Prerequisites for printing?

Posted by adsoftware

|

Prerequisites for printing? January 20, 2014 04:51PM |

Registered: 10 years ago Posts: 23 |

Hi all, is there any precondition for printing, so if temperature of hot end or bed isn't reported to the board, it won't start the print?

(Reason for asking: I know my cable has to be sorted out, so there is no hot end temperature until tomorrow morning and printing is being refused by Mr Ormerod for now)

Which interface are you guys using to start a print, Web UI, PronterFace or any other?

(Reason for asking: I know my cable has to be sorted out, so there is no hot end temperature until tomorrow morning and printing is being refused by Mr Ormerod for now)

Which interface are you guys using to start a print, Web UI, PronterFace or any other?

|

Re: Prerequisites for printing? January 20, 2014 06:41PM |

Registered: 10 years ago Posts: 14,672 |

If you are trying to print a real part, then the gcode file will include a "set temperature and wait till reached" or a "wait for correct temperatures" command. So you can't print a part without the hot end temperature being reported. OTOH you can "print" circle.g because it doesn't actually wait for temperatures or do any extrusion.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Prerequisites for printing? January 20, 2014 07:53PM |

Registered: 10 years ago Posts: 23 |

Good to know that gcode file determines the condition, just opened a file that says:

M190 S65 ; wait for bed temperature to be reached

M109 S205 ; wait for temperature to be reached

Alright, now if I click "Extrude" in PronterFace, I get the juice out of the nozzle at ca 200 C. Starting a print request " Snow Man", the printer mimics to print, but no plastic is flowing, it moves according to the gcode file xyz, printing air (and temperature is on line)? I'm stuck.

M190 S65 ; wait for bed temperature to be reached

M109 S205 ; wait for temperature to be reached

Alright, now if I click "Extrude" in PronterFace, I get the juice out of the nozzle at ca 200 C. Starting a print request " Snow Man", the printer mimics to print, but no plastic is flowing, it moves according to the gcode file xyz, printing air (and temperature is on line)? I'm stuck.

|

Re: Prerequisites for printing? January 21, 2014 03:35AM |

Registered: 10 years ago Posts: 14,672 |

Are the extruder gears moving, if so, how?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Prerequisites for printing? January 21, 2014 05:08AM |

Registered: 10 years ago Posts: 23 |

The extruder gears are moving, however all few seconds they hackle terribly and move reverse a little. I think they have a hard time to get the filament through the nozzle end. Previously, the filament baked a little together with the tube at the heater end which I cut and cleaned. I suspect, the nozzle is rather dirty inside, because I'm seeing a dark white plastic coming out at times. So, how would I clean the nozzle anyway?

|

Re: Prerequisites for printing? January 21, 2014 05:20AM |

Registered: 10 years ago Posts: 14,672 |

Have you tried extruding filament until it comes through smoothly and clean? But check the nozzle height as well. Put the nozzle at x=100 y=100 and slowly lower it until it grips a piece of standard 80gsm paper. Then send G92 Z0.

Edited 1 time(s). Last edit at 01/21/2014 05:22AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 01/21/2014 05:22AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Prerequisites for printing? January 21, 2014 05:32AM |

Registered: 12 years ago Posts: 116 |

For cleaning the nozzle out, it's the same as changing filament/clearing a blocked nozzle (though you may have to do it a couple of times):

1. Heat nozzle to operating temperature (200C for PLA)

2. Extrude a little filament, like 10mm (if possible)

3. Set temperature to 100C

4. Wait for the temperature to drop to 100C, then reverse filament until it comes out of the extruder drive (about 380mm). You can do this at 600mm/min, or by hand if you wish.

5. This should pull out most of the filament, hopefully down to the nozzle. (Also useful for clearing nozzle blockages - repeat as necessary)

6. Command M84 to turn the motors off. Feed the new filament in by hand.

7. Drive/feed the filament to just before the hot end.

8. Set temperature to operating temperature

9. Command the filament to extrude short lengths at 200mm/min until it squirts out of the nozzle. You may need to hold the bowden tube straight for the filament to go down into the hot end easily.

Ian

RepRapPro tech support

1. Heat nozzle to operating temperature (200C for PLA)

2. Extrude a little filament, like 10mm (if possible)

3. Set temperature to 100C

4. Wait for the temperature to drop to 100C, then reverse filament until it comes out of the extruder drive (about 380mm). You can do this at 600mm/min, or by hand if you wish.

