Prints not sticking to bed

Posted by tracyb

|

Prints not sticking to bed January 13, 2014 05:34AM |

Registered: 10 years ago Posts: 29 |

So I have finally finished all the compensation and fine tuning items and was getting down to printing my first item today. I picked the geodesic type sphere that someone else had shown to work on this machine. The first test the hotend turned off and ruined the job. The second print it did the same but I was watching and turned it back on again (happened at roughly the same place) but then after it was back printing sucessfully some filament must have built up and knocked the piece loose from the bed. Once again ruining the print.

Are there any suggestions for why that was happening? Is the piece too small? Does anyone have the gcode for something similar so that I can start experimenting with print quality? I got this from thinyverse (called zortrax-voronoi_sphere) as an stl and converted it using slic3r. I also used the correct ormerod 0.5 settings but changes the extrusion and temp settings as stated in the forums.

Edited 1 time(s). Last edit at 01/13/2014 05:34AM by tracyb.

Ormerod 313

Are there any suggestions for why that was happening? Is the piece too small? Does anyone have the gcode for something similar so that I can start experimenting with print quality? I got this from thinyverse (called zortrax-voronoi_sphere) as an stl and converted it using slic3r. I also used the correct ormerod 0.5 settings but changes the extrusion and temp settings as stated in the forums.

Edited 1 time(s). Last edit at 01/13/2014 05:34AM by tracyb.

Ormerod 313

|

Re: Prints not sticking to bed January 13, 2014 05:47AM |

Registered: 10 years ago Posts: 14,672 |

1. Are you cleaning the bed with isopropanol or acetone before each print?

2. What slic3r settings are you using? In particular, filament and bed temperatures. I found I needed about 205C and 65C using pre-0.53 firmware. With 0.53 or later firmware, 195C is about right. Increase retraction to 4mm and increase the skirt to 2 or 3 loops.

3. Are you using the filament supplied with the kit? I had big problems getting the print to stick after it ran out and I had switched to a new roll bought via Amazon, Eventually I tried a roll from a different supplier via eBay, and all was well again.

4. Getting the nozzle height above the bed at z=0 right is critical for first layer adhesion. If in doubt, heat up the bed, put the nozzle at x=100 y=100, then lower the nozzle until it grips a piece of standard 80gsm paper against the bed not too loosely. Then do G92 Z0, then print.

Edited 2 time(s). Last edit at 01/13/2014 05:49AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

2. What slic3r settings are you using? In particular, filament and bed temperatures. I found I needed about 205C and 65C using pre-0.53 firmware. With 0.53 or later firmware, 195C is about right. Increase retraction to 4mm and increase the skirt to 2 or 3 loops.

3. Are you using the filament supplied with the kit? I had big problems getting the print to stick after it ran out and I had switched to a new roll bought via Amazon, Eventually I tried a roll from a different supplier via eBay, and all was well again.

4. Getting the nozzle height above the bed at z=0 right is critical for first layer adhesion. If in doubt, heat up the bed, put the nozzle at x=100 y=100, then lower the nozzle until it grips a piece of standard 80gsm paper against the bed not too loosely. Then do G92 Z0, then print.

Edited 2 time(s). Last edit at 01/13/2014 05:49AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Prints not sticking to bed January 13, 2014 05:57AM |

Registered: 10 years ago Posts: 578 |

Hi Tracyb - it's surprising that the extruder heater is turning off - do you have an intermittent connection on your thermistor (it would read a temperature of -273ish which would then cause the firmware to turn the heater off, but I think it then latches off if it shut down for that reason). It may be worth checking though. Also maybe try reslicing and disable any temperature commands in slic3r (I manually set my temperatures before running codes so I can swap between materials without having to reslice).

As far as adhesion goes, you need to make sure there's no grease on the kapton film (clean with an alcohol or acetone before a run). I've had great success using solvent cement intended for plastic pipework (marley KS10) - both ABS and PLA stick very firmly to this, and the solvents in it degrease the glass. It tends to peel when you remove the print, but a quick dab of fresh cement blends in quickly. Try bracketing the bed temperature by up to 10 degrees or so (ie 10 degrees higher and lower than you're using now) and see if it increases adhesion. If all else fails, it might be worth printing a brim since the print overhangs quite a lot past the contact area - the brim would make a solid base with a much larger area (but you'd need to remove it afterwards).

