Laser cut parts edges not square.

Posted by tim_h

|

Laser cut parts edges not square. January 08, 2014 06:21AM |

Registered: 10 years ago Posts: 59 |

I've noticed the edges on my laser cut y axis ends are not square on the short sides. This means when the y axis front rod is inserted it will not sit square in the hole, this is a tight fit and has the effect of pulling both arms out of line, like a parallelogram.

I'm not sure if this will cause me a problem, but it certainly doesn't look good!

This effect of laser cut parts not having straight edges appears to be common and is due to the laser optics being out of alignment as described here.

RS Ormerod #472

I'm not sure if this will cause me a problem, but it certainly doesn't look good!

This effect of laser cut parts not having straight edges appears to be common and is due to the laser optics being out of alignment as described here.

RS Ormerod #472

|

Re: Laser cut parts edges not square. January 08, 2014 10:35AM |

Registered: 12 years ago Posts: 116 |

Hi tim_h

The one sat on my desk is like that! However, I measured the distance between the rods, and it was barely 0.1mm difference at each end. You're right, it's not pretty, and it is down to our (heavily overworked, under appreciated and probably under maintained, but still good enough) laser cutter, and the kerf it cuts (along with a small runout in alignment, probably).

Your measurements make it look like there is 2mm difference between each side, but I'm not sure the scale starts at the same point on both sides of the protractor?

Ian

RepRapPro tech support

The one sat on my desk is like that! However, I measured the distance between the rods, and it was barely 0.1mm difference at each end. You're right, it's not pretty, and it is down to our (heavily overworked, under appreciated and probably under maintained, but still good enough) laser cutter, and the kerf it cuts (along with a small runout in alignment, probably).

Your measurements make it look like there is 2mm difference between each side, but I'm not sure the scale starts at the same point on both sides of the protractor?

Ian

RepRapPro tech support

|

Re: Laser cut parts edges not square. January 08, 2014 01:09PM |

Registered: 10 years ago Posts: 59 |

Thanks Ian, I have measured the distance between rods at each end, there is 0.5mm difference between ends.

92.3mm and 92.8mm external, 68.2 and 68.7 internal.

How much of a difference is acceptable?

I have emailed you to request replacement x axis parts, if you felt the y axis arms should be changed you could post them all together.

RS Ormerod #472

92.3mm and 92.8mm external, 68.2 and 68.7 internal.

How much of a difference is acceptable?

I have emailed you to request replacement x axis parts, if you felt the y axis arms should be changed you could post them all together.

RS Ormerod #472

|

Re: Laser cut parts edges not square. February 24, 2014 12:22PM |

Registered: 10 years ago Posts: 3 |

Tim,

how did you resolve the problem? I am facing the same one right now... Quite frustrating, as the y-axis assembly is the first stage. We spent 1-2 hours trying to get the rods gently into the laser-cut acryllic parts, and when they were almost in, the assembly looked like in your picture. Actually, we ended up fracturing both parts on the last mm, so we took the whole thing apart again.

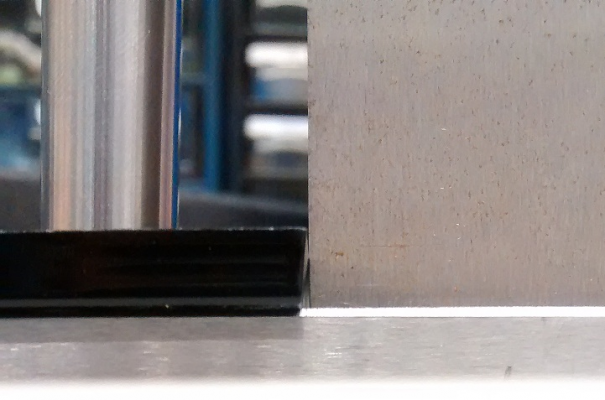

We also have the impression that the laser shot into the part at a considerable angle. This is most obvious on the outside of the part:

When you put the rod in it (which is now easier, thanks to the crack), it it crooked at a similiar angle:

Did you file the part so that the rod goes in straight, or did you end up ordering a replacement part?

how did you resolve the problem? I am facing the same one right now... Quite frustrating, as the y-axis assembly is the first stage. We spent 1-2 hours trying to get the rods gently into the laser-cut acryllic parts, and when they were almost in, the assembly looked like in your picture. Actually, we ended up fracturing both parts on the last mm, so we took the whole thing apart again.

