Fan backwash problem - new parts to fix

Posted by Rory166

|

Re: Fan backwash problem - new parts to fix January 04, 2014 07:32AM |

Registered: 10 years ago Posts: 2,472 |

Hmmm. Treth, I suspect it is a browser or browser add-on compatibility issue. Next time I want to post a pic, I'll try a different browser.

Kwikius, that was my first print using ABS rather than PLA. The bit of discolouration is due to the remains of black PLA in the nozzle. I used the recommended heat setting for ABS (240 C), but I think that it would have been better with a lower hotend temperature. My PLA prints are better at a lower setting also (I use 185 for PLA). Perhaps my temperature sensor reading is inaccurate. I do not use tape on the bed, but coat the glass with the solvent glue sold to join plastic pipes - just spread it out evenly over the glass using the edge of a bit of cardboard as a squeegee. Work quickly because it dries fast. The print sticks well, but also releases easily as well. After printing, the remaining film of glue peels off the glass easily with a light rub under running water, ready for coating for the next print. I'll get hold of some acetone at some stage and try making my own, thinner version by dissolving some filament. I tried using hairspray on the glass instead to get a smoother finish, and have had a few good results with that, but the first layer does not consistently stick to it as well as the PVC glue.

I can now report that my deflector appears to work - a print that always lifted and warped at the rear left corner now remains flat (I'm presently making a set of 5 speaker shelves that hang on my picture rail - they take up 80% of the print area).

Kwikius, that was my first print using ABS rather than PLA. The bit of discolouration is due to the remains of black PLA in the nozzle. I used the recommended heat setting for ABS (240 C), but I think that it would have been better with a lower hotend temperature. My PLA prints are better at a lower setting also (I use 185 for PLA). Perhaps my temperature sensor reading is inaccurate. I do not use tape on the bed, but coat the glass with the solvent glue sold to join plastic pipes - just spread it out evenly over the glass using the edge of a bit of cardboard as a squeegee. Work quickly because it dries fast. The print sticks well, but also releases easily as well. After printing, the remaining film of glue peels off the glass easily with a light rub under running water, ready for coating for the next print. I'll get hold of some acetone at some stage and try making my own, thinner version by dissolving some filament. I tried using hairspray on the glass instead to get a smoother finish, and have had a few good results with that, but the first layer does not consistently stick to it as well as the PVC glue.

I can now report that my deflector appears to work - a print that always lifted and warped at the rear left corner now remains flat (I'm presently making a set of 5 speaker shelves that hang on my picture rail - they take up 80% of the print area).

|

Re: Fan backwash problem - new parts to fix January 04, 2014 06:17PM |

Registered: 10 years ago Posts: 5 |

Much appreciated work here.. I've printed this out and fitted it - works really well and problem solved .

I think that the controller housing fixing nearest to the Y motor needs to be relocated to give more room for this new part. Perhaps using a new hole in the

Y motor mounting component to fix to.?

regards

Ray

I think that the controller housing fixing nearest to the Y motor needs to be relocated to give more room for this new part. Perhaps using a new hole in the

Y motor mounting component to fix to.?

regards

Ray

|

Re: Fan backwash problem - new parts to fix January 04, 2014 07:21PM |

Registered: 10 years ago Posts: 41 |

Made MarkB's original one

Defiantly fixes the backwash problem. But does it reduce cooling ???

Not having a wind tunnel to test I came up with a more pragmatic way to check

Heat hot end to 200deg C

Wait for a bit so temp stabilises

Turn off hot end

Time how long it takes for hot end to drop to 100 degrees.

Fit Cover

Repeat.

I did it twice because I didn't belive the results !!

At least in terms of 'how long to cool back down' the fan cover improves cooling

Without cover, Times 54, 52 seconds

With Cover, Times 41 , 43 Seconds

Not conclusive but it certainly does not seem to be making cooling any worse !!

if the improvement is real it may be that reducing the backflow improves air throughput

and cooling.

Chris

Defiantly fixes the backwash problem. But does it reduce cooling ???

Not having a wind tunnel to test I came up with a more pragmatic way to check

Heat hot end to 200deg C

Wait for a bit so temp stabilises

Turn off hot end

Time how long it takes for hot end to drop to 100 degrees.

Fit Cover

Repeat.

I did it twice because I didn't belive the results !!

At least in terms of 'how long to cool back down' the fan cover improves cooling

Without cover, Times 54, 52 seconds

With Cover, Times 41 , 43 Seconds

Not conclusive but it certainly does not seem to be making cooling any worse !!

if the improvement is real it may be that reducing the backflow improves air throughput

and cooling.

