Fan backwash problem - new parts to fix

Posted by Rory166

|

Re: Fan backwash problem - new parts to fix January 07, 2014 06:42AM |

Registered: 10 years ago Posts: 59 |

Andy, nice work there. I'd be really interested to see the results from the duct design I'm using. It's very good at reducing the draft and is quieter, but I'd like to see how much the output is reduced.

The STL can be downloaded from here.

ps are you skyscraper on fpvhub forum?

Cheers, Tim

RS Ormerod #472

The STL can be downloaded from here.

ps are you skyscraper on fpvhub forum?

Cheers, Tim

RS Ormerod #472

|

Re: Fan backwash problem - new parts to fix January 07, 2014 07:27AM |

Registered: 10 years ago Posts: 1,230 |

Andy

I'm so impressed by your scientific approach!

what I would do if I had your setup, make a quick and dirty static wing test

cut out a slice of aluminium width 10mm or so and roll it into a 40mm ring (maybe material from a beer can will do)

cut a disc of the thin aluminium diameter 40mm

cut out the profile of five wings toward the center

twist the five wings clockwise

put the D 40mm ring around

tape to end of fan

do the test

twist the five wings counterclockwise

do the test again

thank you for your time and great research

Erik

I'm so impressed by your scientific approach!

what I would do if I had your setup, make a quick and dirty static wing test

cut out a slice of aluminium width 10mm or so and roll it into a 40mm ring (maybe material from a beer can will do)

cut a disc of the thin aluminium diameter 40mm

cut out the profile of five wings toward the center

twist the five wings clockwise

put the D 40mm ring around

tape to end of fan

do the test

twist the five wings counterclockwise

do the test again

thank you for your time and great research

Erik

|

Re: Fan backwash problem - new parts to fix January 07, 2014 07:54AM |

Registered: 10 years ago Posts: 256 |

Quote

ormerod168

Andy

I'm so impressed by your scientific approach!

what I would do if I had your setup, make a quick and dirty static wing test

cut out a slice of aluminium width 10mm or so and roll it into a 40mm ring (maybe material from a beer can will do)

cut a disc of the thin aluminium diameter 40mm

cut out the profile of five wings toward the center

twist the five wings clockwise

put the D 40mm ring around

tape to end of fan

do the test

twist the five wings counterclockwise

do the test again

thank you for your time and great research

Erik

Is that a polite way of saying I have it the wrong way around

Could you draw out what you mean?

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 07, 2014 08:03AM |

Registered: 10 years ago Posts: 256 |

Quote

tim_h

Andy, nice work there. I'd be really interested to see the results from the duct design I'm using. It's very good at reducing the draft and is quieter, but I'd like to see how much the output is reduced.

The STL can be downloaded from here.

ps are you skyscraper on fpvhub forum?

Cheers, Tim

Hi Tim ( Yes I'm skyscraper

)

) I do like that design. However I would prefer something thin. Markbees original was only 1.2 mm thick! I am restricting my designs ( somewhat arbitraily) to 5 mm thick currently.

However for anyone that wants to try this the Pitot isnt expensive ( Its the APM airspeed sensor from buildyourowndrone). and it should give repeatable results. And you can also use it on your plane or in your car

EDIT Here is the Arduino script I used in the Nano read_a2d.ino Just send a question mark in Arduino Serial monitor

regards

Andy

Edited 1 time(s). Last edit at 01/07/2014 08:08AM by kwikius.

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 07, 2014 08:48AM |

Registered: 10 years ago Posts: 256 |

Quote

ormerod168

Andy

I'm so impressed by your scientific approach!

what I would do if I had your setup, make a quick and dirty static wing test

cut out a slice of aluminium width 10mm or so and roll it into a 40mm ring (maybe material from a beer can will do)

cut a disc of the thin aluminium diameter 40mm

cut out the profile of five wings toward the center

twist the five wings clockwise

put the D 40mm ring around

tape to end of fan

do the test

twist the five wings counterclockwise

do the test again

thank you for your time and great research

Erik

Is this what you mean. Note that I have changed the sign of the camber. Is this something like it? Higher Reynolds numbers now!