5. This should pull out most of the filament, hopefully down to the nozzle. (Also useful for clearing nozzle blockages - repeat as necessary)

6. Command M84 to turn the motors off. Feed the new filament in by hand.

7. Drive/feed the filament to just before the hot end.

8. Set temperature to operating temperature

9. Command the filament to extrude short lengths at 200mm/min until it squirts out of the nozzle. You may need to hold the bowden tube straight for the filament to go down into the hot end easily.

Ian

RepRapPro tech support

|

Re: Prerequisites for printing? January 21, 2014 12:34PM |

Registered: 10 years ago Posts: 145 |

|

Re: Prerequisites for printing? January 21, 2014 12:36PM |

Registered: 10 years ago Posts: 256 |

Quote

GregL

Just trying my first print - Ormaxis

Concerned that the extruder will sit chattering, when it should clearly be extruding along a long run.

I have to help it turn.

What to do?

Greg

Stop it. Sounds like the nozzle maybe be blocked!

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: Prerequisites for printing? January 21, 2014 12:50PM |

Registered: 10 years ago Posts: 14,672 |

Quote

GregL

Just trying my first print - Ormaxis

Concerned that the extruder will sit chattering, when it should clearly be extruding along a long run.

I have to help it turn.

What to do?

Greg

It may just mean that the head is too low, Test whether it will extrude filament reliably with the head well above the bed. If so, try another print, but don't put the head so close to the bed. It needs to be about 0.1mm above the bed at Z=0.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Prerequisites for printing? January 21, 2014 05:25PM |

Registered: 10 years ago Posts: 23 |

|

Re: Prerequisites for printing? January 22, 2014 05:06AM |

Registered: 10 years ago Posts: 145 |

Ran Ian's 'unblocking' routine -except it refused to extrude at a set temp of 200.

At 205, I could extrude 10mm, then retract once the temp. came down to 100.

No obvious debris to be spotted.

Maybe I need to run it at +5C over normal settings.

One potential problem just spotted when monitoring bed and hot end temps at ambient temperature.

Bed seems rock solid at 21.7, but the extruder is erratic. Mostly 15.6, but it will randomly jump to 18.6, 12.3, 3.6, 8.4

What is going on there?

Ormerod #17

At 205, I could extrude 10mm, then retract once the temp. came down to 100.

No obvious debris to be spotted.

Maybe I need to run it at +5C over normal settings.

One potential problem just spotted when monitoring bed and hot end temps at ambient temperature.

Bed seems rock solid at 21.7, but the extruder is erratic. Mostly 15.6, but it will randomly jump to 18.6, 12.3, 3.6, 8.4

What is going on there?

Ormerod #17

|

Re: Prerequisites for printing? January 22, 2014 05:16AM |

Registered: 10 years ago Posts: 14,672 |

Quote

GregL

Maybe I need to run it at +5C over normal settings.

Which firmware version are you using? Send M115 in Pronterface to find out, and upgrade to 0.57a if you are not already running it. Old versions of the firmware over-reported the extruder temperature.

Quote

GregL

Bed seems rock solid at 21.7, but the extruder is erratic. Mostly 15.6, but it will randomly jump to 18.6, 12.3, 3.6, 8.4

What is going on there?

The extruder thermistor measurement circuit is designed to produce accurate results at extrusion temperatures. At low temperatures the digitisation means that the temperature readout will jump between values rather than go smoothly between them. So getting occasional readings of 12.3 and 18.6 when you normally see 15.3 is quite normal. The 3.6 and 8.4 readings are probably caused by noise.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Prerequisites for printing? January 23, 2014 10:25AM |

Registered: 10 years ago Posts: 145 |

Still have the same problem on trying to print the Ormaxis - extruder stutters.

Although set at 205, the hot end was mostly around the 201.5 region.

Should I:

1. Set the hot end higher still

2. Increase the amps on the extruder motor (if so how?)

3. take the hot end apart and re-assemble

Greg

PS firmware was and still is 057a

Ormerod #17

Although set at 205, the hot end was mostly around the 201.5 region.

Should I:

1. Set the hot end higher still

2. Increase the amps on the extruder motor (if so how?)

3. take the hot end apart and re-assemble

Greg

PS firmware was and still is 057a

Ormerod #17

|

Re: Prerequisites for printing? January 23, 2014 10:54AM |

Registered: 10 years ago Posts: 14,672 |

Quote

GregL

Still have the same problem on trying to print the Ormaxis - extruder stutters.

Although set at 205, the hot end was mostly around the 201.5 region.