Chris

|

Re: Fan backwash problem - new parts to fix January 04, 2014 07:30PM |

Registered: 12 years ago Posts: 1,611 |

The most important thing is that cooling of the top of the nozzle isn't compromised. Set the nozzle to 200C, and measure the aluminium cooling block (that the heatsink is attached to) with and without the shroud. If the filament melts too far up the nozzle, the force required to extrude will increase, eventually causing the extruder to skip.

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: Fan backwash problem - new parts to fix January 04, 2014 08:25PM |

Registered: 10 years ago Posts: 135 |

Chris

Very interesting results. It seems that the chaotic airflow situation we are calling backwash actually interferes with the flow through the fan. The louver as well as directing any backwash upwards as intended is also reducing such interference.

My analysis of the situation is that because the output of the fan is severely constricted the air cannot all be driven forward by the fan as intended. The pressure in the heatsink builds up to more than the fan can generate and some flows back through the fan. Centrifugal force drives this flow to the outside of the fan body. The fan blades impart an anticlockwise flow to the escaping air. On the left side of the fan the louvers will deflect air moving anticlockwise back into the fan on the right side outwards.

Relying on this analysis it would be interesting to try a design which would direct the airflow back into the fan all around the circle. In other words a fixed multibladed fan with blades angled opposite to the rotating fan or to put it another way a contra rotating fan fixed in place. Similar to the static blades in a jet engine compressor.

Rory

Very interesting results. It seems that the chaotic airflow situation we are calling backwash actually interferes with the flow through the fan. The louver as well as directing any backwash upwards as intended is also reducing such interference.

My analysis of the situation is that because the output of the fan is severely constricted the air cannot all be driven forward by the fan as intended. The pressure in the heatsink builds up to more than the fan can generate and some flows back through the fan. Centrifugal force drives this flow to the outside of the fan body. The fan blades impart an anticlockwise flow to the escaping air. On the left side of the fan the louvers will deflect air moving anticlockwise back into the fan on the right side outwards.

Relying on this analysis it would be interesting to try a design which would direct the airflow back into the fan all around the circle. In other words a fixed multibladed fan with blades angled opposite to the rotating fan or to put it another way a contra rotating fan fixed in place. Similar to the static blades in a jet engine compressor.

Rory

|

Re: Fan backwash problem - new parts to fix January 05, 2014 05:01AM |

Registered: 10 years ago Posts: 41 |

>The most important thing is that cooling of the top of the nozzle isn't compromised. Set the nozzle to 200C, and measure the aluminium cooling block (that >the heatsink is attached to) with and without the shroud. If the filament melts too far up the nozzle, the force required to extrude will increase, eventually .>causing the extruder to skip.

I tried to do this first but it is very hard to get an accurate reading of the heat sink temp

my best efforts were inconclusive with the temp seeming to be about 31 deg C with or without the shroud in place.

(using a digital thermomenter, the problem is ensuring consistent contact with the heat sink, I don't have an IR thermomenter

which might work better)

I did try blocking the fan with a bit of card to verify the temp measuring and with the fan blocked it does rise very quickly

and drops back when you unblock the fan.

So to the best of my measurement ability the shroud makes no difference to the heat sink temp.

Chris

I tried to do this first but it is very hard to get an accurate reading of the heat sink temp

my best efforts were inconclusive with the temp seeming to be about 31 deg C with or without the shroud in place.

(using a digital thermomenter, the problem is ensuring consistent contact with the heat sink, I don't have an IR thermomenter

which might work better)

I did try blocking the fan with a bit of card to verify the temp measuring and with the fan blocked it does rise very quickly

and drops back when you unblock the fan.

So to the best of my measurement ability the shroud makes no difference to the heat sink temp.

Chris

|

Re: Fan backwash problem - new parts to fix January 05, 2014 05:30AM |

Registered: 10 years ago Posts: 2,472 |

If the aluminium block gets too hot, not only will it result in the filament melting too early as droftarts says, but the heat will be conducted through the mounting screws and melt the printed part, resulting in the hotend droop that some people have reported. I suspect that those who have suffered from that issue are seeing the consequence of a cooling problem - maybe not good enough thermal contact between the block and the heat sink. My completely non-scientific test was to touch the top of one of those mounting screws with my finger a couple of hours into a 230 deg ABS print job. It did not feel hot. I suppose I could say that I took a reading with my "digital thermometer" :-)

|

Re: Fan backwash problem - new parts to fix January 05, 2014 05:30AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Rory166

Relying on this analysis it would be interesting to try a design which would direct the airflow back into the fan all around the circle. In other words a fixed multibladed fan with blades angled opposite to the rotating fan or to put it another way a contra rotating fan fixed in place. Similar to the static blades in a jet engine compressor.

