Swollen prints - any ideas?

Posted by dc42

|

Swollen prints - any ideas? January 15, 2014 12:12PM |

Registered: 10 years ago Posts: 14,672 |

I'm finding that all my prints come out slightly swollen. I've been trying to print the z-gear and z-driven gear, but the parts I print are too tight to fit on the motor spindle and bearing. If I drill/file them out so that they fit, then the teeth mesh too tightly and won't rotate. So my printed gears are swollen on the inside and the outside.

I've tried reducing the extrusion factor in slic3r, first to 0.95 and now to 0.90. This has helped somewhat, but not enough. I'm going to try reducing it even further. But why should this be necessary? I calibrated the steps/mm for the filament feed and it was spot on at 420. The filament I am using is not oversize, if anything it is nearer 1.70mm than the 1.75mm I set in slic3r.

So I have a couple of questions:

1. What is the tolerance on the diameter of the 0.5mm nozzle?

2. Are there any other factors that might be causing my prints to swell?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I've tried reducing the extrusion factor in slic3r, first to 0.95 and now to 0.90. This has helped somewhat, but not enough. I'm going to try reducing it even further. But why should this be necessary? I calibrated the steps/mm for the filament feed and it was spot on at 420. The filament I am using is not oversize, if anything it is nearer 1.70mm than the 1.75mm I set in slic3r.

So I have a couple of questions:

1. What is the tolerance on the diameter of the 0.5mm nozzle?

2. Are there any other factors that might be causing my prints to swell?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Swollen prints - any ideas? January 15, 2014 12:16PM |

Registered: 10 years ago Posts: 191 |

Hi dc42,

did you try to print the gears with lower speed, say 10mm/s? That works fine for me.

I usually slow down when I need high accuracy/ resolution.

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

did you try to print the gears with lower speed, say 10mm/s? That works fine for me.

I usually slow down when I need high accuracy/ resolution.

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

|

Re: Swollen prints - any ideas? January 15, 2014 12:34PM |

Registered: 10 years ago Posts: 14,672 |

Markus, do you reduce all the speeds to 10mm/s, or just some of them?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Swollen prints - any ideas? January 15, 2014 12:38PM |

Registered: 10 years ago Posts: 191 |

Hi dc42,

only some of them where I think they are important for finer structures like perimeter e.g.

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

only some of them where I think they are important for finer structures like perimeter e.g.

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

|

Re: Swollen prints - any ideas? January 15, 2014 12:41PM |

Registered: 10 years ago Posts: 578 |

dc42,

The Slic3r manual (or website, I forget which) recommends measuring the extrudate's width (extruded from up high and measured at a few points then using the average) to find a useful value to enter as the the nozzle size. They also suggest printing a single wall shell noting the expected thickness in the gcode then comparing to measured thickness, and using that ratio to set the extrusion factor (this last on top of the calibrations you've already done - if you have the extrusion factor set to say 0.90 and find the expected/actual width is 0.9, then you need to compound the two and set it to 0.81, or just set it to 1 before you run the test). You can quickly make a test shell by slicing a simple cube stl with no infill, no top layers, two or three bottom layers and a single perimeter (rather like the gearfail.gcode I uploaded recently) - the (newish) spiral vase slic3r option may be quicker .

to get more "accurate" prints, I find it helps to constrain the layer width - I set the default width to 0.5mm and it really does seem to help getting parts to fit.

Ray

The Slic3r manual (or website, I forget which) recommends measuring the extrudate's width (extruded from up high and measured at a few points then using the average) to find a useful value to enter as the the nozzle size. They also suggest printing a single wall shell noting the expected thickness in the gcode then comparing to measured thickness, and using that ratio to set the extrusion factor (this last on top of the calibrations you've already done - if you have the extrusion factor set to say 0.90 and find the expected/actual width is 0.9, then you need to compound the two and set it to 0.81, or just set it to 1 before you run the test). You can quickly make a test shell by slicing a simple cube stl with no infill, no top layers, two or three bottom layers and a single perimeter (rather like the gearfail.gcode I uploaded recently) - the (newish) spiral vase slic3r option may be quicker .

to get more "accurate" prints, I find it helps to constrain the layer width - I set the default width to 0.5mm and it really does seem to help getting parts to fit.