Should I:

1. Set the hot end higher still

2. Increase the amps on the extruder motor (if so how?)

3. take the hot end apart and re-assemble

Greg

PS firmware was and still is 057a

If you lift the nozzle well above the bed and heat it to 200C, can you extrude filament smoothly?

- If no, you have a nozzle blockage, possibly some PTFE in it. I suggest you dismantle the nozzle assembly.

- If yes but it stutters when trying to print the first layer, then the nozzle is too close to the bed when you start printing.

- If yes and it is OK on the first layer but stutters on subsequent layers, then the z drive is not working properly. Check you are running the latest firmware, and that the z-gears are rotating smoothly. I had this problem when the gears were too stiff.

Edited 2 time(s). Last edit at 01/23/2014 10:56AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Prerequisites for printing? January 23, 2014 01:15PM |

Registered: 10 years ago Posts: 578 |

GregL - check that the E motor connector is properly seated on the board (mines come loose a couple of times and it results in the extruder twitching). If the stutter is a definite grinding and slipping, then you should make sure to retract the filament and chop it back to where it has worn out once you've fixed the original issue - the hobbed bolt will have worn away the filament where it stalled and won't be able to get a grip.

It may be worth letting the hotend drop to 100, then pulling the filament out (after cutting power to the motors) - the solidifying plug in the extruder may bring debris with it (also, jamming can be caused by heat tracking up higher into the filament and softening it - this then jams the hotend, letting it cool a bit then pulling back can help in this scenario too).

Ray

It may be worth letting the hotend drop to 100, then pulling the filament out (after cutting power to the motors) - the solidifying plug in the extruder may bring debris with it (also, jamming can be caused by heat tracking up higher into the filament and softening it - this then jams the hotend, letting it cool a bit then pulling back can help in this scenario too).

Ray

|

Re: Prerequisites for printing? January 23, 2014 01:50PM |

Registered: 10 years ago Posts: 2,472 |

Take out the tongue that holds the bowden tube into the extruder, and extrude 300mm of filament - which will push the bowden tube out of the extruder and give you a length of filament to the bowden tube. Then heat the hotend to 200 and try to extrude by pushing the filament into the bowden tube by hand. If that is not possible or requires very strong force, set the hotend temperature to 240 degrees and try again - just in case your thermistor is over-reading by a large amount. If you still cannot push the filament by hand, your nozzle is blocked - let it cool to 100 or so and pull the filament out slowly by hand. Then dismantle the hotend and check it carefully - I used a hot air gun on the upside-down nozzle and a bit of thin wire (a single strand of copper from a flex) to clear the hole. A Primus stove pricker would probably be better.

If you can extrude the filament reasonably easily by hand but the extruder stutters, your extruder gears are not turning smoothly - perhaps you left out a washer on a bearing? Take it off, disassemble and find the problem - it should easily drive a filament by hand (with bowden tube disconnected), with the filament being very difficult to move at all if the gears are held immobile.

Dave

(#106)

If you can extrude the filament reasonably easily by hand but the extruder stutters, your extruder gears are not turning smoothly - perhaps you left out a washer on a bearing? Take it off, disassemble and find the problem - it should easily drive a filament by hand (with bowden tube disconnected), with the filament being very difficult to move at all if the gears are held immobile.

Dave

(#106)

|

Re: Prerequisites for printing? January 24, 2014 03:03AM |

Registered: 10 years ago Posts: 145 |

@Dave

At 200C, gentle pressure on the filament is enough to extrude. With the motors off, I can turn the big extruder cog to extrude - but the force is not the same. Implication that the two cogs are not perfectly matched all the way round. I shall investigate.

@Ray

All the motor connectors look OK at the Duet.

@dc42

I am happy that there is not a blockage (I had previously run Ian's unblocking technique - with no offending particles found)

I do have a problem with the Z gears: the rod movement is eccentric at the Z gear, and there is cyclic noise clearly associated with the rotation of the gear. I have also had quite a few inconsistencies when trying the bed levelling - ie go back to the first point to find its Z level has changed. How do I tackle those Z gears?

Greg

Ormerod #17

At 200C, gentle pressure on the filament is enough to extrude. With the motors off, I can turn the big extruder cog to extrude - but the force is not the same. Implication that the two cogs are not perfectly matched all the way round. I shall investigate.

@Ray

All the motor connectors look OK at the Duet.