Rory

..incoming train of thought - If anyone happens to have a 10mm fan, design an print out one static counterclock running ditto as an ad-on, maybe a 10mm will put more air through than the 20mm when fed correctly, and it would take care of all backwash for sure

This is how a vacuum cleaners are build to ad to the static pressure, moving part, static counter ditto, moving part etc.

If I could design and print I would make one, but I'm not there yet

Erik

|

Re: Fan backwash problem - new parts to fix January 05, 2014 06:49AM |

Registered: 10 years ago Posts: 256 |

Quote

ormerod168

Quote

Rory166

Relying on this analysis it would be interesting to try a design which would direct the airflow back into the fan all around the circle. In other words a fixed multibladed fan with blades angled opposite to the rotating fan or to put it another way a contra rotating fan fixed in place. Similar to the static blades in a jet engine compressor.

Rory

..incoming train of thought - If anyone happens to have a 10mm fan, design an print out one static counterclock running ditto as an ad-on, maybe a 10mm will put more air through than the 20mm when fed correctly, and it would take care of all backwash for sure

This is how a vacuum cleaners are build to ad to the static pressure, moving part, static counter ditto, moving part etc.

If I could design and print I would make one, but I'm not there yet

Erik

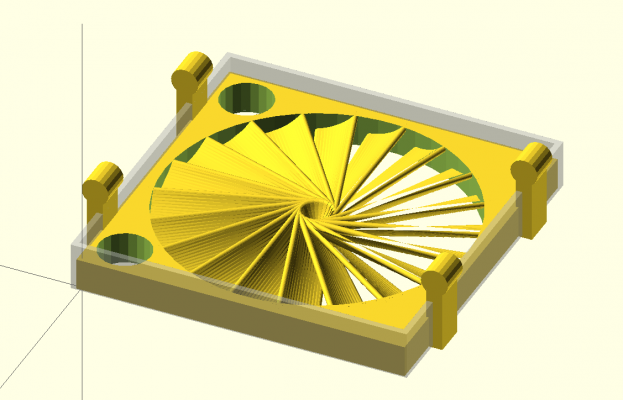

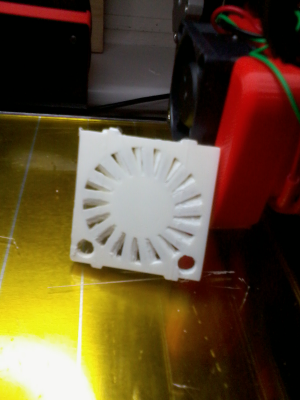

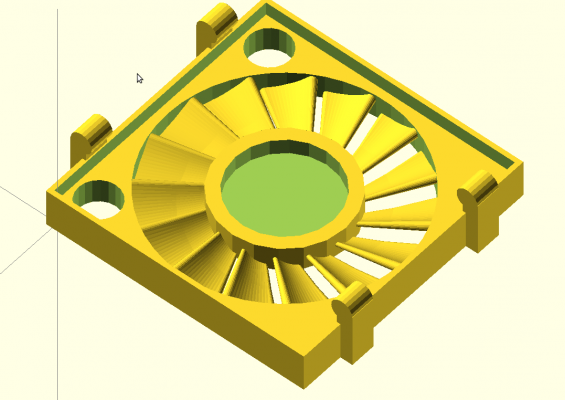

How about this ...?

Though maybe aerofoil should be other way up ?

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 05, 2014 07:30AM |

Registered: 12 years ago Posts: 1,611 |

chriscain: sorry, I miss-read your numbers; I assumed the without fan would be quicker at cooling! It must be smoothing out the flow of air through the heatsink, or allowing more of the heatsink to be usable, with less turbulence/static air. I guess the only other thing to check is that the nozzles put out a similar amount of cooling air as before.

I don't think a 10mm fan will have the static pressure to get the air through the fan duct, though confess we haven't tried it.

Ian

RepRapPro tech support

I don't think a 10mm fan will have the static pressure to get the air through the fan duct, though confess we haven't tried it.

Ian

RepRapPro tech support

|

Re: Fan backwash problem - new parts to fix January 05, 2014 08:08AM |

Registered: 10 years ago Posts: 256 |

Quote

droftarts

I guess the only other thing to check is that the nozzles put out a similar amount of cooling air as before.

Ian

RepRapPro tech support

Could use a pitot tube. I have one I think somewhere from my model aeroplanes. I will see if I can hook it up

Here is next incarnation. of the circular foil version

May try printing this one..

