Nozzle too high

Posted by 9600

|

Nozzle too high January 17, 2014 05:05PM |

Registered: 10 years ago Posts: 2 |

Hello,

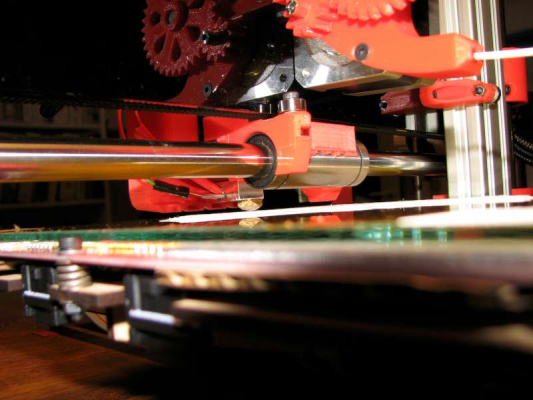

I've assembled one of the early kits (#005) and it's working fine in terms of axis movement, homing and extruding. However, when setting Z I can't seem to get the nozzle any closer than 2-3mm from the bed before the proximity sensor crashes into it. So, as you can imagine, if you attempt to print something it doesn't stick.

I did wonder if the X plate/rib or aluminium extrusion might be twisted, but I checked these over and everything seems fine. Also, when attempting to print something the fan duct pushes the bulldog clips off the bed as it moves to one end — which again suggests to me that the hot end is too low / nozzle too high. I did also re-check the hot end and the nozzle is set up so that the cone of the nozzle continues the cone of the nut etc.

Any ideas?

Cheers,

Andrew

I've assembled one of the early kits (#005) and it's working fine in terms of axis movement, homing and extruding. However, when setting Z I can't seem to get the nozzle any closer than 2-3mm from the bed before the proximity sensor crashes into it. So, as you can imagine, if you attempt to print something it doesn't stick.

I did wonder if the X plate/rib or aluminium extrusion might be twisted, but I checked these over and everything seems fine. Also, when attempting to print something the fan duct pushes the bulldog clips off the bed as it moves to one end — which again suggests to me that the hot end is too low / nozzle too high. I did also re-check the hot end and the nozzle is set up so that the cone of the nozzle continues the cone of the nut etc.

Any ideas?

Cheers,

Andrew

|

Re: Nozzle too high January 17, 2014 05:18PM |

Registered: 12 years ago Posts: 1,611 |

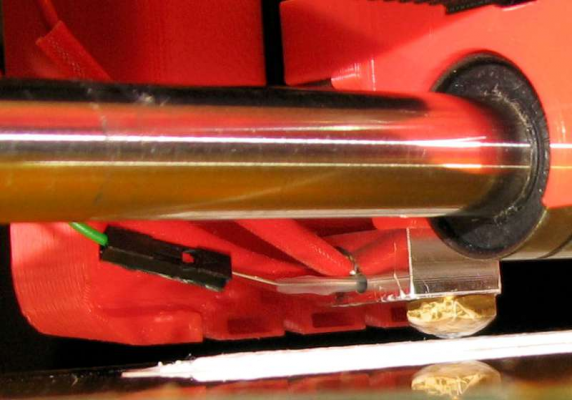

- Check the Bowden tube brass union is screwed all the way into the aluminium block, and the stainless one-piece nozzle screws up against it. If you can see any thread of the brass union, it's too high; this will lift the nozzle relative to the fan ducts and proximity sensor.

- Check you have put the mdf spacer between the printed nozzle mount and the aluminium cooling block.

- Looking along the x axis, check the hot end is square, not sagging down. Adjust the x-carriage idler bearing (on the back of the x-axis-plate), to lift the hot end up.

- You can put a couple of extra washers between the mdf spacer and aluminium cooling block, if you are still having problems.

Post a picture if this doesn't help.

Ian

RepRapPro tech support

- Check you have put the mdf spacer between the printed nozzle mount and the aluminium cooling block.

- Looking along the x axis, check the hot end is square, not sagging down. Adjust the x-carriage idler bearing (on the back of the x-axis-plate), to lift the hot end up.

- You can put a couple of extra washers between the mdf spacer and aluminium cooling block, if you are still having problems.

Post a picture if this doesn't help.

Ian

RepRapPro tech support

|

Re: Nozzle too high January 17, 2014 05:36PM |

Registered: 10 years ago Posts: 314 |

With my build and everything square and aligned on #007, but I still had this issue.

[edit] typos

Edited 2 time(s). Last edit at 01/17/2014 05:38PM by Treth.

Ormerod #007 (shaken but not stirred!)

Solved this perfectly, and I believe also gives improved thermal insulation due to the air gap, but this may be insignificant compared to the route throgh the scres, but certainly does no harm.Quote

droftarts

- You can put a couple of extra washers between the mdf spacer and aluminium cooling block, if you are still having problems.

[edit] typos

Edited 2 time(s). Last edit at 01/17/2014 05:38PM by Treth.