@dc42

I am happy that there is not a blockage (I had previously run Ian's unblocking technique - with no offending particles found)

I do have a problem with the Z gears: the rod movement is eccentric at the Z gear, and there is cyclic noise clearly associated with the rotation of the gear. I have also had quite a few inconsistencies when trying the bed levelling - ie go back to the first point to find its Z level has changed. How do I tackle those Z gears?

Greg

Ormerod #17

|

Re: Prerequisites for printing? January 24, 2014 03:48AM |

Registered: 10 years ago Posts: 14,672 |

Quote

GregL

I do have a problem with the Z gears: the rod movement is eccentric at the Z gear, and there is cyclic noise clearly associated with the rotation of the gear. I have also had quite a few inconsistencies when trying the bed levelling - ie go back to the first point to find its Z level has changed. How do I tackle those Z gears?

Greg

My z-rod was eccentric at the z-driven-gear too, but that didn't cause a problem. What did cause a problem is that after I printed a new z-driven gear to try to stop the z-wobble, the gears became stiff at one point in the rotation, causing the stepper to miss steps sometimes. With the power off, try turning the threaded rod by hand. It should turn easily and should not tend to stick at any particular point in the rotation. If it does, then mark the teeth that mesh when it sticks, take the gears off, examine them and fettle as necessary.

Edited 2 time(s). Last edit at 01/24/2014 08:28AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Prerequisites for printing? January 24, 2014 08:06AM |

Registered: 10 years ago Posts: 2,472 |

I found that if the plastic gears are stiff to turn, first remove and file off any obvious nibs with a needle file, then reassemble and put a bit of valve grinding paste on the teeth and rotate by hand for a while to wear them in (paste available in car parts stores, e.g. "Halfords" in the UK). Then wash off all the paste and replace with a small dab of grease before putting back into service. Don't overdo the grinding else the gears will be too loose & have backlash.

I've not had to do that with any of the Ormerod gears, but I have with the gears on some of my own designs.

Dave

(#106)

I've not had to do that with any of the Ormerod gears, but I have with the gears on some of my own designs.

Dave

(#106)

|

Re: Prerequisites for printing? January 24, 2014 10:25AM |

Registered: 10 years ago Posts: 145 |

Dis-assembled the extruder gear, and looked carefully at it.

What I discovered, I should have seen and attended to at first assembly.

1.The motor spindle was rubbing on the Extruder drive block - partly from a small blob where a corner of the motor went, but mostly because the hole was not concentric with the spindle. A little file sorted that.

2.The large extruder gear teeth were slightly too tall for the small gear. Took the tops off a tad.

3.The motor and spindle were not perfectlty square with the Extruder drive block, and the small gear had clearly been rubbing on it over about a 45 degree arc. Made sure the small gear was not pressed too firmly down, added one extra washer to the large gear assembly, and gave a squirt of Graphite Lock Lube under the small gear.

Result is a much freer running extruder; much easier to turn by hand.

Now to set up the bed, and run a trial print (after the grandchildren have gone)

How long does the Ormaxis take to print?

Greg

Ormerod #17

What I discovered, I should have seen and attended to at first assembly.

1.The motor spindle was rubbing on the Extruder drive block - partly from a small blob where a corner of the motor went, but mostly because the hole was not concentric with the spindle. A little file sorted that.

2.The large extruder gear teeth were slightly too tall for the small gear. Took the tops off a tad.

3.The motor and spindle were not perfectlty square with the Extruder drive block, and the small gear had clearly been rubbing on it over about a 45 degree arc. Made sure the small gear was not pressed too firmly down, added one extra washer to the large gear assembly, and gave a squirt of Graphite Lock Lube under the small gear.

Result is a much freer running extruder; much easier to turn by hand.

Now to set up the bed, and run a trial print (after the grandchildren have gone)

How long does the Ormaxis take to print?

Greg

Ormerod #17

|

Re: Prerequisites for printing? January 24, 2014 11:46AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Prerequisites for printing? January 25, 2014 06:15AM |

Registered: 10 years ago Posts: 145 |

Well, just about an hour into my first proper print - Ormaxis - and it seems to have got to Z=4.55mm

A little Extruder stutter ( at high X numbers) as it was laying down the first few layers, so I may not have got the bed compensation just right.

There definitely seems to be a 0.1mm hysterisis on the Z axis. Drop the Z until it just grabs my piece of paper (using pronterface)

Up 0.1mm (still grabbing). Up 0.1mm: paper free. Down 0.1mm: paper still free.