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 05, 2014 09:10AM |

Registered: 10 years ago Posts: 191 |

Hi all again,

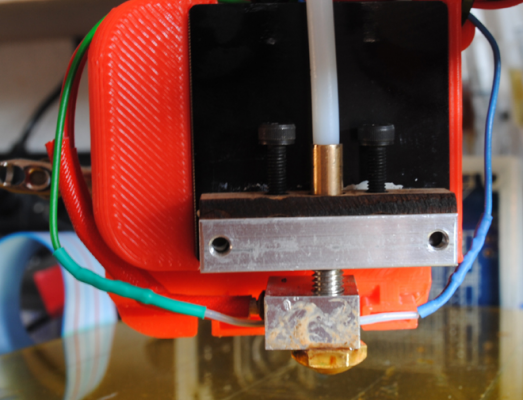

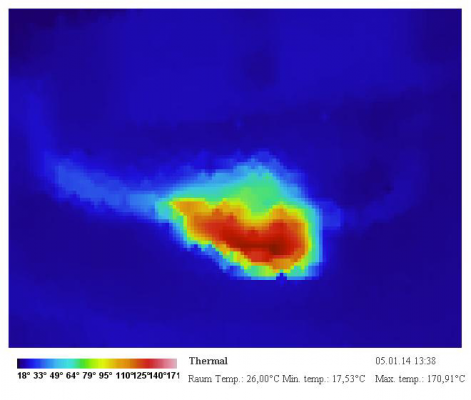

I did some additional tests with my plate designed against the backwash. As Ian stated one should have to look for any heat crawling up the hot end (aluminium block) which could lead to trouble with melted filament.

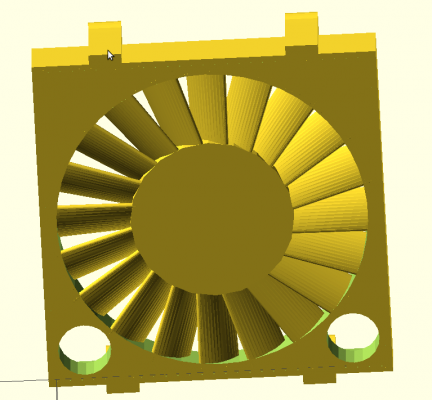

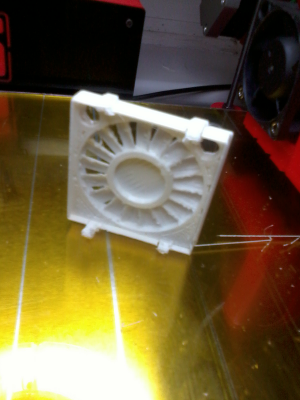

As already shown this is my current backwash plate:

First a picture of the DUT in real life:

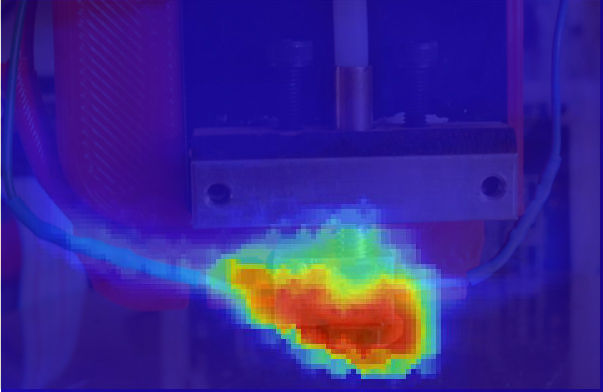

I made a thermal picture WITHOUT the backplate. Settings: 205°C hot end. This thermal image looked like this:

I compared this to a picture WITH the backplate on:

I made a composite picture where hot end and fan assembly is overlapped with the thermal picture and it is clearer to see which part is which:

I couldn't see any major differences so I call this a success. Two things I observed while testing:

1. The fan with the backwash plate is a bit more quiet

2. The heat looks a bit or minimally more focused to the hot end WITH the backplate on

For now I'm fine with this solution so I will concentrate now on 0.12mm layer printing

Happy Sunday,

Markus

Edited 1 time(s). Last edit at 01/05/2014 09:35AM by markbee.

XBee & electronics blog: [lookmanowire.blogspot.com]

I did some additional tests with my plate designed against the backwash. As Ian stated one should have to look for any heat crawling up the hot end (aluminium block) which could lead to trouble with melted filament.