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 07, 2014 12:48PM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Fan backwash problem - new parts to fix January 07, 2014 01:03PM |

Registered: 10 years ago Posts: 1,230 |

Quote

kwikius

Is this what you mean. Note that I have changed the sign of the camber. Is this something like it? Higher Reynolds numbers now!

regards

Andy

No this is what i mean, it will make the fan move more air for sure - or try to move more air that is - it will go down in speed and you may end up with the same result..and it may make a sound like a diving Stuka :-)

Notice that it's a reversed stationary version of the original Ormerod fan

just for the fun of it I did a test with three identical fans (115vac), stacked in a row, one after the other, but the middle one reversed and made stationary with tape (stationary, as in "not able to rotate"), I had no way of measuring the air pressure, but it went up for sure

But that's three in a row

High pressure blowers are built that way active-passive-active etc.

Erik

|

Re: Fan backwash problem - new parts to fix January 07, 2014 01:15PM |

Registered: 10 years ago Posts: 1,230 |

..and if one was to re-design the whole thing this blower or something like that might be a better choice

Farnell 1012796 - NMB TECHNOLOGIES - BM4515-04W-B30-L00 - FAN, BLOWER, 45X44X15MM, 12VDC

[uk.farnell.com]

Erik

Farnell 1012796 - NMB TECHNOLOGIES - BM4515-04W-B30-L00 - FAN, BLOWER, 45X44X15MM, 12VDC

[uk.farnell.com]

Erik

|

Re: Fan backwash problem - new parts to fix January 07, 2014 02:58PM |

Registered: 10 years ago Posts: 256 |

OK. So I just want the exact same shape as the fan blade but turned around.

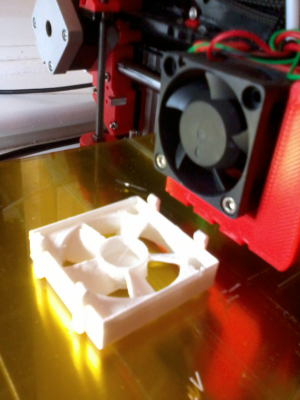

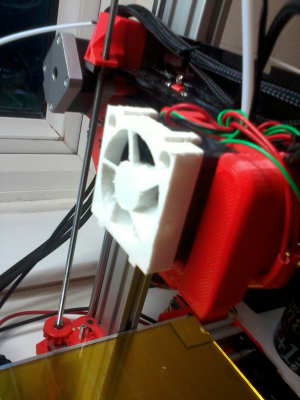

I printed the last one as shown below before I saw your reply, but its a mirror image of the fan blade, which is incorrect?

Anyway It works very well to stop air blowing in front of the fan!

Maybe I will try it the other way around!

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

I printed the last one as shown below before I saw your reply, but its a mirror image of the fan blade, which is incorrect?

Anyway It works very well to stop air blowing in front of the fan!

Maybe I will try it the other way around!

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 07, 2014 03:13PM |

Registered: 10 years ago Posts: 256 |

Quote

ormerod168

..and if one was to re-design the whole thing this blower or something like that might be a better choice

Farnell 1012796 - NMB TECHNOLOGIES - BM4515-04W-B30-L00 - FAN, BLOWER, 45X44X15MM, 12VDC

[uk.farnell.com]

Erik

What about this one ( Maybe a netbook fan)?

Looks like it might fit nicely, if the output was facing down onto those ducts 40 mm x 50 mm blower fan on ebay

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 07, 2014 03:24PM |

Registered: 10 years ago Posts: 14,672 |

You need to look at the fan specifications. This one, which looks similar to the one supplied in the kit, has a higher specified flow rate at zero pressure than either of those two. However, the NMB one linked to by ormerod168 can produce a higher static pressure, so might be more suitable in an application like this where the output is constrained.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix January 08, 2014 03:57AM |

Registered: 10 years ago Posts: 256 |

Quote

dc42

You need to look at the fan specifications. This one, which looks similar to the one supplied in the kit, has a higher specified flow rate at zero pressure than either of those two. However, the NMB one linked to by ormerod168 can produce a higher static pressure, so might be more suitable in an application like this where the output is constrained.

Yes a netbook fan would probably be too weedy!

I suppose I could try printing one, Using the motor from the existing fan

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 08, 2014 04:54AM |

Registered: 10 years ago Posts: 94 |

|

Re: Fan backwash problem - new parts to fix January 08, 2014 01:54PM |

Registered: 10 years ago Posts: 135 |

Hi All

At work today I saw an interesting Fan which was 80x80x38 and supplied by RS. The interesting aspect was that it has a fixed blade array built in. The static pressure was quoted as 0.75 inch H2O which I thought interesting in todays metric world. The benefit of such an arragement would seem two fold: the mounting of the motor has a function rather than merely an obstruction and the motor can be the full length of both sets of blades. It is not easy to see in the lists which fans have this arrangement also static pressure is not often specified.

