Fan backwash problem - new parts to fix

Posted by Rory166

|

Re: Fan backwash problem - new parts to fix January 09, 2014 07:05AM |

Registered: 10 years ago Posts: 256 |

Quote

dc42

Andy, are you sure you have put the correct files in the zip? File fan_deflector_v4.scad contains this:

use <fan_deflector_v2_aerofoil.scad>

but the actual file supplied is fan_deflector_v4_aerofoil.scad

Thanks... just uploaded a corrected version so should be fixed now. In fact its the same file so you can just change that line to

use <fan_deflector_v4_aerofoil.scad>

regards

Andy

Edited 3 time(s). Last edit at 01/09/2014 07:07AM by kwikius.

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 12, 2014 12:38PM |

Registered: 10 years ago Posts: 14,672 |

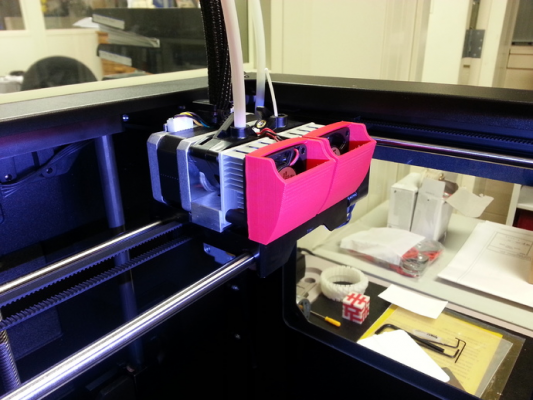

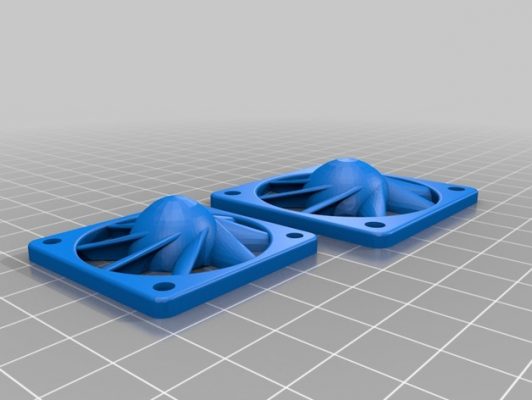

I've just adapted Andy's design for my own Omerod. Mine has a 7-bladed fan with a larger hub. I also wanted to make it thin enough to slide behind the electronics box. I reasoned that not having the number of stationary blades the same as the number of fan blades would be likely to make the fan quieter, and after experimenting with the design, I settled on 9 stationary blades. I found the skirt that fits around the fan was too thin on the original and broke easily, so I thickened it by 1mm.

I have put the openscad and stl files here, and here is a photo of the installed fan inlet.

It seems to be working fine. The backwash is gone and the airflow at the front seems just as strong as before. If I print it again, I will reduce the size of the hub by 0.5mm or possibly 1mm radius. The blades are rather thin at their thinnest edge and there are some tiny gaps between a few of the filaments, so I think the blades could be a little thicker, or the print done in 0.12mm layers.

Edited 4 time(s). Last edit at 01/12/2014 12:40PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I have put the openscad and stl files here, and here is a photo of the installed fan inlet.

It seems to be working fine. The backwash is gone and the airflow at the front seems just as strong as before. If I print it again, I will reduce the size of the hub by 0.5mm or possibly 1mm radius. The blades are rather thin at their thinnest edge and there are some tiny gaps between a few of the filaments, so I think the blades could be a little thicker, or the print done in 0.12mm layers.

Edited 4 time(s). Last edit at 01/12/2014 12:40PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix January 13, 2014 04:28AM |

Registered: 10 years ago Posts: 256 |

Hi DC42

Glad its working well

Running fan_deflector_v4.scad in openscad, it looks like the skirt needs a tweak to skim a bit more from the faces front and back. Patch attached:

fan_deflector_tweak.patch

BTW the thickness of the blades is controlled by the thickness parameter in module "aerofoil" in fan_deflector_v4_aerofoil.scad . The thickness parameter controls the ratio thickness / chord. Unfortunately changing thickness changes foil length slightly due to the changing diameter of the circle on the ends of the foil. Ideally the aerofoil foil should have a chord length of 1 but I just added the radius on the ends.

Some day will try to make everything a bit more generic .. and add some comments!

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

Glad its working well

Running fan_deflector_v4.scad in openscad, it looks like the skirt needs a tweak to skim a bit more from the faces front and back. Patch attached:

fan_deflector_tweak.patch

BTW the thickness of the blades is controlled by the thickness parameter in module "aerofoil" in fan_deflector_v4_aerofoil.scad . The thickness parameter controls the ratio thickness / chord. Unfortunately changing thickness changes foil length slightly due to the changing diameter of the circle on the ends of the foil. Ideally the aerofoil foil should have a chord length of 1 but I just added the radius on the ends.