As already shown this is my current backwash plate:

First a picture of the DUT in real life:

I made a thermal picture WITHOUT the backplate. Settings: 205°C hot end. This thermal image looked like this:

I compared this to a picture WITH the backplate on:

I made a composite picture where hot end and fan assembly is overlapped with the thermal picture and it is clearer to see which part is which:

I couldn't see any major differences so I call this a success. Two things I observed while testing:

1. The fan with the backwash plate is a bit more quiet

2. The heat looks a bit or minimally more focused to the hot end WITH the backplate on

For now I'm fine with this solution so I will concentrate now on 0.12mm layer printing

Happy Sunday,

Markus

Edited 1 time(s). Last edit at 01/05/2014 09:35AM by markbee.

XBee & electronics blog: [lookmanowire.blogspot.com]

|

Re: Fan backwash problem - new parts to fix January 05, 2014 10:38AM |

Registered: 10 years ago Posts: 13 |

to kwikius for the design

to kwikius for the designI downloaded and printed the backwash deflector - the print started lifting on the second layer - but I let it carry on.

After printing I fitted the deflector and immediately ran the print job again this time the print completed with no lifting at all - not conclusive as I changed filament colour from blue to red between prints.

Thanks for sharing the design.

Edited 1 time(s). Last edit at 01/05/2014 10:43AM by markm.

Mark

Ormerod #350

|

Re: Fan backwash problem - new parts to fix January 05, 2014 11:25AM |

Registered: 10 years ago Posts: 14,672 |

I printed markbee's design and fitted it:

I had originally planned to so a similar design which uses countersunk screws to hold it on the fan, but the clips on markbee's design are adequate. The two holes fit over the heads of the cap screws just fine. I can feel that the backwash is being diverted upwards. Thanks, markbee!

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I had originally planned to so a similar design which uses countersunk screws to hold it on the fan, but the clips on markbee's design are adequate. The two holes fit over the heads of the cap screws just fine. I can feel that the backwash is being diverted upwards. Thanks, markbee!

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix January 05, 2014 11:36AM |

Registered: 10 years ago Posts: 59 |

I've been following this thread, but didn't like the idea of the louvered designs next to the fan. I'm not up with any of the 3d cad software yet, but I did find this design thingamaprint.com which I had a go at printing out. It needs support material to keep the guard away from the moving fan and my support structure would not come away from the circle properly, but it's fixed on without fouling on the fan.

To attach it I used a couple of self tapping screws into the top holes.

I tried to attach the gcode to the post, but it was over the maximum file size...

In use there is now no turbulence or backwash below the hot end. Using my thermal imaging camera I tried it with and without the duct and there is only negligible difference to the temperature of the top and bottom of the heatsink, screws and mdf separator. Hotend was left to stabilise for 15 minutes before temperature readings were taken.

With duct, heatsink:

Without duct, heatsink:

With duct, screws:

Without duct, screws:

With duct, MDF:

Without duct, MDF:

RS Ormerod #472

To attach it I used a couple of self tapping screws into the top holes.

I tried to attach the gcode to the post, but it was over the maximum file size...

In use there is now no turbulence or backwash below the hot end. Using my thermal imaging camera I tried it with and without the duct and there is only negligible difference to the temperature of the top and bottom of the heatsink, screws and mdf separator. Hotend was left to stabilise for 15 minutes before temperature readings were taken.

With duct, heatsink:

Without duct, heatsink:

With duct, screws:

Without duct, screws:

With duct, MDF:

Without duct, MDF:

RS Ormerod #472

|

Re: Fan backwash problem - new parts to fix January 05, 2014 11:45AM |

Registered: 10 years ago Posts: 59 |

I've made a short youtube video attempting to show the difference in turbulance. Sorry, it's a bit shakey!

youtube.com

RS Ormerod #472

youtube.com

RS Ormerod #472

|

Re: Fan backwash problem - new parts to fix January 05, 2014 11:52AM |

Registered: 10 years ago Posts: 1,230 |

Quote

kwikius

Here is next incarnation. of the circular foil version

regards

Andy

Yes that's what I'm talking about!, you don't realy have any airflow in the middle - but you got the direction wrong me think, the blades should be counter running with opposite curves, think about looking from the top on the fan wing without the casing and your ad-on, together they should look as an mirror'd long drawn S aka the fan should "cut and reverse" the curve of the air

..anyway, that's my theory until proven wrong, please don't be mad if I waste your time...and btw, made my first print ever this minute, and it was perfect! - woo-hooo! :-)

|

Re: Fan backwash problem - new parts to fix January 05, 2014 02:03PM |

Registered: 10 years ago Posts: 135 |

Andy

I like the look of your second attempt, although I would like to see a smaller central boss. I know the fan is solid behind but I would still want as much air as possible. I am not certain about any curve of the blades so why not sit on the fence and have no curve.