Ray

|

Re: Swollen prints - any ideas? January 15, 2014 12:58PM |

Registered: 10 years ago Posts: 191 |

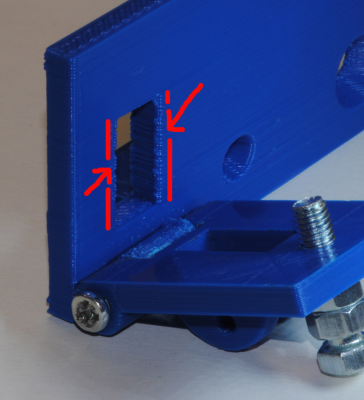

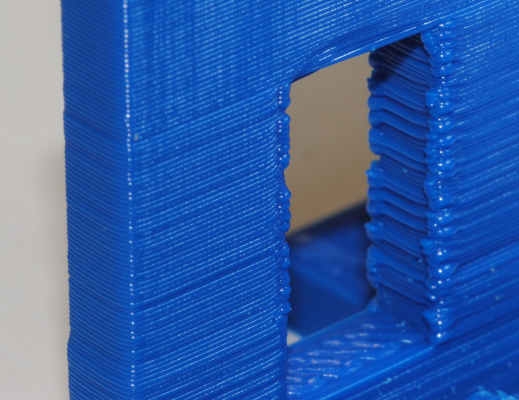

As we are talking settings - any ideas how to get rid of those "blobs" in inner edges? Outer edges are ok...

Like so:

Markus

Sorry dc42 no hijacking intended!

Edited 1 time(s). Last edit at 01/15/2014 01:20PM by markbee.

XBee & electronics blog: [lookmanowire.blogspot.com]

Like so:

Markus

Sorry dc42 no hijacking intended!

Edited 1 time(s). Last edit at 01/15/2014 01:20PM by markbee.

XBee & electronics blog: [lookmanowire.blogspot.com]

|

Re: Swollen prints - any ideas? January 15, 2014 01:17PM |

Registered: 10 years ago Posts: 2,472 |

Quote

markbee

As we are taking settings - any ideas how to get rid of those "blobs" in inner edges? Outer edges are ok...

My guess is that they are caused at the start or end of a non-print move that is made without retracting the filament. Make sure you have changed the setting to retract 4mm instead of the default of 1mm, and try a print after unticking the box that says "Only retract when crossing perimeters" in the "Print Settings" / "Infill" page of Slic3r.

Dave

(#106)

|

Re: Swollen prints - any ideas? January 15, 2014 02:06PM |

Registered: 10 years ago Posts: 578 |

|

Re: Swollen prints - any ideas? January 15, 2014 02:13PM |

Registered: 10 years ago Posts: 191 |

I'd also like the option "wipe on saturdays"

SCNR

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

SCNR

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

|

Re: Swollen prints - any ideas? January 16, 2014 04:32AM |

Registered: 10 years ago Posts: 191 |

Thx dmould and Ray,

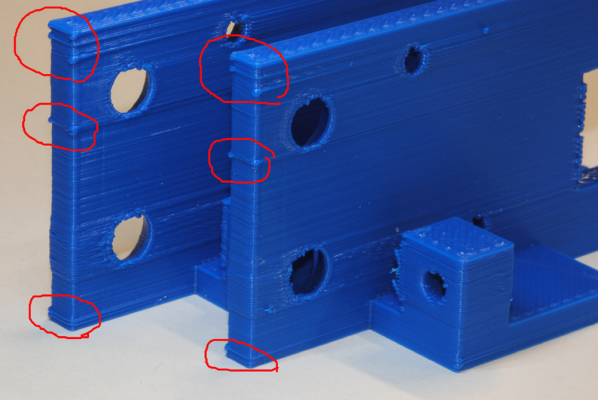

I tested those settings but still get the same result. It's even like the printing errors also on other parts of the print almost always repeat at the same places, so it could be a software/ slicer or firmware issue?

The settings for the prints shown in the photo are changed between those prints (and some more) but the errors always stays the same. Settings changed: randomize starting point, retraction length, wipe on retraction, only retract when crossing perimeters - but to no avail.

A photo of the recurring errors regardless of the settings change:

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

I tested those settings but still get the same result. It's even like the printing errors also on other parts of the print almost always repeat at the same places, so it could be a software/ slicer or firmware issue?

The settings for the prints shown in the photo are changed between those prints (and some more) but the errors always stays the same. Settings changed: randomize starting point, retraction length, wipe on retraction, only retract when crossing perimeters - but to no avail.

A photo of the recurring errors regardless of the settings change:

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

|

Re: Swollen prints - any ideas? January 16, 2014 04:41AM |

Registered: 10 years ago Posts: 578 |

one thing that seems to be happening is that the upper two circled features are on the same layer as the top or bottom of holes further along the print. if you look at the edge near the lower large hole (uncircled) you can see that the whole wall is offset a little, looking to the right of that hole, there's a line that also coincides with the top of a small hole just visible towards the rear of the print.

Maybe your head, or your table is moving a little when the head snags on these boundaries?