Ray

As far as adhesion goes, you need to make sure there's no grease on the kapton film (clean with an alcohol or acetone before a run). I've had great success using solvent cement intended for plastic pipework (marley KS10) - both ABS and PLA stick very firmly to this, and the solvents in it degrease the glass. It tends to peel when you remove the print, but a quick dab of fresh cement blends in quickly. Try bracketing the bed temperature by up to 10 degrees or so (ie 10 degrees higher and lower than you're using now) and see if it increases adhesion. If all else fails, it might be worth printing a brim since the print overhangs quite a lot past the contact area - the brim would make a solid base with a much larger area (but you'd need to remove it afterwards).

Ray

|

Re: Prints not sticking to bed January 13, 2014 06:03AM |

Registered: 10 years ago Posts: 578 |

Quote

dc42

4. Getting the nozzle height above the bed at z=0 right is critical for first layer adhesion. If in doubt, heat up the bed, put the nozzle at x=100 y=100, then lower the nozzle until it grips a piece of standard 80gsm paper against the bed not too loosely. Then do G92 Z0, then print.

I do something similar - I lower by 0.1 until it just starts to grip the paper (my photocopy paper is exactly 0.10mm) then remove the paper and drop another 0.1 then do G92 Z0

I haven't been compensating the bed for sometime now, the bed is pretty level and all of my prints are less than 50mm by 50mm and I get away with doing the Z zeroing in the centre of where the print will be (normally 100,100)

Ray

|

Re: Prints not sticking to bed January 13, 2014 08:24AM |

Registered: 10 years ago Posts: 103 |

Assuming you have everything else dialled in (Z0, bed compensation, working bed heater.

The key for me is to clean the bed with pure acetone before every prints.

Even with worn Kapton tape the parts stick to the bed like sh*t to a blanket. It is actually pretty amazing to see how much effort it takes to get the parts off after a print.

I heat my bed at 60degC with PLA.

I hoave not done anything to my fan as I do not seem to suffer from backdraft. I have printed over a kilo of PLA now with parts ranging from very large to modestly small.

Hope this helps,

The key for me is to clean the bed with pure acetone before every prints.

Even with worn Kapton tape the parts stick to the bed like sh*t to a blanket. It is actually pretty amazing to see how much effort it takes to get the parts off after a print.

I heat my bed at 60degC with PLA.

I hoave not done anything to my fan as I do not seem to suffer from backdraft. I have printed over a kilo of PLA now with parts ranging from very large to modestly small.

Hope this helps,

|

Re: Prints not sticking to bed January 13, 2014 08:27AM |

Registered: 10 years ago Posts: 103 |

Assuming you have everything else dialled in (Z0, bed compensation, working bed heater) then I think it all comes down to how clean the bed is. I clean the bed with pure acetone before every prints.

Even with worn Kapton tape the parts stick to the bed like sh*t to a blanket. It is actually pretty amazing to see how much effort it takes to get the parts off after a print.

I heat my bed at 60degC with PLA.

I hoave not done anything to my fan as I do not seem to suffer from backdraft. I have printed over a kilo of PLA now with parts ranging from very large to modestly small.

Hope this helps,

Even with worn Kapton tape the parts stick to the bed like sh*t to a blanket. It is actually pretty amazing to see how much effort it takes to get the parts off after a print.

I heat my bed at 60degC with PLA.

I hoave not done anything to my fan as I do not seem to suffer from backdraft. I have printed over a kilo of PLA now with parts ranging from very large to modestly small.

Hope this helps,

|

Re: Prints not sticking to bed January 17, 2014 02:45PM |

Registered: 10 years ago Posts: 31 |

Hi Arnauld31,

Thank you for your help in the past, it is much appreciated. I can now lay plastic.

Now for a silly question

It is not clear to me, even after studying all of the assembly pictures, how the kapton tape system is meant to work,

Is the tape on the topside and thus what the filament builds on??

Some people write as though they build on the glass (as I do with moderate sucess)

Your message seems to suggest that you build on the kapton.

What should I be doing??

Baffled

Dennis

Thank you for your help in the past, it is much appreciated. I can now lay plastic.

Now for a silly question

It is not clear to me, even after studying all of the assembly pictures, how the kapton tape system is meant to work,

Is the tape on the topside and thus what the filament builds on??

Some people write as though they build on the glass (as I do with moderate sucess)

Your message seems to suggest that you build on the kapton.

What should I be doing??

Baffled

Dennis

|

Re: Prints not sticking to bed January 17, 2014 03:27PM |

Registered: 10 years ago Posts: 578 |

Hi Dennis,

That's right, you need to clean the glass, then cover it with kapton tape and keep this clean before each print (like i said above in this thread when I mentioned I find it easier and quicker to use solvent cement than the kapton). When applying the kapton, try to keep it bubble/wrinkle free and non-everlapping (I find this tricky -someone mentioned a "wet method" for applying it, but I didn't see any further details on this.