We also have the impression that the laser shot into the part at a considerable angle. This is most obvious on the outside of the part:

When you put the rod in it (which is now easier, thanks to the crack), it it crooked at a similiar angle:

Did you file the part so that the rod goes in straight, or did you end up ordering a replacement part?

|

Re: Laser cut parts edges not square. February 24, 2014 12:49PM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Laser cut parts edges not square. February 24, 2014 07:50PM |

Registered: 10 years ago Posts: 859 |

I found when I built mine the instructions said hit with a hammer, but be careful cos the plastic might shatter....

So..... I just gripped the rod, and gently twisted it in to the holes.....

They do go in that way nearly all the way... Then I finished them off with some gentle taps with the rubber

handle of my pliers.... It went well till the pliers nipped me..... Then the air was blue....

Tim, the laser cut plastic frame your motor end looks bent, but it might be because the rods not in flush.

Try giving it a tap with something soft and gentle (like next doors cat..... I'm teasing...).

But the frame at the idler end is bowing in because either the belt is to tight, or the green printed end it

joins to is either warped or needs fetling a bit to get it true.

I had my belt to tight at one time, and it was pulling that end in. I noticed some black dust building up on the desk

that end, and realized the belt was rubbing on the printed frame part.... One of my next mod will be to make a small

ally pulley with shoulders on to stop that when I get home. The Y belt tension is a little tricky in that you don't want it to tight cos it'll

put to much load on the motor bearings, but then when the printer is working you don't want the belt to HOG as it's coming

away from the pulley. It's a case of getting that happy mix of just taught enough...

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

So..... I just gripped the rod, and gently twisted it in to the holes.....

They do go in that way nearly all the way... Then I finished them off with some gentle taps with the rubber

handle of my pliers.... It went well till the pliers nipped me..... Then the air was blue....

Tim, the laser cut plastic frame your motor end looks bent, but it might be because the rods not in flush.

Try giving it a tap with something soft and gentle (like next doors cat..... I'm teasing...).

But the frame at the idler end is bowing in because either the belt is to tight, or the green printed end it

joins to is either warped or needs fetling a bit to get it true.

I had my belt to tight at one time, and it was pulling that end in. I noticed some black dust building up on the desk

that end, and realized the belt was rubbing on the printed frame part.... One of my next mod will be to make a small

ally pulley with shoulders on to stop that when I get home. The Y belt tension is a little tricky in that you don't want it to tight cos it'll

put to much load on the motor bearings, but then when the printer is working you don't want the belt to HOG as it's coming

away from the pulley. It's a case of getting that happy mix of just taught enough...

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Laser cut parts edges not square. February 24, 2014 08:26PM |

Registered: 10 years ago Posts: 859 |

@MJH I think you'll find you can straighten that out quite simply by twisting the rod to bed it in to the hole.

The rods don't really have much depth in the plastic laser cut frames to be held true. You'd need a good

25 to 30mm for it hold it true... The main job of the laser cut frames is to hold the rods at an equal distance

from each other so the Table frame doesn't get pinched as it moves up and down...

When I do my table mod on my printer I'll be using the bearings to gently tap the frame off my rods like using

a slide hammer.... But it'll be gentle taps...

If you really find it hard work getting the rods in, then use washing up liquid on the ends of the rod as lubrication.

When assembled, just hold the joint under the hot tap, and the washing up liquid will get washed away.

(I use that dodge on all manner of things that protest about being put together, even bike and car tyres).

(BTW A drop of washing up liquid is good lubrication for putting on wood screws when screwing down floor boards and the like).

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

The rods don't really have much depth in the plastic laser cut frames to be held true. You'd need a good

25 to 30mm for it hold it true... The main job of the laser cut frames is to hold the rods at an equal distance

from each other so the Table frame doesn't get pinched as it moves up and down...

When I do my table mod on my printer I'll be using the bearings to gently tap the frame off my rods like using

a slide hammer.... But it'll be gentle taps...

If you really find it hard work getting the rods in, then use washing up liquid on the ends of the rod as lubrication.

When assembled, just hold the joint under the hot tap, and the washing up liquid will get washed away.

(I use that dodge on all manner of things that protest about being put together, even bike and car tyres).

(BTW A drop of washing up liquid is good lubrication for putting on wood screws when screwing down floor boards and the like).

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Laser cut parts edges not square. February 24, 2014 08:47PM |

Registered: 10 years ago Posts: 578 |

|

Re: Laser cut parts edges not square. February 25, 2014 01:59AM |

Registered: 10 years ago Posts: 191 |

Normally it's no problem to lasercut the parts. The .dxf is accurate as I lasercut the stuff for a second Ormerod already. They fit very good.

I think printing would be less effective.