Rory

At work today I saw an interesting Fan which was 80x80x38 and supplied by RS. The interesting aspect was that it has a fixed blade array built in. The static pressure was quoted as 0.75 inch H2O which I thought interesting in todays metric world. The benefit of such an arragement would seem two fold: the mounting of the motor has a function rather than merely an obstruction and the motor can be the full length of both sets of blades. It is not easy to see in the lists which fans have this arrangement also static pressure is not often specified.

Rory

|

Re: Fan backwash problem - new parts to fix January 08, 2014 02:01PM |

Registered: 10 years ago Posts: 1,230 |

Quote

kwikius

OK. So I just want the exact same shape as the fan blade but turned around.

I printed the last one as shown below before I saw your reply, but its a mirror image of the fan blade, which is incorrect?

Yes, your image, acdsee/edit/flip/<->

Its now a CC model of the original ormerod fan, mounted inlet against inlet, the ormerod fan will be fed the air clockwise

..but as you noted, your print solved the backwash problem, so there's clearly nothing incorrect about it! - and not much to gain with a low pressure fan anyway

Erik

|

Re: Fan backwash problem - new parts to fix January 08, 2014 02:12PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Joar107

Just a thought how would it work with compressed air instead of the fan, it would be easy to regulate the flow and it would be very silent.... as long the compressor doesnt start

/Joar #25

Yes, that would work just fine, a bit expensive in energy consumption though - and be very careful not to block the outlet if you feed it with 10bar :-)

..and make sure the air is clean, you don't want to spray oil on the bed :-)

Erik

|

Re: Fan backwash problem - new parts to fix January 08, 2014 02:27PM |

Registered: 10 years ago Posts: 1,230 |

Quote

dc42

You need to look at the fan specifications. This one, which looks similar to the one supplied in the kit, has a higher specified flow rate at zero pressure than either of those two. However, the NMB one linked to by ormerod168 can produce a higher static pressure, so might be more suitable in an application like this where the output is constrained.

Agreed, a centrifugal blower would be a better start, mounted top down, heat sink turned 90 degrees, close the hole from the old side mounted fan, what's not to like?

..and most importantly, implement a air activated micro switch in line with the heating element for safety in case the fan should fail

Erik

|

Re: Fan backwash problem - new parts to fix January 08, 2014 02:33PM |

Registered: 10 years ago Posts: 14,672 |

I've looked at the specs of various 40x40x20mm fans available from Farnell (sadly the best ones are "US stock"). The static pressure varies between models in the same range (Multicomp) by around 2.5:1, from 0.11" H2O to 0.27" H2O. So it would be interesting to hear from RRP what the specs and/or part #s of the fans they ship are, so that we can establish whether there is a better replacement in the same form factor.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix January 08, 2014 03:28PM |

Registered: 10 years ago Posts: 94 |

Or water... no is not such a good ideaQuote

ormerod168

Quote

Joar107

Just a thought how would it work with compressed air instead of the fan, it would be easy to regulate the flow and it would be very silent.... as long the compressor doesnt start

/Joar #25

Yes, that would work just fine, a bit expensive in energy consumption though - and be very careful not to block the outlet if you feed it with 10bar :-)

..and make sure the air is clean, you don't want to spray oil on the bed :-)

Erik

|

Re: Fan backwash problem - new parts to fix January 08, 2014 03:55PM |

Registered: 12 years ago Posts: 1,611 |

Quote

ormerod168

Agreed, a centrifugal blower would be a better start, mounted top down, heat sink turned 90 degrees, close the hole from the old side mounted fan, what's not to like?

..and most importantly, implement a air activated micro switch in line with the heating element for safety in case the fan should fail

Erik

Haha, I suggested a very similar arrangement a few days ago...

Ian

RepRapPro tech support

|

Re: Fan backwash problem - new parts to fix January 08, 2014 04:08PM |

Registered: 10 years ago Posts: 1,230 |

Quote

droftarts

Quote

ormerod168

Agreed, a centrifugal blower would be a better start, mounted top down, heat sink turned 90 degrees, close the hole from the old side mounted fan, what's not to like?

..and most importantly, implement a air activated micro switch in line with the heating element for safety in case the fan should fail

Erik

Haha, I suggested a very similar arrangement a few days ago...

