Slack!

Posted by kwikius

Video speaks for itself I think: Clearly this method of fastening the y belt just doesnt cut it! This has to be the reason for all the problems I have had in shear. Will certainly try the fix proposed in the y-axis ideas thread

Slack (Youtube)!

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

Slack (Youtube)!

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Slack! January 16, 2014 06:54PM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Slack! January 16, 2014 07:44PM |

Registered: 10 years ago Posts: 27 |

As Ian above said, a cable tie is a solution to your issue.

See this thread - hopefully will make it clearer.

Regards,

Simon

RS Ormerod No 192

See this thread - hopefully will make it clearer.

Regards,

Simon

RS Ormerod No 192

|

Re: Slack! January 17, 2014 04:38AM |

Registered: 10 years ago Posts: 256 |

Quote

droftarts

Put a cable tie around the two belts, on the left hand side of the rib, and push it up to the rib, then tighten. That stops it.

Ian

RepRapPro tech support

I have no doubt that fixes it but its not very elegant. The way the belt is fixed to the bed justs looks like a temporary bodge up and so after spending my £600, a long list of fixes I spent another day on another wild goose chase changing acceleration motor current etc etc.. The fun is starting to go out of finding the next issue and then trying to figure out a satisfactory solution

.

. regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Slack! January 18, 2014 06:24AM |

Registered: 10 years ago Posts: 256 |

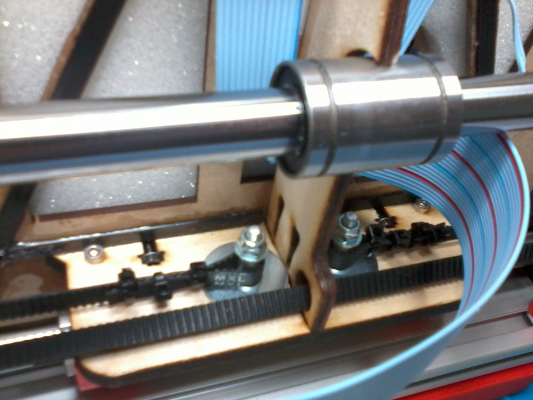

Well I hope that I have fixed this.

The solution is based on Iamburnys solution here, however since I had already dismantled the printer I decided to make something from what I had rather than putting it back together to print that out.

On the rear side of the 6 mm ply y axis cross rib ( where the two linear bearings go), I glued on a piece of 3 mm dural between the bearings, drilled and countersunk that for the M4 screws. There is about 4 mm clearance back there to the ground rod so just enough room for a 3 mm plate. On the front I slipped some 6 mm od 4 mm id ally tube onto the screw as the posts. The m4 washers at each end of the tube prevent the belt slipping off. Penny washers were added to spread the load on the ply to prevent play developing as time goes by. I rounded it off with some nyloc nuts for good measure. I used cable ties to make loops on the belt. The only thing that I can see going wrong is the belt slipping along the cable ties. Other than that it seems bulletproof.

So we shall see!

regards

Andy

Edited 1 time(s). Last edit at 01/18/2014 06:47AM by kwikius.

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

The solution is based on Iamburnys solution here, however since I had already dismantled the printer I decided to make something from what I had rather than putting it back together to print that out.

On the rear side of the 6 mm ply y axis cross rib ( where the two linear bearings go), I glued on a piece of 3 mm dural between the bearings, drilled and countersunk that for the M4 screws. There is about 4 mm clearance back there to the ground rod so just enough room for a 3 mm plate. On the front I slipped some 6 mm od 4 mm id ally tube onto the screw as the posts. The m4 washers at each end of the tube prevent the belt slipping off. Penny washers were added to spread the load on the ply to prevent play developing as time goes by. I rounded it off with some nyloc nuts for good measure. I used cable ties to make loops on the belt. The only thing that I can see going wrong is the belt slipping along the cable ties. Other than that it seems bulletproof.

So we shall see!

regards

Andy

Edited 1 time(s). Last edit at 01/18/2014 06:47AM by kwikius.

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Slack! January 18, 2014 06:39AM |

Registered: 12 years ago Posts: 1,611 |

Andy - Nice! I think bullet-proof is an understatement... The other nice thing about this is that, though you have to cut off half-a-dozen cable ties (2 is usually plenty - if I'm doing this I usually use one and go around twice), when you adjust the belt tension you get half-tooth adjustments, and you can do it from one side of the belt, which tends to make it a bit easier.

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: Slack! January 18, 2014 07:13AM |

Registered: 10 years ago Posts: 578 |

Nice idea

I printed and fitted Matt's solution yesterday - which works fine (thanks Matt), but doing your mod would have saved me an hour or two and it's probably much easier to tension than on Matt's the belt was a very tight fit the way I printed it . One advantage of Matt's is that the two clamps butt up to the rear support and stop the rib swaying (adding to the rigidity of the table and preventing the little wiggle around Z I'd been having).

Cheers

Ray

I printed and fitted Matt's solution yesterday - which works fine (thanks Matt), but doing your mod would have saved me an hour or two and it's probably much easier to tension than on Matt's the belt was a very tight fit the way I printed it . One advantage of Matt's is that the two clamps butt up to the rear support and stop the rib swaying (adding to the rigidity of the table and preventing the little wiggle around Z I'd been having).

Cheers

Ray

|

Re: Slack! January 18, 2014 07:22AM |

Registered: 10 years ago Posts: 256 |

Thanks droftarts ! I will have to try the single cable tie idea, though I hope now I wont have to take it apart again for a while! ( Just getting on to setting it up to try prining again now...)

Without much trouble it could be modified ( secure the screw to y- axis cross rib with a nut before slipping on the tube over it, or get some M4 threaded standoffs in place of the tube) so that removing one of the nuts and washers means you could slip that end of the belt on and off easily, making tensioning and maintenance simple.

regards

Andy

Edited 1 time(s). Last edit at 01/18/2014 07:22AM by kwikius.

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

Without much trouble it could be modified ( secure the screw to y- axis cross rib with a nut before slipping on the tube over it, or get some M4 threaded standoffs in place of the tube) so that removing one of the nuts and washers means you could slip that end of the belt on and off easily, making tensioning and maintenance simple.

regards

Andy

Edited 1 time(s). Last edit at 01/18/2014 07:22AM by kwikius.

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Slack! January 18, 2014 07:37AM |

Registered: 10 years ago Posts: 256 |

Quote

rayhicks

Nice idea

I printed and fitted Matt's solution yesterday - which works fine (thanks Matt), but doing your mod would have saved me an hour or two and it's probably much easier to tension than on Matt's the belt was a very tight fit the way I printed it . One advantage of Matt's is that the two clamps butt up to the rear support and stop the rib swaying (adding to the rigidity of the table and preventing the little wiggle around Z I'd been having).

Cheers

Ray

Thanks. FWIW I used a generous fillet of cyanoacrylate on every joint I could find beween all the y-axis ply and mdf parts. I have a feeling that works well .. In fact with the addition of that and carbon fibre reinforcement as described here, I think there is probably now less give in the bed transmission so that slipping at the belt/bed joint became more of a problem since there is more strain on it.

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Slack! : SOLVED January 18, 2014 11:48AM |

Registered: 10 years ago Posts: 256 |

Sorry, only registered users may post in this forum.