[EDIT] It's also quite normal that lasercut parts - esp. where the laser is a bit out of focus or too weak for the part to cut - the cuts and holes get angled. Additionaly the structure of the cut differs sometimes much depending what material is used.

Markus

Edited 1 time(s). Last edit at 02/25/2014 02:07AM by markbee.

XBee & electronics blog: [lookmanowire.blogspot.com]

I think printing would be less effective.

[EDIT] It's also quite normal that lasercut parts - esp. where the laser is a bit out of focus or too weak for the part to cut - the cuts and holes get angled. Additionaly the structure of the cut differs sometimes much depending what material is used.

Markus

Edited 1 time(s). Last edit at 02/25/2014 02:07AM by markbee.

XBee & electronics blog: [lookmanowire.blogspot.com]

|

Re: Laser cut parts edges not square. February 25, 2014 12:21PM |

Registered: 10 years ago Posts: 3 |

Thanks, everyone, for the suggestions!

But the holes in our parts were simply too tight. No amount of gentle or not so gentle tapping, bending, twisting, and lubrication would help getting the rods in. We also dipped the metal rods into liquid nitrogen before trying them in (this makes the metal contract a bit) - no help.

Because of this tightness, the 4 mm board was definitely thick enough to keep the rods locked at the crooked angle - twisting did not help. The way the angles played out in both end-plates led to the parallelogram-shape that you can see in Tim's first picture. In our case, this was just after the first few steps of assembly - there was no belt or other structure that could have cause this. The fractures in the boards happened when we tried to gently bend the whole thing straight.

We did not have a 12mm drill bit handy to enlarge the holes, but we found the following solution: We took the 3d-printed parts off of the laser-cut parts, so that we only have the flat laser-cut pieces and the smooth rods to worry about. We used a heatgun to heat up the ends of the smooth rods and pushed them into the holes in laser-cut parts. The hot rods melted enough material at the side to make them go in. This procedure is a bit tricky: The plastic becomes soft and you have to carefully align everything against a square by hand. I recommend not trying to do this alone - four hands make this go a lot smoother.

But the holes in our parts were simply too tight. No amount of gentle or not so gentle tapping, bending, twisting, and lubrication would help getting the rods in. We also dipped the metal rods into liquid nitrogen before trying them in (this makes the metal contract a bit) - no help.

Because of this tightness, the 4 mm board was definitely thick enough to keep the rods locked at the crooked angle - twisting did not help. The way the angles played out in both end-plates led to the parallelogram-shape that you can see in Tim's first picture. In our case, this was just after the first few steps of assembly - there was no belt or other structure that could have cause this. The fractures in the boards happened when we tried to gently bend the whole thing straight.

We did not have a 12mm drill bit handy to enlarge the holes, but we found the following solution: We took the 3d-printed parts off of the laser-cut parts, so that we only have the flat laser-cut pieces and the smooth rods to worry about. We used a heatgun to heat up the ends of the smooth rods and pushed them into the holes in laser-cut parts. The hot rods melted enough material at the side to make them go in. This procedure is a bit tricky: The plastic becomes soft and you have to carefully align everything against a square by hand. I recommend not trying to do this alone - four hands make this go a lot smoother.

|

Re: Laser cut parts edges not square. February 25, 2014 12:25PM |

Registered: 12 years ago Posts: 1,611 |

There's always a kerf on laser cut parts, which is caused by the cone of the cutting laser. This can be reduced by using a final lens with a longer focal length. However, this problem is more due to poor alignment of the laser cutter mirrors, and usually effects parts at the extreme ends of the laser cutter bed the most.

We have recently had our lasercutter serviced (as well as buying two new ones), which should correct these problems. We're happy to replace parts if they are not going to work, or break during fitting. The Ormerod that's sat on my desk printing spare parts has the same problem, but it doesn't effect the spacing between the Y smooth rods.

Why don't we print them? Because we can laser cut them, and large flat areas are particularly suited to laser cutting. Also, it may make the difference between making all the parts fit on one bed, or needing two, so it's about efficient production.

Ian

RepRapPro tech support

We have recently had our lasercutter serviced (as well as buying two new ones), which should correct these problems. We're happy to replace parts if they are not going to work, or break during fitting. The Ormerod that's sat on my desk printing spare parts has the same problem, but it doesn't effect the spacing between the Y smooth rods.

Why don't we print them? Because we can laser cut them, and large flat areas are particularly suited to laser cutting. Also, it may make the difference between making all the parts fit on one bed, or needing two, so it's about efficient production.

Ian

RepRapPro tech support

Sorry, only registered users may post in this forum.