Greg

Ormerod #17

A little Extruder stutter ( at high X numbers) as it was laying down the first few layers, so I may not have got the bed compensation just right.

There definitely seems to be a 0.1mm hysterisis on the Z axis. Drop the Z until it just grabs my piece of paper (using pronterface)

Up 0.1mm (still grabbing). Up 0.1mm: paper free. Down 0.1mm: paper still free.

Greg

Ormerod #17

|

Re: Prerequisites for printing? January 25, 2014 09:19AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Prerequisites for printing? February 02, 2014 07:02AM |

Registered: 10 years ago Posts: 145 |

Unfortunately, I did not get one of your new adjustable Zrunners Ian.

Removing a couple of layers of Kapton from the extrusion meant freer running.

I was already on the 057a firmware.

Careful levelling meant I got a good Ormaxis print - which was perfectly square. Then followed by a very poor Snowman which did not stick to the bed properly.

Since then I am on a more recent firmware version from dc42, and running a recent version of Matt's web interface. Put in three springs and longer screws to adjust the bed - I adjust these before a run, so no bed compensation required.

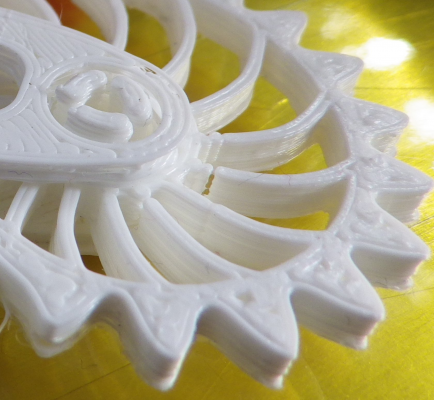

Printed off some Nautilus gears, which are good - but not perfect.

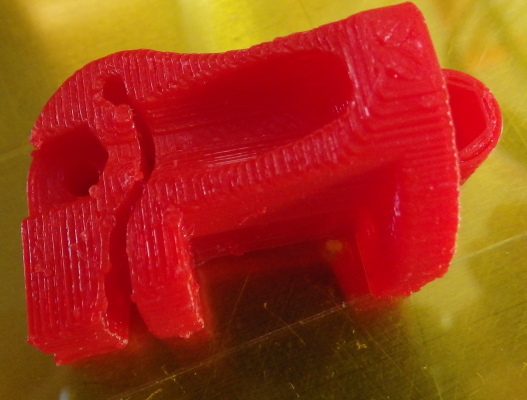

Best of all, I now have a new adjustable Zrunner (in almost the right red).

My wife is really very impressed

I would welcome ideas on improving those prints, and I would like suggestions on a suitable demonstration object which can be printed at Ormerod's maximum accuracy.

Greg

Edited 2 time(s). Last edit at 02/02/2014 07:03AM by GregL.

Ormerod #17

Removing a couple of layers of Kapton from the extrusion meant freer running.

I was already on the 057a firmware.

Careful levelling meant I got a good Ormaxis print - which was perfectly square. Then followed by a very poor Snowman which did not stick to the bed properly.

Since then I am on a more recent firmware version from dc42, and running a recent version of Matt's web interface. Put in three springs and longer screws to adjust the bed - I adjust these before a run, so no bed compensation required.

Printed off some Nautilus gears, which are good - but not perfect.

Best of all, I now have a new adjustable Zrunner (in almost the right red).

My wife is really very impressed

I would welcome ideas on improving those prints, and I would like suggestions on a suitable demonstration object which can be printed at Ormerod's maximum accuracy.

Greg

Edited 2 time(s). Last edit at 02/02/2014 07:03AM by GregL.

Ormerod #17

|

Re: Prerequisites for printing? February 02, 2014 01:34PM |

Registered: 10 years ago Posts: 14,672 |

I think your printer may be under-extruding. Check the filament extrusion rate calibration (described in the Commissioning instructions). Also measure the filament you are using, at several places, and put that value in the slic3r settings. If those are already correct, try increasing the extrusion multiplier in the slic3r filament settings

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Prerequisites for printing? February 02, 2014 04:05PM |

Registered: 10 years ago Posts: 1,230 |

Quote

GregL

...and I would like suggestions on a suitable demonstration object which can be printed at Ormerod's maximum accuracy.

Greg

How about "Single Wall Alignment Test" from thingiverse, it's very fragile and delicate and great for testing ormerod accuracy, belt tension, extrusion etc.

[www.thingiverse.com]

Erik

Sorry, only registered users may post in this forum.