Some day will try to make everything a bit more generic .. and add some comments!

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix January 13, 2014 06:37AM |

Registered: 10 years ago Posts: 578 |

I'll be printing one of these excellent mods asap, but since Markus pointed out the problem I've been using a much lower-tech solution (which has held up for a few hundred grams of ABS and is ultra-slimline). I applied a strip of Kapton tape across the lower part of the fan pictured printing a threadless ballscrew in ABS on Marley KS10 bed coating (there's some motion blur):

|

Re: Fan backwash problem - new parts to fix January 13, 2014 07:12AM |

Registered: 10 years ago Posts: 256 |

Quote

rayhicks

I'll be printing one of these excellent mods asap, but since Markus pointed out the problem I've been using a much lower-tech solution (which has held up for a few hundred grams of ABS and is ultra-slimline). I applied a strip of Kapton tape across the lower part of the fan pictured printing a threadless ballscrew in ABS on Marley KS10 bed coating (there's some motion blur):

[attachment 24661 backwashmod.jpg]

Now I know that all the time I spent designing 5 different versions of the fan deflector was surely not wasted

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Fan backwash problem - new parts to fix February 09, 2014 07:38AM |

Registered: 10 years ago Posts: 14,672 |

I had a problem with the tabs on the fan defector, they almost broke off after fitting and replacing it a few times. I printed a new one, but I couldn't get it on the fan without breaking two of the tabs. Maybe the 7-bladed fan I have has different dimensions from the 5-bladed one that I think Andy worked with. So I modified the design further to replacing the cap head screws that hold the hot end together by 50mm countersunk M3 screws, which go through the backwash plate. Here is a photo and the openscad file.

I don't really like using slotted screws, but they were all my local supplied had in 50mm M3 csk. I considered instead attaching the deflector to the two threaded brass bushes that my fan has in the top 2 holes, however they don't appear to be a metric thread, an M3 screw goes in them but gets stuck after a few turns.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I don't really like using slotted screws, but they were all my local supplied had in 50mm M3 csk. I considered instead attaching the deflector to the two threaded brass bushes that my fan has in the top 2 holes, however they don't appear to be a metric thread, an M3 screw goes in them but gets stuck after a few turns.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix February 09, 2014 07:20PM |

Registered: 10 years ago Posts: 265 |

I've completed and tested a "beta" version of a replacement one piece air duct for the hot end, I have rotated the heat sink by 90 degrees so the airflow is much more direct, meaning a slower, quieter, narrower fan can be used with similar air flow to the current design, backwash is nearly all eliminated, a fan cover is really only needed for finger safety now. It's also much easier to print and has better clearance over the print job. I'll post some pics after a few more tests.

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

Matt

Limited Edition Red RS Ormerod 1 #144 of 200 - RRP 1.09fw

iamburnys Ormerod Upgrades Github

Follow me on ThingiVerse My Designs

|

Re: Fan backwash problem - new parts to fix February 10, 2014 08:15AM |

Registered: 10 years ago Posts: 780 |

Hi,

I thought I had printed the latest version but after printing it looks nothing like the green one on the recent posts. The one I printed has clips top and bottom and has 15 openings, looking like a fan. However, it does not quite fit width seems OK but the height is short. This may be my printer settings, I am re checking everything today and re-commissioning.

Could somebody provide the agreed best version in an stl file please.

Thank you

Paul

I thought I had printed the latest version but after printing it looks nothing like the green one on the recent posts. The one I printed has clips top and bottom and has 15 openings, looking like a fan. However, it does not quite fit width seems OK but the height is short. This may be my printer settings, I am re checking everything today and re-commissioning.

Could somebody provide the agreed best version in an stl file please.

Thank you

Paul

|

Re: Fan backwash problem - new parts to fix February 10, 2014 08:25AM |

Registered: 10 years ago Posts: 14,672 |

Paul, there are at least 2 different models of fan supplied with the kit, so I don't think a standard fan deflector design is possible. Andy's original one was I think designed for a 5-bladed fan. My fan has 7 blades and a larger central core, so it needed some design changes. Also I wanted to reduce the depth of the deflector so that the print head still fits behind the Duet box in its standard position, increase the number of deflector blades to make it quieter, and (as I said in my recent post) the clasps on Andy's original don't fit my fan well.