Ian

RepRapPro tech support

Sorry, I'm a bit slow! ;-)

|

Re: Fan backwash problem - new parts to fix January 08, 2014 05:17PM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Fan backwash problem - new parts to fix January 09, 2014 03:25AM |

Registered: 10 years ago Posts: 256 |

Regarding my previous tests. I tried redoing them but got different results. I guess to do it properly I should get a more sensitive differntial pressure guage, and drill a hole somewhere in the ducts and attach a nipple to get consistent readings. Someday I may get round to trying the different fan arrangements and even have a go at redesigning the part with a centrifugal fan.

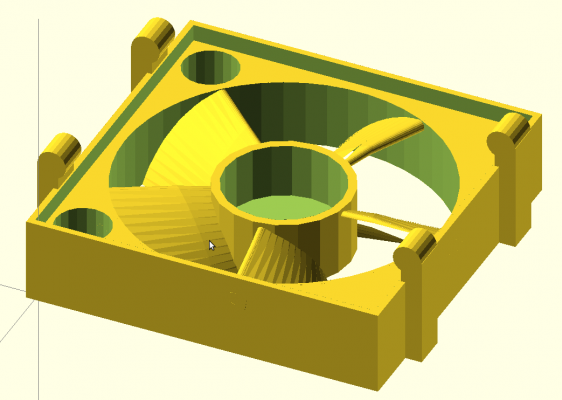

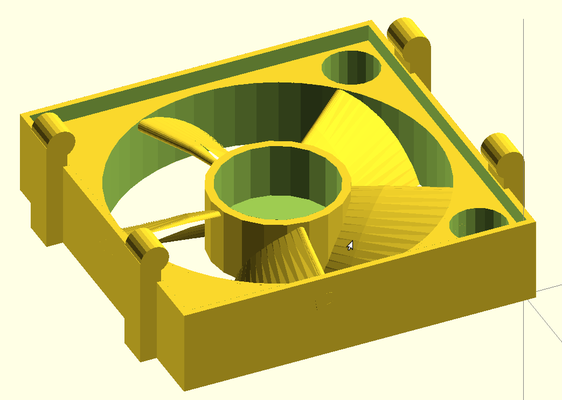

Meantime I am quite pleased with my last fan deflector. This one is around 10 mm deep. There is no discernible backwash ( a piece of cotton on a wand, held nearby, is drawn in to the deflector at all positions on the open face); there seems to be very little restriction to the flow and, being a circular design, the effect should be uniform in all directions. All together I did 5 different versions in fact so now I had better move on to something else for a while.

Unfortunately the stl is too big to attach,

EDIT: you can download the zip with stl from here : http://www.zoomworks.org/3d-printing/ormerod-fan-deflector/ormerod_fan_deflector_v4.zip

but here are the OpenSCAD files, though you need OpenSCAD version 2013.06 which allows scaling of an extrusion, else the blades are rendered without a taper

fan_deflector_v4.scad

fan_deflector_v4_aerofoil.scad

regards

Andy

Edited 1 time(s). Last edit at 01/09/2014 05:02AM by kwikius.

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

Meantime I am quite pleased with my last fan deflector. This one is around 10 mm deep. There is no discernible backwash ( a piece of cotton on a wand, held nearby, is drawn in to the deflector at all positions on the open face); there seems to be very little restriction to the flow and, being a circular design, the effect should be uniform in all directions. All together I did 5 different versions in fact so now I had better move on to something else for a while.

Unfortunately the stl is too big to attach,

EDIT: you can download the zip with stl from here : http://www.zoomworks.org/3d-printing/ormerod-fan-deflector/ormerod_fan_deflector_v4.zip

but here are the OpenSCAD files, though you need OpenSCAD version 2013.06 which allows scaling of an extrusion, else the blades are rendered without a taper

fan_deflector_v4.scad

fan_deflector_v4_aerofoil.scad

regards

Andy

Edited 1 time(s). Last edit at 01/09/2014 05:02AM by kwikius.

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 09, 2014 03:53AM |

Registered: 10 years ago Posts: 14,672 |

Nice work, Andy! I think I see what's going on here. The load on the fan is greater than the fan is designed for, which means that what the fan really needs is finer-pitch blades. Your deflector induces a rotation of the incoming air in the opposite direction to the rotation of the blades, so that when the air meets the fan blades, the angle between the two has changed to give the same effect as a finer blade pitch. So your mod should increase the efficiency of the fan, hence improve hot end cooling, as opposed to just deflecting the backwash out of the way like the louvre-style deflector.

