the fasteners since the very first kit. However, the instructions have changed, and in various places the screw use has been corrected since the first draft, to match our original design files, and the beta machines we built and tested. So it may be you've used the wrong screws earlier in the build, due to our inaccurate instructions. Sorry! But, like I said, I'm going through all the assemblies and checking the instructions. And building another Ormerod as I go, updating pictures etc, and making things clearer based on feedback. It's a process that took about 6 months with the Tricolour instructions, and people still complain about them!

Ian

RepRapPro tech support

We haven't changed the fasteners since the very first kit. However, the instructions have changed, and in various places the screw use has been corrected since the first draft, to match our original design files, and the beta machines we built and tested. So it may be you've used the wrong screws earlier in the build, due to our inaccurate instructions. Sorry! But, like I said, I'm going through all the assemblies and checking the instructions. And building another Ormerod as I go, updating pictures etc, and making things clearer based on feedback. It's a process that took about 6 months with the Tricolour instructions, and people still complain about them!

Ian

RepRapPro tech support

Sorry, only registered users may post in this forum.