I must say I like the way this forum is progressing, I post a half thought rambling idea at 1.45 am and by 11.45am you have come up with a design. all we need now is for someone to build and try it. I never got the chance to ask my own designer to come up with something.

Re 10mm fans, what about having two 10mm fans with 2 perhaps 3 of these static deflectors attached to make a higher pressure compressor. The idea of the 3rd one would be to catch the rotational element of the output and direct it forward.

Rory

Edit: Now having had the chance to study axial flow compresors. The concave surface should face the rear and the wider section is at the front.

Edited 1 time(s). Last edit at 01/05/2014 03:30PM by Rory166.

I like the look of your second attempt, although I would like to see a smaller central boss. I know the fan is solid behind but I would still want as much air as possible. I am not certain about any curve of the blades so why not sit on the fence and have no curve.

I must say I like the way this forum is progressing, I post a half thought rambling idea at 1.45 am and by 11.45am you have come up with a design. all we need now is for someone to build and try it. I never got the chance to ask my own designer to come up with something.

Re 10mm fans, what about having two 10mm fans with 2 perhaps 3 of these static deflectors attached to make a higher pressure compressor. The idea of the 3rd one would be to catch the rotational element of the output and direct it forward.

Rory

Edit: Now having had the chance to study axial flow compresors. The concave surface should face the rear and the wider section is at the front.

Edited 1 time(s). Last edit at 01/05/2014 03:30PM by Rory166.

|

Re: Fan backwash problem - new parts to fix January 05, 2014 02:19PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Rory166

Re 10mm fans, what about having two 10mm fans with 2 perhaps 3 of these static deflectors attached to make a higher pressure compressor. The idea of the 3rd one would be to catch the rotational element of the output and direct it forward.

In that arrangement, the two fans should really have different pitch blades (the second with a courser pitch), or rotate at different speeds (the second one faster). You might be able to compensate for that by having the static deflector between them add the right amount of opposing rotation to the airflow. I think this might indeed be more efficient than the current 20mm fan, which is working under conditions (i.e. high back pressure) far from what it was designed for.

Edited 2 time(s). Last edit at 01/05/2014 02:20PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix January 05, 2014 02:27PM |

Registered: 10 years ago Posts: 135 |

DC

By paying higher prices to RS and the like it is indeed possible to have the second fan faster ie 8,500 r.p.m. rather than the usual 5,500 r.p.m. these days. The current rating of the faster motor is also higher so in the event of no speed info. the higher current model should be faster.

Rory

By paying higher prices to RS and the like it is indeed possible to have the second fan faster ie 8,500 r.p.m. rather than the usual 5,500 r.p.m. these days. The current rating of the faster motor is also higher so in the event of no speed info. the higher current model should be faster.

Rory

|

Re: Fan backwash problem - new parts to fix January 05, 2014 02:35PM |

Registered: 10 years ago Posts: 256 |

Ormerod168 Rory166

I hit the print button just before I read your posts!

Unfortunately my printing is rubbish! but This deflector is impressive even if the sizes, angles etc are not optimal! I think its the way to go! I guess I should get my pitot rigged up and get some experimental data. To start I got a bit of cotton on a piece of wire. On this one the cotton always stays attached to the deflector at all points. On the last louvre one its fine at x < fan , but at x > fan the air shoots out the side.

Anyway I'm going to try a redesign with less blades and more airflow!

BTW My prints are stringy. Is that because my extruder rate is too high?

Hey certainly not wasting my time. This is my 4th print. I'm learning with each one and they only take < 2 m of filamant per go!

regards

Andy

Edited 2 time(s). Last edit at 01/05/2014 02:57PM by kwikius.

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

I hit the print button just before I read your posts!

Unfortunately my printing is rubbish! but This deflector is impressive even if the sizes, angles etc are not optimal! I think its the way to go! I guess I should get my pitot rigged up and get some experimental data. To start I got a bit of cotton on a piece of wire. On this one the cotton always stays attached to the deflector at all points. On the last louvre one its fine at x < fan , but at x > fan the air shoots out the side.

Anyway I'm going to try a redesign with less blades and more airflow!

BTW My prints are stringy. Is that because my extruder rate is too high?

Hey certainly not wasting my time. This is my 4th print. I'm learning with each one and they only take < 2 m of filamant per go!

regards

Andy

Edited 2 time(s). Last edit at 01/05/2014 02:57PM by kwikius.