Andy has published the OpenScad files (and I have published the corresponding files for my variant), so you are free to do your own variant to suit your particular requirements.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Andy has published the OpenScad files (and I have published the corresponding files for my variant), so you are free to do your own variant to suit your particular requirements.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix August 10, 2014 05:26AM |

Registered: 9 years ago Posts: 7 |

Hi All,

I have 5 blade fan, but I like dc42's slim design so I thought I would give it a try. It works fantastic!

I was having a lot of trouble with severe warping in the corner near the duet board; you could feel the draft bouncing of the duet enclosure. With the deflector there is no longer any backwash, and no warping. It's also quieter (not that the noise was a problem...I like the sound of construction).

Great mod, thanks!!

Alex.

I have 5 blade fan, but I like dc42's slim design so I thought I would give it a try. It works fantastic!

I was having a lot of trouble with severe warping in the corner near the duet board; you could feel the draft bouncing of the duet enclosure. With the deflector there is no longer any backwash, and no warping. It's also quieter (not that the noise was a problem...I like the sound of construction).

Great mod, thanks!!

Alex.

|

Re: Fan backwash problem - new parts to fix January 03, 2016 05:37AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

I am actually looking for a new design for my Ormerods as the clip on designs do not work for my fans or at least for the Ormerod 2 fan. My Ormerod 2 uses another nozzle that needs not so much cooling, but I have too much backwash so even PLA warps.

Has anyone tested this design? looks wuite interesting:

[www.thingiverse.com]

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I am actually looking for a new design for my Ormerods as the clip on designs do not work for my fans or at least for the Ormerod 2 fan. My Ormerod 2 uses another nozzle that needs not so much cooling, but I have too much backwash so even PLA warps.

Has anyone tested this design? looks wuite interesting:

[www.thingiverse.com]

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Fan backwash problem - new parts to fix January 03, 2016 05:43AM |

Registered: 10 years ago Posts: 14,672 |

I gave up with clip-on designs because the clips broke. I now use four screws, which requires drilling 2 more holes in the heatsink and using longer screws, with nyloc nuts at the back of the 2 extra screws. See [www.thingiverse.com]. It's working well on my dual extrusion Ormerod, and I can't feel any backwash.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Fan backwash problem - new parts to fix January 03, 2016 06:05AM |

Registered: 9 years ago Posts: 1,699 |

As I have another nozzle I would have the 4 screws. I needed 4 screws to securely connet the two pieces which hold the nozzle together. That would be not a big deal. I do not like the countersunk screw design otherwise I would have taken your design.

I guess I will first try this one:

[www.thingiverse.com]

The first design I posted above looks interesting because it transfers the air completely up, but maybe it blocks also too much.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I guess I will first try this one:

[www.thingiverse.com]

The first design I posted above looks interesting because it transfers the air completely up, but maybe it blocks also too much.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Fan backwash problem - new parts to fix July 25, 2017 07:49AM |

Registered: 6 years ago Posts: 174 |

How did that design work for you guys?

Also what is the latest update on this?

I see that you refer to the fan blowing but on my machine the fan seems to suck air from the three holes under by the print nozzle and then past the heat sink and out by the van.

Is this correct?

Edited 1 time(s). Last edit at 07/26/2017 11:29AM by Karoo Klong.

Also what is the latest update on this?

I see that you refer to the fan blowing but on my machine the fan seems to suck air from the three holes under by the print nozzle and then past the heat sink and out by the van.

Is this correct?

Quote

Treito

As I have another nozzle I would have the 4 screws. I needed 4 screws to securely connet the two pieces which hold the nozzle together. That would be not a big deal. I do not like the countersunk screw design otherwise I would have taken your design.

I guess I will first try this one:

[www.thingiverse.com]

The first design I posted above looks interesting because it transfers the air completely up, but maybe it blocks also too much.

Edited 1 time(s). Last edit at 07/26/2017 11:29AM by Karoo Klong.

|

Re: Fan backwash problem - new parts to fix July 29, 2017 08:07PM |

Registered: 10 years ago Posts: 22 |

|

Re: Fan backwash problem - new parts to fix July 31, 2017 07:47AM |

Registered: 6 years ago Posts: 174 |

Thank you Pete

I checked if the fan sucks or blows.

I was misled by the backwash from the fan. It does indeed suck air and blow it down to the nozzle.

I also understand the backwash problem much better now.

I checked if the fan sucks or blows.

I was misled by the backwash from the fan. It does indeed suck air and blow it down to the nozzle.

I also understand the backwash problem much better now.

Quote

Peterdl

The fan should BLOW out of the 3 holes by the nozzle. The fan housing should have 2 arrows on it somewhere. One arrow shows the direction of the blades and the other shows the direction of the airflow. The airflow arrow should be pointing TO the heatsink.

Pete.

Sorry, only registered users may post in this forum.