Ormerod #007 (shaken but not stirred!)

|

Re: Nozzle too high January 17, 2014 05:38PM |

Registered: 10 years ago Posts: 14,672 |

Quote

9600

Also, when attempting to print something the fan duct pushes the bulldog clips off the bed as it moves to one end

That is unfortunately intrinsic to the design. See item 7 in my unofficial troubleshooting guide at [forums.reprap.org]. For the sensor hitting the bed before the nozzle does, see Ian's reply. You can also adjust the sensor height a little because the screw holes in it are a little oversize.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Nozzle too high January 17, 2014 06:23PM |

Registered: 10 years ago Posts: 578 |

On top of all of the useful stuff Ian wrote: On mine I also found that looking along Y and making sure that the whole thing was level also helped - I loosened off the screws holding the fan duct to the heatsink and mount, then twisted the assembly until it was level to the bed's X axis (ie looking from the Y motor along the Y axis, the bottom of the orange case is horizontal relative to teh bed and the x axis rib) then I tightened up the screws and that massively diminished the number of drag-offs I had from the fan ducts (which were almost always from the corner opposite the z-probe)Quote

droftarts

- Looking along the x axis, check the hot end is square, not sagging down. Adjust the x-carriage idler bearing (on the back of the x-axis-plate), to lift the hot end up.

Ray

|

Re: Nozzle too high January 18, 2014 08:46PM |

Registered: 10 years ago Posts: 9 |

My sensor is fine but the fan duct keeps hitting the bed clip no matter what I do. (pic attached)

Is the only solution for this is to get new clips?

Also I tried adjusting the x carriage idler bearing but it doesn't really make much difference. At the tightest angle, the carriage still sags a little bit. Is it supposed to do that?

Is the only solution for this is to get new clips?

Also I tried adjusting the x carriage idler bearing but it doesn't really make much difference. At the tightest angle, the carriage still sags a little bit. Is it supposed to do that?

|

Re: Nozzle too high January 19, 2014 02:36AM |

Registered: 10 years ago Posts: 314 |

I think everyone has removed that clip for this reason!

I run my bed with the three remaining clips without problems, but I will follow the modified clip post (which I can't find!) where the top side is cut down to make it flat. You need a adapter to get it on the bed, but the design of this was also covered.

There has also been some posts using glass picture frame clips which also look good.

Ormerod #007 (shaken but not stirred!)

I run my bed with the three remaining clips without problems, but I will follow the modified clip post (which I can't find!) where the top side is cut down to make it flat. You need a adapter to get it on the bed, but the design of this was also covered.

There has also been some posts using glass picture frame clips which also look good.

Ormerod #007 (shaken but not stirred!)

|

Re: Nozzle too high January 19, 2014 02:55AM |

Registered: 10 years ago Posts: 256 |

Quote

Treth

I think everyone has removed that clip for this reason!

I run my bed with the three remaining clips without problems, but I will follow the modified clip post (which I can't find!) where the top side is cut down to make it flat. You need a adapter to get it on the bed, but the design of this was also covered.

There has also been some posts using glass picture frame clips which also look good.

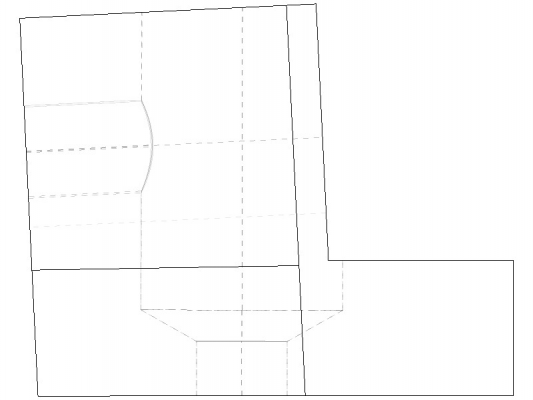

Modified clips

Alternative clips and discussion of the problem

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Nozzle too high January 19, 2014 04:01AM |

Registered: 10 years ago Posts: 1,230 |

Quote

ntroufan

My sensor is fine but the fan duct keeps hitting the bed clip no matter what I do. (pic attached)

You can also slice of a bit of the fan duct, did, about 1-2mm as far as I remember, you don't have to leave much, it's low pressure air, use new sharp sandpaper only

Quote

Is the only solution for this is to get new clips?

You could try "the stiff upper lip clip mod" Andy is linking to, did ;-)

Quote

Also I tried adjusting the x carriage idler bearing but it doesn't really make much difference. At the tightest angle, the carriage still sags a little bit. Is it supposed to do that?

I changed the bearing for a 10mm (623), same inner D

Erik

|

Re: Nozzle too high January 20, 2014 02:19AM |

Registered: 10 years ago Posts: 29 |

I had the same problem and fixed it by adding a few washers to the screws attached to the head to lift it a bit. It will still crash into the clip if you leave in unmodified but I can get right onto the bead without the sensor touching.

Edited 1 time(s). Last edit at 01/20/2014 02:47AM by tracyb.

Ormerod 313

Edited 1 time(s). Last edit at 01/20/2014 02:47AM by tracyb.

Ormerod 313

|

Re: Nozzle too high February 09, 2014 05:20AM |

Registered: 10 years ago Posts: 132 |

I finally got tired of looking at the exruder drooping slightly. No adjustment of the x-carriage idler bearing would make the extruder level. Got it so tight at one point that it locked the X carrage

I have modified the nozzle support to put a slight angle on it to compensate for the droop. Now with the X idler bearing fairly loose the extruder sits level and lifts the air vents higher above the print I have attached the STL if anyone would like a copy

I have modified the nozzle support to put a slight angle on it to compensate for the droop. Now with the X idler bearing fairly loose the extruder sits level and lifts the air vents higher above the print I have attached the STL if anyone would like a copy

Sorry, only registered users may post in this forum.