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 05, 2014 02:41PM |

Registered: 10 years ago Posts: 14,672 |

Rory, it's actually the product of RPM and pitch that matters (assuming constant blade diameter). The higher RPM fans from RS will have finer pitch to compensate, assuming they are designed to accelerate air from standstill just like the lower-speed ones. What this design needs for the second stage fan is higher RPM than the first stage but the same pitch, or same RPM and courser pitch. I think low-RPM fans would be easier to use, because you wouldn't have to impart as much opposite rotation in the static deflector.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix January 05, 2014 03:36PM |

Registered: 10 years ago Posts: 135 |

DC

I wonder if it is possible to remove the blade from a cheap 10mm fan and reproduce with a coarser pitch? Any thoughts on the relative power consumption of the stages in a compressor?

Andy

I am interested in your pitot, my crude experiments indicate the first nozzle has much less flow than the others. I did design baffles to address this but an not printing yet. [tinkercad.com]#

Rory

Edited 2 time(s). Last edit at 01/05/2014 03:48PM by Rory166.

I wonder if it is possible to remove the blade from a cheap 10mm fan and reproduce with a coarser pitch? Any thoughts on the relative power consumption of the stages in a compressor?

Andy

I am interested in your pitot, my crude experiments indicate the first nozzle has much less flow than the others. I did design baffles to address this but an not printing yet. [tinkercad.com]#

Rory

Edited 2 time(s). Last edit at 01/05/2014 03:48PM by Rory166.

|

Re: Fan backwash problem - new parts to fix January 05, 2014 04:27PM |

Registered: 10 years ago Posts: 1,230 |

Quote

kwikius

Ormerod168 Rory166

I hit the print button just before I read your posts!

Bummer! :-)

Quote

Hey certainly not wasting my time. This is my 4th print. I'm learning with each one and they only take < 2 m of filamant per go!

regards

Andy

Glad to hear that, and I sure can't give you any advice, just finished my first print ever - coathanger anyone? he he...

I did try to print the snowman but he would'nt stick to the bed, maybe Al Gore was right and global bloody warming dunnit..

Anyway, about the theory of blades

what we want to do is to increase the relative velocity of the volume of air moved by preventing the incoming air from rotating

that's why we want counter formed blades - when the air changes direction the relative velocity between the moving and the static blade increases, it also makes it harder for inlet air to move back

energy equals mass times velocity squared

but we also want a smooth transition of air from the static to the rotating blades, we don't want any turbulence

therefore the layout, as seen from above, the rotating blade and the static blade should in extension of each other look like a mirrorred long drawn S

if I had a counter rotating fan I could block the blades from turning and mount it on the original to make a test but I have'nt

Erik

|

Re: Fan backwash problem - new parts to fix January 05, 2014 05:10PM |

Registered: 10 years ago Posts: 14,672 |

kwicius, if you are getting stringy prints, what worked for me was increasing the retraction distance in the slic3r printer->extruder 1 settings to 4mm (default is 1mm AFAIR).

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix January 05, 2014 05:35PM |

Registered: 10 years ago Posts: 256 |

Quote

Rory166

Andy

I am interested in your pitot, my crude experiments indicate the first nozzle has much less flow than the others. I did design baffles to address this but an not printing yet. [tinkercad.com]#

Rory

The pitot is for model aircraft. I got it here, but looks like they are out of stock at the moment Tomorrow I will try to hook it up. Would be nice to move the hot end around across the bed and do readings in several points. Will have to study chriscain's script

DC42. Thanks for the tip. I'll give it a try. I have some way to go yet to get good prints methinks!

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 05, 2014 05:56PM |

Registered: 10 years ago Posts: 59 |

Forgot to add the photos to my earlier post. This design is working well for me, the only compromise is I have had to slide the electronics enclosure along by about 20mm.

The fan seems to be quieter too. It might be my hearing, but it also sounds as if it is running faster as well, not sure if that would be possible though.

RS Ormerod #472

The fan seems to be quieter too. It might be my hearing, but it also sounds as if it is running faster as well, not sure if that would be possible though.

RS Ormerod #472

|

Re: Fan backwash problem - new parts to fix January 06, 2014 11:11AM |

Registered: 10 years ago Posts: 14,672 |

BTW markbee's design (and probably most of the other designs) acts as a finger guard too. I cut my finger on the fan once when I was rather careless while the fan was running, so this is a welcome safety benefit IMO.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix January 06, 2014 02:22PM |

Registered: 10 years ago Posts: 256 |

Still designing. I found that the latest version of OpenSCAD can extrude, rotate and scale at the same time (though I had to bulld it) , so my blades are looking much better. Wider at outside

I have been working on using the pitot to test the airflow but got waylaid . Ive been experimenting with talking direct to the Ormerod rather than using the low level assembly language in pronterface. It would be nice to just say

move_x(120 mm) wait_for_key_press() , get_position() , etc, rather than the low level commands.