Ray

Maybe your head, or your table is moving a little when the head snags on these boundaries?

Ray

|

Re: Swollen prints - any ideas? January 16, 2014 04:45AM |

Registered: 10 years ago Posts: 14,672 |

Markus, I can't see that "retract only on crossing perimeters" will make much difference because that only affects infill. The critical change for me was increasing retraction to 4mm. I've also increased the max filament speed.

What extruder temperature and which firmware version are you using? I think you may have the temperature a little high.

Edited 1 time(s). Last edit at 01/16/2014 04:45AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

What extruder temperature and which firmware version are you using? I think you may have the temperature a little high.

Edited 1 time(s). Last edit at 01/16/2014 04:45AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Swollen prints - any ideas? January 16, 2014 05:03AM |

Registered: 12 years ago Posts: 116 |

Hi Markus

It looks more like a Z axis movement problem to me, like those layers are not moving up enough, so it squashes out like the filling in a sandwich. Are you on the latest firmware?

The nodules on corners look like you need to increase retraction distance and/or speed.

Ian

RepRapPro tech support

It looks more like a Z axis movement problem to me, like those layers are not moving up enough, so it squashes out like the filling in a sandwich. Are you on the latest firmware?

The nodules on corners look like you need to increase retraction distance and/or speed.

Ian

RepRapPro tech support

|

Re: Swollen prints - any ideas? January 16, 2014 05:03AM |

Registered: 10 years ago Posts: 191 |

Hi dc42,

I had retraction set to 4mm and speed to 30mm/s. Firmware was 058 but I had those errors with firmware versions before. Extruder temp is 200 for the first layer and 190 for the subsequent layer.

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

I had retraction set to 4mm and speed to 30mm/s. Firmware was 058 but I had those errors with firmware versions before. Extruder temp is 200 for the first layer and 190 for the subsequent layer.

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

|

Re: Swollen prints - any ideas? January 16, 2014 08:04AM |

Registered: 10 years ago Posts: 2,472 |

When I got slightly uneven layers I tracked it down to very occasional slipped steps in the Y axis. This happened more when the bed made small fast movements (e.g. during short non-printing moves) than when making large movements. There was no progressive movement because the machine seemed to miss steps in one direction just as often as it did in the other, so it averaged out over the whole print, but exhibited different effects on layers containing small movements than layers containing large movements - looking very similar to the effects your photos show, and layers containing holes etc. cause different moves to layers that do not. My first solution was to slow the speed to 20mm/s for all moves (printing and non-printing) and that seemed to work, but gave very long print times. Later I increased the motor current to 1000mA in the startup g file, and the problem appears to have disappeared, so now I can print at faster speeds again. In fact I should have been playing with the acceleration settings, because it is acceleration rather than speed that causes missed steps. My bed moves very easily and smoothly when the machine is switched off, and I've oiled the runner, so it's not a sticking bed - I think 800mA may be a little too low for the inertia of the bed, and 1000mA is well within the specs of the stepper motors.

Also, if the Y belt is a bit too loose there will be backlash, which I found causes a slight bulge on the edges of the print in the direction of Y movement, but the side of the bulge depends on the direction of travel that the layer was printed, so can change from layer to layer. I will definitely be trying the clothes peg trick to tension the Y belt as soon as my machine is running again (thanks to whoever posted that video).

Or maybe I mis-diagnosed the fault and am spouting rubbish - although what I did appears to have worked!

Dave

(#106)

Also, if the Y belt is a bit too loose there will be backlash, which I found causes a slight bulge on the edges of the print in the direction of Y movement, but the side of the bulge depends on the direction of travel that the layer was printed, so can change from layer to layer. I will definitely be trying the clothes peg trick to tension the Y belt as soon as my machine is running again (thanks to whoever posted that video).

Or maybe I mis-diagnosed the fault and am spouting rubbish - although what I did appears to have worked!

Dave

(#106)

|

Re: Swollen prints - any ideas? January 16, 2014 09:18AM |

Registered: 10 years ago Posts: 12 |

Quote

dmould

Also, if the Y belt is a bit too loose there will be backlash, which I found causes a slight bulge on the edges of the print in the direction of Y movement, but the side of the bulge depends on the direction of travel that the layer was printed, so can change from layer to layer. I will definitely be trying the clothes peg trick to tension the Y belt as soon as my machine is running again (thanks to whoever posted that video).

Dave

(#106)

That was me

- I was getting offsets in layers along the Y axis before using it which I presumed was from the direction changes as I could see the belt flexing.

- I was getting offsets in layers along the Y axis before using it which I presumed was from the direction changes as I could see the belt flexing. Daryl

RS Ormerod #299

Sorry, only registered users may post in this forum.