Now I'm wondering whether a thinner (say 5mm) deflector might be effective enough? Or whether the gain in efficiency is enough to permit a 10mm or 15mm fan to be used?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Now I'm wondering whether a thinner (say 5mm) deflector might be effective enough? Or whether the gain in efficiency is enough to permit a 10mm or 15mm fan to be used?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix January 09, 2014 04:22AM |

Registered: 10 years ago Posts: 94 |

@ Andy I followed your designs and like them but I can't open scad files can you export in a neutral format like step?Quote

kwikius

Regarding my previous tests. I tried redoing them but got different results. I guess to do it properly I should get a more sensitive differntial pressure guage, and drill a hole somewhere in the ducts and attach a nipple to get consistent readings. Someday I may get round to trying the different fan arrangements and even have a go at redesigning the part with a centrifugal fan.

Meantime I am quite pleased with my last fan deflector. This one is around 10 mm deep. There is no discernible backwash ( a piece of cotton on a wand, held nearby, is drawn in to the deflector at all positions on the open face); there seems to be very little restriction to the flow and, being a circular design, the effect should be uniform in all directions. All together I did 5 different versions in fact so now I had better move on to something else for a while.

[attachment 24351 Photo0025.jpg]

Unfortunately the stl is too big to attach, but here are the OpenSCAD files, though you need OpenSCAD version 2013.06 which allows scaling of an extrusion, else the blades are rendered without a taper

[attachment 24352 fan_deflector_v4.scad]

[attachment 24353 fan_deflector_v4_aerofoil.scad]

regards

Andy

Kind regards Joar #25

|

Re: Fan backwash problem - new parts to fix January 09, 2014 04:35AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Joar107

Unfortunately the stl is too big to attach, but here are the OpenSCAD files, though you need OpenSCAD version 2013.06 which allows scaling of an extrusion, else the blades are rendered without a taper

@ Andy I followed your designs and like them but I can't open scad files can you export in a neutral format like step?

[/quote]

Or make the STL available via Dropbox/Skydrive/etc. ?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix January 09, 2014 04:59AM |

Registered: 10 years ago Posts: 256 |

Quote

dc42

Nice work, Andy! I think I see what's going on here. The load on the fan is greater than the fan is designed for, which means that what the fan really needs is finer-pitch blades. Your deflector induces a rotation of the incoming air in the opposite direction to the rotation of the blades, so that when the air meets the fan blades, the angle between the two has changed to give the same effect as a finer blade pitch. So your mod should increase the efficiency of the fan, hence improve hot end cooling, as opposed to just deflecting the backwash out of the way like the louvre-style deflector.

Now I'm wondering whether a thinner (say 5mm) deflector might be effective enough? Or whether the gain in efficiency is enough to permit a 10mm or 15mm fan to be used?

The 10 mm width is more satisfying since as the width decreases, then so does the Reynolds Number , however as this is now the 5th deflector I have done, I think I'm going to leave this one for now!

Anyway I have uploaded the stl, gcode and scad source files to to my website in the following zip file for anyone who wants to try making one:

http://www.zoomworks.org/3d-printing/ormerod-fan-deflector/ormerod_fan_deflector_v4.zip

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 09, 2014 05:01AM |

Registered: 10 years ago Posts: 256 |

Quote

dc42

Quote

Joar107

Unfortunately the stl is too big to attach, but here are the OpenSCAD files, though you need OpenSCAD version 2013.06 which allows scaling of an extrusion, else the blades are rendered without a taper

@ Andy I followed your designs and like them but I can't open scad files can you export in a neutral format like step?

Or make the STL available via Dropbox/Skydrive/etc. ?[/quote]

All in the zip file there:

http://www.zoomworks.org/3d-printing/ormerod-fan-deflector/ormerod_fan_deflector_v4.zip

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 09, 2014 06:24AM |

Registered: 10 years ago Posts: 14,672 |

Thanks, Andy. I'm going to try scaling it down to 7 or 8mm thick, because then it would just clear the electronics box in my build.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix January 09, 2014 06:34AM |

Registered: 10 years ago Posts: 14,672 |

Andy, are you sure you have put the correct files in the zip? File fan_deflector_v4.scad contains this:

use <fan_deflector_v2_aerofoil.scad>

but the actual file supplied is fan_deflector_v4_aerofoil.scad

Edited 1 time(s). Last edit at 01/09/2014 06:35AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

use <fan_deflector_v2_aerofoil.scad>

but the actual file supplied is fan_deflector_v4_aerofoil.scad

Edited 1 time(s). Last edit at 01/09/2014 06:35AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.