Maybe there is already a higher level language that can output Gcode commands?

Anyway hope to get some output from the pitot tomorrow.

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

I have been working on using the pitot to test the airflow but got waylaid . Ive been experimenting with talking direct to the Ormerod rather than using the low level assembly language in pronterface. It would be nice to just say

move_x(120 mm) wait_for_key_press() , get_position() , etc, rather than the low level commands.

Maybe there is already a higher level language that can output Gcode commands?

Anyway hope to get some output from the pitot tomorrow.

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 07, 2014 06:11AM |

Registered: 10 years ago Posts: 256 |

Got around to testing the various deflectors.

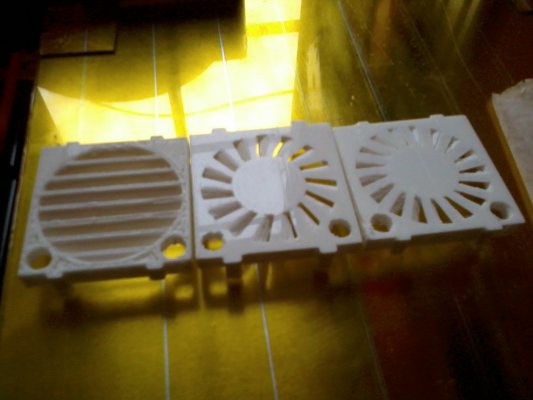

Here are the various deflectors I tested. from left to right V1, V3, V2

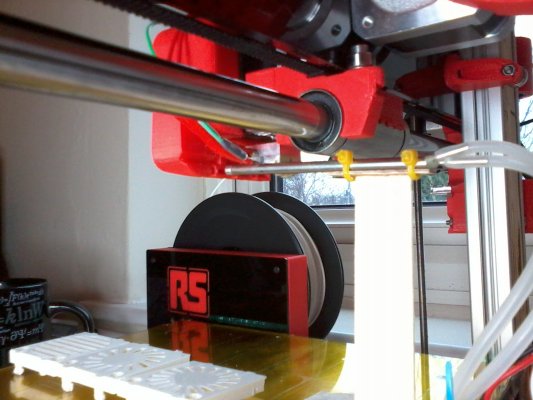

Here is the test setup. I tried to get the pitot butting against the centre of the duct.

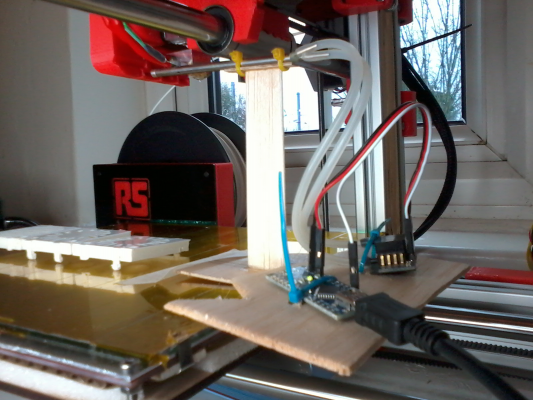

Here is a wider view. The sensor and the Arduino Nano I used to read the sensor analog values ( 0 = 0V , 1023 = 5V )

Here is the differential pressure sensor IC used.

MPXV7002

I took the average of 10 samples and then took the difference from fan off reading

The results: ( The raw results are attached in deflector_results.xls )

No Deflector 9

V1 7

V2 4.6

V3 5.2

I havent translated the numbers into units, but it seems clear that these deflectors do reduce the airflow at the output.

Against that, the V2 and V3 deflectors are excellent at stopping the draft at the wrong side of the fan.

regards

Andy

Edited 1 time(s). Last edit at 01/07/2014 06:13AM by kwikius.

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

Here are the various deflectors I tested. from left to right V1, V3, V2

Here is the test setup. I tried to get the pitot butting against the centre of the duct.

Here is a wider view. The sensor and the Arduino Nano I used to read the sensor analog values ( 0 = 0V , 1023 = 5V )

Here is the differential pressure sensor IC used.

MPXV7002

I took the average of 10 samples and then took the difference from fan off reading

The results: ( The raw results are attached in deflector_results.xls )

No Deflector 9

V1 7

V2 4.6

V3 5.2

I havent translated the numbers into units, but it seems clear that these deflectors do reduce the airflow at the output.

Against that, the V2 and V3 deflectors are excellent at stopping the draft at the wrong side of the fan.

regards

Andy

Edited 1 time(s). Last edit at 01/07/2014 06:13AM by kwikius.

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

Sorry, only registered users may post in this forum.