Ray

Edited 1 time(s). Last edit at 01/17/2014 03:28PM by rayhicks.

That's right, you need to clean the glass, then cover it with kapton tape and keep this clean before each print (like i said above in this thread when I mentioned I find it easier and quicker to use solvent cement than the kapton). When applying the kapton, try to keep it bubble/wrinkle free and non-everlapping (I find this tricky -someone mentioned a "wet method" for applying it, but I didn't see any further details on this.

Ray

Edited 1 time(s). Last edit at 01/17/2014 03:28PM by rayhicks.

|

Re: Prints not sticking to bed January 17, 2014 04:30PM |

Registered: 10 years ago Posts: 157 |

The first time I applied the tape, I tried the dry method.

It was difficult to place the tape without trapping air bubbles.

When I had to repair the tape, I tried this wet mount method.

It was a lot easier to correct because it did not stick to the bed,

the bubbles were easier to remove because they were droplets.

You might want to fold the edges of the tape under the glass though, mine did not stick very good...

RS-Online Ormerod #263, Kossel mini with Minitronics, Prusa i3 MK2

It was difficult to place the tape without trapping air bubbles.

When I had to repair the tape, I tried this wet mount method.

It was a lot easier to correct because it did not stick to the bed,

the bubbles were easier to remove because they were droplets.

You might want to fold the edges of the tape under the glass though, mine did not stick very good...

RS-Online Ormerod #263, Kossel mini with Minitronics, Prusa i3 MK2

|

Re: Prints not sticking to bed January 17, 2014 05:22PM |

Registered: 10 years ago Posts: 14,672 |

According to [www.matterhackers.com] you can print PLA direct on glass, if it is heated to 70C. Has anyone tried this?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Prints not sticking to bed January 17, 2014 05:22PM |

Registered: 10 years ago Posts: 578 |

|

Re: Prints not sticking to bed January 17, 2014 05:32PM |

Registered: 10 years ago Posts: 314 |

If you try printing on glass, try both sides as they are different. One has a minuscule amount of tin present from the float process. This does affect the wetting which can some times be observed with clean glass and a droplet water, or the professional method is short range UV where you see fluorescence on one side, from the tin I believe. BUT a print test will be the quickest!

Ormerod #007 (shaken but not stirred!)

Ormerod #007 (shaken but not stirred!)

|

Re: Prints not sticking to bed January 17, 2014 05:41PM |

Registered: 10 years ago Posts: 157 |

Quote

rayhicks

Ah, yes it was you 3D-ES - thanks for the link!

Actually, I'm not sure if that was me, perhaps it was and I don't remember anymore...

I should probably sleep more, but it's hard... This printer is a real sleep killer...

RS-Online Ormerod #263, Kossel mini with Minitronics, Prusa i3 MK2

|

Re: Prints not sticking to bed January 17, 2014 06:12PM |

Registered: 10 years ago Posts: 578 |

|

Re: Prints not sticking to bed January 18, 2014 08:26AM |

Registered: 10 years ago Posts: 8 |

Hi guys,

Here's another video of the 'wet process' for applying Kapton tape - it's the same concept as the video above.

I've just tried it myself, and it is much easier than applying the tape 'dry'!

[www.makerbot.com]

After applying the tape to the wet glass, use a 'squidgy' to remove air bubbles. I actually used a piece of polysterene from a disposable plate, cut to 30 x 70mm, just because I had it to hand! Be careful not to disturb the strips that you have already squeezed down when applying the subsequent strips!

There is talk on other forums of using hairspray, or solvent based adhesives on the bed.

When I get my Ormerod working, I will try an experiment with 3M Repositionable Adhesive, because I know it stays 'tacky' for quite a while and that 3M make a dedicated solvent to remove it.

Here's another video of the 'wet process' for applying Kapton tape - it's the same concept as the video above.

I've just tried it myself, and it is much easier than applying the tape 'dry'!

[www.makerbot.com]

After applying the tape to the wet glass, use a 'squidgy' to remove air bubbles. I actually used a piece of polysterene from a disposable plate, cut to 30 x 70mm, just because I had it to hand! Be careful not to disturb the strips that you have already squeezed down when applying the subsequent strips!

There is talk on other forums of using hairspray, or solvent based adhesives on the bed.

When I get my Ormerod working, I will try an experiment with 3M Repositionable Adhesive, because I know it stays 'tacky' for quite a while and that 3M make a dedicated solvent to remove it.

|

Re: Prints not sticking to bed January 18, 2014 08:42AM |

Registered: 12 years ago Posts: 1,611 |

Applying Kapton to the bed can be a taxing process, and there's no real 'knack' to it. I get to do it quite a lot on our production machines, so have got pretty used to doing it 'dry'! If you are applying it wet, you have to let it dry. You can squeegee it out, but until the water has evaporated (through the Kapton, I suppose), the Kapton won't stick well, and can take a few hours. You can put it on the printer and heat it gently, but I've never been keen doing that with all the exposed power connections and water! Put it on a radiator. You can get much wider Kapton tape and sheet - up to 200mm wide. If you're using the wet method, you may as well get wider Kapton. The reel we supply with the kit is a compromise between reasonable width, and difficult applying!

The hairspray/PVA glue/double sided carpet tape and other options are often single-use solutions, or for getting ABS to stick. Generally PLA should stick to clean Kapton, and if you're careful the Kapton should last a long time - our production printers print 20 hours a day, 6 days a week, and the Kapton lasts for around 4 months, cleaned once a week with a wipe over with clean kitchen towel and acetone.

Ian

RepRapPro tech support

The hairspray/PVA glue/double sided carpet tape and other options are often single-use solutions, or for getting ABS to stick. Generally PLA should stick to clean Kapton, and if you're careful the Kapton should last a long time - our production printers print 20 hours a day, 6 days a week, and the Kapton lasts for around 4 months, cleaned once a week with a wipe over with clean kitchen towel and acetone.

Ian

RepRapPro tech support

|

Re: Prints not sticking to bed January 18, 2014 04:44PM |

Registered: 10 years ago Posts: 1,230 |

Quote

3D-ES

The first time I applied the tape, I tried the dry method.

It was difficult to place the tape without trapping air bubbles....

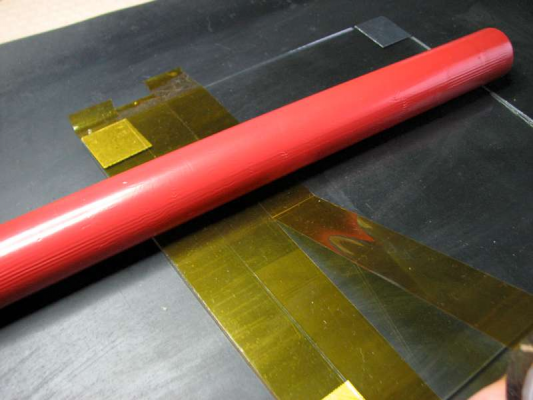

I use a ?..something-something from an old copy machine, it's made of very soft silicone rubber, perfect for the job, still not easy though, gotta keep the tape in high incoming angle to keep the air from entering...and the glass should be fixed on the table or you will need 3 hands (old pic, alu changed for flat white of cause)

Erik

|

Re: Prints not sticking to bed January 19, 2014 06:35PM |

Registered: 10 years ago Posts: 275 |

Quote

dc42

According to [www.matterhackers.com] you can print PLA direct on glass, if it is heated to 70C. Has anyone tried this?

Yes.. I'm printing directly on the glass..

[www.dropbox.com]

I do not feel comfortable with the tape

To clean the glass I use distilled malt vinegar at 80 °C

For PLA is fine.

The link you posted is really to read!

Dario

Edited 2 time(s). Last edit at 01/19/2014 07:14PM by Ormerod187.

|

Re: Prints not sticking to bed January 20, 2014 04:04AM |

Registered: 10 years ago Posts: 103 |

Quote

dc42

According to [www.matterhackers.com] you can print PLA direct on glass, if it is heated to 70C. Has anyone tried this?

have not tried but have found that I sometime get my parts cupping, sagging at the interface with the bed so have gradually reduced my bed temperature and am now printing with bed no hotter than 55deg which has cured problem of cupping. So I would not want to have to heat bed to 70deg...

|

Re: Prints not sticking to bed January 20, 2014 05:01AM |

Registered: 10 years ago Posts: 29 |

|

Re: Prints not sticking to bed January 20, 2014 10:37AM |

Registered: 10 years ago Posts: 103 |

Quote

tracyb

Surely you would only print at 70 for the first layer and then reduce for the subsequent ones?

as far as I am concerned the damage would be done anyhow, I iwill try to upload a picture later to show you what too much heat does on bed does to the parts, not a great deal when you expect parts to fit together it is enough to cause some minor upset.

i can't see the need for this anyway as discussed in another thread, I have changed the Kapton tape once in 3kg of PLA printing, and have no problem getting prints to stick to the bed with now 3 different suppliers of PLA.

Sorry, only registered users may post in this forum.